Professional Documents

Culture Documents

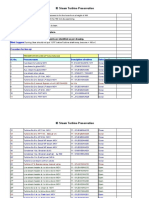

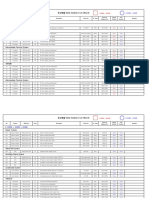

Commissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date Remarks

Uploaded by

talhaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date Remarks

Uploaded by

talhaCopyright:

Available Formats

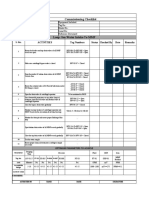

Commissioning Checklist

Client: Equipment Included:

Project: Tag No.:

Date: Model No.:

Service: Serial No.:

Document No: Reference Document:

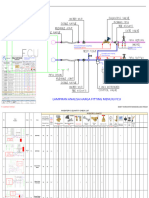

Loop: Sea Water Intake To MMF

S. No. ACTIVITIES Tag Numbers Status Checked By Date Remarks

1 Ensure feed valves and top drain valves of all MMF BFV-08A To BFV-08J = Open

vessels are open BFV-10A To BFV-10J = Open

2 Make sure centrifugal bypass valve is closed BFV-05-8" = Closed

BFV-09A To BFV-09J = Closed

Keep the product & bottom drain valves of all MMF

3 BFV-11A To BFV-11J = Closed

Vessels close

BV-04A To BV-04J = Closed

AV-02-6" = Closed

4 Ensure the actuator valve at RO Feed of both trains and at AV-03-2" = Closed

RO Dump is closed AV-05-6" = Closed

AV-06-2" = Closed

6 Open the drain valve of centrifugal seperator To be mentioned in P&ID

Once favourable parameters are met after chemical

BFV-06-12" = Open

7 treatment, open the feed valve and Product valve of

BFV-07-12" = Open

centrifugal seperator.

Close the bypass drain valve gradually BFV-04-12" = Closed

Monitor vacuum breaker of centrifugal seperator and

8 VB-03-1", VB-04A To VB-04J

MMF Vessels for the evacuation of air from this loop

Monitor the drain pit and ensure proper flushing of this

9 -

loop

BFV-11A To BFV-11J = Open

Open bottom drain valves of all MMF vessels gradually

BV-04A To BV-04J = Open

Close the top drain valves of all MMF vessels gradually BFV-10A To BFV-10J = Closed

10 Test the water sample -

Ensure proper chemical treatment according to sample

11 -

test results

OPTIMUM PARAMETERS TO ACHIEVE

Purging

Parameter Pressure Flow ORP Iron

Time

MMF

Tag No. AV-01-2" PT-02 PI-005 PI-006 PI-007 PI-008 PT-03 FT-01 ORP-01

Product

Unit Minutes Psi Psi Psi Psi Psi Psi GPM mV PPM

Acceptable

Range 5-10 45-55 45-55 45-55 45-55 45-55 45-55 1000-1100 mV<=275 PPM<=0.1

Current Value

COMMENTS:

ATTESTED BY NAME DATE SIGNATURE

You might also like

- 520L0211 - PVG 32 Spares - May 2008Document68 pages520L0211 - PVG 32 Spares - May 2008jose manuel barroso pantojaNo ratings yet

- CV - Bifold Group CatalogDocument576 pagesCV - Bifold Group Catalogking4life50% (2)

- Workshop Manual Checking Fluid Level PDKDocument11 pagesWorkshop Manual Checking Fluid Level PDKEderson BJJNo ratings yet

- 02 BOPE - Description & SelectionDocument81 pages02 BOPE - Description & SelectionKhanh Pham Minh100% (3)

- Hydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1Document1 pageHydraulic Power Unit Cum Control Panel: Sheet No. 1 of 1rakeshsundaramurthyNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Instruction Manual Book 2 PDFDocument284 pagesInstruction Manual Book 2 PDFRM HaroonNo ratings yet

- 2011 Land Rover Range Rover SpecsDocument4 pages2011 Land Rover Range Rover Specssportutilityvehicle100% (1)

- Drilling Well Control: Eng. Karim ZakariaDocument20 pagesDrilling Well Control: Eng. Karim ZakariaRizwan FaridNo ratings yet

- Bolt Head Fillet Stress Concentration Factors in Cylindrical Pressure VesselsDocument6 pagesBolt Head Fillet Stress Concentration Factors in Cylindrical Pressure Vesselsacadjournals. comNo ratings yet

- Manual Handbook Maintenance-2017Document87 pagesManual Handbook Maintenance-2017Elliza IshakNo ratings yet

- Standard Testing Method For Water Analysis For Reverse Osmosis and NanofiltrationDocument2 pagesStandard Testing Method For Water Analysis For Reverse Osmosis and NanofiltrationtalhaNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- KladivarDocument107 pagesKladivaranta77No ratings yet

- Concrete Test Cube ProcedureDocument4 pagesConcrete Test Cube ProcedureEE007CA67% (6)

- CT - 100 - SPC - Rev01 Mar 2015Document67 pagesCT - 100 - SPC - Rev01 Mar 2015Ittoop and sons AutomobileNo ratings yet

- HYD0006 Solar Control Valve KVMG270 PDFDocument53 pagesHYD0006 Solar Control Valve KVMG270 PDFSergey100% (2)

- Design Criteria For Large Box Culverts (Main Road)Document9 pagesDesign Criteria For Large Box Culverts (Main Road)Yoshua YangNo ratings yet

- Danfoss Sem Safe Section Valve Deluge Pipe SystemDocument5 pagesDanfoss Sem Safe Section Valve Deluge Pipe SystemYusuf ÖğrenNo ratings yet

- Protection & InterlockDocument112 pagesProtection & Interlockarunrajmech09No ratings yet

- E PR 491Document41 pagesE PR 491aizzuan_1No ratings yet

- Bis-Dk-Ut 1152 - 1200-24-VC01Document6 pagesBis-Dk-Ut 1152 - 1200-24-VC01TomasPavlovicNo ratings yet

- Test Case Job Pack - For Reference OnlyDocument8 pagesTest Case Job Pack - For Reference OnlyErick AguadoNo ratings yet

- Pressure Losses in Pipes Bends and FittingsDocument31 pagesPressure Losses in Pipes Bends and FittingsMayuresh ChavanNo ratings yet

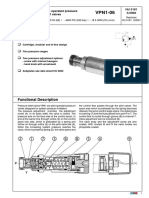

- VPN1 06Document10 pagesVPN1 06Marcelo ArayaNo ratings yet

- ICSS To WHCP 13 Sequence OPEN-CLOSEDocument4 pagesICSS To WHCP 13 Sequence OPEN-CLOSECường Đặng ViếtNo ratings yet

- ICSS To WHCP 13 Sequence OPEN-CLOSE PDFDocument4 pagesICSS To WHCP 13 Sequence OPEN-CLOSE PDFCường Đặng ViếtNo ratings yet

- DagdogaDocument3 pagesDagdogashehab nabilNo ratings yet

- Pre - Boiler Flushing Condensate & Feed Water StatusDocument8 pagesPre - Boiler Flushing Condensate & Feed Water StatusAdnan MahmudNo ratings yet

- Installation Instructions / Operating & Maintenance Manual Reduced Pressure Zone (RPZ) Valves Type "BA" DevicesDocument3 pagesInstallation Instructions / Operating & Maintenance Manual Reduced Pressure Zone (RPZ) Valves Type "BA" DevicesCire Lop CastroNo ratings yet

- Ba BM: Backflow Preventer With Verifiable Reduced Pressure Zone With Funnel IncorporatedDocument4 pagesBa BM: Backflow Preventer With Verifiable Reduced Pressure Zone With Funnel IncorporatedPriyanka rajpurohitNo ratings yet

- 부산복합 Valve Isolation List Rev.ADocument7 pages부산복합 Valve Isolation List Rev.ADK YooNo ratings yet

- MSG11 3500UK OfflineDocument854 pagesMSG11 3500UK Offlinemanuel sebastian avendanoNo ratings yet

- GAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Document15 pagesGAC-12-VX-RMH-LAH-006 - Rev 1 - Attachments - 1 To 9Dipayan DasNo ratings yet

- Commissioning Procedure - LPG Liquid ReceivingDocument5 pagesCommissioning Procedure - LPG Liquid ReceivingAba ShahrilNo ratings yet

- TDBFP Isolation & Normalisation ChecklistDocument6 pagesTDBFP Isolation & Normalisation ChecklistpradeepmloboNo ratings yet

- Flow Control Valves: Hydraulic ComponentsDocument28 pagesFlow Control Valves: Hydraulic ComponentsMohamed IbrahimNo ratings yet

- Wfi Final RinseDocument3 pagesWfi Final RinseappusheteNo ratings yet

- High TAN Study SummuaryDocument3 pagesHigh TAN Study Summuary00083583rfNo ratings yet

- 2016 ElectricalDocument31 pages2016 ElectricalEdison lunaNo ratings yet

- m731 e K3 v04 5554 en PDFDocument22 pagesm731 e K3 v04 5554 en PDFtsdcnNo ratings yet

- SK480-8LC ElectricDocument12 pagesSK480-8LC ElectricAgus RahmanNo ratings yet

- DETAIL FCU For Material InventoryDocument4 pagesDETAIL FCU For Material Inventoryressurection.lufNo ratings yet

- Hydraulics 12: CatalogueDocument107 pagesHydraulics 12: CatalogueПетр ШкильNo ratings yet

- Vyago Engineers: ISO 9001:2015 Certified CompanyDocument20 pagesVyago Engineers: ISO 9001:2015 Certified CompanyScripts TeamNo ratings yet

- 부산복합 Valve Isolation List Rev.0 - REDocument7 pages부산복합 Valve Isolation List Rev.0 - REDK YooNo ratings yet

- Early Gas WP Area MC Requirements PDFDocument134 pagesEarly Gas WP Area MC Requirements PDFYousuf Nasser ALAbriNo ratings yet

- Mock Drill Report On IA Failure Dated 09.04.2023Document6 pagesMock Drill Report On IA Failure Dated 09.04.202300083583rfNo ratings yet

- Test # 1: 250 PSI / 3750 PSIDocument13 pagesTest # 1: 250 PSI / 3750 PSIMurtda AL-SayadNo ratings yet

- Pressure Losses in Pipes Bends and FittingsDocument30 pagesPressure Losses in Pipes Bends and FittingsMayuresh ChavanNo ratings yet

- Hyco Total Catalog201901 English 3way Test Valve Needle Valve Refrigerant Valve Flaretype Valve TestDocument16 pagesHyco Total Catalog201901 English 3way Test Valve Needle Valve Refrigerant Valve Flaretype Valve TestCo3lh4No ratings yet

- CHPT 4 FeedDocument6 pagesCHPT 4 FeedManuelNo ratings yet

- TVS 5000 D KTC Fluid Control ArmstrongDocument4 pagesTVS 5000 D KTC Fluid Control ArmstrongElleuch HaithemNo ratings yet

- Control Valves Modulating: Customer: Contractor: Plant: LocationDocument64 pagesControl Valves Modulating: Customer: Contractor: Plant: LocationJorge GonzalezNo ratings yet

- Fcu-Lv-Wpv-1120 (Ok)Document5 pagesFcu-Lv-Wpv-1120 (Ok)abuhamid368No ratings yet

- Valve Breather Caps: TechnopolymerDocument2 pagesValve Breather Caps: TechnopolymerKOMATSU SHOVELNo ratings yet

- Wa0000Document60 pagesWa0000Radha Raman Mishra100% (1)

- r5v Sales d049Document6 pagesr5v Sales d049Junior Francisco QuijanoNo ratings yet

- Valvula de Bloqueo b17 PDFDocument3 pagesValvula de Bloqueo b17 PDFRonan CristhiamNo ratings yet

- IOM APV ChokeDocument24 pagesIOM APV ChokeKia McNo ratings yet

- S SPS100 Silo Protection System User Guide Issue 4Document22 pagesS SPS100 Silo Protection System User Guide Issue 4aditya jangidNo ratings yet

- Orifice and Jet Flow AppDocument40 pagesOrifice and Jet Flow AppMayuresh ChavanNo ratings yet

- Agp 22050 TP Pip E01 1004.00Document14 pagesAgp 22050 TP Pip E01 1004.00angelito bernalNo ratings yet

- High Energy Drain Valve Downstream Temp - 20 04 2020Document2 pagesHigh Energy Drain Valve Downstream Temp - 20 04 2020bhaskarNo ratings yet

- Kidde Engineered Fire Suppression System: 3-Way Directional Ball Valve Data SheetDocument10 pagesKidde Engineered Fire Suppression System: 3-Way Directional Ball Valve Data SheetEmad SalamaNo ratings yet

- RecommendationsDocument1 pageRecommendationsMuhammad SalmanNo ratings yet

- MV 12a Single Phase Under Voltage or Over Voltage RelayDocument2 pagesMV 12a Single Phase Under Voltage or Over Voltage RelayProsenjitroy RoyNo ratings yet

- Commissioning Checklist: S. No. Activities Tag Numbers Status Date Remarks Checked byDocument1 pageCommissioning Checklist: S. No. Activities Tag Numbers Status Date Remarks Checked bytalhaNo ratings yet

- Loop: Sea Water Intake To Drain Bypass: Commissioning ChecklistDocument4 pagesLoop: Sea Water Intake To Drain Bypass: Commissioning ChecklisttalhaNo ratings yet

- Commissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date RemarksDocument2 pagesCommissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date RemarkstalhaNo ratings yet

- Commissioning Checklist: S. No. Activities Tag Numbers Status Date Remarks Checked byDocument1 pageCommissioning Checklist: S. No. Activities Tag Numbers Status Date Remarks Checked bytalhaNo ratings yet

- Commissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date RemarksDocument2 pagesCommissioning Checklist: S. No. Activities Tag Numbers Status Checked by Date RemarkstalhaNo ratings yet

- Order-Id Tracking ID Amz Price Item-Price Shipping-PriceDocument8 pagesOrder-Id Tracking ID Amz Price Item-Price Shipping-PricetalhaNo ratings yet

- Check Out The Original Dashboard by Mynda Treacy Here: Https://Youtu - Be/5Qtsiote2Wy Check Out The Original Dashboard by HereDocument28 pagesCheck Out The Original Dashboard by Mynda Treacy Here: Https://Youtu - Be/5Qtsiote2Wy Check Out The Original Dashboard by HereAbu ZubayrNo ratings yet

- Physical Inspection ReportDocument3 pagesPhysical Inspection ReporttalhaNo ratings yet

- Check Out The Original Dashboard by Mynda Treacy Here: Https://Youtu - Be/5Qtsiote2Wy Check Out The Original Dashboard by HereDocument28 pagesCheck Out The Original Dashboard by Mynda Treacy Here: Https://Youtu - Be/5Qtsiote2Wy Check Out The Original Dashboard by HereAbu ZubayrNo ratings yet

- Project Management Dashboard PDFDocument1 pageProject Management Dashboard PDFAshish GondaneNo ratings yet

- Assignment No. 01 Talha Alam Khan IM-045 Business Process Re-EngineeringDocument3 pagesAssignment No. 01 Talha Alam Khan IM-045 Business Process Re-EngineeringtalhaNo ratings yet

- GFSignet 9900 Manual English Rev E 100814Document72 pagesGFSignet 9900 Manual English Rev E 100814talhaNo ratings yet

- Billing Summary Customer Details: Total Amount Due (PKR) : 1,837Document1 pageBilling Summary Customer Details: Total Amount Due (PKR) : 1,837talhaNo ratings yet

- EAV FormulaeDocument4 pagesEAV FormulaetalhaNo ratings yet

- Understanding To-Complete Performance Index (TCPI) in Project Cost ManagementDocument12 pagesUnderstanding To-Complete Performance Index (TCPI) in Project Cost ManagementtalhaNo ratings yet

- Reliability Test RunDocument11 pagesReliability Test RuntalhaNo ratings yet

- Malard SolutionDocument1 pageMalard SolutiontalhaNo ratings yet

- Calibration Standards Kit: Instruction SheetDocument2 pagesCalibration Standards Kit: Instruction SheettalhaNo ratings yet

- Earned Value AnalysisDocument4 pagesEarned Value AnalysistalhaNo ratings yet

- Assignment No. 01 Talha Alam Khan IM-045 Business Process Re-EngineeringDocument3 pagesAssignment No. 01 Talha Alam Khan IM-045 Business Process Re-EngineeringtalhaNo ratings yet

- Project Management Dashboard PDFDocument1 pageProject Management Dashboard PDFAshish GondaneNo ratings yet

- Reliability Test RunDocument11 pagesReliability Test RuntalhaNo ratings yet

- Reliability Test Procedure Rev-B 11-03-2015 JKDocument8 pagesReliability Test Procedure Rev-B 11-03-2015 JKJaroslav KurucNo ratings yet

- User Manual: U1000 V2 Ultrasonic Flowmeter U1000 V2 HM Ultrasonic FlowmeterDocument44 pagesUser Manual: U1000 V2 Ultrasonic Flowmeter U1000 V2 HM Ultrasonic FlowmetertalhaNo ratings yet

- Re: Packaging and Labelling Update For Sandvik Welding ConsumablesDocument2 pagesRe: Packaging and Labelling Update For Sandvik Welding ConsumablestalhaNo ratings yet

- Income Tax Payment Challan: PSID #: 143186538Document1 pageIncome Tax Payment Challan: PSID #: 143186538talhaNo ratings yet

- Calibration Standards Kit: Instruction SheetDocument2 pagesCalibration Standards Kit: Instruction SheettalhaNo ratings yet

- Problem Set 4Document5 pagesProblem Set 4Jobelle SDNo ratings yet

- DBR ChecklistDocument9 pagesDBR ChecklistJai ThakkarNo ratings yet

- CEPSA Lubricants WindpowerDocument5 pagesCEPSA Lubricants WindpowerVaida Man KanNo ratings yet

- Fluids Gas Engines A001072 - 06EDocument126 pagesFluids Gas Engines A001072 - 06Episton brokeNo ratings yet

- Transmotauto 2015Document107 pagesTransmotauto 2015zoragiNo ratings yet

- Designing A DC MotorDocument7 pagesDesigning A DC MotorPravat SatpathyNo ratings yet

- Plane Stress Model: Transforming Stress Components and DirectionsDocument7 pagesPlane Stress Model: Transforming Stress Components and DirectionsEngr Aizaz AhmadNo ratings yet

- KTA 3205 - 2 - Engl - 2018 - 10 PDFDocument35 pagesKTA 3205 - 2 - Engl - 2018 - 10 PDFMIKAEL HENRIOTNo ratings yet

- User List PDFDocument2 pagesUser List PDFroooyyNo ratings yet

- Ufgs 41 22 13.15Document60 pagesUfgs 41 22 13.15Abdul wahid ButtNo ratings yet

- New Twist On Interpreting Vibration Analysis FaultsDocument11 pagesNew Twist On Interpreting Vibration Analysis FaultsSérgio CruzNo ratings yet

- Problem Set 2.projectile MotionDocument9 pagesProblem Set 2.projectile MotionChristian OconNo ratings yet

- Simulation of ExcavationDocument13 pagesSimulation of Excavationnishan_ravinNo ratings yet

- 1422 Chapt 15 ThermodynamicsDocument40 pages1422 Chapt 15 Thermodynamicstomm01No ratings yet

- Raw Mill Patroller Checklist Route 1Document5 pagesRaw Mill Patroller Checklist Route 1AbasiemekaNo ratings yet

- Concrete Power Trowel ManualDocument28 pagesConcrete Power Trowel ManualManish Kumar SharmaNo ratings yet

- Module 7 - Time Dependant Properties of ConcreteDocument9 pagesModule 7 - Time Dependant Properties of ConcreteMuhammad AbubakarNo ratings yet

- Notes - Measurement of Air ConsumptionDocument7 pagesNotes - Measurement of Air ConsumptionAnil Frivolous Abstemious100% (2)

- J H Hooper Confectionery Packaging EquipmentDocument283 pagesJ H Hooper Confectionery Packaging Equipmentphucborso1No ratings yet

- CPP Report 2020-1Document20 pagesCPP Report 2020-1UnmayNo ratings yet

- Lekm2005 Ai Guide 3600Document88 pagesLekm2005 Ai Guide 3600Jose MoralesNo ratings yet

- Product Data Sheet 6500 Multi Purpose Sample Gas Conditioning System Rosemount en 69434Document4 pagesProduct Data Sheet 6500 Multi Purpose Sample Gas Conditioning System Rosemount en 69434Zeeshan ShamsiNo ratings yet

- Hwang Et All Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam Column Joints For Seismic PDFDocument14 pagesHwang Et All Analytical Model For Predicting Shear Strengths of Interior Reinforced Concrete Beam Column Joints For Seismic PDFEduardo MarquesNo ratings yet