Professional Documents

Culture Documents

Experion PKS: Fundamentals - C300 Troubleshooting and Maintenance

Uploaded by

Mohamed AmarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experion PKS: Fundamentals - C300 Troubleshooting and Maintenance

Uploaded by

Mohamed AmarCopyright:

Available Formats

Experion PKS: Fundamentals – C300

Troubleshooting and Maintenance

Course Overview Prerequisite/Skill Requirements

Course number: EXP-05C3R500 Prerequisite Course(s)

Course length: 5 days None

Required Skills and/or Experience

Need to maintain an Experion® Process Knowledge System Able to navigate Station application in Experion

(PKS)?

Working knowledge of Windows Server 2016 Standard

This course provides participants with a full understanding of both and/or Windows 10 Enterprise

the hardware and software facets of the Experion PKS C300

controller interfaces. Hands-on lab exercises, utilizing a full-

Desirable Skills and/or Experience

functioning process simulator, comprise 70% of the course.

Participants will be required to install, configure and commission Working knowledge of your process.

I/O, and configure Regulatory Control and Digital Composite.

An understanding of basic electrical concepts, test

Participants will learn safer and more effective troubleshooting

equipment, and drawing symbols

procedures that not only consider the hardware (cards, cables,

power supplies, etc.), but also the impact of the loop parameter Working experience with field instruments, electrical

settings, and automatic controls. components, valves, transmitters, and basic

instrumentation

Who Should Take This Course?

Course Topics

Experion PKS Plant Maintenance Technicians:

Required to make routine additions and changes to You will learn how to…

controls on C300 Build a C300 controller/Series C I/O

Expected to troubleshoot C300 controllers and points Build and commission loops using a hardware simulator

Required to identify level one faults in other parts of the Typical loops include feedback, positioning and digital

Experion PKS control

Troubleshooting with system displays to locate and rectify

faults in C300 field connections, I/O, redundancy, power

Course Benefits supply, and communications to server

Builds confidence in maintaining your System Use Experion PKS operating, configuration, and

Hands on troubleshooting troubleshooting displays to identify (not rectify) network

faults in FTE, Server, Station, and Security connections

Identify the spare capacity on C300 controllers

Review the troubleshooting, diagnostic, and correction

Locate, analyze, and rectify faults associated with the process for faults using 1-5v, 4-20 mA, and HART (Not

C300 controller and points included: Fieldbus, Profibus and DeviceNet)

Analyze and localize faults associated with field Perform routine maintenance on the C300

equipment Utilize PDF Collection to look for additional information to

Respond to problems on the system support these tasks

Course Delivery Options Additional Training

In-Center Instructor-Led Training To increase your knowledge and skills, there are additional

courses available from Automation College.

On-Site Instructor-Led Training

For more information and registration, visit

https://www.honeywellprocess.com/en-US/training.

Rev. 072717

You might also like

- Experion PKS: Fundamentals - Server & Controller Engineering (R431)Document2 pagesExperion PKS: Fundamentals - Server & Controller Engineering (R431)Manoj MittalNo ratings yet

- Experion Pks & Masterlogic: Fundamentals - Configuration and Implementation - Student ProgramDocument3 pagesExperion Pks & Masterlogic: Fundamentals - Configuration and Implementation - Student ProgramMohammad SafdarNo ratings yet

- 2 - Brochure - Experion PKSDocument2 pages2 - Brochure - Experion PKSperegrinumNo ratings yet

- Exp-1002 r431 Rev02-0Document1 pageExp-1002 r431 Rev02-0salaheddinneNo ratings yet

- Bma-0001-En-Des-514-R400 1-Rev01-0-Blending-And-Movement-Fundamentals-Experion-Ratio-Controller-MaintenanceDocument1 pageBma-0001-En-Des-514-R400 1-Rev01-0-Blending-And-Movement-Fundamentals-Experion-Ratio-Controller-MaintenanceAndres OrozcoNo ratings yet

- Experion PKS Fundamentals - Configuration PDFDocument2 pagesExperion PKS Fundamentals - Configuration PDFSohil RajeshirkeNo ratings yet

- Course Order Course Title Pre Requisit Course(s) Skill Requirements Instructor Cost (Man/day Rials)Document1 pageCourse Order Course Title Pre Requisit Course(s) Skill Requirements Instructor Cost (Man/day Rials)sadeghNo ratings yet

- 14 Industrial Automation Engineer PDFDocument2 pages14 Industrial Automation Engineer PDFpritish_09No ratings yet

- Basic and Intermediate PLC TrainingDocument2 pagesBasic and Intermediate PLC Trainingakpan InnocentNo ratings yet

- Industrial Process AutomationDocument24 pagesIndustrial Process AutomationAli Ahmad100% (2)

- HONEYWELL Corporate and Student Training ScheduleDocument20 pagesHONEYWELL Corporate and Student Training ScheduleSyed Salman AliNo ratings yet

- 01 20R300 1 Orientation and Course IntroductionDocument14 pages01 20R300 1 Orientation and Course Introductionavandetq15No ratings yet

- CHP115 - Relion670-650 Series With PCM600 - Operation & MaintenanceDocument2 pagesCHP115 - Relion670-650 Series With PCM600 - Operation & MaintenanceMichael Parohinog GregasNo ratings yet

- Exp-01-En-Des-202-R500-Rev02-0-Experion-Pks-Fundamentals-Controller-Operation - CopieDocument2 pagesExp-01-En-Des-202-R500-Rev02-0-Experion-Pks-Fundamentals-Controller-Operation - Copiemohamed regagdaNo ratings yet

- Veraz Course CatalogDocument26 pagesVeraz Course Cataloganwar20663No ratings yet

- CHP184 - Digital Substation Architecture Design - System SolutionsDocument2 pagesCHP184 - Digital Substation Architecture Design - System SolutionsMichael Parohinog GregasNo ratings yet

- CHP113 - REB500-REB500sys Busbar and Station Protection System - Operation & MaintenanceDocument2 pagesCHP113 - REB500-REB500sys Busbar and Station Protection System - Operation & MaintenanceMichael Parohinog GregasNo ratings yet

- Exp 30 en Des 192 r450 Rev01 0 Experion Pks Advanced Field Device ManagerDocument1 pageExp 30 en Des 192 r450 Rev01 0 Experion Pks Advanced Field Device ManagersalaheddinneNo ratings yet

- Reduce Risk and Improve Your Plant's Performance: Emerson Complete Operator Training SolutionsDocument5 pagesReduce Risk and Improve Your Plant's Performance: Emerson Complete Operator Training SolutionsIzalmouna HamidNo ratings yet

- GE Brochure WebDocument2 pagesGE Brochure Webdragan_stamenkovicNo ratings yet

- Performance Learning Platform Product Data Sheet en 5282176 PDFDocument5 pagesPerformance Learning Platform Product Data Sheet en 5282176 PDFisctomaslopezNo ratings yet

- Exp 05C3Document762 pagesExp 05C3ziyaddinNo ratings yet

- Customer TrainingDocument2 pagesCustomer TrainingAhmad NilNo ratings yet

- E20 575 SA RecoverPoint Specialist ExamDocument3 pagesE20 575 SA RecoverPoint Specialist ExamFrancisMachadoNo ratings yet

- Ag Devicediagnostics PDFDocument22 pagesAg Devicediagnostics PDFAnonymous cXjAZTNo ratings yet

- Computer Systems Servicing NC IiDocument26 pagesComputer Systems Servicing NC IiHitomi KanzakiNo ratings yet

- M04 Adminstrate Network & H.PDocument103 pagesM04 Adminstrate Network & H.Punknown temptationsNo ratings yet

- Access Campus Fundamentals Rev. 22.41Document3 pagesAccess Campus Fundamentals Rev. 22.41Roan VillalobosNo ratings yet

- DCAN-100 Networking Associate Exam PDFDocument4 pagesDCAN-100 Networking Associate Exam PDFmore_nerdyNo ratings yet

- CCA163 - PowerFlex 700 Maintenance and TroubleshootingDocument2 pagesCCA163 - PowerFlex 700 Maintenance and TroubleshootingCong, Nguyen PhiNo ratings yet

- CHP574 - NSD570 Teleprotection EquipmentDocument2 pagesCHP574 - NSD570 Teleprotection EquipmentMichael Parohinog GregasNo ratings yet

- CCA159 PowerFlex 70 Maintenance and Troubleshooting PDFDocument2 pagesCCA159 PowerFlex 70 Maintenance and Troubleshooting PDFبلال حسيني0% (1)

- CHP560 - AFF FirewallDocument2 pagesCHP560 - AFF FirewallMichael Parohinog GregasNo ratings yet

- Truepoint 6500Document3 pagesTruepoint 6500Vishal Mehta0% (1)

- Avaya 7130X Exam Questions - Free DemoDocument7 pagesAvaya 7130X Exam Questions - Free DemoPass4 Leads DumpsNo ratings yet

- DCPPE-200 PowerEdge Professional ExamDocument4 pagesDCPPE-200 PowerEdge Professional Exammore_nerdy0% (1)

- CRISP Provides Technical Training and Consultancy ServicesDocument2 pagesCRISP Provides Technical Training and Consultancy ServicesDanish AlamNo ratings yet

- Cse CoursesDocument39 pagesCse CoursesAnjani KunwarNo ratings yet

- Certified Data Centre Professional: Would You Like To Join The Elite Group of Certified Data Centre Professionals?Document3 pagesCertified Data Centre Professional: Would You Like To Join The Elite Group of Certified Data Centre Professionals?ashfaqultanim007No ratings yet

- Advertisement Website ICAT 052019Document7 pagesAdvertisement Website ICAT 052019Muhammed NoorulNo ratings yet

- Repair & Maintenance of ECG and ICCU Equipments - 0Document17 pagesRepair & Maintenance of ECG and ICCU Equipments - 0Amir mushtaqNo ratings yet

- Supervise Work-Based LearningDocument13 pagesSupervise Work-Based LearningJoviner Yabres LactamNo ratings yet

- Experion PKS - Control Execution EnvironmentDocument2 pagesExperion PKS - Control Execution EnvironmentProtheuss01No ratings yet

- S7 Service 1 Course (ST-SERV1) : Short DescriptionDocument2 pagesS7 Service 1 Course (ST-SERV1) : Short DescriptionIndustrial ItNo ratings yet

- 3BDS011567-143 - I - en - OPC Data - E143 - Troubleshooting - 800xa - Core - SystemDocument1 page3BDS011567-143 - I - en - OPC Data - E143 - Troubleshooting - 800xa - Core - Systemmokhtache tNo ratings yet

- E20 375 IE RecoverPoint Specialist ExamDocument4 pagesE20 375 IE RecoverPoint Specialist ExamFrancisMachadoNo ratings yet

- Trainee's Individual Progress ChartDocument6 pagesTrainee's Individual Progress Chartjohnny rodriguezNo ratings yet

- CHP153 - REB500-REB500sys For Busbar and Station Protection Solutions - Operation & ConfigurationDocument2 pagesCHP153 - REB500-REB500sys For Busbar and Station Protection Solutions - Operation & ConfigurationMichael Parohinog GregasNo ratings yet

- CHP589 - SV9500 Standard Server Telephone SystemDocument2 pagesCHP589 - SV9500 Standard Server Telephone SystemMichael Parohinog GregasNo ratings yet

- C D C SDocument4 pagesC D C SandriNo ratings yet

- CHP412 EGATROL Application and Maintenance: Course GoalDocument1 pageCHP412 EGATROL Application and Maintenance: Course Goalrafik1995No ratings yet

- ControlEdge PLC Implementation (ExperionDocument2 pagesControlEdge PLC Implementation (ExperionperegrinumNo ratings yet

- Datasheet 595849 (80-3355-A0) enDocument7 pagesDatasheet 595849 (80-3355-A0) enpcnishantNo ratings yet

- CHP126 - Substation Automation System - MaintenanceDocument2 pagesCHP126 - Substation Automation System - MaintenanceMichael Parohinog GregasNo ratings yet

- 2PAA104725 A en Safeguard 400 Series Course A290 Handling and MaintenanceDocument2 pages2PAA104725 A en Safeguard 400 Series Course A290 Handling and MaintenanceTARIK DERDOURINo ratings yet

- Dics b10123 00 7600 SMSCP Onepager Jobprofile 1 144Document2 pagesDics b10123 00 7600 SMSCP Onepager Jobprofile 1 144saeedNo ratings yet

- PROFIBUS Commissioning CourseDocument2 pagesPROFIBUS Commissioning CourseRizky MuhammadNo ratings yet

- Charles Mathew-Senior EngineerDocument3 pagesCharles Mathew-Senior EngineerCHARLES MATHEW100% (1)

- NSQF-Field Technician Computer & Peripherals PDFDocument13 pagesNSQF-Field Technician Computer & Peripherals PDFNitin SharmaNo ratings yet

- The CompTIA Network+ & Security+ Certification: 2 in 1 Book- Simplified Study Guide Eighth Edition (Exam N10-008) | The Complete Exam Prep with Practice Tests and Insider Tips & Tricks | Achieve a 98% Pass Rate on Your First Attempt!From EverandThe CompTIA Network+ & Security+ Certification: 2 in 1 Book- Simplified Study Guide Eighth Edition (Exam N10-008) | The Complete Exam Prep with Practice Tests and Insider Tips & Tricks | Achieve a 98% Pass Rate on Your First Attempt!No ratings yet

- Auto Flight Maintenance Manual ChapterDocument66 pagesAuto Flight Maintenance Manual ChapterGims BuafNo ratings yet

- 97-99 Mitsubishi Eclipse Electrical ManualDocument540 pages97-99 Mitsubishi Eclipse Electrical Manualdustyboner98% (60)

- Trouble CodeDocument108 pagesTrouble Codethe broatherNo ratings yet

- Ology Troubleshooting Guide PDFDocument7 pagesOlogy Troubleshooting Guide PDFandyNo ratings yet

- Manual Centrifuga UniversalDocument35 pagesManual Centrifuga Universallebiatan89No ratings yet

- Basic PneumaticsDocument10 pagesBasic PneumaticsTimothy FieldsNo ratings yet

- HP R3000 XR UPS Maintenance and Service GuideDocument49 pagesHP R3000 XR UPS Maintenance and Service Guideianwashere123No ratings yet

- Unlock The Puzzle Picture !: Direction: Arrange The Pieces of Picture To Create The FigureDocument27 pagesUnlock The Puzzle Picture !: Direction: Arrange The Pieces of Picture To Create The FigureVhergel MhartinezNo ratings yet

- Harbor Freight Truck CraneDocument12 pagesHarbor Freight Truck CraneManuel SterlingNo ratings yet

- Chapter 9 Lab 9-1, Network Mirror: Ccnpv7 TshootDocument8 pagesChapter 9 Lab 9-1, Network Mirror: Ccnpv7 TshootJean-Pierre Roux0% (3)

- 056-047 Out of Sync and Failed To CloseDocument2 pages056-047 Out of Sync and Failed To Closeharigopalk12100% (2)

- HWS2000 ManualDocument30 pagesHWS2000 Manualmarius vasile0% (1)

- Instrument TechnicianDocument2 pagesInstrument TechnicianKaycee EstrellaNo ratings yet

- S 6d95l-b2 Diesel-EngineDocument27 pagesS 6d95l-b2 Diesel-EngineDavid100% (2)

- L655 L656 Manual de ServicioDocument79 pagesL655 L656 Manual de Serviciojesuscantuarias67% (6)

- HP Designjet t2300 Service ManualDocument461 pagesHP Designjet t2300 Service ManualOFBA srlNo ratings yet

- 2291B1 3500 33 16Document52 pages2291B1 3500 33 16usman379No ratings yet

- HP Scitex FB500, FB700 (Service Manual)Document511 pagesHP Scitex FB500, FB700 (Service Manual)Дмитрий Разуваев100% (4)

- Getting Better Prints - 3DVerkstan Knowledge BaseDocument18 pagesGetting Better Prints - 3DVerkstan Knowledge BaseEladio García DelaMorenaNo ratings yet

- Manual de Instrucciones - Bloque Térmico Benchmark Scientific BSH5001Document16 pagesManual de Instrucciones - Bloque Térmico Benchmark Scientific BSH5001MARIA ALEJANDRA SIERRA GILNo ratings yet

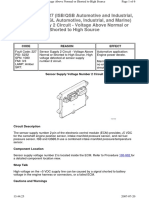

- FAULT CODE 227 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Sensor Supply 2 Circuit - Voltage Above Normal or Shorted To High SourceDocument6 pagesFAULT CODE 227 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Sensor Supply 2 Circuit - Voltage Above Normal or Shorted To High SourceAhmedmahNo ratings yet

- Xerox Phaser 3020 Service Manual: 702P02829 June 2014Document116 pagesXerox Phaser 3020 Service Manual: 702P02829 June 2014Bruno Henrique VoicoleskoNo ratings yet

- Incident Management Process DescriptionsDocument35 pagesIncident Management Process DescriptionsTrupti Suryawanshi100% (1)

- Samsung ML-1610 Service Manual - 06 - TroubleshootingDocument23 pagesSamsung ML-1610 Service Manual - 06 - Troubleshootingiraklitosp100% (2)

- Technical Help Desk Troubleshooter - Role DescriptionDocument2 pagesTechnical Help Desk Troubleshooter - Role DescriptionSơn HồNo ratings yet

- 2012 Plasma TV Troubleshooting GuideDocument39 pages2012 Plasma TV Troubleshooting GuideNsb El-kathiriNo ratings yet

- Jaltest Ohw Catalogo Digital en 1228 PDFDocument27 pagesJaltest Ohw Catalogo Digital en 1228 PDFMC 3AEEDNo ratings yet

- Stylus Photo R280 285 290 Artisan50 StylusPhotoT50 T59 T60 CDocument129 pagesStylus Photo R280 285 290 Artisan50 StylusPhotoT50 T59 T60 CAkira LiNo ratings yet

- Error Code Komatsu FB25-12Document6 pagesError Code Komatsu FB25-12Aighn NartNo ratings yet

- CAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven EquipmentDocument2 pagesCAT - 3516H Engine Shutdown or Start Inhibit Initiated by Driven Equipmentwagner_guimarães_1100% (1)