Professional Documents

Culture Documents

ReadmeFasten5950 1 2000

ReadmeFasten5950 1 2000

Uploaded by

Chong Wee LinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ReadmeFasten5950 1 2000

ReadmeFasten5950 1 2000

Uploaded by

Chong Wee LinCopyright:

Available Formats

Fasten595020030119-.

xlt

From Techno Consultants Ltd

An Excel Template for finding the Capacity of

Bolts and Welds to BS5950-1: 2000

Introduction

Fasten5950 is an Excel Template for finding the Capacities of Bolts and Welds to BS5950-1: 2000.

The bolts can be Ordinary, Countersunk or High Strength Friction Grip Bolts. Welds can be Fillet

or Butt.

Loading the Template on to your computer

Fasten5950 is supplied as an Excel 97 Template, having .XLT as its filename extension.

To load Fasten5950 on to your computer, copy this file into Microsoft Office folder for its

Templates. Generally the path to this folder in Excel 97 is:

C:\Program Files\Microsoft Office\Templates

If you are using Excel 2000, the path to this folder is:

C:\Windows\Application Data\Microsoft\Templates

To load and use the Template in Excel 97 or Excel 2000, choose:

File, New and the select the file Fasten595020030119-

If you receive an Excel Warning about running Macros and are prompted for whether to load them,

answer YES to Load and Enable Macros. Fasten5950 incorporates VB Macros and to allow your

computer to use them is vital for its operation.

Features

Fasten5950 gives capacities of Hexagon Head Bolts, Countersunk Bolts, High Strength Friction

Grip Bolts, Fillet Welds and Butt Welds using BS5950-1:2000..

It also includes data worksheets for detailing bolts. The information includes: dimensions of bolts

and nuts, washers, various bolt hole sizes, spacing of holes and back marks, bolt symbols, etc. The

Tensile Stress Areas are taken from BS 4190 for Ordinary Black Bolts, BS 3692 for Precision Bolts

and BS 4933 for Countersunk Bolts. The Tensile Stress Areas and Proof Loads for HSFG Bolts are

taken from BS 4395: Part 1 for General Grade and BS 4395: Part 2 for Higher Grade (Parallel

Shank). Scope & method details of various worksheets are described below.

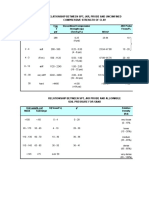

Non-preloaded Hexagon Head & Countersunk Bolts

This worksheet calculates various capacities: Tensile, Single Shear, Double Shear and Bearing for

various Ply thicknesses. The features are:

Bolt Heads can be: Normal or Countersunk

Bolt Grades can be: 4.6, 6.8, 8.8, 10.9 and HSFG General and HSFG Higher Grade

File: 558408759.doc Page 1/3

Shear Plane can be: Bolt Threads or Shank

When Shear Plane in the Shank is selected, a warning is displayed to remind that Threads should

not be in the Shear Plane and that the use of many washers may be necessary to achieve it.

Bolt Holes can be Clearance, Over-size, Short-slotted, Long-slotted and Kidney-shaped

Bolt Diameters are: M1.6, M2, M2.5, M3, M4, M5, M6, M8, M10, M12, (M14), M16, (M18),

M20, (M22), M24, (M27), M30, (M33), M36, (M39), M42, (M45), (M52), M56, (M60), M64 and

(M68), the sizes in brackets being non-preferred.

Hole Edge Distance can be any user-typed value from 1.25 to 2.0 of the Bolt Hole Diameter D.

Connected Ply Grades can be: S275, S355 and S460

Connected Ply Thicknesses can be any User-Typed Values. They can be changed at the head row

of bearing values (shown in light green cell background) to suit any value required for design.

The Combined Tension and Shear Capacity can also be calculated for each bolt diameter. For any

typed value of Applied Tension Ft, the corresponding Shear Capacity Fs of Threads or Shank is

displayed in the adjacent cell.

Three Colours and Font styles are used to display Bearing Capacities. Values below the single shear

capacity are displayed in Red and Normal font. Values above the single shear and below the double

shear capacity are displayed in Blue and Bold. Values above the double shear capacity are shown in

Green and Italic.

Preloaded HSFG Bolts

This worksheet calculates: Proof Load, Tension Capacity, Slip Resistance in Single/Double Shear

and After-slip Bearing Capacities of bolts in various Ply thicknesses. for High Strength Friction

Grip Bolts. The features are:

Bolt Grades can be: General Grade to BS4604: Part 1 and Higher Grade to BS4604: Part 2

Bolt Diameters are: M12, M16, M20, M22, M24, M27, M30 and M36 for General Grade and M16,

M20, M22, M24, M27, M30 and M33 for Higher Grade Bolts

Bolt Holes can be: Clearance, Oversize, Short Slotted and Long Slotted Perpendicular to Load and

Long-slotted parallel to load as defined in BS5950: Part 1

Slip Factor can be 0.2, 0.3, 0.4 and o.5, depending upon the condition of faying surfaces described

in Table 35 of the Code.

Design criteria for connections can be Non-slip in service and Non-slip under factored loads

Connected Ply Grades can be: S275, S355 and S460

File: 558408759.doc Page 2/3

Connected Ply Thicknesses can be any User-Typed Values. They can be changed at the head row

of bearing values (shown in light green cell background) to suit any value required for design.

The Combined Tension and Shear Capacity can also be calculated for each bolt diameter. For any

typed value of Applied Tension Ft, the corresponding Shear Capacity Fs of Threads or Shank is

displayed in the adjacent cell.

To display bearing capacities 3 colours and font styles are used. The values below the single shear

capacity are shown in Red and Normal font. The values above the single shear and below the

double shear capacity are shown in Blue and Bold. The values above the double shear capacity are

shown in Green and Italic.

Fillet Weld Capacities

Two worksheets give Fillet Weld Capacities for Steel Grades S275, S355 and S460, using E35, E42

and E50 Electrodes.

One worksheet uses the Simple Method as per clause 6.8.7.2 and the other uses the Directional

Method as per Clause 6.8.7.3 of the code.

Butt Weld Capacities

Gives Capacities for Full Penetration Butt Welds. The capacities calculated are Shear and

Tension/Compression strength for Steel Grades S275, S355 and S460using E35, E42 and E50

electrodes respectively.

File: 558408759.doc Page 3/3

You might also like

- Trinity Guitar Grade 7 PDFDocument26 pagesTrinity Guitar Grade 7 PDFMiltonDm100% (17)

- Fasteners To AISC and BS449Document11 pagesFasteners To AISC and BS449bgmenotmanNo ratings yet

- NADCA Tolerances 2009Document44 pagesNADCA Tolerances 2009Tom Hagerty100% (1)

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsFrom EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Read Me Fasten 449Document2 pagesRead Me Fasten 449DannyDurhamNo ratings yet

- Flanges InfoDocument10 pagesFlanges Infomohd farid abdjalilNo ratings yet

- Purl in 4600Document9 pagesPurl in 4600Hendra GintingNo ratings yet

- Machinedesign 3417 Specifying Fastener TorqueDocument5 pagesMachinedesign 3417 Specifying Fastener TorqueStarlord PlazaNo ratings yet

- Design Tables For Steel GradesDocument29 pagesDesign Tables For Steel Gradesdiego_is_onlineNo ratings yet

- 5 SlimDek Connection - AW 48240Document12 pages5 SlimDek Connection - AW 48240in678No ratings yet

- Limits & Fits PDFDocument24 pagesLimits & Fits PDFaman_ranhotra0% (1)

- Nadca 402 4aDocument44 pagesNadca 402 4awholenumberNo ratings yet

- Or Less: How To Determine The Best Connections For Steel Joists and Metal DeckDocument4 pagesOr Less: How To Determine The Best Connections For Steel Joists and Metal DeckMinh Tâm TrầnNo ratings yet

- Connection Design Standards: Document No: Cds-1 Second Edition Date: December 9, 2005Document47 pagesConnection Design Standards: Document No: Cds-1 Second Edition Date: December 9, 2005Rajesh Jellelu100% (6)

- NADCA Tolerances 2009Document44 pagesNADCA Tolerances 2009Pedjman GhaderiNo ratings yet

- Wes Beam Roof ProductsDocument64 pagesWes Beam Roof ProductsAwais Safder MalikNo ratings yet

- Castellated Beams STAAD-Pro2004Document13 pagesCastellated Beams STAAD-Pro2004Lukman Nul HakimNo ratings yet

- Article - Structural BoltsDocument6 pagesArticle - Structural Boltsing_weroNo ratings yet

- Bolt Torquing AnalysisDocument7 pagesBolt Torquing AnalysisEleonor MaderazoNo ratings yet

- Steel QuizDocument2 pagesSteel Quizron_danyNo ratings yet

- Tee L Nterc A G: Ses Evio SDocument2 pagesTee L Nterc A G: Ses Evio Sfarhadmrt6923No ratings yet

- Fargo Kula5Document39 pagesFargo Kula5Vulebg VukoicNo ratings yet

- Kisssoft Bolt Analysis ManualDocument24 pagesKisssoft Bolt Analysis Manualanhntran4850No ratings yet

- Steel Framing ConnectioDocument21 pagesSteel Framing ConnectioJamesNo ratings yet

- Design of BoltsDocument19 pagesDesign of Boltsmoganna73No ratings yet

- Weld CalcDocument8 pagesWeld CalcOmil RastogiNo ratings yet

- A FEDS Structural BoltsDocument6 pagesA FEDS Structural BoltsCrimsonPoshNo ratings yet

- Bolt Design For Steel Connections As Per AISCDocument24 pagesBolt Design For Steel Connections As Per AISCJayachandra PelluruNo ratings yet

- Connection - Bolt 2022Document80 pagesConnection - Bolt 2022LUGHANO NGAJILONo ratings yet

- Beam Web Opening - AnalysisDocument4 pagesBeam Web Opening - Analysisk.m.ariful islamNo ratings yet

- Structural Connections - Scia5203: Unit - IDocument77 pagesStructural Connections - Scia5203: Unit - IVignesh DhuruvanNo ratings yet

- Limits and FitsDocument38 pagesLimits and FitsBagus Bramantya bagusbramantya.2019No ratings yet

- C2 Flange Calc Leak StressDocument20 pagesC2 Flange Calc Leak StressahmedalishNo ratings yet

- Coupling DesignDocument3 pagesCoupling DesignMochammad Syaiful BakriNo ratings yet

- Unit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 FinishDocument8 pagesUnit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 Finisheetua100% (2)

- Design and Analysis of Simple ConnectionsDocument88 pagesDesign and Analysis of Simple ConnectionsSabih Hashim Alzuhairy100% (2)

- Ladc/Spe 35037: Premium Connector ConfigurationsDocument10 pagesLadc/Spe 35037: Premium Connector Configurationssigit praNo ratings yet

- Structural Analysis and Design: STAAD - Pro Concrete Design (FAQ)Document7 pagesStructural Analysis and Design: STAAD - Pro Concrete Design (FAQ)turbobrikNo ratings yet

- Machine DesignDocument495 pagesMachine DesignWalter Zert100% (2)

- HSS Steel AvailabilityDocument2 pagesHSS Steel Availabilityaams_sNo ratings yet

- Understanding Machinery Fits and TolerancesDocument11 pagesUnderstanding Machinery Fits and TolerancesManojkumar ThilagamNo ratings yet

- User Notes For Ubucmember: Ub & Uc Member Design To Bs 5950-1:2000Document6 pagesUser Notes For Ubucmember: Ub & Uc Member Design To Bs 5950-1:2000Sara BookerNo ratings yet

- Design of Bolted ConnectionsDocument15 pagesDesign of Bolted ConnectionsAritroNo ratings yet

- Everything You Need To Know About Flatteners and Levelers For Coil Processing-Part 3 - The FabricatorDocument8 pagesEverything You Need To Know About Flatteners and Levelers For Coil Processing-Part 3 - The FabricatorSIMONENo ratings yet

- Structural Steel DesignDocument32 pagesStructural Steel Designshaluka100% (1)

- Structural Steel Design Cie 552: Hopeson Kasumba M.Eng, B.Eng, Macez, Meiz, PR - Eng, R.EngDocument30 pagesStructural Steel Design Cie 552: Hopeson Kasumba M.Eng, B.Eng, Macez, Meiz, PR - Eng, R.EngPenelope MalilweNo ratings yet

- Basics of Steel Connections PDFDocument74 pagesBasics of Steel Connections PDFSantosh Rai100% (1)

- Thesis SpringbackDocument8 pagesThesis SpringbackINeedSomeoneToWriteMyPaperCanada100% (2)

- Which Process?: A Guide to the Selection of Welding and Related ProcessesFrom EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Handloader's Digest: The World's Greatest Handloading BookFrom EverandHandloader's Digest: The World's Greatest Handloading BookRating: 2 out of 5 stars2/5 (1)

- Modelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyFrom EverandModelling of Vibrations of Overhead Line Conductors: Assessment of the TechnologyGiorgio DianaNo ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Buttress Wall - R1Document110 pagesButtress Wall - R1عصام السامرائيNo ratings yet

- Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General ApplicationDocument4 pagesSteel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat Resistant, For General Applicationعصام السامرائيNo ratings yet

- KDC19 Container Concept C Mk3a 17 10 19 Rev E Master S7 - ModelDocument1 pageKDC19 Container Concept C Mk3a 17 10 19 Rev E Master S7 - Modelعصام السامرائيNo ratings yet

- Form F - Application For Registration Renewal 13112019-1 PDFDocument1 pageForm F - Application For Registration Renewal 13112019-1 PDFعصام السامرائيNo ratings yet

- C Geo5Document23 pagesC Geo5عصام السامرائيNo ratings yet

- Geo5 OutputDocument23 pagesGeo5 Outputعصام السامرائيNo ratings yet

- Plaxis ValidationDocument5 pagesPlaxis Validationعصام السامرائيNo ratings yet

- N (Flow/Ft.) Consistency Cqu Uncomfined Compressive JKR Probe 2 Strength (Qu) Flows/Ft. PSF (Ton/Sq - FT.) kN/m2Document8 pagesN (Flow/Ft.) Consistency Cqu Uncomfined Compressive JKR Probe 2 Strength (Qu) Flows/Ft. PSF (Ton/Sq - FT.) kN/m2عصام السامرائيNo ratings yet

- Mesy Tapak BilDocument2 pagesMesy Tapak Bilعصام السامرائيNo ratings yet

- Base Plate DesignMS601a Good MahfuzDocument4 pagesBase Plate DesignMS601a Good MahfuzDavid PuenNo ratings yet

- Sepakat Setia Perunding SDN BHD: Design Information DimensionsDocument30 pagesSepakat Setia Perunding SDN BHD: Design Information Dimensionsعصام السامرائيNo ratings yet

- Design of Raft FoundationDocument9 pagesDesign of Raft FoundationМилош ЈанићијевићNo ratings yet

- Transactionhistory PDFDocument3 pagesTransactionhistory PDFعصام السامرائيNo ratings yet

- CL - Ms Premalatha Sukumaran - 17th August 2018Document1 pageCL - Ms Premalatha Sukumaran - 17th August 2018عصام السامرائيNo ratings yet

- Pac Pdpa NoticeDocument1 pagePac Pdpa Noticeعصام السامرائيNo ratings yet

- Catalino Gallemit, vs. Ceferino Tabiliran: FactsDocument1 pageCatalino Gallemit, vs. Ceferino Tabiliran: Factsjeljeljelejel arnettarnettNo ratings yet

- WHFRP Shadows Over BogenhafenDocument6 pagesWHFRP Shadows Over BogenhafenAdam Ogelsby100% (1)

- Music Tech Focus - Mastering 2014Document132 pagesMusic Tech Focus - Mastering 2014Michael Clark100% (1)

- Chapter 1 QuizDocument2 pagesChapter 1 QuizAlejandro AcostaNo ratings yet

- NWS 2023 December NewsletterDocument14 pagesNWS 2023 December NewsletternationalwatercolorsocietyNo ratings yet

- A New Power in South AsiaDocument3 pagesA New Power in South AsiaRayyan SiddiquiNo ratings yet

- Incorporated in 1995: Add A Footer 1Document18 pagesIncorporated in 1995: Add A Footer 1Yashika ChandraNo ratings yet

- CactiDocument33 pagesCactiabc123No ratings yet

- Agriculture Science SBA SampleDocument10 pagesAgriculture Science SBA SampleClinton O'NeilNo ratings yet

- Optimization of Three Wheeler Front Suspension Coil SpringDocument6 pagesOptimization of Three Wheeler Front Suspension Coil SpringSrikanth DNo ratings yet

- Faculty Position OpeningsDocument6 pagesFaculty Position Openingsluaweb123No ratings yet

- MIB GrenobleDocument2 pagesMIB GrenobleKamal GuptaNo ratings yet

- CMS Report 1 PDFDocument13 pagesCMS Report 1 PDFRecordTrac - City of OaklandNo ratings yet

- The Question Form in English - RevisionDocument13 pagesThe Question Form in English - RevisionDeforeitNo ratings yet

- DemoDocument12 pagesDemoGenelie Morales SalesNo ratings yet

- SOCSO CasesDocument16 pagesSOCSO CasesAbdul Hadi OmarNo ratings yet

- Giáo Án Anh 8 Global Success Unit 1Document31 pagesGiáo Án Anh 8 Global Success Unit 1Vương Bảo ChiNo ratings yet

- Module 7 Weathering As Exogenic ProcessDocument7 pagesModule 7 Weathering As Exogenic Processrose belle garciaNo ratings yet

- Indian SPACE COMPANIESDocument14 pagesIndian SPACE COMPANIESChujja ChuNo ratings yet

- Cleft Lip & PalateDocument33 pagesCleft Lip & PalatedyahNo ratings yet

- Listof Approved Pesticide Equipment Inspectors 211123231123Document4 pagesListof Approved Pesticide Equipment Inspectors 211123231123jimhuanggNo ratings yet

- Scan Nov 16 2020 2Document2 pagesScan Nov 16 2020 2api-530928785No ratings yet

- Chemical One Act Play 2k19Document16 pagesChemical One Act Play 2k19Roshan Kumar LohaniNo ratings yet

- Science Assessment TaskDocument4 pagesScience Assessment TaskNabiha SyedaNo ratings yet

- Vibratory Sieve Shaker AS 200 Control: General InformationDocument11 pagesVibratory Sieve Shaker AS 200 Control: General InformationSupriyo PNo ratings yet

- Cambridge International AS & A Level: Economics 9708/42 March 2020Document10 pagesCambridge International AS & A Level: Economics 9708/42 March 2020Blade CheesyNo ratings yet

- Nus Career Fest 2020 PDFDocument8 pagesNus Career Fest 2020 PDFweiweiahNo ratings yet

- Genealogy of Jesus Pictures2-Locked PDFDocument1 pageGenealogy of Jesus Pictures2-Locked PDFDanielaNo ratings yet

- Sports Injury PaperDocument9 pagesSports Injury PaperdmatherNo ratings yet