Professional Documents

Culture Documents

4132 Measurement of Thread Parameters Using Floatingcarriage Micrometer

Uploaded by

RICKY MARTIN J 4096Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4132 Measurement of Thread Parameters Using Floatingcarriage Micrometer

Uploaded by

RICKY MARTIN J 4096Copyright:

Available Formats

ME 8513 Metrology and Measurements Lab Department of Mechanical Engineering 2019– 2020

NAME:VISNU VARTHAN V.

EX. NO:17 DATE:19/10/20

MEASUREMENT OF THREAD PARAMETERS USING FLOATINGCARRIAGE

MICROMETER

AIM

To measure the major diameter, minor diameter & Effective diameter by using floating carriage

micrometer.

DEFINITION

It is a precision measuring equipment, primarily used for measurement of major, minor and

effective diameter of thread gauges and precision threaded components.

PRIOR CONCEPTS

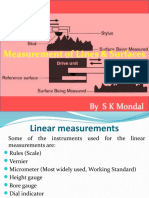

Working and use of micrometer , terminology of screw thread ( Pitch, major diameter, minor

diameter, lead, etc.) and types of threads.

APPARATUS REQUIRED

Floating carriage micrometer, set of standard wires and cylinders, thread plug gauge, threaded

COMPONENT :

Micrometer Thimble, Setting cylinders and Standard wires.

FORMULA:

Major diameter = D – (M – W)

Where,

D = Diameter of setting master

M =Micrometer reading over setting master.

W = Micrometer reading of threaded work space.

Minor Diameter

C = D – 2 [(Mp – Wp) + (M – W)]

Mp = Reading over master and prism

Wp = Reading over work piece and prism

D = Diameter of master

C (MD) = Core or minor diameter of the work piece

Effective Diameter E = T + P

T = D - (Mw-Ww)

P = ½ p cotα - (cosecα -1) w

E = Effective or pitch diameter

T = Measured dimension under cylinders

Mw = Reading measured over setting master with wire

Ww = Reading measured over work piece over wire

'w' = Mean diameter of the cylinders or wires used.

'P' = Constant depending on the pitch and angle of the thread,

and the mean diameter of wires used. (Ready "p" values for different threads are given along with

wires to be used.)

p' = pitch of thread

For metric thread, ∞-60° For BSW thread, ∞-55°

For BSW, pitch = (1/no. of threads per inch)*25.4mm

PROCEDURE

1. Select a plain setting cylinder of a size nearer to workpiece under test.

2. Select a set of standard wires by referring chart 'A'.

3. Hold the selected setting cylinder between centers.

4. Calculate the best wire size and hang the standard wires so that they can contact the

setting cylinder on both sides.

5. Set the floating carriage at right angles to axis of center so that the anvils of micrometer

head and fiducial indicator contact the hanging wires as shown in figure (a).

6. Apply the spring pressure by rotating the thimble screw so that fiducial indicator is set to

zero. Zero error setting is avoided by rotating the setting cylinder so that it rolls over the wires.

7. Note the micrometer reading 'Rs'.

St. Joseph’s Institute of Technology

ME 8513 Metrology and Measurements Lab Department of Mechanical Engineering 2019– 2020

8. Replace the setting cylinder by a threaded component which is to be checked.

9. Insert the standard wires in root of the thread on each side of the component.

10. Apply the spring pressure as stated in earlier step above.

11. Note the micrometer reading 'R' as shown in the figure (b).

12. Note the various observations and calculate effective diameter.

OBSERVATION :

Pitch of thread (p) Diameter of Wire (d) Distance over wire Effective diameter of

S.No (mm) (mm) (m) (mm) wire (DE )

(mm)

1. 2 6.597 5.082 12.342

2.

CALCULATION :

Major diameter = D – (M – W)

Where,

Diameter of setting master (D) =13.86

Micrometer reading over setting masterM =.

Micrometer reading of threaded work spaceW =

Minor Diameter

C = D – 2 [(Mp – Wp) + (M – W)]

Reading over master and prismMp =

Reading over work piece and prism Wp =

Diameter of masterD =

Core or minor diameter of the work pieceC (MD) =

Effective Diameter E = T + P

T = D - (Mw-Ww)

P = ½ p cotα - (cosecα -1) w

Measured dimension under cylindersT =

Reading measured over setting master with wire Mw =

Reading measured over work piece over wire Ww =

Mean diameter of the cylinders or wires used.'w' =

Constant depending on the pitch and angle of the thread,'P' =

Effective or pitch diameterE =

RESULT :

Effective diameter of a threaded component is found to be (E) = …............. mm.

INFERENCE:

From this experiment I learnt about measurement of thread parameters using

floating carriage micrometer.

VIVA QUESTIONS

1. What is the difference between metric thread and whitworth thread ?

2. What is the use of floating carriage micrometer.

3. List the applications of thread plug gauge.

4. What is meant by effective diameter ?

5.What is the use of micrometer thimble ?

St. Joseph’s Institute of Technology

You might also like

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Metrology 2 Wire and 3 Wire Method Exp Manual PDFDocument9 pagesMetrology 2 Wire and 3 Wire Method Exp Manual PDFphanindra kumar100% (1)

- Faculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, PuneDocument57 pagesFaculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, Puneraghav maskeNo ratings yet

- JJ204 Workshop Technology Semester 2Document150 pagesJJ204 Workshop Technology Semester 2Ye ChonnNo ratings yet

- Form MetrologyDocument67 pagesForm Metrologymrbalaji88No ratings yet

- Chapter 1 Screw ThreadDocument29 pagesChapter 1 Screw ThreadWan Muhamad FaizNo ratings yet

- Metrology: Floating Carriage Laboratory AssignmentsDocument7 pagesMetrology: Floating Carriage Laboratory AssignmentsRhys LambadariosNo ratings yet

- Experiment 6 Measureing Screw Thread Parameter With Optical Profile ProjectorDocument9 pagesExperiment 6 Measureing Screw Thread Parameter With Optical Profile ProjectorCao KhảiNo ratings yet

- 6-Screw and Gear MeasurementDocument50 pages6-Screw and Gear MeasurementRohit BhangaleNo ratings yet

- Measurement of Screw ParametersDocument2 pagesMeasurement of Screw Parametersnavneetkpatil8409No ratings yet

- 7 FCMDocument11 pages7 FCMAbhijeetKhandagaleNo ratings yet

- Manufacturing Processes Lab - MEM564 / LS03/Ziyadi Rev. 01-2014Document3 pagesManufacturing Processes Lab - MEM564 / LS03/Ziyadi Rev. 01-2014Ahmad Syazni Bin MoktarNo ratings yet

- Lab Manual: Metrology and Industrial InspectionDocument29 pagesLab Manual: Metrology and Industrial InspectionFaysal AhmedNo ratings yet

- Tapers and ScrewDocument7 pagesTapers and Screwstolen mechieducNo ratings yet

- Metrology Lab ManualDocument8 pagesMetrology Lab ManualNallappan Rajj ANo ratings yet

- MM 2Document7 pagesMM 2Vaibhav SHRIMALINo ratings yet

- Mechanical Testing SOP for Spiral PC WireDocument3 pagesMechanical Testing SOP for Spiral PC WireNirmal WiresNo ratings yet

- L21 Screw Thread2Document13 pagesL21 Screw Thread2chaitanyamohod2020No ratings yet

- Profile Measurement Full ReportDocument16 pagesProfile Measurement Full ReportAman RedhaNo ratings yet

- ScrewDocument20 pagesScrewIxora MyNo ratings yet

- CE6192 MTech Lab ManualDocument38 pagesCE6192 MTech Lab ManualSathish Kumar VNo ratings yet

- TITLE: Dimensional Measurement of Screw ThreadDocument11 pagesTITLE: Dimensional Measurement of Screw ThreadBroAmirNo ratings yet

- Department of Mechanical Engineering: Metrology Laboratory III B.TECH - I SEMESTER (2015-16)Document23 pagesDepartment of Mechanical Engineering: Metrology Laboratory III B.TECH - I SEMESTER (2015-16)Shresth SanskarNo ratings yet

- Measurement of Tapers: Type Equation HereDocument11 pagesMeasurement of Tapers: Type Equation Hereimma coverNo ratings yet

- Metrology & Measurement Assignment Guide ME-504Document2 pagesMetrology & Measurement Assignment Guide ME-504Sharthak GhoshNo ratings yet

- Micro-Hole Drilling On Thin Sheet Metals by Micro-EdmDocument11 pagesMicro-Hole Drilling On Thin Sheet Metals by Micro-EdmAmit Kumar SinghNo ratings yet

- Andrey Elenkov's Measurement and Instrumentation LecturesDocument223 pagesAndrey Elenkov's Measurement and Instrumentation LecturesManuel Adrian Vidal PenedoNo ratings yet

- Measurements and Metrology Laboratory ManualDocument20 pagesMeasurements and Metrology Laboratory Manualbossanand05100% (3)

- Design and Analyses Re - Bar Bending MachineDocument3 pagesDesign and Analyses Re - Bar Bending MachineMircea100% (1)

- MM 322 Lab 3Document7 pagesMM 322 Lab 3william taloNo ratings yet

- Measure Dimensions Using Metrology ToolsDocument21 pagesMeasure Dimensions Using Metrology ToolselavarasanNo ratings yet

- Lab 1 Metrology (Measurement of Screw Thread) (FKM PENANG)Document4 pagesLab 1 Metrology (Measurement of Screw Thread) (FKM PENANG)jojoNo ratings yet

- CFD Analysis of Wind Turbine Blade: H. V. Mahawadiwar, V.D. Dhopte, P.S.Thakare, Dr. R. D. AskhedkarDocument7 pagesCFD Analysis of Wind Turbine Blade: H. V. Mahawadiwar, V.D. Dhopte, P.S.Thakare, Dr. R. D. AskhedkarPatrickAndradeNo ratings yet

- QuickGuide Internal MicrometersDocument2 pagesQuickGuide Internal MicrometersMohamed SamyNo ratings yet

- (Course Code:18ME36B) : Mechanical Measurements and MetrologyDocument42 pages(Course Code:18ME36B) : Mechanical Measurements and MetrologyJay SathwaraNo ratings yet

- TVET 1 (Worksheet 4)Document5 pagesTVET 1 (Worksheet 4)Abrigondo, Vindel J.No ratings yet

- 5.EMM Lab ManualDocument38 pages5.EMM Lab ManualRakeshkumarcegNo ratings yet

- Various Parameter Measurement - Jan 2022 - R1Document7 pagesVarious Parameter Measurement - Jan 2022 - R1Anih Kishor (RA1911002010062)No ratings yet

- Module B Practicum Report - Structural AnalysisDocument13 pagesModule B Practicum Report - Structural AnalysisShiela Ariesta EfendiNo ratings yet

- METROLOGY LAB MANUALDocument30 pagesMETROLOGY LAB MANUALSanju JohnNo ratings yet

- whatispiping.com-MITER BEND Formula to Calculate Length Angle of Cut Weight and Cut-back of the Miters With PDFiftypeoDocument9 pageswhatispiping.com-MITER BEND Formula to Calculate Length Angle of Cut Weight and Cut-back of the Miters With PDFiftypeoamlanfacebookNo ratings yet

- Index: Ex. No Name of The Experiment Page No. Cycle IDocument29 pagesIndex: Ex. No Name of The Experiment Page No. Cycle Iprakashrs295No ratings yet

- Tool Makers MicroscopeDocument7 pagesTool Makers MicroscopeAnand Babu100% (2)

- Physics Labwork: For MechanicsDocument24 pagesPhysics Labwork: For MechanicsSang NguyễnNo ratings yet

- 1.tool Makers MicroscopeDocument7 pages1.tool Makers MicroscopeelavarasanNo ratings yet

- Screw GaugeDocument7 pagesScrew GaugeAbdul AhadNo ratings yet

- VIT University Optoelectronics Lab ManualDocument22 pagesVIT University Optoelectronics Lab ManualkameshwariNo ratings yet

- Stress Analysis of Bell Crank Lever Using FEM and PhotoelasticityDocument8 pagesStress Analysis of Bell Crank Lever Using FEM and PhotoelasticityAnonymous kTVBUxrNo ratings yet

- Ch-25 Measurement of Lines - SurfacesDocument92 pagesCh-25 Measurement of Lines - SurfacesManojNo ratings yet

- Compact Dielectric Resonator Antenna With Band-Notched Characteristics For Ultra-Wideband ApplicationsDocument12 pagesCompact Dielectric Resonator Antenna With Band-Notched Characteristics For Ultra-Wideband ApplicationsMarulina StewartNo ratings yet

- Strain GaugeDocument11 pagesStrain Gaugemontaser.nalawiNo ratings yet

- Report Experiment ThreadDocument11 pagesReport Experiment Threadsparklingstars2705No ratings yet

- Design of machine elements lab manualDocument22 pagesDesign of machine elements lab manualSHANIL PARMARNo ratings yet

- National Institute of Technology Warangal Department of Mechanical Engineering Warangal - 506 004Document50 pagesNational Institute of Technology Warangal Department of Mechanical Engineering Warangal - 506 004Venu Gopal AnneNo ratings yet

- Design A Square Microstrip Patch Antenna at 2.4 GHZ, and Comparison Between Unslotted and Slotted VersionDocument6 pagesDesign A Square Microstrip Patch Antenna at 2.4 GHZ, and Comparison Between Unslotted and Slotted VersionAnonymous XZUyueNNo ratings yet

- BME Mannual BT 203-1Document41 pagesBME Mannual BT 203-1shivanshu tiwariNo ratings yet

- Design and Analysis of Lead Screw For FixtureDocument7 pagesDesign and Analysis of Lead Screw For FixtureA PPNo ratings yet

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of GearboxChandrakiran AlapatiNo ratings yet

- Comprehensive Cellulose Chemistry - Vol. 1 - Fundamentals and Analytical MethodsDocument286 pagesComprehensive Cellulose Chemistry - Vol. 1 - Fundamentals and Analytical MethodsrodsNo ratings yet

- Pianti Pelajaran KenuanDocument93 pagesPianti Pelajaran KenuanUziNo ratings yet

- Electronic Circuit Style CV by SlidesgoDocument39 pagesElectronic Circuit Style CV by SlidesgoHelmanz NugrahaNo ratings yet

- The Role of District Heating in Future Renewable Energy SystemsDocument10 pagesThe Role of District Heating in Future Renewable Energy SystemsSrinivas RaghavanNo ratings yet

- Study of Transparent Concrete: Presented ByDocument17 pagesStudy of Transparent Concrete: Presented ByGaurav JainNo ratings yet

- Bronze Age EuropeDocument10 pagesBronze Age EuropeVíctor Alfonso Medina LugoNo ratings yet

- Problems Involving Inverse FunctionsDocument3 pagesProblems Involving Inverse FunctionsDominic Dalton Caling0% (1)

- 1.2 Amount of Substance Exam QsDocument15 pages1.2 Amount of Substance Exam QsEmoryNo ratings yet

- AAC Activity 1 (Life Process)Document2 pagesAAC Activity 1 (Life Process)JamesNo ratings yet

- Existentialism in EducationDocument6 pagesExistentialism in EducationTiffany AquinoNo ratings yet

- Module 1 Lesson 2Document4 pagesModule 1 Lesson 2SOMERA Princess Nicole V.No ratings yet

- PHY End Sem Lab Report GuideDocument2 pagesPHY End Sem Lab Report GuideAdith SaiNo ratings yet

- MP3 FFDocument20 pagesMP3 FFabeck1713100% (2)

- Biology Biology: Meiosis and Sexual Life CyclesDocument13 pagesBiology Biology: Meiosis and Sexual Life CyclesRosemond FabienNo ratings yet

- 5 - Organization ChartDocument2 pages5 - Organization ChartYass AhmedNo ratings yet

- Thermal controller for semiconductor switching devicesDocument15 pagesThermal controller for semiconductor switching devicesAnonymous G1iPoNOKNo ratings yet

- Speech Language Stimulation TechniquesDocument33 pagesSpeech Language Stimulation TechniquesRamanakumar MohanNo ratings yet

- Finnish National Annex TO EN 1990-A2 Basis of Structural Design Annex A2: Application For Bridges (Normative)Document22 pagesFinnish National Annex TO EN 1990-A2 Basis of Structural Design Annex A2: Application For Bridges (Normative)chong pak limNo ratings yet

- Taking Off-ABCDocument3 pagesTaking Off-ABChello.testduluNo ratings yet

- IJLL - SanskritDocument6 pagesIJLL - SanskritSudarshan RaghununanNo ratings yet

- Luciana Session 3 - Mindvana Session NotesDocument5 pagesLuciana Session 3 - Mindvana Session NotesNehaNo ratings yet

- The Genius Formula With Robin Sharma Masterclass Workbook SP 7Document12 pagesThe Genius Formula With Robin Sharma Masterclass Workbook SP 7Kunal Shiinde0% (1)

- Frolova 2022Document77 pagesFrolova 2022Simratjeet KaurNo ratings yet

- Lattice Vibrations and Electronic Properties of GaSe Nanosheets From First PrinciplesDocument8 pagesLattice Vibrations and Electronic Properties of GaSe Nanosheets From First PrinciplesMuosa BejaniNo ratings yet

- Improved Line Voltage Zero-Crossing Detection Techniques For PV InvertersDocument6 pagesImproved Line Voltage Zero-Crossing Detection Techniques For PV InvertersJAHANGEER AHMADNo ratings yet

- Bus MathDocument100 pagesBus MathApple Michaela Asiatico PaloNo ratings yet

- Fundamentals of FractionsDocument5 pagesFundamentals of FractionssingenaadamNo ratings yet

- Algebra Class 9Document18 pagesAlgebra Class 9Santosh UpadhyayNo ratings yet

- Class 2 NSO Preparation Free Sample Test: Aabbaa Ababab Abbabb Aababb A. B. C. DDocument11 pagesClass 2 NSO Preparation Free Sample Test: Aabbaa Ababab Abbabb Aababb A. B. C. DamarpreetsethiNo ratings yet

- QualitativeDocument306 pagesQualitativeParintins Parintins100% (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontRating: 4.5 out of 5 stars4.5/5 (18)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaFrom EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaRating: 4 out of 5 stars4/5 (1)

- Busted!: Drug War Survival Skills and True Dope DFrom EverandBusted!: Drug War Survival Skills and True Dope DRating: 3.5 out of 5 stars3.5/5 (7)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Principles of direct and superior responsibility in international humanitarian lawFrom EverandPrinciples of direct and superior responsibility in international humanitarian lawNo ratings yet

- Slow Violence and the Environmentalism of the PoorFrom EverandSlow Violence and the Environmentalism of the PoorRating: 4 out of 5 stars4/5 (5)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- New Paradigms in Environmental Biomonitoring Using PlantsFrom EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariNo ratings yet

- Environmental Education in Practice: Concepts and ApplicationsFrom EverandEnvironmental Education in Practice: Concepts and ApplicationsNo ratings yet

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933From EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933No ratings yet

- Down to the Wire: Confronting Climate CollapseFrom EverandDown to the Wire: Confronting Climate CollapseRating: 4.5 out of 5 stars4.5/5 (8)

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksFrom EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksNo ratings yet

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010From EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Rating: 5 out of 5 stars5/5 (2)

- Climate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysFrom EverandClimate Action Challenge: A Proven Plan for Launching Your Eco-Initiative in 90 DaysNo ratings yet

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontFrom EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontRating: 4.5 out of 5 stars4.5/5 (9)