Professional Documents

Culture Documents

Spiral Weld Calculation Using Electrode E90Xx: BAUER Foundations Philippines, Inc

Uploaded by

Mac-Ross CordovaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spiral Weld Calculation Using Electrode E90Xx: BAUER Foundations Philippines, Inc

Uploaded by

Mac-Ross CordovaCopyright:

Available Formats

BAUER Foundations Philippines, Inc.

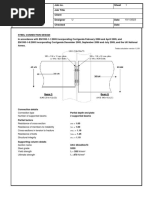

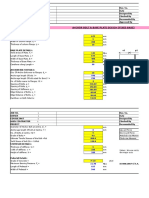

SPIRAL WELD CALCULATION USING ELECTRODE E90XX

PROJECT DETAILS

PROJECT Q-NUMBER: P2471 PROJECT TITLE: FGEN LNG Multi-Purpose Jetty and Gas Receiving Facility

DATE CREATED: 10/11/2021 REVISION NO.: Rev01

PREPARED BY: Noreen Tarac (Design Engineer) REVIEWED BY: Julian Sandoval (Design Manager)

REQUIRED STRENGTH CALCULATION DRAWING

WELD DESIGN SHEAR STRENGTH Symbol Value Unit

Diameter of the spiral bar db 16.00 mm

Number of spiral bar - 2.00 nos

Area of rebar: Aspiral 402.12 mm2

Grade: Gr. 60.00

Tensile Strength: fy 414.00 MPa

Tensile force requirement: Ftension 166.48 kN

ANALYSIS OF WELDED AREA

Welding properties Symbol value unit

Electrode (e.g. E60xx, E70xx): E90XX 90 kips/sq. in

Nominal Stress [Fw=0.6(E60x6.9)]: Fw 372.6 MPa

Throat dimension: tweld 0.707 mm

Thickness of weld: wweld 6 mm

Length of weld: Lweld 250 mm

Weld nomimal shear strength: Rn=(0.707wLFw) 395.1423 kN

ALLOWABLE STRENGTH DESIGN APPROACH Factor of Safety, Ω = 2.00

WELD DESIGN SHEAR STRENGTH Symbol Value Unit

Weld desig strength: (Rn/ Ω)=(0.707wLFw)/(2.07) Rn/ Ω 197.57 kN

>

Tensile force requirement: Ftension 166.48 kN

∴ Weld design shear strength > force requirement

CONCLUSION

TOTAL LENGTH OF WELD FOR EVERY SPIRAL LAPLENGTH 40Ø: 250.00 mm

REFERENCE NOTE

The design strength calculation presented in this report is based on Allowable Strength Design (ASD) approach.

The design reference of ASD approach is followed from American Institute of Steel Construction, Inc. (AISC) Steel Construction Manual 13TH Edition (2005) under Section J2 for Welds.

The factor of safety and multiplier use for calculation are based in Table J2.5.

You might also like

- SB46 Along GL-2 SummaryDocument2 pagesSB46 Along GL-2 Summarymhazarath murariNo ratings yet

- Advances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967From EverandAdvances in Machine Tool Design and Research 1967: Proceedings of the 8th International M.T.D.R. Conference (Incorporating the 2nd International CIRP Production Engineering Research Conference), the University of Manchester Institute of Science and Technology, September 1967S. A. TobiasRating: 4 out of 5 stars4/5 (1)

- Butt Weld Calculator (Version: 2021 (Build 250183000, 183) ) : Project InfoDocument3 pagesButt Weld Calculator (Version: 2021 (Build 250183000, 183) ) : Project InfoELIECER SANCHEZNo ratings yet

- 1 VB Connection 2lto HL Beam One G.PL NSFDocument32 pages1 VB Connection 2lto HL Beam One G.PL NSFWintun73No ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- Aisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANDocument5 pagesAisc 14 Edition (Asd) : 0 1 18/jan/16 13/jun/16 SN SN AN ANGousePeerzadeNo ratings yet

- 02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Document117 pages02) PIPE244.5x6.3 V-BRACE - GUSSET PLT.Asaru Deen100% (1)

- Foundation 1 Design ReportDocument6 pagesFoundation 1 Design ReportDinesh RajaNo ratings yet

- Calculation Sheet: Yb For UB BeamDocument2 pagesCalculation Sheet: Yb For UB BeamrammohanNo ratings yet

- SC15 Along GL-D' SummaryDocument2 pagesSC15 Along GL-D' Summarymhazarath murariNo ratings yet

- SC21B-A Along GL-4 SummaryDocument2 pagesSC21B-A Along GL-4 Summarymhazarath murariNo ratings yet

- Beam Connection DesignDocument10 pagesBeam Connection DesignLuqman ZolkibliNo ratings yet

- CN 05Document3 pagesCN 05GousePeerzadeNo ratings yet

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- Column Base PlateDocument4 pagesColumn Base PlateYHK3001No ratings yet

- Steel To Concrete Simple Connection Example 1Document12 pagesSteel To Concrete Simple Connection Example 1CSEC Uganda Ltd.No ratings yet

- Typical Beam To Beam Connection Design Calcultion - Fin PLTDocument122 pagesTypical Beam To Beam Connection Design Calcultion - Fin PLTAsaru DeenNo ratings yet

- Aisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1Document2 pagesAisc 14 Edition (Asd) : 14/jan/16 SN SN 0 1GousePeerzadeNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument13 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofanto3harrish3fdo100% (1)

- Beam To Column Connection ExampleDocument9 pagesBeam To Column Connection ExampleLuqman ZolkibliNo ratings yet

- Design Calc@Main StageDocument5 pagesDesign Calc@Main StageAbdul Hameed100% (1)

- Column Splice Detail (UC 203x203x86)Document2 pagesColumn Splice Detail (UC 203x203x86)Sudhakar KrishnamurthyNo ratings yet

- Bow String Girder Steel Members Design As Per IRC Code Bow-String Girder - DesignDocument967 pagesBow String Girder Steel Members Design As Per IRC Code Bow-String Girder - DesignStructural SpreadsheetsNo ratings yet

- Anchor Bolt and Base Plate Design CheckDocument48 pagesAnchor Bolt and Base Plate Design CheckmaheshbandhamNo ratings yet

- Foundation 1 Design ReportDocument5 pagesFoundation 1 Design Reportyug draciNo ratings yet

- Technical ProposalDocument10 pagesTechnical ProposalSiddiqui Muhammad AshfaqueNo ratings yet

- Anchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDDocument11 pagesAnchoring Conditions: Non-Cracked Concrete 25 6 900 115 100 10 190 40 31.66667 6.666667 150 Hilti HIT-RE 500-SDTimothy PinchinNo ratings yet

- Welding Design For Diaphragm ReinforcementDocument8 pagesWelding Design For Diaphragm ReinforcementmalithNo ratings yet

- Design Report 60m High Tower1Document221 pagesDesign Report 60m High Tower1ShashankSinghNo ratings yet

- Site: Date: Job No. Designer: Sheet No.: Calculation/ SketchDocument5 pagesSite: Date: Job No. Designer: Sheet No.: Calculation/ SketchAlma M. LaraNo ratings yet

- Design Condition 41C101Document64 pagesDesign Condition 41C101arifinzaky27No ratings yet

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Design of One Way Slab As Per Is456-2000Document6 pagesDesign of One Way Slab As Per Is456-2000HANISH0% (1)

- Ground Floor Slab DesignDocument4 pagesGround Floor Slab DesignRaju SainiNo ratings yet

- Splice DesignDocument5 pagesSplice DesignBunkun15No ratings yet

- ProkonDocument9 pagesProkonyoonyohan04No ratings yet

- Api Tank 400M3 HCDocument10 pagesApi Tank 400M3 HCCharles DogneNo ratings yet

- Column Base Plate Design (BS5950)Document2 pagesColumn Base Plate Design (BS5950)nicekannaNo ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design ReportEdwinBastidasNo ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design ReportEdwinBastidasNo ratings yet

- Unreinforced Bellows Design Calculation Sheet: (Ejma Nineth Edition)Document1 pageUnreinforced Bellows Design Calculation Sheet: (Ejma Nineth Edition)TriadBellowsNo ratings yet

- Moment Connection DesignDocument2 pagesMoment Connection DesignmaheshbandhamNo ratings yet

- Design of RCC SlabDocument8 pagesDesign of RCC Slabrajseema_n2180% (5)

- Punching Shear DesignDocument36 pagesPunching Shear DesignYanfei JinNo ratings yet

- MB4 (Rafter To Corner Column)Document63 pagesMB4 (Rafter To Corner Column)Crystal JaneNo ratings yet

- 2 Pilecap Design-ACIDocument2 pages2 Pilecap Design-ACIShamim Ahsan ZuberyNo ratings yet

- 50NB Tubular Joint Stiffner Connection-03 (DBR) (27-03-2024)Document8 pages50NB Tubular Joint Stiffner Connection-03 (DBR) (27-03-2024)Dass MNo ratings yet

- Amine Vessel Out FinalDocument273 pagesAmine Vessel Out FinalVanshika MishraNo ratings yet

- Foundation 1 Design Report (8 Metros)Document7 pagesFoundation 1 Design Report (8 Metros)EdwinBastidasNo ratings yet

- POT Design R0Document9 pagesPOT Design R0VB665No ratings yet

- Is 2062 (Sa 36)Document3 pagesIs 2062 (Sa 36)Abhishek ShuklaNo ratings yet

- Foundation 1 Design ReportDocument7 pagesFoundation 1 Design ReportEdwinBastidasNo ratings yet

- PLATE Beam To BeamDocument73 pagesPLATE Beam To BeamKutty Mansoor100% (1)

- Solid Filter - DatasheetDocument1 pageSolid Filter - Datasheetbmanojkumar16No ratings yet

- Beam Shear ConnDocument26 pagesBeam Shear Connraghav abudhabiNo ratings yet

- UW-2 OutDocument48 pagesUW-2 Out966571016208No ratings yet

- Master Link - 1.OKDocument1 pageMaster Link - 1.OKMac-Ross CordovaNo ratings yet

- Man Basket Cert 7101Document1 pageMan Basket Cert 7101Mac-Ross Cordova100% (1)

- Master Link - 1.OKDocument1 pageMaster Link - 1.OKMac-Ross CordovaNo ratings yet

- Man Basket Cert 7101Document1 pageMan Basket Cert 7101Mac-Ross Cordova100% (1)

- Genset 5649Document2 pagesGenset 5649Mac-Ross CordovaNo ratings yet

- CCO For MercuryDocument8 pagesCCO For Mercuryapi-3728602No ratings yet

- Emb MC 2020 007 PDFDocument2 pagesEmb MC 2020 007 PDFMac-Ross CordovaNo ratings yet

- Draft CancerDocument33 pagesDraft CancerMac-Ross CordovaNo ratings yet

- Envirnmntl Values Formation N Sustainable Devt MODULEDocument58 pagesEnvirnmntl Values Formation N Sustainable Devt MODULEMac-Ross CordovaNo ratings yet

- Crosby User Lifting GuideDocument8 pagesCrosby User Lifting GuideMac-Ross CordovaNo ratings yet

- Framework - PcoDocument51 pagesFramework - PcoMac-Ross CordovaNo ratings yet

- Smoking HandoutDocument1 pageSmoking HandoutMac-Ross CordovaNo ratings yet

- Clean Water Act-OVERVIEWDocument30 pagesClean Water Act-OVERVIEWMac-Ross CordovaNo ratings yet

- Pco Requirements New and Renewal 1Document1 pagePco Requirements New and Renewal 1JovanNo ratings yet

- Self Tapping Vs Self Drilling Vs Sheet Metal Screws GuideDocument1 pageSelf Tapping Vs Self Drilling Vs Sheet Metal Screws GuideMac-Ross CordovaNo ratings yet

- DAO 2000-81 - IRR of Clean Air ActDocument81 pagesDAO 2000-81 - IRR of Clean Air ActPacific Spectrum100% (4)

- DDP400 Open-Frame and U-Chassis :: ROAL Living EnergyDocument12 pagesDDP400 Open-Frame and U-Chassis :: ROAL Living EnergyroalscribdNo ratings yet

- Modul Ke-4 Perhitungan Sieve AnalisisDocument36 pagesModul Ke-4 Perhitungan Sieve AnalisisFredi CherboundNo ratings yet

- AQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of HydrologyDocument23 pagesAQUATOOL A Generalized Decision Support System For Water Resources Planning and Operational Management 1996 Journal of Hydrologyhoc_kinowNo ratings yet

- Course Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Document14 pagesCourse Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Eushane Chiya SyNo ratings yet

- NTSE Stage - 1 Mock Test - 3Document16 pagesNTSE Stage - 1 Mock Test - 3Apex Institute100% (1)

- Method Comparison Study Report For The ISO 16140-2:2016 Validation of Compact Dry EC, For The Enumeration of ColiformsDocument24 pagesMethod Comparison Study Report For The ISO 16140-2:2016 Validation of Compact Dry EC, For The Enumeration of ColiformsKAREEMNo ratings yet

- ErrorsDocument498 pagesErrorsIsmael DiasNo ratings yet

- LoadRunner BasicsDocument74 pagesLoadRunner BasicsmadhugangulaNo ratings yet

- JCrenshaw ImplementingCRCsDocument17 pagesJCrenshaw ImplementingCRCsspyeagleNo ratings yet

- Class and ObjectsDocument15 pagesClass and ObjectsIwan SaputraNo ratings yet

- University Insitute of Engineering Electrical EngineeringDocument85 pagesUniversity Insitute of Engineering Electrical EngineeringPyrenean IbexNo ratings yet

- Exercises 5Document1 pageExercises 5Jonathhan RecaldeNo ratings yet

- Method IvivcDocument15 pagesMethod IvivcHari Krishnan100% (1)

- Physics Paper 2 Nov 2004Document16 pagesPhysics Paper 2 Nov 2004tommyliuNo ratings yet

- Registry TweaksDocument5 pagesRegistry TweaksArlie TaylorNo ratings yet

- Dcs 2019 Questions PaperDocument14 pagesDcs 2019 Questions PaperDASHARATH VISHAWAKARMANo ratings yet

- Speciifactions and Cross Reference Bosch Spark PlugDocument3 pagesSpeciifactions and Cross Reference Bosch Spark Plugcarlos puerto100% (1)

- Understand Concept of Multi-Rate Signal Processing: (Autonomous College Affiliated To University of Mumbai)Document2 pagesUnderstand Concept of Multi-Rate Signal Processing: (Autonomous College Affiliated To University of Mumbai)nicO neeNo ratings yet

- Flanges: SI SMEDocument16 pagesFlanges: SI SMEbalaNo ratings yet

- Determinants of Profitability Performance: An Analysis of Class I Railroads in The United StatesDocument18 pagesDeterminants of Profitability Performance: An Analysis of Class I Railroads in The United StatesJayaniNo ratings yet

- Fabry PerotDocument11 pagesFabry PerotG. P HrishikeshNo ratings yet

- Sap PP 01 Organizational Structure Overview PDFDocument52 pagesSap PP 01 Organizational Structure Overview PDFMahesh KamdeyNo ratings yet

- Eaton Fuller - Autoshift 16 Service Manual (T20891)Document81 pagesEaton Fuller - Autoshift 16 Service Manual (T20891)Miller Andres ArocaNo ratings yet

- PIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1Document17 pagesPIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1samarrana1234679No ratings yet

- UNIX Intro and Basic C Shell Scripting: Khaldoun Makhoul Khaldoun@nmr - Mgh.harvard - EduDocument36 pagesUNIX Intro and Basic C Shell Scripting: Khaldoun Makhoul Khaldoun@nmr - Mgh.harvard - Edudaitoan402No ratings yet

- Jain 2018Document10 pagesJain 2018Pablo Ignacio Contreras EstradaNo ratings yet

- Coding Bobol ExcelDocument4 pagesCoding Bobol ExcelMuhammad IsmunandarsyahNo ratings yet

- Lista Ejercicios 3 PPEDocument25 pagesLista Ejercicios 3 PPEKarla HermorNo ratings yet

- SMD TR60-1.0mm With 12mm Bar (Office Floor 3.64m Span) PDFDocument2 pagesSMD TR60-1.0mm With 12mm Bar (Office Floor 3.64m Span) PDFabhijitkolheNo ratings yet

- Experiment 3: Department of Civil Engineering, IIT DelhiDocument2 pagesExperiment 3: Department of Civil Engineering, IIT DelhiSRNo ratings yet