Professional Documents

Culture Documents

Blower Tuthill MD-CS-PD7000 - 1st - 3-21

Uploaded by

Elvis Saavedra PonceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blower Tuthill MD-CS-PD7000 - 1st - 3-21

Uploaded by

Elvis Saavedra PonceCopyright:

Available Formats

M-D PNEUMATICS PD PLUS BLOWERS

PD PLUS | 7010, 7013, 7017, 7021, 7026

PD Plus

Model 7000 Heavy Duty

Bi-directional Rotation

Series Options:

Horizontal Air Flow

Vertical Air Flow

Horizontal Flow, Single Envelope Gas Service

Vertical Flow, Single Envelope Gas Service

Horizontal Flow, Double Envelope Gas Service

Vertical Flow, Double Envelope Gas Service

Max. Max. Nominal Min. Nominal Max.

Model Displ.

Press. Vac. RPM @ Max. RPM @ Max.

Model 7000 PD PLUS heavy duty industrial blowers are designed Size CFR

PSI (in. Hg) Disch. Press. Disch. Press.

for high performance applications, up to 18 PSIG pressure boost or

7010 18 17 1700 3000 .593

17” Hg dry vacuum (24” Hg water injected). 7013 18 17 1650 3000 .752

Vertical & Horizontal Air Flow 7017 15 15 1150 3000 .983

This series has wide application in pneumatic conveying, 7021 15 15 1150 3000 1.214

wastewater treatment, and the general process industry where high 7026 12 15 1150 3000 1.503

pressure, high volume air is required. Seal areas are vented to

atmosphere to relieve process pressure against the internal lip seals, Material Specifications:

and to provide oil-free air.

Housing: Cast iron

Vertical & Horizontal Single Envelope Gas Service End Plates: Cast iron

This series is utilized in such applications as closed loop pneumatic End Covers: Cast iron

conveying, fuel or process gas handling, or elevated pressure

Rotors: Ductile iron

applications up to 100 PSIG discharge. Vent openings are tapped

and plugged to prevent gas leakage. These fittings can also accept Shafts: Ductile iron cast integrally with rotor

an inert gas purge for positive containment of the process gas. Bearings: Rotors - Double row ball

Drive shaft - Cylindrical roller

Vertical & Horizontal Double Envelope Gas Service

Built to laboratory standards where virtually complete sealing is Drive Shaft: SAE 4140 forged alloy steel

required. In addition to the features shown on the single envelope Gears: Heat treated alloy steel, helical cut

series, the drive shaft is mechanically sealed and the oil sumps are Seals: Standard - Lip and labyrinth type on rotor shafts;

plugged to provide an even higher degree of leakage protection. lip seal on the drive shaft

Optional Cooling Coils Single Envelope Gas Service - Mechanical and

Optional cooling coils available to provide cooling of lubricating labyrinth type on rotor shafts; lip seal on drive shaft

oil with less than 1 GPM cooling water for high performance Double Envelope Gas Service - Same as Single

applications where external lubrication is not desired or practical.

Envelope series plus mechanical sealing on drive shaft

Flexibility by Design Lubrication: Oil splash system, both ends

Detachable mounting feet allow field conversion from horizontal to

vertical flow, or vice versa without additional components. For elevated pressure applications, single and double envelope gas

service series are available with high pressure sealing and testing

Maximum Efficiency to allow discharge pressures as high as 100 PSIG (18 PSI nominal

Includes extended tip rotor profile for increased displacement and maximum pressure boost)*

operating efficiency versus any other blower in its class. * Blowers operating with a discharge pressure above 20 PSIG require

mechanical rotor shaft sealing; above 25 PSIG requires hydrostatic

Extra Capacity Oil Sumps

testing and special high pressure seal leakage testing.

Oversized end covers for the largest oil capacity of any blower in

its class. End covers also include external ribbing for applications

where cooling water is not available. Oil drain plugs are O-ring

sealed for protection against leakage.

Special Materials Special Coatings

Ductile Iron* Bi-Protec® (Nickel/Armoloy®)

Optional Lubrication Systems Stainless Steel**

Available with integral pressure lubrication to provide positive bearing Carbon Steel*** *7010, 7017, 7021 & 7026 only

lubrication and filtration of lubricant for extreme applications. Optional **7013 & 7017 only, ***7013 only

lubrication can be specified.

M-D PNEUMATICS • 4840 W. KEARNEY ST., SPRINGFIELD, MO 65803 USA

P: 417-865-8715 OR 1-800-825-6937 • F: 417-865-2950

WWW.MDPNEUMATICS.COM MD-CS-PD7000 1st Ed. 3/21

Performance Tables

In conjunction with our program of continuous testing and design upgrading, all specifications are subject to change without notice. All data are approximate.

Request a quotation for your specific application.

Pressure (14.70 PSIA and 70° F Inlet)

BLOWER SPEED 2 PSIG 5 PSIG 8 PSIG 10 PSIG 12 PSIG 15 PSIG 18 PSIG Max. Vacuum

MODEL (RPM) CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP CFM BHP “ Hg CFM BHP

1200 586 8.5 513 18 460 27 430 33 403 40 367 49 15 370 25

1750 912 13 839 26 786 40 756 49 730 58 693 71 660 85 16 672 39

7010

2400 1297 17 1224 36 1172 54 1142 67 1115 79 1079 98 1046 116 17 1032 57

3000 1653 21 1580 45 1527 68 1498 83 1471 99 1434 122 1402 145 17 1388 71

1200 749 10 660 22 596 34 560 42 527 50 483 61 15 486 31

1750 1163 15 1074 32 1010 49 974 61 941 72 897 89 857 107 16 871 49

7013

2400 1652 20 1563 44 1499 68 1462 83 1430 99 1385 123 1345 146 17 1329 70

3000 2103 26 2014 55 1950 85 1914 104 1881 124 1837 153 1797 183 17 1780 88

1200 985 13 872 28 790 44 744 54 703 64 647 79 15 651 40

1750 1526 18 1413 41 1331 63 1285 78 1244 93 1187 116 16 1155 62

7017

2400 2165 25 2051 56 1970 87 1924 108 1882 128 1826 159 17 1754 91

3000 2754 32 2641 70 2560 109 2514 134 2472 160 2416 199 17 2344 113

1200 1225 15 1090 34 993 53 939 66 889 79 822 98 15 827 49

1750 1893 22 1758 50 1661 78 1606 96 1557 115 1490 142 15 1495 72

7021

2400 2682 30 2547 68 2450 106 2395 132 2346 157 2279 195 15 2284 98

3000 3410 38 3276 85 3178 133 3124 165 3074 196 3007 244 15 3012 123

1200 1527 18 1367 42 1251 65 1186 81 1127 97 14 1101 56

1750 2354 26 2193 61 2078 95 2012 118 1953 141 15 1879 88

7026

2400 3331 36 3170 83 3055 131 2989 162 2930 193 15 2856 121

3000 4233 45 4072 104 3956 163 3891 202 3832 242 15 3758 151

PD Plus 7000 - DD - EPS 2

Dimensions Horizontal Flow Vertical Flow

A

B C

F FF FLANGE 12 12

A

150# ANSI DRILLING 1 B C

7.81

7.81

12

Ø 2.3745

25.75 ± .0005

25.63

13.63 12

Ø 2.3745

± .0005 10.13 1.63

Ø 25/32 7.25

4 HOLES 14.5 11.19 E

11.19 E 19 D

19 D

21.25

10.63

MODEL A B C D E F NET WT. (lbs.)* 3.5

7010 44.94 26.38 18.56 14.75 7.38 6 FLG 1125

7013 47.69 27.75 19.94 17.50 8.75 8 FLG 1230

7017 51.69 29.75 21.94 21.50 10.75 10 FLG 1365

7021 55.69 31.75 23.94 25.50 12.75 12 FLG 1525

7026 60.69 34.75 26.44 30.50 15.25 12 FLG 1690 ALTERNATE

13.63 DRIVE

SHAFT

Values are approximate and should not be used for construction. LOCATION

Certain dimensions for double envelope gas-service differ slightly from those shown above.

Certified prints are available through your local M-D Pneumatics Sales Professional.

7.25

Ø 25/32

*Approximate shipping weight. 4 HOLES 14.5

CONTACT US Your Local Sales Professional:

For more information, contact your

Regional Sales Manager or call us at:

1-800-825-6937

M-D PNEUMATICS • 4840 W. KEARNEY ST., SPRINGFIELD, MO 65803 USA

P: 417-865-8715 OR 1-800-825-6937 • F: 417-865-2950

WWW.MDPNEUMATICS.COM MD-CS-PD7000 1st Ed. 3/21

You might also like

- Intermediate Five BookDocument24 pagesIntermediate Five BookCristian CabiaNo ratings yet

- Writing 2 - Elvis Saavedra.Document1 pageWriting 2 - Elvis Saavedra.Elvis Saavedra PonceNo ratings yet

- HalloweenDocument1 pageHalloweenElvis Saavedra PonceNo ratings yet

- Writing 1 Intermedio 4 Grace CamposDocument1 pageWriting 1 Intermedio 4 Grace CamposElvis Saavedra PonceNo ratings yet

- English ExamDocument5 pagesEnglish ExamElvis Saavedra PonceNo ratings yet

- Image A Is As Similar As Image B in The Sense That Both Express Fear or TerrorDocument2 pagesImage A Is As Similar As Image B in The Sense That Both Express Fear or TerrorElvis Saavedra PonceNo ratings yet

- Intermediate Five BookDocument24 pagesIntermediate Five BookCristian CabiaNo ratings yet

- Writing 2 - Elvis Saavedra.Document1 pageWriting 2 - Elvis Saavedra.Elvis Saavedra PonceNo ratings yet

- Writing 1 - Intermediate 2Document2 pagesWriting 1 - Intermediate 2Elvis Saavedra PonceNo ratings yet

- Writing 2 - Elvis Saavedra.Document1 pageWriting 2 - Elvis Saavedra.Elvis Saavedra PonceNo ratings yet

- Writing 1 Intermedio 4 Grace CamposDocument1 pageWriting 1 Intermedio 4 Grace CamposElvis Saavedra PonceNo ratings yet

- Writing 3Document1 pageWriting 3Elvis Saavedra PonceNo ratings yet

- Solutions To Deal With Stress On These Pandemic Days: IntermediateDocument9 pagesSolutions To Deal With Stress On These Pandemic Days: IntermediateElvis Saavedra PonceNo ratings yet

- Image A Is As Similar As Image B in The Sense That Both Express Fear or TerrorDocument2 pagesImage A Is As Similar As Image B in The Sense That Both Express Fear or TerrorElvis Saavedra PonceNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Writing 2 - Elvis Saavedra.Document1 pageWriting 2 - Elvis Saavedra.Elvis Saavedra PonceNo ratings yet

- Accepting An Invitation To A PartyDocument1 pageAccepting An Invitation To A PartyElvis Saavedra PonceNo ratings yet

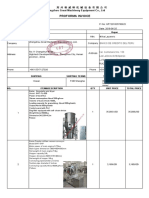

- Proforma Invoice: Zhengzhou Great Machinery Equipment Co., LTDDocument2 pagesProforma Invoice: Zhengzhou Great Machinery Equipment Co., LTDElvis Saavedra PonceNo ratings yet

- Writing 1 - Intermediate 2Document2 pagesWriting 1 - Intermediate 2Elvis Saavedra PonceNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Verb TensesDocument2 pagesVerb TensesElvis Saavedra PonceNo ratings yet

- Third WritingDocument1 pageThird WritingElvis Saavedra PonceNo ratings yet

- Combustion Chambers Hot Gas Generators 2Document12 pagesCombustion Chambers Hot Gas Generators 2Mll RaghebNo ratings yet

- HalloweenDocument1 pageHalloweenElvis Saavedra PonceNo ratings yet

- Verb TensesDocument2 pagesVerb TensesElvis Saavedra PonceNo ratings yet

- 1.-How Does COVID-19 Spread?Document2 pages1.-How Does COVID-19 Spread?Elvis Saavedra PonceNo ratings yet

- Primer Manual Granulador OriginalDocument20 pagesPrimer Manual Granulador Originalsixto zeladaNo ratings yet

- Spray Drying Technology ReviewDocument46 pagesSpray Drying Technology Reviewedison58No ratings yet

- Writing 1 Intermedio 4 Grace CamposDocument1 pageWriting 1 Intermedio 4 Grace CamposElvis Saavedra PonceNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Method Statement of T-Beams PDFDocument14 pagesMethod Statement of T-Beams PDFKAmi KaMranNo ratings yet

- Wheatley Hp600 Quintuplex Plunger PumpDocument2 pagesWheatley Hp600 Quintuplex Plunger Pumpmetasoniko2014No ratings yet

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Document1 pageProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanNo ratings yet

- VisakhapatnamDocument27 pagesVisakhapatnamCherukupalli Gopala KrishnaNo ratings yet

- Uptime KitsDocument3 pagesUptime KitsMtto Materia PrimaNo ratings yet

- N100 Rle Back MassageDocument24 pagesN100 Rle Back MassagerlinaoNo ratings yet

- SUNANDA Hack Aid Plast SPL PDFDocument2 pagesSUNANDA Hack Aid Plast SPL PDFSheezan KhanNo ratings yet

- ASD Fan CalculatorsDocument14 pagesASD Fan CalculatorslubricacionNo ratings yet

- Intercont Tersus DatasheetDocument5 pagesIntercont Tersus DatasheetJocemir FerstNo ratings yet

- B11 - Overload Relays (Ref) ENDocument20 pagesB11 - Overload Relays (Ref) ENAhmed AbazaNo ratings yet

- BDSM List FixedDocument4 pagesBDSM List Fixedchamarion100% (3)

- Pre Post Tests For HPPDocument3 pagesPre Post Tests For HPPapi-434982019No ratings yet

- C P P P: Rain'S Etrophysical Ocket ALDocument54 pagesC P P P: Rain'S Etrophysical Ocket ALviya7100% (4)

- Essentials of o Ste 00 DaveDocument112 pagesEssentials of o Ste 00 DaveGeki Iovan100% (1)

- Ap Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDocument102 pagesAp Art and Design Drawing Sustained Investigation Samples 2019 2020 PDFDominic SandersNo ratings yet

- The Past Is A Foreign Country-1.2Document25 pagesThe Past Is A Foreign Country-1.2Xinyu DongNo ratings yet

- Roland RS-5 Manual Del UsuarioDocument180 pagesRoland RS-5 Manual Del Usuariodavevad12345No ratings yet

- 10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtDocument145 pages10 de Thi Tieng Anh Hướng Dẫn Giải Chi TiếtVuong DiepNo ratings yet

- Middle East ManufacturerDocument6 pagesMiddle East Manufacturerhsco rdNo ratings yet

- Rig 166 Data SheetDocument2 pagesRig 166 Data SheetEstuardo OlanNo ratings yet

- Art Lab For Little Kids - Susan Schwake PDFDocument146 pagesArt Lab For Little Kids - Susan Schwake PDFEmma Alfonzo67% (3)

- Hira - For Shot Blasting & Upto 2nd Coat of PaintingDocument15 pagesHira - For Shot Blasting & Upto 2nd Coat of PaintingDhaneswar SwainNo ratings yet

- Testo-Flue Gas in Industry 3-27-2008Document149 pagesTesto-Flue Gas in Industry 3-27-2008leruaitesNo ratings yet

- Better Place - Heaven or HellDocument3 pagesBetter Place - Heaven or HellToto SammyNo ratings yet

- YES-O Action-Plan - 2022-2023Document2 pagesYES-O Action-Plan - 2022-2023carmina duldulao100% (6)

- CMR ArtifactDocument51 pagesCMR ArtifactAdel SALLAMNo ratings yet

- Troublesshooting Manual 3b6 PDFDocument50 pagesTroublesshooting Manual 3b6 PDFAgnieszka Wawrzyniak Rybka100% (1)

- PTFE HZ-2 HoerbigerDocument2 pagesPTFE HZ-2 HoerbigerТатьяна ВасильеваNo ratings yet

- UCSP Module 4Document20 pagesUCSP Module 4Agas FamilyNo ratings yet

- RB in Poultry Feed - 3Document17 pagesRB in Poultry Feed - 3Vishwanath HebbiNo ratings yet