Professional Documents

Culture Documents

Commissioning Checklist: S. No. Activities Tag Numbers Status Date Remarks Checked by

Uploaded by

talhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning Checklist: S. No. Activities Tag Numbers Status Date Remarks Checked by

Uploaded by

talhaCopyright:

Available Formats

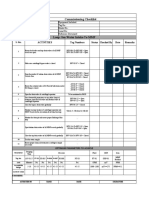

Commissioning Checklist

Client: Equipment Included:

Project: Tag No.:

Date: Model No.:

Service: Serial No.:

Document No: Reference Document:

Loop: MMF To RO Feed Train B

Checked

S. No. ACTIVITIES Tag Numbers Status Date Remarks

By

1 Ensure CIP hand valve of RO Train A is closed BFV-18-4" = Closed

2 Keep sample valves at cartridge filter inlet & outlet SV-09 = Open

open for the air to evacuate SV-10 = Open

3 Ensure HPP feed hand valve is open BFV-16-6" = Open

4 Ensure air release valve of cartridge filter is open and ARV-03 = Open

drain valve of cartridge filter is closed BV-08 = Closed

5 Ensure sample valves of all RO vessels and Polishing SV-30 to SV-41 = Open

RO vessels are open in order to vent the air properly SV-45 to SV-47 = Open

Ensure hand valve at CIP mixing and CIP pump

BFV-17-4" = Open

6 suction is open for flushing and the air to vent from

BFV-19-4" = Open

that loop

7 Ensure drain valve of CIP tank is closed BFV-09-2" = Closed

8 Remove the cap of CIP tank for air evacuation RFCT-02 = Open

TV-02-02" = Open

Ensure the throttle valves at RO Product and

9 TV-04-03" = Open

Polishing RO Feed abd Polishing RO Reject are open

TV-06-03" = Open

Make sure chemical treatment systems at RO feed and

10 RO product are installed and dosing rate is set -

according to required specifications

11 Gradually open RO Feed Actuator Valve open and AV-05-6" = Open

close Dump Actuator Valce simultaneously AV-06-2" = Closed

12 Start chemical treatment accordingly -

COMMENTS:

ATTESTED BY NAME DATE SIGNATURE

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Load ScheduleDocument8 pagesLoad SchedulemerebookNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Practical Approach To Classical YogaDocument39 pagesA Practical Approach To Classical Yogaabhilasha_yadav_1No ratings yet

- Time Series - Practical ExercisesDocument9 pagesTime Series - Practical ExercisesJobayer Islam TunanNo ratings yet

- 06ESL37 Analog Electronics Lab MANUALDocument70 pages06ESL37 Analog Electronics Lab MANUALSan AngadiNo ratings yet

- MIKE21BW Step by Step GuideDocument124 pagesMIKE21BW Step by Step Guideflpbravo100% (2)

- Standard Testing Method For Water Analysis For Reverse Osmosis and NanofiltrationDocument2 pagesStandard Testing Method For Water Analysis For Reverse Osmosis and NanofiltrationtalhaNo ratings yet

- Commissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date RemarksDocument2 pagesCommissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date RemarkstalhaNo ratings yet

- Loop: Sea Water Intake To Drain Bypass: Commissioning ChecklistDocument4 pagesLoop: Sea Water Intake To Drain Bypass: Commissioning ChecklisttalhaNo ratings yet

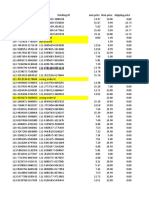

- Order-Id Tracking ID Amz Price Item-Price Shipping-PriceDocument8 pagesOrder-Id Tracking ID Amz Price Item-Price Shipping-PricetalhaNo ratings yet

- Assignment No. 01 Talha Alam Khan IM-045 Business Process Re-EngineeringDocument3 pagesAssignment No. 01 Talha Alam Khan IM-045 Business Process Re-EngineeringtalhaNo ratings yet

- Understanding To-Complete Performance Index (TCPI) in Project Cost ManagementDocument12 pagesUnderstanding To-Complete Performance Index (TCPI) in Project Cost ManagementtalhaNo ratings yet

- User Manual: U1000 V2 Ultrasonic Flowmeter U1000 V2 HM Ultrasonic FlowmeterDocument44 pagesUser Manual: U1000 V2 Ultrasonic Flowmeter U1000 V2 HM Ultrasonic FlowmetertalhaNo ratings yet

- Re: Packaging and Labelling Update For Sandvik Welding ConsumablesDocument2 pagesRe: Packaging and Labelling Update For Sandvik Welding ConsumablestalhaNo ratings yet

- Income Tax Payment Challan: PSID #: 143186538Document1 pageIncome Tax Payment Challan: PSID #: 143186538talhaNo ratings yet

- Calibration Standards Kit: Instruction SheetDocument2 pagesCalibration Standards Kit: Instruction SheettalhaNo ratings yet

- DRS Rev.0 GTP-TR1!01!002 Condensate RecyclingDocument4 pagesDRS Rev.0 GTP-TR1!01!002 Condensate RecyclingBalasubramanianNo ratings yet

- Emerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsDocument21 pagesEmerging Therapeutic Options in The Management of Diabetes Recent Trends, Challenges and Future DirectionsGabriela PachecoNo ratings yet

- MHT-CET 2021 Question Paper: 25 September 2021Document3 pagesMHT-CET 2021 Question Paper: 25 September 2021Sank DamNo ratings yet

- E11133 MB Pin Definition v2 Print Vendor Only PDFDocument18 pagesE11133 MB Pin Definition v2 Print Vendor Only PDFLuciano MalancaNo ratings yet

- Relatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaDocument56 pagesRelatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaMagda RuanoNo ratings yet

- Module II Activated Sludge Math ProblemsDocument5 pagesModule II Activated Sludge Math ProblemsArashNo ratings yet

- Neoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaDocument26 pagesNeoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaErwin SuryanaNo ratings yet

- Company ProfileDocument36 pagesCompany ProfileShahzad Nasir SayyedNo ratings yet

- The Sparkle EffectDocument22 pagesThe Sparkle EffectVida Betances-ReyesNo ratings yet

- Aircraft Structures - Ii (AER18R372)Document15 pagesAircraft Structures - Ii (AER18R372)sarathkumar sebastinNo ratings yet

- 9 Daftar Pustaka VaricelaDocument2 pages9 Daftar Pustaka VaricelaAfrina FaziraNo ratings yet

- 01programming SZGH CNC990TDb (V2.4)Document120 pages01programming SZGH CNC990TDb (V2.4)Rodrigo DiverNo ratings yet

- Naskah Soal PeroranganDocument16 pagesNaskah Soal PeroranganRiza FatimahNo ratings yet

- 7MBR75VB120-50: IGBT MODULE (V Series) 1200V / 75A / PIMDocument8 pages7MBR75VB120-50: IGBT MODULE (V Series) 1200V / 75A / PIMDanielle ButlerNo ratings yet

- Anatomia Dezvoltarii PancreasuluiDocument49 pagesAnatomia Dezvoltarii Pancreasuluitarra abuNo ratings yet

- Infineon IRFZ44N DataSheet v01 - 01 ENDocument9 pagesInfineon IRFZ44N DataSheet v01 - 01 ENIkram RidhoNo ratings yet

- Website Catalog MOTORS v2 PDFDocument8 pagesWebsite Catalog MOTORS v2 PDFИгорь КернякевичNo ratings yet

- 5 - Oral Mucosa and Salivary Glands (Mahmoud Bakr)Document115 pages5 - Oral Mucosa and Salivary Glands (Mahmoud Bakr)MobarobberNo ratings yet

- Lecture2 v1Document69 pagesLecture2 v1c.ronaldo2012777No ratings yet

- Mits Chocolates: Let The Life Be More Sweet'Document30 pagesMits Chocolates: Let The Life Be More Sweet'Azaz NathaniNo ratings yet

- Material Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Document5 pagesMaterial Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Thais Roberta CamposNo ratings yet

- Sop Toh Engine PT MarminDocument5 pagesSop Toh Engine PT MarminBeni WantaraNo ratings yet

- 2020 Landfill Capacity Calculation Work SheetDocument4 pages2020 Landfill Capacity Calculation Work SheetLYNo ratings yet

- Department of Mechanical EnginneringDocument11 pagesDepartment of Mechanical EnginneringViraj SukaleNo ratings yet