Professional Documents

Culture Documents

Vin L (Drive Belt) - Alldata Repair

Vin L (Drive Belt) - Alldata Repair

Uploaded by

francisco alba0 ratings0% found this document useful (0 votes)

9 views3 pagesOriginal Title

Vin l (Drive Belt) - Alldata Repair

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesVin L (Drive Belt) - Alldata Repair

Vin L (Drive Belt) - Alldata Repair

Uploaded by

francisco albaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

osrr2re021 INL (Drive Belt - ALLDATA Repair

2010 Chevy Truck Express 4500 V8-6.6L DSL Turbo

Vehicle > Engine, Cooling and Exhaust > Engine > Drive Belts, Mounts, Brackets and Accessories > Drive Belt >

Testing and Inspection > Component Tests and General Diagnostics > Drive Belt Falls Off and Excessive Wear

Diagnosis

VINL

Drive Belt Falls Off and Excessive Wear Diagnosis

Diagnostic Aids

If the drive belt repeatedly falls off the drive belt pulleys, this is because of pulley misalignment.

‘An extra load that is quickly applied on released by an accessory drive component may cause the drive belt to fall

off the pulleys. Verify the accessory drive components operate properly.

If the drive belt is the incorrect length, the drive belt tensioner may not keep the proper tension on the drive belt,

Excessive wear on a drive belt is usually caused by an incorrect installation or the wrong drive belt for the

application.

Minor misalignment of the drive belt pulleys will not cause excessive wear, but will probably cause the drive belt to

make a noise or to fall off.

Excessive misalignment of the drive belt pulleys will cause excessive wear but may also make the drive belt fall off.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2. This inspection is to verify the condition of the drive belt. Damage may of occurred to the drive belt when the drive

belt fell of. The drive belt may of been damaged, which caused the drive belt to fall off. Inspect the belt for cuts,

tears, sections of ribs missing, or damaged belt plys.

4, Misalignment of the pulleys may be caused from improper mounting of the accessory drive component, incorrect

installation of the accessory drive component pulley, of the pulley bent inward or outward from a previous repait.

Test for a misaligned pulley using a straight edge in the pulley grooves across two or three pulleys. If a misaligned

pulley is found refer to that accessory drive component for the proper installation procedure of that pulley.

5. Inspecting the pulleys for being bent should include inspecting for a dent or other damage to the pulleys that

would prevent the drive belt from not seating properly in all of the pulley grooves or on the smooth surface of a

pulley when the back side of the belt is used to drive the pulley.

6. Accessory drive component brackets that are bent or cracked will et the drive belt fall off.

7. Inspection of the fasteners can eliminate the possibility that a wrong bolt, nut, spacer, or washer was installed.

Missing, loose, or the wrong fasteners may cause pulley misalignment from the bracket moving under load, Over

tightening of the fasteners may cause misalignment of the accessory component bracket.

13. The inspection is to verify the drive belt is correctly installed on all of the drive belt pulleys. Wear on the drive bel

may be caused by mis-positioning the drive belt by one groove on a pulley.

14, The installation of a drive belt that is too wide or too narrow will cause wear on the drive belt. The drive belt ribs

should match all of the grooves on all of the pulleys.

15. This inspection is to verify the drive belt is not contacting any parts of the engine or body while the engine is

hitpsimy.alléata,comrepairtirepatiartcle/A7918/component920;type/283/nonstandard/1 36740 /selRetLinkialse 18

osrizr202 VIN L (Orve Belt) - ALLOATA Repair

operating. There should be sufficient clearance when the drive belt accessory drive components load varies. The

drive belt should not come in contact with an engine or a body component when snapping the throttle.

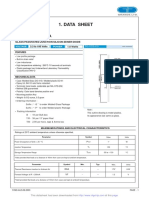

Se) ‘ation Yes) We

‘Caution: Rater Bat Dressing Gaston

DEFINITION: The dive be als fhe pulleys or may note correct onthe pus

DEFINITION: ear at th cutee cb of he crv et de oan ncorrect neal dive bok

Di you review the Drive Bot Symptom operation and perform the necessary Go10 [Bote Symptons - Engine

lnspectons? ‘692 _Mecnaneat

"© agnosing excosve wear, proceed io sep 3.

2. | # Hagnosing active beta ale of iepect for a damaged ce bet «

Did you tnd conion? sep | Gowsups

insta anew dve bel. Refer to Dive Bel Replacement - Accessor or A Conioning

[Compressor Bet Replacement

cow

Doss the cive bet continue fa of? step System OK

Inspector misalignment ofthe pulleys

4 cow

Did you find and rep the contion? step? | _Gotosteps

Inspector a bento dente pully. BS

Did you find and repair the contion? sept2 | Gotosieps

Inspecticr bento a racked bracket, «

Di you tnd and repathe conion? septz | Gowsiep7

7 | eto meropenem ase ow

id you find ose or missing fastoras? sect | Gotosiene

‘Caution: ete o Fastener Cation

1. Taten ny lose fastenrs. tert Fastener Tightening Spectestons

8 | 2. Replace improper or missing fastens cow

Does the ave bet conte fa of? S09 System OK.

Teste dive bel tersioner for operating Svecy. Por Dive Bak Toa

9 [Diagn coms

Dose the eve bot tnsioner operat covey? septt | Gowseep10

eplae the drive belt tensioner, Refer to Dive Bek Tensioner Replacement Acoastor |

0 cow

Does the aie bet conte fa of? step 11 System OK

Inepect orf rive bat ler and rie bet teiner pley Basing «

Di you tnd and reps the conten? tap 12 [ote Diagnostic Ase

(Operate the system in det vee he apa

2 System

Did you comet he contin? OK ote Step 13,

Inspect the ceive bel fr the proper rtalaion, Pele Ove Bel Replaerient

1a_|Atbeesory or Ar Condtonng Compressor Bet Replacement a

Di you tnd is contion? steps | _Gowstep 14

1g iP o De oer ve Ba cow

Di you tnd his conction? step | Got step 15

Inepect orth dive Bot rubbing apt a rack, ooo, oF Wing PAGES 7

Di you find and repathe conion? step” [Goto Diagnoste Ase

-tps:iimy.alléata.com/reparitreparartce!47918/component920/type/283inonstandard/1367401/seHRetLinkfalse

osrizr202 VIN L (Orve Belt) - ALLOATA Repair

sen) Telia Yer Ne

Replace heave bel Rate to Dive Bek Repacement-hacessory oA Conionng|

1g [Compressor Be Replacement

Goto

[Did you complete he replaersent? step 17

[Sperat he eystom in oc very he repair

7 system

Di youconoct the condition? ‘on

-tps:iimy.alléata.com/reparitreparartce!47918/component920/type/283inonstandard/1367401/seHRetLinkfalse

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- P0036 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairDocument6 pagesP0036 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA Repairfrancisco albaNo ratings yet

- Troubleshooting (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairDocument6 pagesTroubleshooting (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA Repairfrancisco albaNo ratings yet

- Valve Lash (Clearance) (Valve Clearance) - ALLDATA RepairDocument4 pagesValve Lash (Clearance) (Valve Clearance) - ALLDATA Repairfrancisco albaNo ratings yet

- Data Sheet: 1N4728A 1N4764ADocument5 pagesData Sheet: 1N4728A 1N4764Afrancisco albaNo ratings yet

- p1400 MonteroDocument2 pagesp1400 Monterofrancisco albaNo ratings yet

- Printing From ABS INFINITYundefinedDocument2 pagesPrinting From ABS INFINITYundefinedfrancisco albaNo ratings yet

- P22 Transmison Montero Fallo PrincipalDocument4 pagesP22 Transmison Montero Fallo Principalfrancisco albaNo ratings yet

- P28 TransmisionDocument7 pagesP28 Transmisionfrancisco albaNo ratings yet

- Guía para MultisimDocument6 pagesGuía para Multisimfrancisco albaNo ratings yet

- Plantas de Potencia Módulo I-3 A 5 Parcial No.2Document26 pagesPlantas de Potencia Módulo I-3 A 5 Parcial No.2francisco albaNo ratings yet