Professional Documents

Culture Documents

Lift Lug Spreadsheet

Lift Lug Spreadsheet

Uploaded by

andry4jcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lift Lug Spreadsheet

Lift Lug Spreadsheet

Uploaded by

andry4jcCopyright:

Available Formats

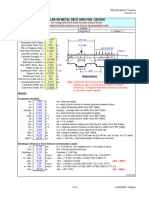

CALCULATION SHEET

Job Number: Sheet 1 of

Customer: Revision: 1 Date:

Project: Title: Lifting Lug Design By:

P.O. number: Appr'd by:

Tag number: W = Total weight 1061

N = Number of lugs 2

H= 2

Fv W= 3.3125

Fr t= 0.5

D= 0.75

R= 0.875

Dp = Shackle pin diameter = 0.5

F = Actual load per lug = 530.5

I = Impact factor = 1.5

Fh Fv = Vertical load = F x I = 795.75

Fh = Fr(CosS) = 796

S = Sling angle (Minimum = 60 ) o

45

Fr = Resultant force = Fv/sin S = 1125

Lug Material: Dplx 2205

Material Yield Stress = 25000

Notes: Effect of gusset perpendicular to lug

is not considered.

Thickness of gusset is considered.

Ss = Shear stress = Fh / (2 x t x (R-D/2)) Ss allowable = 0.5 x Yield stress =

fv = 1592 psi Shear stress is OK

fb + ft = Bending plus tension stress (longitudinal)=fb + ft allowable = 0.8 x Yield stress =

Fh x H + Fv + (.10)Fr x H = 3852 Bending + tension stress is OK

t x (W2/6) t x W t x (W2/6) psi

fg = Bearing stress = Fr / (.85 x t x Dp) = fg allowable = 0.5 x Yield stress =

fg = 5296 psi Bearing stress is OK

Weld Size Calculations

Weld length = L = 2W + 2t = 7.63 Max. allowable stress of base metal

Section Modulus = Sx = Wt + W2/3 = 5.31

Bending Stress = fb = Fh x H / Sx = 299.50 min. weld size = f / fw =

Shear Stress = fv = Fh / L = 104.36

Tension Stress = ft = Fv / L = 104.36 Actual fillet weld size =

Combined Stress = f Maximum allowable Stress = fw

f = sq rt ((fb + ft)2 + fv2) = 417.13 fw = 0.45 x Sa =

1

18-Dec-14

(pounds)

(inches)

(inches)

(inches)

(inches)

(inches)

(inches)

(pounds)

(pounds)

(pounds)

(degrees)

(pounds)

(psi)

perpendicular to lug

sset is considered.

12500

psi

20000

psi

12500

psi

20000

0.05

0.375

9000

You might also like

- Spreader Beam BLOCK EDocument23 pagesSpreader Beam BLOCK Evaminos85% (13)

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- Padeye Design CheekDocument3 pagesPadeye Design CheekBolarinwa89% (9)

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationDaison Paul63% (8)

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Lifting Lug CalculationDocument3 pagesLifting Lug Calculationdhirendarji83% (6)

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationsalman1566No ratings yet

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- Lifting Lug CalculationDocument7 pagesLifting Lug CalculationErin JohnsonNo ratings yet

- Lifting Lug Calcs (Frame)Document5 pagesLifting Lug Calcs (Frame)Mudasir MughalNo ratings yet

- Guideline Lifting Lug DesignDocument10 pagesGuideline Lifting Lug Designye-kyaw-aung80% (10)

- Design of Pad Eye Using Check PlatesDocument3 pagesDesign of Pad Eye Using Check Plateshyoung65No ratings yet

- Design Data 610 3450 9.5 1650 2 3300 2 1650 120Document3 pagesDesign Data 610 3450 9.5 1650 2 3300 2 1650 120miteshpatel191100% (1)

- Padeye Calculation For Lifting AnalysisDocument3 pagesPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- Vitec Equipments PVT LTD Filename: Spreader Beam CalculationDocument48 pagesVitec Equipments PVT LTD Filename: Spreader Beam CalculationDarshan PanchalNo ratings yet

- 17 Padeye - Spreadsheet Rev ADocument12 pages17 Padeye - Spreadsheet Rev Aoluomo1No ratings yet

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- Padeye Calculation LatestDocument10 pagesPadeye Calculation LatestPavan RayNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Lifting Lug Design Calcs As 4100Document2 pagesLifting Lug Design Calcs As 4100Ede Jaimes100% (2)

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Spreader Bar Plus Free BodyDocument17 pagesSpreader Bar Plus Free BodyMichael HaiseNo ratings yet

- Lug Design (XLS)Document4 pagesLug Design (XLS)Bhartendu Patni100% (1)

- (B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationDocument7 pages(B) Schematic Diagram of 2 Nos Lugs With No Tailing Lug: .0 Lifting Lug Design CalculationArt G. Enzi100% (1)

- 8 Padeye - Spreadsheet Check1Document4 pages8 Padeye - Spreadsheet Check1oluomo1No ratings yet

- Lifting Lug Calculation-1Document1 pageLifting Lug Calculation-1dtgpand100% (4)

- Lifting Lug DesignDocument17 pagesLifting Lug Designguravdr100% (2)

- Lifting LugDocument2 pagesLifting LugKeyurNo ratings yet

- Lifting Lug SampleDocument1 pageLifting Lug Sampleabdul marpaung0% (1)

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Lifting Lug DesignDocument7 pagesLifting Lug Designnitinphadtare100% (1)

- Lifting Lug DesignDocument18 pagesLifting Lug DesignRui Salvador0% (1)

- Calculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightDocument14 pagesCalculation of Lifting (Horizontal Position) Piperack Module 14A 24tons Total WeightrustamriyadiNo ratings yet

- Tail Lifting Lug Calculation MS WordDocument11 pagesTail Lifting Lug Calculation MS WordWijayanto BekasiNo ratings yet

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- Skid Lifitng Lug CalculationsDocument9 pagesSkid Lifitng Lug CalculationsMohamed ImthiyasNo ratings yet

- Flange Analysis - Traditional Method 14sep10Document1 pageFlange Analysis - Traditional Method 14sep10Lava SatNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connectionmhel_almoNo ratings yet

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Lifting Calculation - RunwayDocument8 pagesLifting Calculation - Runwaysivasan10006098No ratings yet

- Calculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessDocument6 pagesCalculation For Lifting Lug On Channel Shell: Provided Thickness Is More Than Required ThicknessErin JohnsonNo ratings yet

- Pressure Tank CalculationDocument6 pagesPressure Tank CalculationdharodiNo ratings yet

- Skid LiftDocument2 pagesSkid LiftAmi PutraNo ratings yet

- Connessione Controvento 2UPN EC3 IngleseDocument15 pagesConnessione Controvento 2UPN EC3 Inglesemihai_serban13No ratings yet

- Isolated Footing Design by SefianDocument6 pagesIsolated Footing Design by SefianManoj Kumar Pal80% (5)

- Lifting Lug Design CalculationDocument8 pagesLifting Lug Design Calculationmano_gceNo ratings yet

- Lifting Lug Design Calcs As 4100Document2 pagesLifting Lug Design Calcs As 4100JONHCENA13No ratings yet

- LRFD Pre-Stressed Beam Example With MATHCADDocument71 pagesLRFD Pre-Stressed Beam Example With MATHCADistructeNo ratings yet

- Shear Wall (Problems)Document18 pagesShear Wall (Problems)Arian AhmedNo ratings yet

- Bracket - 4 DesignDocument1 pageBracket - 4 Designbjreddy100% (2)

- DECKSLABDocument4 pagesDECKSLABjustjeff4bpiNo ratings yet

- By: Bhavitha Job.-Typical Slab Date: Client: APPHC Doc. No.: CHD - YNVD Date:21-8-15 Job No. - Sh. 1 of 1 Rev. No. R0Document1 pageBy: Bhavitha Job.-Typical Slab Date: Client: APPHC Doc. No.: CHD - YNVD Date:21-8-15 Job No. - Sh. 1 of 1 Rev. No. R0Dheeraj YalavarthiNo ratings yet

- GRC ColumnDocument9 pagesGRC ColumnKilaru HareeshNo ratings yet

- Page 57Document1 pagePage 57Rahar BhujelNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalNo ratings yet

- Mathcad - Bolt Loading VDI M39 01Document10 pagesMathcad - Bolt Loading VDI M39 01Pete SwiftNo ratings yet