Professional Documents

Culture Documents

Satyam Bhuyan IJTC 2006

Uploaded by

satyambhuyan_5338070Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Satyam Bhuyan IJTC 2006

Uploaded by

satyambhuyan_5338070Copyright:

Available Formats

Proceedings of IJTC 2006

STLE/ASME International Joint Tribology Conference

October 22-25, 2006 San Antonio, Texas USA

IJTC2006- 12228

BOUNDARY LUBRIATION PROPERTIES OF LIPID-BASED COMPOUNDS EVALUATED

USING MICROTRIBOLOGICAL METHODS

S. Bhuyana, S. Sundararajana, 1 , L. Yaob, E.G. Hammondb, T. Wangb

a

Department of Mechanical Engineering, Iowa State University, Ames, Iowa 50011

b

Department of Food Science and Human Nutrition, Iowa State University, Ames, Iowa 50011

ABSTRACT been on long chain compounds and on the effect of chain

Microscale friction tests were utilized to evaluate the length, unsaturation and polarity on boundary lubrication.

boundary lubrication behavior of three sets of branched Predominantly, compounds with longer chains show lower

compounds and their corresponding linear compounds. The friction and lower wear than those with shorter ones [4-8]. The

performances of the compounds were compared to that of lipid- saturated compounds show better behavior than the unsaturated

based saturated and unsaturated acids, esters and alcohols as ones [3, 9-11] and acids with a high degree of polarity exhibit

well as to that of commercial synthetic lubricant formulations. improved tribological properties compared to esters whose

At low concentrations (~0.5%) in paraffin oil and for the load polarity is less [3]. Lipid-based compounds however have two

conditions used, the branched compounds showed minor major disadvantages; their application is limited by poor

differences in friction behavior as compared to their linear oxidative stability and poor low temperature fluidity properties.

counterparts. The ester compounds by comparison showed Branching can eliminate the necessity of choosing between

higher friction behavior than alcohols and acids. oxidative stability and low temperature pourability in bio-based

lubricants. However few studies have evaluated the tribological

behavior of branched bio-based lubricants with a branched

INTRODUCTION radical. Weller and Perez [5] have shown that the straight-chain

Due to the poor biodegradability of petroleum based and the branched molecules show comparable friction. In this

fluids, there is a growing interest in developing and using paper, microscale friction tests are used to study the friction of

vegetable oil based lubricants and fluids for industrial normal and branched-chained compounds under light boundary

applications [1]. In addition, bio-based esters derived from lubrication conditions and their behavior is compared to other

plants and vegetable oils exhibit better performance at lower lipid-based compounds, specifically saturated and unsaturated

cost compared to synthetic esters [2]. Typical vegetable oils by compounds with various degrees of polarity.

their chemical nature are long chain fatty acid tri-esters of

glycerol and provide most of the desired lubricant properties

such as good boundary lubrication, high viscosity index, high

flash point and low volatility [3]. So far a majority of the

tribological characterization studies of bio-based products have

1

To whom correspondence should be addressed at 2025 Black Engineering Building, Iowa State University, Ames, IA 50011.

Tel: +1 515-294-1050; E-mail: srirams@iastate.edu

1 Copyright © 2006 by ASME

Table 1. Molecular formulae of all the compounds used. of the interface is dictated by the behavior at these asperity

contacts. By understanding the mechanisms responsible for

Compounds Molecular Formula tribological behavior at these contacts, the behavior of the

Methyl stearate CH3(CH2)16COOCH3 macroscopic interface can be predicted. For the experiments

Methyl 17-methylstearate (CH3)2CH(CH2)15COOCH3 described in this paper, a custom-built reciprocating ball-on-flat

Methyl palmitate CH3(CH2)14COOCH3 microtribometer that can produce a microscale (apparent area

Methyl 15- (CH3)2CH(CH2)13COOCH3 ~1000 square microns) multi-asperity contact [14] was used.

methylpalmitate Microscale tests are also beneficial when only a limited

Methyl myristate CH3(CH2)12COOCH3 quantity of the test material is available. A schematic of its

Methyl 13- (CH3)2CH(CH2)11COOCH3 major components is shown in Figure 1. A spherical probe is

methylmyristate placed at the end of a crossed I-beam structure which is

Stearic acid CH3(CH2)16COOH lowered using a linear stage to apply a desired normal load to

Steryl alcohol CH3(CH2)17OH the sample. The normal and friction (lateral) forces are

Oleic acid CH3(CH2)7 measured using semiconductor strain gages on the cantilevers.

CH=CH(CH2)7COOH Friction forces can be resolved to approximately ±5 μN and

Methyl oleate CH3(CH2)7 normal forces to approximately ±15 μN. The signal from the

CH=CH(CH2)7COOCH3 normal load is monitored and used in a feedback loop to

Oleyl alcohol CH3(CH2)7 CH=CH(CH2)8OH maintain the desired normal force regardless of any slope or

waviness in the surface of the sample. A flat sample (substrate)

of desired material is affixed to another stage set perpendicular

MATERIALS to the beam, which provides linear motion. For this study a

The molecular formulae of all the samples are substrate material of steel (AISI 52100, hardness 848 VHN and

indicated in Table 1. Three pairs of branched and unbranched elastic modulus 210 GPa) was used. The steel was fabricated

compounds were tested for their boundary lubrication behavior. into 10 mm-thick sample discs with a diameter of 50 mm. They

They consisted of saturated methyl ester of stearic (C-18), were grinded to yield a finer polish with an RMS roughness of

palmitic (C-16) and myristic acids (C-14). The branched 128 ± 22 nm.

compounds in this case were the methyl-esters of the aforesaid

compounds with a single methyl branched to one of the carbon

atoms on the fatty acid chain. These compounds were isolated

from lanolin (wool wax) by saponification and subsequently

methylated [12]. All compounds were available in its nearly

pure form with concentrations greater than 95 % (w/w). In

order to study the effect of polarity and saturation of the bio-

lubricant constituents the boundary lubrication behavior of

saturated compounds stearic acid, stearyl alcohol, methyl

stearate were compared to the unsaturated compounds oleic

acid, oleyl alcohol and methyl oleate. These were obtained

commercially from Nu-Chek Prep, Inc., Elysian, MN. Two

commercial grade synthetic lubricants, i.e. multigrade engine

oil of grade SAE 5W20 (brands Amsoil and Castrol), were

used as a benchmark for the boundary lubrication response of

the bio-based compounds. This grade of oil particularly shows

better high temperature viscosity and hence reduces friction

while maintaining a full fluid film separation between the

lubricating surfaces [13]. The compounds were tested as 60%

(w/w) blend in paraffin oil except the branched compounds

which were available in limited amounts, were tested as a 0.5%

(C-18), 0.63% (C-16) and 0.75% (C-18) (w/w) blend in

paraffin oil.

METHODS Figure 1. Schematic of the custom built microtribometer setup

Microscale Friction Tests used in this study.

Contact between engineering surfaces occurs at multiple

discrete locations (asperities) and the tribological performance Surface roughness characterizations of the steel surfaces

indicated that they are Gaussian in nature. All samples were

2 Copyright © 2006 by ASME

cleaned with acetone in an ultrasonic bath for 15 minutes and behavior, although in varying degrees as indicated in Table 2

dried using dry air prior to tests. and 3. Some oscillatory effects were seen in the friction

To obtain the coefficient of friction, a ramped load response, typical of confined molecular films [17]. Figure 3

tests were performed in which the load was increased linearly shows the percentage reduction in the coefficient of friction for

with the sliding distance. An AISI 52100 steel ball of radius 1.2 all the compounds tested with respect to the coefficient of

mm and RMS roughness of 4 nm was used to probe the test friction of the base oil.

steel samples. The load was increased from 0.2 to 180 mN as

the probe was moved across a stroke distance of 45 mm at 10

mm/s. Preliminary tests showed that, for our load conditions,

sliding speed has only a small effect on friction and wear

relative to other factors. All tests for the acids, esters and

alcohols were performed at 70 0C ( melting point of stearic

acid = 67 0C). The exception was for the low concentration

straight and branched compounds which were heated slightly

(40 0C) to blend in paraffin but were tested at room temperature

environment of 25 0C. The tests were performed at room

humidity of 50%. Tests on unlubricated surfaces were

conducted at RH 20% to avoid water meniscus based effects.

Four sets of friction measurements were performed for each

sample. For the loading condition used, the Hertzian contact

pressures were in the range of 0-710 MPa. Hertzian contact

theory predicts an elastic response [15]. However, evaluation of

the plasticity index, based on Onion and Archard’s definition,

yields a value greater than 1 for the interfaces, which is the

local plastic deformation limit. This suggests that local plastic

deformation at the asperity levels may be occurring.

Viscosity Measurements

Sample viscosities were measured with a cone and

plate-system of a computer-controlled RS150 RheoStress

rheometer (Haake, NJ). A Ti cone with 60-mm diameter and 20

angle was used. The temperature was controlled with TC81

Peltier (Haake, NJ) and a water bath. The measurements were

performed by raising temperature gradually step by step, and

keeping all other measurement conditions constant. Each

sample was held at each measuring temperature for one minute

to equilibrate before data was taken. Viscosities of liquid

samples were measured from 40 to 100°C. Viscosity of samples

Figure 2. Representative friction vs. normal load plots obtained

that were solid at room temperature were measured from from ramped-load friction tests for (a) straight and branched

temperatures above each sample's melting point and within a chain esters at 0.5% (w/w) and (b) selected acids and esters at

50 degree range. Shear rate was controlled at 1000 revolution/s. 60% (w/w) concentration in base oil.

Triplicate measurements were done for each sample.

Effect of Branching. All sets of linear and

RESULTS AND DISCUSSION branched compounds demonstrated lower friction force

Friction Test response (8-28%) compared to the base oil. The friction force

Figure 2 shows representative friction data for several observed increased with a decrease in carbon chain length of

of the samples tested. The unlubricated system exhibits typical the linear compounds, which is consistent with previous reports

stick-slip type of behavior associated with the dry sliding of [4-8]. There were very minor differences in friction response

like mating surfaces (steel-steel). It can be seen that the base of the branched compounds and their linear counterparts. As

oil by itself does not provide any significant form of lubrication shown in Figure 3(a) and Table 2, at 0.5% concentration the

to the interface. This is in agreement with past studies on pure branched C-18 methyl ester shows slightly higher friction than

paraffin oil [16]. The long chained alkane monomers of the straight chain ester. But, the straight methyl esters of other

paraffin do not form strong hydrogen bonding amongst compounds (C-16 and C-14) have slightly lower frictions than

themselves thereby becoming vulnerable to breakdown. All the their branched counterpart. This suggests that there is a

test compounds, however, resulted in improved friction combined effect of base chain length and branching. Pooley

3 Copyright © 2006 by ASME

and Tabor have argued that side groups may hinder lubricating film and show lower friction compared to esters.

translational motion and result in increased friction [18], The conclusion from friction tests, indicated in Figure 3(b) and

whereas other results indicate that branched compounds retain Table 3, is that this is generally true – alcohols exhibit higher

better fluid-like performance at higher pressures as compared friction than esters, with the difference being higher for

to linear compounds [19]. The small magnitude of the saturated compounds. A considerable difference was noticed in

differences in friction observed between the branched and the friction levels of saturated and unsaturated alcohols. Stearyl

straight compounds could be due to the small branch length alcohol displays a 36.7% reduction of friction coefficient but

(single methyl group). oleyl alcohol shows 32.5%. The polar groups in alcohol

compounds form a strong bond with the surface material

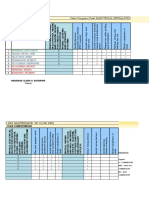

Table 2. Coefficient of friction and standard deviation values of thereby rendering strong boundary lubrication. However,

steel against steel with different linear and branched chained results from the friction tests suggest that this protective film

compounds. Average and standard deviation values have been may not be as strong as those formed by free fatty acids.

taken from four tests on the sample at room temperature.

Coefficient of friction ± Standard Deviation

Unlubricat- Base Series ~0.5 % (w/w)

ed surface oil solution in base

oil

0.140 0.139 Straight C-18 0.099 ± 0.001

± 0.001 ± methyl-ester

0.001 Branched C-18 0.112 ± 0.001

methyl-ester

Straight C-16 0.115 ± 0.004

methyl-ester

Branched C-16 0.104 ± 0.001

methyl-ester

Straight C-14 0.124 ± 0.003

methyl-ester

Branched C-14 0.097 ± 0.001

methyl-ester

Effect of Polarity. It was found that, relative to the

base oil, stearic acid demonstrates a 38.3 % reduction in

friction coefficient whereas methyl stearate shows 30.8 %

reduction in friction coefficient as shown in Figure 3(b) and

Table 3. Oleic acid and methyl oleate reduces the friction

coefficient by 34.2 % and 26.7% respectively when compared

with the base oil. In general the results show that acids exhibit

lower friction performance than esters. These significant

reductions can be attributed to the fact that the thin surface film

that develops in boundary lubrication is formed by the

adsorption of polar compounds at the metal surface of the

mating pair or by chemical reaction of the lubricant at the

surface [20] . Since boundary lubrication by fatty acids is

associated with the adsorption of the acid by dipolar attraction

at the surface, they are capable of reducing the friction between Figure 3. Bar chart indicating the percentage reduction of

the surfaces. Esters have a much lower polarity compared to friction coefficient with respect to the base oil for (a) 0.5% (w/w)

concentration of C-18, 0.63% (w/w) of C-16 and 0.15 (w/w) of

acids and hence cannot form a strong protective boundary

C-14 straight and branched chained methyl esters and (b) 60%

layer. In fact, a larger concentration of esters would be (w/w) concentration of acids, esters and alcohols.

necessary to reduce friction as effectively as acid. The studies

herein suggest that acids can indeed form a much better Effect of saturation. Figure 3(b) and Table 3

protective layer compared to esters. indicate that the saturated stearic acid reduces friction

The samples consisting of saturated steryl alcohol and coefficient by 38.3% compared to double-bonded oleic acid

unsaturated oleyl alcohol are more polar in nature than their which reduces by 34.2 %. Similarly, in the ester series, methyl

esters. The alcohols were therefore expected to form a stronger stearate and methyl oleate reduces friction coefficient by 30.8%

4 Copyright © 2006 by ASME

Table 3. Coefficient of friction and standard deviation values of steel against steel with different compounds. Average and standard

deviation values have been taken from four tests on the sample at 70 oC.

Coefficient of friction ± Standard Deviation

Unlubri- Base oil Amsoil Castrol Series Acids Ester Alcohol

cated

0.122 0.120 0.080 0.092 Saturated 0.074 0.083 0.076

± 0.001 ± 0.001 ± 0.001 ± 0.001 ± 0.001 ± 0.002 ± 0.003

Unsaturated 0.079 0.088 0.081

± 0.001 ± 0.001 ± 0.003

and 26.7% respectively. In general, introduction of a double

bond increases friction. This is generally in agreement with

previously reported work. The strength of molecular

interaction plays a part in boundary lubrication [21]. In

saturated acids like stearic acid which contains no double

bond, it is possible for the molecules to align themselves in

straight chains and be closely packed on the surface providing

a strong protective layer. Addition of a double bond prevents

rotation and forces the chain to bend, thereby making it unable

to pack closely together and resulting in a weaker protective

layer [5].

Oxidation of the lipid molecules leads to

polymerization and degradation of the bio-lubricants [2]. The

ease of oxidation depends on the fatty acid composition of the

vegetable oil. Unsaturated fatty acids are less resistant to

oxidation at high temperatures that are generated during

boundary lubrication. They react with molecular oxygen to

form free radicals that lead to polymerization and

fragmentation. The protective film becomes unstable and

breaks down over time thereby increasing friction. Greater Figure 4. Representative plots of viscosity as a function of

temperature for selected acids and esters.

intermolecular distance between the adsorbed unsaturated

molecules results in lower dispersion interaction [10]. The

friction test results support the idea that among these long Under boundary lubrication conditions, the friction

lipid molecules, saturated compounds have superior boundary behavior of the compounds should generally be unaffected by

lubrication as opposed to their unsaturated counterparts. It is their viscosities. The lubrication regime for the compounds

noted that that all bio-based compounds showed comparable and testing conditions in this study was predicted by

or better friction performance than the synthetic blends as evaluating the film parameter λ, defined as follows [22]

reported in Table 3.

λ = hmin /( Rq21 + Rq22 )1 / 2 (1)

Viscosity.

As shown in Figure 4, the viscosity of the lipid-based where hmin is the minimum film thickness for the ball-on-flat

materials decreases when temperature was raised for all contact region and Rq1 and Rq2 are the RMS roughness of the

samples. The functional group affected the viscosity to various sample and probe respectively. A λ value of less than unity

extents. Free carboxyl groups gave the highest viscosity generally corresponds to a boundary lubrication regime.

followed by free hydroxyl groups while ester groups gave the Roughness values were obtained from atomic force

lowest viscosity. This trend was observed regardless of the

microscopy scans of the surfaces (15 μm scans). The

existence of double bonds. The viscosity difference between

parameter hmin was estimated for each lubricant using the

acids and alcohols was small. Also, in the case of acids and

measured viscosity of the compounds and the analysis of

alcohols, double bonds increased viscosity, but not for esters.

Hamrock and Dowson for elliptical contacts [22]. Table 4

The viscosity of methyl stearate was higher than that of

indicates the viscosity values at 70 °C and the range of λ for

methyl oleate. There were insufficient samples to evaluate the

the lubricants tested for the load ranges used. All the values

viscosity of the branched methyl esters.

are lower than unity, thereby corresponding to boundary

5 Copyright © 2006 by ASME

lubrication. However, on comparing viscosity and friction

data for the various lubricants, it was generally observed that REFERENCES

Table 4 Viscosities of the test samples at 70 oC and estimation

of the λ parameter to verify lubrication regime. [1] Bartz, W., 1998, "Lubricants and the Environment",

1

Tribology International 31(1-3), pp. 35-47.

Sample Viscosity η(cP) λ parameter [2] Kodali, D.R., 2002, "High Performance Ester

Stearic acid 8.67 0.010-0.017 Lubricants from Natural Oils", Industrial Lubrication

Methyl 3.05 0.005-0.008 and Tribology 54(4), pp. 165-170.

stearate [3] Adhvaryu, A., Erhan, S.Z., and Perez, J.M., 2004,

Steryl alcohol 7.20 0.009-0.015 "Tribological Studies of Thermally and Chemically

Oleic acid 7.23 0.009-0.015 Modified Vegetable Oils for Use as Environmentally

Methyl oleate 2.52 0.004-0.007 Friendly Lubricants", Wear 257(3-4), pp. 359-367.

Oleyl alcohol 5.45 0.008-0.012 [4] Jahanmir, S., 1985, "Chain Length Effects in

1

λ reported for load range used: 0.2 mN – 200 mN Boundary Lubrication", Wear 102(4), pp. 331-349.

[5] Weller, D.E., Jr. and Perez, J.M., 2000, "A Study of

compounds with higher viscosity exhibited lower friction. the Effect of Chemical Structure on Friction and

This suggests that the lubrication regime may be in a mixed Wear: Part I - Synthetic Ester Base Fluids",

regime and that hydrodynamic component (and hence the Lubrication Engineering 56(11), pp. 39-44.

viscosity) affects the friction behavior. In the case of acids, [6] Havet, L., Blouet, J., Valloire, F.R., Brasseur, E., and

their hydrogen bonding capability enhances molecular affinity Slomka, D., 2001, "Tribological Characteristics of

and they exist as weak dimmers, which increases their Some Environmentally Friendly Lubricants", Wear

viscosity. They also bind more strongly to the metal surface 248(1-2), pp. 140-146.

and hence a larger force is required to overcome the greater [7] Weller, D.E., Jr. and Perez, J.M., 2001, "A Study of

resistance of shear forces in order to maintain a smooth flow. the Effect of Chemical Structure on Friction and

This behavior is opposite in esters. Esters have a lower Wear: Part 2 - Vegetable Oils and Esters",

viscosity and for the same reasons have a higher friction. Lack Lubrication Engineering 57(5), pp. 20-26.

of ability to form hydrogen bonds can separate the molecules [8] Waara, P., Norrby, T., and Prakash, B., 2004,

easily and much smoother flow is observed. The viscosities "Tribochemical Wear of Rail Steels Lubricated with

and friction reducing capabilities of the hydroxyl group lies Synthetic Ester-Based Model Lubricants", Tribology

somewhere in between acids and esters. Letters 17(3), pp. 561-568.

[9] Asadauskas, S., Perez, J.M., and Duda, J.L., 1996,

SUMMARY AND CONCLUSION "Oxidative Stability and Antiwear Properties of High

In summary, the adhesive friction behavior of a range Oleic Vegetable Oils", Lubrication Engineering

of lipid-based and synthetic lubricants was evaluated to 52(12), pp. 877-882.

understand the effect of molecular structure on the boundary [10] Kondo, H., 1997, "Effect of Double Bonds on

lubrication performance. Branch compounds exhibit slightly Friction in the Boundary Lubrication of Magnetic

higher friction than corresponding linear compounds and this Thin Film Media", Wear 202(2), pp. 149-153.

trend reverses as the chain length becomes shorter. The studies [11] Biresaw, G., Adhvaryu, A., and Erhan, S.Z., 2003,

also showed that, polar compounds exhibit lower friction than "Friction Properties of Vegetable Oils", Journal of the

non-polar compounds as evident from acids showing lower American Oil Chemists Society 80(7), pp. 697-704.

friction than alcohols and esters. Saturated compounds can [12] Yao, L. and Hammond, E.G., 2006, "Isolation and

reduce friction more efficiently than unsaturated ones. Melting Properties of Branched Fatty Esters from

However, the polarity effect is more dominant than the effect Lanolin", Journal of American Oil Chemist Society

of saturation. More studies on branched bio-based compounds (,submitted).

are necessary to establish their lubricative effectiveness. It will [13] Lansdown, A.R., 2004, Lubrication and Lubricant

be particularly interesting to see how the length of the Selection, Third edn., in Tribology in Practice Series,

branched radical will affect the boundary lubrication behavior. Professional Engineering Publishing Limited,

London and Bury St Edmunds, pp. 59-82.

ACKNOWLEDGMENTS [14] Check, J., Karuppiah, K.S.K., and Sundararajan, S.,

This study was funded in part by a grant from the Center 2005, "Comparison of the Effect of Surface

for Crops Utilization Research at Iowa State University. Roughness on the Micro/Nanotribological Behavior

of Ultra-High-Molecularweight Polyethylene

(Uhmwpe) in Air and Bovine Serum Solution",

6 Copyright © 2006 by ASME

Journal of Biomedical Materials Research Part A

74A(4), pp. 687-695.

[15] Bhushan, B., 1999, Principles and Application of

Tribology, John Wiley & Sons, Inc., New York, pp.

198-293.

[16] Gates, R.S. and Hsu, S.M., 1995, "Silicon-Nitride

Boundary Lubrication - Effect of Oxygenates",

Tribology Transactions 38(3), pp. 607-617.

[17] Israelachvili, J., 1991, in Intermolecular & Surface

Forces, Academic Press, San Diego, pp. 260-287.

[18] Pooley, C.M. and Tabor, D., 1972, "Friction and

Molecular Structure - Behavior of Some

Thermoplastics", Proc. R. Soc. A(329 (1578)), pp.

251.

[19] Cho, Y.K. and Granick, S., 1996, "Shear of Confined

Perfluorinated Molecules: Effect of Side Branching",

Wear 200(1-2), pp. 346-352.

[20] Davey, W., 1950, "Boundary Lubrication of Steel -

Blends of Acids, Esters, and Soaps in Mineral Oil",

Industrial and Engineering Chemistry 42(9), pp.

1837-1841.

[21] Fox, N.J., Tyrer, B., and Stachowiak, G.W., 2004,

"Boundary Lubrication Performance of Free Fatty

Acids in Sunflower Oil", Tribology Letters 16(4), pp.

275-281.

[22] Hamrock, B.J., Schmid, S.R., and Jacobson, B.O.,

2004, Fundamentals of Fluid Film Lubrication,

Marcel Dekker, New York, pp. 489-523.

7 Copyright © 2006 by ASME

You might also like

- Sharma 2021Document56 pagesSharma 2021upendra mauryaNo ratings yet

- Qu 2012Document6 pagesQu 2012murad8rahimovNo ratings yet

- How Ingredients Influence Unsaturated Polyester PropertiesDocument28 pagesHow Ingredients Influence Unsaturated Polyester Propertiesresinc100% (4)

- Formulation of Emulsifiable Cutting FluiDocument7 pagesFormulation of Emulsifiable Cutting FluiIván GutiérrezNo ratings yet

- Acrylonitrile Polymers, Survey and SanDocument25 pagesAcrylonitrile Polymers, Survey and SanEmmanuel Chang100% (1)

- Lubrication of Steel-Steel Contacts by CHCL ILs (Lawes Et Al)Document8 pagesLubrication of Steel-Steel Contacts by CHCL ILs (Lawes Et Al)murad8rahimovNo ratings yet

- Coek - Info - Corrosion Resistance Properties of OrganicinorganiDocument8 pagesCoek - Info - Corrosion Resistance Properties of Organicinorganib3ry 17No ratings yet

- 1 s2.0 S0300944007001737 MainDocument8 pages1 s2.0 S0300944007001737 MainMohammed JamaliNo ratings yet

- Frother Structure-Property Relationship - Aliphatic Alcohols and Bubble Rise VelocityDocument6 pagesFrother Structure-Property Relationship - Aliphatic Alcohols and Bubble Rise VelocityJose Luis Barrientos RiosNo ratings yet

- Effect of morphology and hydrophobization of MoS2 microparticles on the stability of poly-α-olefins lubricantsDocument8 pagesEffect of morphology and hydrophobization of MoS2 microparticles on the stability of poly-α-olefins lubricantsZoubir SaidiNo ratings yet

- Satyam Bhuyan Tribology International 2010 2Document7 pagesSatyam Bhuyan Tribology International 2010 2satyambhuyan_5338070No ratings yet

- SPE 164135 Mechanical and Thermal Stability of Polyacrylamide-Based Microgel Products For EORDocument11 pagesSPE 164135 Mechanical and Thermal Stability of Polyacrylamide-Based Microgel Products For EORLeopold Roj DomNo ratings yet

- Effects of Fatty Acids On Low-Sulfur Diesel LubricityDocument8 pagesEffects of Fatty Acids On Low-Sulfur Diesel LubricityAashish GauravNo ratings yet

- Molecular Simulation, Quantum Chemical Calculations and Electrochemical Studies For Inhibition of Mild Steel by TriazolesDocument9 pagesMolecular Simulation, Quantum Chemical Calculations and Electrochemical Studies For Inhibition of Mild Steel by TriazolesManal NaciriNo ratings yet

- 234-Article Text-2909-2-10-20120708Document8 pages234-Article Text-2909-2-10-20120708nataliacaveroNo ratings yet

- 10.1351 Pac197542040551Document61 pages10.1351 Pac197542040551linkin 11 parkNo ratings yet

- Synthetics Lubricant Basestock Brochure - ExxonMobilDocument13 pagesSynthetics Lubricant Basestock Brochure - ExxonMobilRafael Nakazato RecioNo ratings yet

- Nb2O5 Catalyzed Kinetics of Fatty Acids Esterifica 2015 Chemical EngineeringDocument10 pagesNb2O5 Catalyzed Kinetics of Fatty Acids Esterifica 2015 Chemical EngineeringMajidJgrNo ratings yet

- Pseudo ModelDocument8 pagesPseudo ModelJon Bisu DebnathNo ratings yet

- Interacción Surfactante-Polímero Sobre Las Propiedades Interfaciales de Una SustanciaDocument9 pagesInteracción Surfactante-Polímero Sobre Las Propiedades Interfaciales de Una SustanciaJesus BcNo ratings yet

- Greenberg 2004Document8 pagesGreenberg 2004sabariNo ratings yet

- EosolyDocument5 pagesEosolyRudy Dwi PrasetyoNo ratings yet

- Experimental Study of The Flow BehaviourDocument13 pagesExperimental Study of The Flow BehaviourraviNo ratings yet

- Multifunctional Acrylates As Anti Reversion Agents in Sulfur Cured SystemsDocument20 pagesMultifunctional Acrylates As Anti Reversion Agents in Sulfur Cured SystemsTejender SinghNo ratings yet

- Bonilla 2013Document10 pagesBonilla 2013MaringanNo ratings yet

- Effect of Ethanol Treatment On Mechanical Properties of Heat-Polymerized Polymethyl Methacrylate Denture Base PolymerDocument8 pagesEffect of Ethanol Treatment On Mechanical Properties of Heat-Polymerized Polymethyl Methacrylate Denture Base PolymerGladis ARNo ratings yet

- MES - Myths, Mysteries and Perspectives On Properties and UseDocument17 pagesMES - Myths, Mysteries and Perspectives On Properties and UseRichard DinglasanNo ratings yet

- Effects of Hydroprocessing On Structure and Properties of Base Oils Using NMRDocument8 pagesEffects of Hydroprocessing On Structure and Properties of Base Oils Using NMRAvyan KelanNo ratings yet

- LubricantDocument11 pagesLubricantmechatronics NITWNo ratings yet

- Mechanism Studies On The Application of The Mixed Cationic-Anionic Surfactant Systems To Enhance Oil RecoveryDocument10 pagesMechanism Studies On The Application of The Mixed Cationic-Anionic Surfactant Systems To Enhance Oil RecoveryDavid LópezNo ratings yet

- Heuristic Synthesis and Shortcut Design of Separation Processes Using Residue Curve Maps - A ReviewDocument18 pagesHeuristic Synthesis and Shortcut Design of Separation Processes Using Residue Curve Maps - A ReviewFDNo ratings yet

- Hargreaves, Douglas Tang, JohnDocument23 pagesHargreaves, Douglas Tang, JohnTomas Muñoz VergaraNo ratings yet

- Optimization of Tribological Performance of hBN/AL O Nanoparticles As Engine Oil AdditivesDocument7 pagesOptimization of Tribological Performance of hBN/AL O Nanoparticles As Engine Oil Additiveskamal touilebNo ratings yet

- Tribology of Lipid Based LubricantDocument24 pagesTribology of Lipid Based Lubricantsatyambhuyan_5338070No ratings yet

- Bera, 2013 PDFDocument10 pagesBera, 2013 PDFMónica Tatiana HerreraNo ratings yet

- Study On Stress Degradation Behaviour of Abiraterone Acetate in Film Coated Tablets and Identification of Major Stress DDocument11 pagesStudy On Stress Degradation Behaviour of Abiraterone Acetate in Film Coated Tablets and Identification of Major Stress DvinayNo ratings yet

- RETRACTED ARTICLE Tribological Characteristics of Mongongo-Oil Based Biodiesel Blended LubricantDocument8 pagesRETRACTED ARTICLE Tribological Characteristics of Mongongo-Oil Based Biodiesel Blended LubricantAnirudh PooniaNo ratings yet

- Bioinspired Materials Science and EngineeringFrom EverandBioinspired Materials Science and EngineeringGuang YangNo ratings yet

- Hasanina 2017Document10 pagesHasanina 2017Chiew Fei HaNo ratings yet

- Article: Daniel Molina-V., Roika Angulo, Fay Zuly Dueñez, and Alexander GuzmanDocument35 pagesArticle: Daniel Molina-V., Roika Angulo, Fay Zuly Dueñez, and Alexander GuzmanJesus Alejandro RangelNo ratings yet

- Study of Physiochemical Properties of Cetyltrimethylammonium Bromide (CTAB) Surfactant Its Micellization, Almond Oil Water Emulsification and Industrial ApplicationsDocument4 pagesStudy of Physiochemical Properties of Cetyltrimethylammonium Bromide (CTAB) Surfactant Its Micellization, Almond Oil Water Emulsification and Industrial ApplicationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Kinetics of The Corrosion of Mild Steel in Petroleum-Water Mixture Using Ethyl Ester of Lard As InhibitorDocument9 pagesKinetics of The Corrosion of Mild Steel in Petroleum-Water Mixture Using Ethyl Ester of Lard As InhibitortheijesNo ratings yet

- Investigation of Abrasive Wear Resistance of Ferrous-Based Coatings With Scratch TesterDocument4 pagesInvestigation of Abrasive Wear Resistance of Ferrous-Based Coatings With Scratch Testeravencl100% (2)

- Assessment of Micro-Hardness, Degree of Conversion, and Flexural Strength For Single-Shade Universal Resin CompositesDocument16 pagesAssessment of Micro-Hardness, Degree of Conversion, and Flexural Strength For Single-Shade Universal Resin CompositesNattaporn VerayangkuraNo ratings yet

- Materials Chemistry and Physics: Omar Hussain, Sheikh Shahid Saleem, Babar AhmadDocument9 pagesMaterials Chemistry and Physics: Omar Hussain, Sheikh Shahid Saleem, Babar AhmadWahyu DwilestariNo ratings yet

- Synthesis and Properties of A High Solids Triethoxysilane-Modified Alkyd CoatingsDocument10 pagesSynthesis and Properties of A High Solids Triethoxysilane-Modified Alkyd Coatingsأحمد الشبيبيNo ratings yet

- Effectiveness Ofo-Bridged Cationic Gemini Surfactants As Corrosioninhibitors For Stainless Steel in 3 M HCL Experimental Andtheoretical StudiesDocument12 pagesEffectiveness Ofo-Bridged Cationic Gemini Surfactants As Corrosioninhibitors For Stainless Steel in 3 M HCL Experimental Andtheoretical StudiesROBERTA BASTOS VASQUES alu.ufc.brNo ratings yet

- Gemini Review PDFDocument14 pagesGemini Review PDFMuhammad Shehzad KamalNo ratings yet

- Richie Et Al IJTC2008-71165 Final PaperDocument3 pagesRichie Et Al IJTC2008-71165 Final PaperniszahNo ratings yet

- 2862-Article Text-16501-1Document14 pages2862-Article Text-16501-1BUN SaretNo ratings yet

- The Impact of Organic Friction Modifiers On Engine Oil TribofilmsDocument13 pagesThe Impact of Organic Friction Modifiers On Engine Oil TribofilmsPreshit DalviNo ratings yet

- Fluid Compatibility of Elastomers in Oilfield EnvironmDocument8 pagesFluid Compatibility of Elastomers in Oilfield EnvironmJesus VelizNo ratings yet

- Pull Out TestDocument11 pagesPull Out TestAM SaatNo ratings yet

- DLC en Los LubricantesDocument13 pagesDLC en Los LubricantesMatías LuckNo ratings yet

- Introduction To Blending of Elastomers For Tires and Industrial Products ApplicationsDocument19 pagesIntroduction To Blending of Elastomers For Tires and Industrial Products ApplicationsRubber TeamNo ratings yet

- Begalhouse CGCE Paper TemplateDocument8 pagesBegalhouse CGCE Paper TemplatedhairNo ratings yet

- Comparative Study of N - 4 Methoxyphenyl - Morpholin 4 Yl Meth - 2017 - ArabianDocument13 pagesComparative Study of N - 4 Methoxyphenyl - Morpholin 4 Yl Meth - 2017 - Arabianlucian_lovNo ratings yet

- Synthesis of Using The Nanocomposite Catalyst: Biodiesel Mg/Al/Zn Hydrotalcite/SBA-15Document24 pagesSynthesis of Using The Nanocomposite Catalyst: Biodiesel Mg/Al/Zn Hydrotalcite/SBA-15Vikash ChandravanshiNo ratings yet

- Xanthium Strumarium Leaves Extracts As A Friendly Corrosion Inhibitor of Low Carbon Steel in Hydrochloric Acid: Kinetics and Mathematical StudiesDocument9 pagesXanthium Strumarium Leaves Extracts As A Friendly Corrosion Inhibitor of Low Carbon Steel in Hydrochloric Acid: Kinetics and Mathematical StudiesAllia AsriNo ratings yet

- Davis 2011Document9 pagesDavis 2011satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Wear 2011Document5 pagesSatyam Bhuyan Wear 2011satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Wear 2010Document6 pagesSatyam Bhuyan Wear 2010satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Wear 2007Document9 pagesSatyam Bhuyan Wear 2007satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Tribology International 2010 2Document7 pagesSatyam Bhuyan Tribology International 2010 2satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Soft Matter 2013 PDFDocument10 pagesSatyam Bhuyan Soft Matter 2013 PDFsatyambhuyan_5338070No ratings yet

- Satyam Bhuyan Tribology International 2010 3Document9 pagesSatyam Bhuyan Tribology International 2010 3satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Tribology International 2010 1Document7 pagesSatyam Bhuyan Tribology International 2010 1satyambhuyan_5338070No ratings yet

- Satyam Bhuyan MRS Communications 2012Document4 pagesSatyam Bhuyan MRS Communications 2012satyambhuyan_5338070No ratings yet

- Satyam Bhuyan IJTC 2007Document3 pagesSatyam Bhuyan IJTC 2007satyambhuyan_5338070No ratings yet

- Satyam Bhuyan EHS 2019Document10 pagesSatyam Bhuyan EHS 2019satyambhuyan_5338070No ratings yet

- Satyam Bhuyan Soft Matter 2013 PDFDocument10 pagesSatyam Bhuyan Soft Matter 2013 PDFsatyambhuyan_5338070No ratings yet

- A Model To Predict The Wear Properties of Bio-Based Polymers As A Function of The Crosslinking DensityDocument12 pagesA Model To Predict The Wear Properties of Bio-Based Polymers As A Function of The Crosslinking Densitysatyambhuyan_5338070No ratings yet

- Failure Mechanism of MEMS DeviceDocument9 pagesFailure Mechanism of MEMS Devicesatyambhuyan_5338070No ratings yet

- A Study of Bimorphs As An Energy Harvester: Satyam Bhuyan and Benjamin PecholtDocument15 pagesA Study of Bimorphs As An Energy Harvester: Satyam Bhuyan and Benjamin Pecholtsatyambhuyan_5338070No ratings yet

- Tribology of Lipid Based LubricantDocument24 pagesTribology of Lipid Based Lubricantsatyambhuyan_5338070No ratings yet

- Project ReportDocument23 pagesProject Reportsatyambhuyan_5338070No ratings yet

- PresentationDocument14 pagesPresentationsatyambhuyan_5338070No ratings yet

- Bio-Based Polymer (Crosslinked)Document23 pagesBio-Based Polymer (Crosslinked)satyambhuyan_5338070No ratings yet

- Failure Mechanism of MEMS DeviceDocument9 pagesFailure Mechanism of MEMS Devicesatyambhuyan_5338070No ratings yet

- Biotribology SeminarDocument25 pagesBiotribology Seminarsatyambhuyan_5338070No ratings yet

- Winter Intership SyllabusDocument14 pagesWinter Intership SyllabusAjayNo ratings yet

- Ordinal Logistic Regression: 13.1 BackgroundDocument15 pagesOrdinal Logistic Regression: 13.1 BackgroundShan BasnayakeNo ratings yet

- JAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The CockpitDocument17 pagesJAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The Cockpitfranciss87No ratings yet

- Chameleon ChipDocument2 pagesChameleon ChipChetan KumarNo ratings yet

- Differential EquationDocument17 pagesDifferential EquationAashika DhareNo ratings yet

- EagleBurgmann - API682 4th Facts, Innovations, SolutionsDocument26 pagesEagleBurgmann - API682 4th Facts, Innovations, SolutionsTasawwur Tahir100% (1)

- Total Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsDocument14 pagesTotal Phenolic and Flavonoid Contents of Srikaya (Annona Squamosa L.) Leaf Fermented ExtractsAhmad HidayahNo ratings yet

- G12 NCERT Unit-14 BiomoleculesDocument15 pagesG12 NCERT Unit-14 Biomoleculescherryakila05No ratings yet

- Fds 8878Document12 pagesFds 8878Rofo2015No ratings yet

- Tutorial Book 0.4Document27 pagesTutorial Book 0.4TonyandAnthonyNo ratings yet

- What Is A ComputerDocument29 pagesWhat Is A ComputerRellie CastroNo ratings yet

- Flume User GuideDocument48 pagesFlume User GuideRajulNo ratings yet

- Biology Paper 6 NotesDocument5 pagesBiology Paper 6 NotesbNo ratings yet

- A Simulation of Attempts To Influence Crowd Dynamics'Document6 pagesA Simulation of Attempts To Influence Crowd Dynamics'KhairulNo ratings yet

- Chapter 4 Structure EditedDocument9 pagesChapter 4 Structure Editedyeshi janexoNo ratings yet

- Workspace Satisfaction - The Privacy-Communication Trade-Off in Open-Plan OfficesDocument9 pagesWorkspace Satisfaction - The Privacy-Communication Trade-Off in Open-Plan OfficesAyşe Nur TürkerNo ratings yet

- Hydraulic Structure - 16 - 30 - FianalDocument26 pagesHydraulic Structure - 16 - 30 - FianalMahmood YounsNo ratings yet

- EX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and ViewsDocument44 pagesEX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and Viewslalit thakur100% (1)

- PHYSICS Lab Manual - 2023-24Document30 pagesPHYSICS Lab Manual - 2023-24Vinushree Santhoshkumar100% (4)

- Seam Strength of Corrugated Plate With High Strength SteelDocument15 pagesSeam Strength of Corrugated Plate With High Strength SteelMariano SalcedoNo ratings yet

- Question Bank-JavaDocument3 pagesQuestion Bank-Javarachana saiNo ratings yet

- Mds Ti-Alloy Ta15 0720 enDocument3 pagesMds Ti-Alloy Ta15 0720 enshahin_723No ratings yet

- LANTUS XR Label InformationDocument17 pagesLANTUS XR Label InformationMichaelJonatanNo ratings yet

- Imn 903000 E06Document158 pagesImn 903000 E06Paul CasaleNo ratings yet

- Class Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Document2 pagesClass Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Shairrah Claire Bañares BatangueNo ratings yet

- TUC5+ Modbus ID Details PDFDocument10 pagesTUC5+ Modbus ID Details PDFvijikeshNo ratings yet

- A Quick Tutorial On RSLogix Emulator 5000Document9 pagesA Quick Tutorial On RSLogix Emulator 5000slavezerorjNo ratings yet

- Sarvani ProfileDocument12 pagesSarvani Profiledox4print100% (1)

- Astar - 23b.trace - XZ Bimodal Next - Line Next - Line Next - Line Next - Line Drrip 1coreDocument4 pagesAstar - 23b.trace - XZ Bimodal Next - Line Next - Line Next - Line Next - Line Drrip 1corevaibhav sonewaneNo ratings yet

- MDM Heiana Nadia Hamzah: Prepared byDocument50 pagesMDM Heiana Nadia Hamzah: Prepared bySyarfa FurzanneNo ratings yet