Professional Documents

Culture Documents

Aggregate Unit Calculations

Uploaded by

EKREM ÇAMURLUOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate Unit Calculations

Uploaded by

EKREM ÇAMURLUCopyright:

Available Formats

PART 1

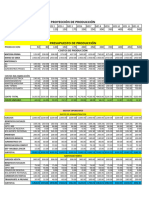

In order to conduct aggregate planning for multiproduct, firstly we should calculate aggregate

unit. Because we want to plan the production for three different products, we should calculate

aggregate unit of products a worker can produce in a day. It is important to note that a

working day is assumed to be 8 hours=480 minutes and workers work with full efficiency

100% for calculations. Aggregate unit is calculated as below;

1. Calculate total demands for each product.

2. Divide demand of each product and find the percentages.

3. Calculate total processing time for each product (it is given in the case study file).

4. ∑(Percentage*processing time) gives us aggregate unit labor time.

5. Divide total available time in a day by aggregate unit labor time to find aggregate unit

of products a worker can produce in a day.

6. In order to find aggregate demand values of the weeks do the similar calculation in

step 4; ∑(Percentage*That weeks order quantity) gives us aggregate demands of

weeks.

Aggregate unit calculations

After calculating aggregate unit of demands and production capacity of a worker, we tried to plan the production with constant workforce and

zero inventory models which yielded a total cost of 2.003.676,81 dollars and 1.625.779,85 dollars respectively. It is important to note that a

weekday is assumed to be 8 hours=480 minutes and workers work with full efficiency 100% for calculations. A year is assumed to be exactly

52 weeks, thus, weekly inventory carriage rate is calculated by dividing annual carriage rate by 52. Calculations are given in the below tables

and the details and formulas are on the Excel file.

Constant workforce plan

Zero inventory plan

Comparison of costs for these two models are given below. Finally, it is important to note

that zero inventory plan did not converge with actually zero inventory because while

calculating worker and product needs we rounded up the calculated number and while

calculating production output we rounded down the calculated value. Thus, small

decimals resulted in minimal stock levels but not zero. Similar situation is also observed

in constant workforce plan as a result of identical approach to rounding the numbers up or

down. The calculations tell us that zero inventory plan should be preferred due to less cost

incurring.

Costs Constant Workforce Zero Inventory

Cost of Hiring $0,00 $4.500,00

Cost of Firing $11.200,00 $19.600,00

Inventory Cost $1.546,81 $159,85

Labor Cost $136.800,00 $108.000,00

Manufacturing Cost $1.854.130,00 $1.493.520,00

Total Cost $2.003.676,81 $1.625.779,85

Cost comparison of two plans

PART 2

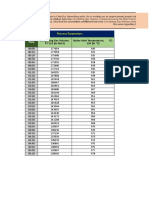

The results of master production scheduling and capacity planning is given below. According

to the calculations, red areas denote where requirements exceed capacity available. It can be

inferred from the figure that, Lathe and rip saw are perfectly sufficient for this demand levels

but rest of the departments are not especially tenon and finish. So capacity increase should be

considered in these departments.

Week 20 21 22 23 24 25 26 27 28 29 30 31 Initial Inventories

Stool 88 99 121 113 97 86 106 105 86 99 104 113 Stool 80 Department Stool Rocker Swing Available (Hours) Available (Minutes)

Forecast Demand Rocker 281 341 302 303 324 311 320 312 341 350 364 310 Rocker 300 Drill 7 10 11 70 4200

Swing 25 25 22 21 28 198 177 173 65 295 264 204 Swing 110 Lathe 15 0 0 35 2100

Crosscut

Stool 0 0 0 0 0 0 0 0 0 0 0 0 3 16 10 105 6300

saw

Inventory

Rocker 19 0 0 0 0 0 0 0 0 0 0 0 Rip Saw 1 3 4 40 2400

Swing 85 60 38 17 0 0 0 0 0 0 0 0 Mortise 0 10 8 70 4200

Stool 8 99 121 113 97 86 106 105 86 99 104 113 Tenon 3 22 11 105 6300

Router/Sha

MPS Rocker 0 322 302 303 324 311 320 312 341 350 364 310 0 5 3 35 2100

per

Swing 0 0 0 0 11 198 177 173 65 295 264 204 Plane 0 13 7 70 4200

Sand 5 25 35 145 8700

Week 20 21 22 23 24 25 26 27 28 29 30 31 Assemble 12 30 45 200 12000

Drill 56 3913 3867 3821 4040 5890 5889 5758 4727 7438 7272 6135 Finish 5 15 22 80 4800

Lathe 120 1485 1815 1695 1455 1290 1590 1575 1290 1485 1560 1695

Crosscut saw 24 5449 5195 5187 5585 7214 7208 7037 6364 8847 8776 7339

Rip Saw 8 1065 1027 1022 1113 1811 1774 1733 1369 2329 2252 1859

Mortise 0 3220 3020 3030 3328 4694 4616 4504 3930 5860 5752 4732

Tenon 24 7381 7007 7005 7540 9278 9305 9082 8475 11242 11224 9403

Router/Shaper 0 1610 1510 1515 1653 2149 2131 2079 1900 2635 2612 2162

Plane 0 4186 3926 3939 4289 5429 5399 5267 4888 6615 6580 5458

Sand 40 8545 8155 8140 8970 15135 14725 14380 11230 19570 18860 15455

Assemble 96 10848 10512 10446 11379 19272 18837 18405 14187 24963 24048 19836

Finish 40 5325 5135 5110 5587 9451 9224 9011 6975 12235 11788 9703

Master production scheduling and capacity planning

PART 3

MRP table is given below. For ease and accuracy requirements of these two items are shown

in the same table as F is common in both BOM trees. It is important to note that in order to

successfully execute the master production scheduling we should take our first action 8

weeks, 2 months before starting to production process and order 1450 units of Y.

Weeks

Part Level Lead On Hand Safety

Lot Size

Name Code Time Inventory Stock 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Required 125 250 122 110 250 110 150 164 256

Schedule Receipts

On hand Inventory 0

Stool 0 LFL 2 0 0

Net Requirements 125 0 250 122 110 0 250 0 110 150 164 256

Planned Orders 125 0 250 122 110 0 250 0 110 150 164 256

Given Orders 0 0 0 0 0 0 125 0 250 122 110 0 250 0 110 150 164 256 0 0

Required 200 20 50 25 112 251 125 26 15 18

Schedule Receipts

On hand Inventory 0

Swing 0 LFL 2 0 0

Net Requirements 200 20 50 25 112 0 0 251 125 26 15 18

Planned Orders 200 20 50 25 112 0 0 251 125 26 15 18

Given Orders 0 0 0 0 0 0 200 20 50 25 112 0 0 251 125 26 15 18 0 0

Required 0 0 0 0 0 0 650 40 600 294 444 0 500 502 470 352 358 548 0 0

Schedule Receipts

On hand Inventory 100 100 100 100 100 100 100 0 0 0 0 0 0 0 0 0 0 0 0 0 0

J 1 LFL 2 0 0

Net Requirements 0 0 0 0 0 0 550 40 600 294 444 0 500 502 470 352 358 548 0 0

Planned Orders 0 0 0 0 0 0 550 40 600 294 444 0 500 502 470 352 358 548 0 0

Given Orders 0 0 0 0 550 40 600 294 444 0 500 502 470 352 358 548 0 0 0 0

Required 0 0 0 0 0 0 375 0 750 366 330 0 750 0 330 450 492 768 0 0

Schedule Receipts 100

On hand Inventory 500 500 500 500 500 500 500 125 125 0 100

F 1 LFL 2 0 0

Net Requirements 0 0 0 0 0 0 0 0 625 266 330 0 750 0 330 450 492 768 0 0

Planned Orders 0 0 0 0 0 0 0 0 625 266 330 0 750 0 330 450 492 768 0 0

Given Orders 0 0 0 0 0 0 625 266 330 0 750 0 330 450 492 768 0 0 0 0

Required 0 0 0 0 0 0 1250 532 660 0 1500 0 660 900 984 1536 0 0 0 0

Schedule Receipts 250

On hand Inventory 250 250 250 250 250 250 250 0 0 0 0 0 0 0 250

R 2 LFL 2 0 0

Net Requirements 0 0 0 0 0 0 1000 532 660 0 1500 0 660 650 984 1536 0 0 0 0

Planned Orders 0 0 0 0 0 0 1000 532 660 0 1500 0 660 650 984 1536 0 0 0 0

Given Orders 0 0 0 0 1000 532 660 0 1500 0 660 650 984 1536 0 0 0 0 0 0

Required 0 0 0 0 0 0 6250 2660 3300 0 7500 0 3300 4500 4920 7680 0 0 0 0

Schedule Receipts

On hand Inventory 100 100 100 100 100 100 100 0

X 2 LFL 2 0 0

Net Requirements 0 0 0 0 0 0 6150 2660 3300 0 7500 0 3300 4500 4920 7680 0 0 0 0

Planned Orders 0 0 0 0 0 0 6150 2660 3300 0 7500 0 3300 4500 4920 7680 0 0 0 0

Given Orders 0 0 0 0 6150 2660 3300 0 7500 0 3300 4500 4920 7680 0 0 0 0 0 0

Required 0 0 0 0 0 0 800 80 200 100 448 0 0 1004 500 104 60 72 0 0

Schedule Receipts

On hand Inventory 50 50 50 50 50 50 50 0

Z 1 LFL 3 0 0

Net Requirements 0 0 0 0 0 0 750 80 200 100 448 0 0 1004 500 104 60 72 0 0

Planned Orders 0 0 0 0 0 0 750 80 200 100 448 0 0 1004 500 104 60 72 0 0

Given Orders 0 0 0 750 80 200 100 448 0 0 1004 500 104 60 72 0 0 0 0 0

Required 0 0 0 1500 160 400 200 896 0 0 2008 1000 208 120 144 0 0 0 0 0

Schedule Receipts 300

On hand Inventory 50 50 50 50 0 300 300

Y 2 LFL 3 0 0

Net Requirements 0 0 0 1450 160 400 200 896 0 0 2008 1000 208 120 144 0 0 0 0 0

Planned Orders 0 0 0 1450 160 400 200 896 0 0 2008 1000 208 120 144 0 0 0 0 0

Given Orders 1450 160 400 200 896 0 0 2008 1000 208 120 144 0 0 0 0 0 0 0 0

MRP table

You might also like

- Government Publications: Key PapersFrom EverandGovernment Publications: Key PapersBernard M. FryNo ratings yet

- Technical Data, Caps & ClosuresDocument5 pagesTechnical Data, Caps & ClosuresUpendra PulapatiNo ratings yet

- MP VRD Brahim & DioufDocument54 pagesMP VRD Brahim & DioufBouye DioufNo ratings yet

- Net Drum With Installation For 1 Netdrum (Karnafully)Document5 pagesNet Drum With Installation For 1 Netdrum (Karnafully)M Jobayer AzadNo ratings yet

- Blanko UTDocument5 pagesBlanko UTnovi antiNo ratings yet

- Excel SolutionsDocument20 pagesExcel SolutionsEKREM ÇAMURLUNo ratings yet

- Simulation ReplacementDocument15 pagesSimulation ReplacementSapna AdityaNo ratings yet

- Title: Particle Size Analysis Via Mechanical Sieve: CEE 346L - Geotechnical Engineering I LabDocument6 pagesTitle: Particle Size Analysis Via Mechanical Sieve: CEE 346L - Geotechnical Engineering I LabAbhishek RayNo ratings yet

- Procesos Industriales - T4 Curva de AprendizajeDocument4 pagesProcesos Industriales - T4 Curva de AprendizajeKenneth MosqueraNo ratings yet

- HRS-STD-ENG-004 Produktivitas Loader - Rev.1Document1 pageHRS-STD-ENG-004 Produktivitas Loader - Rev.1hazfi ariqiNo ratings yet

- Exam Gestion Financier Ratt 2018 Prof MESK - Faculté HASSAN 2 CASABLANCADocument1 pageExam Gestion Financier Ratt 2018 Prof MESK - Faculté HASSAN 2 CASABLANCAAbdoNo ratings yet

- okDocument1 pageokay71421777No ratings yet

- Component Units 1 2 3 4 5 6: F G F GDocument6 pagesComponent Units 1 2 3 4 5 6: F G F Gbighead3158No ratings yet

- Scala Dynamic Cone Penetrometer Test: KM KM KM KM KMDocument3 pagesScala Dynamic Cone Penetrometer Test: KM KM KM KM KMroy darlanNo ratings yet

- Materials, labor and cost estimates for concrete, steel, masonry and plaster workDocument59 pagesMaterials, labor and cost estimates for concrete, steel, masonry and plaster workdeje1726No ratings yet

- EMPRENDIMIENTO COSTO TOTALnathalyRDocument2 pagesEMPRENDIMIENTO COSTO TOTALnathalyRNathaly RoseroNo ratings yet

- Excel TicDocument11 pagesExcel TicTheo Agustin Colque ValentinNo ratings yet

- Advanced Capital Budgeting 3 HW - q7Document3 pagesAdvanced Capital Budgeting 3 HW - q7sairad1999No ratings yet

- Compiled ReportDocument24 pagesCompiled ReportkartikNo ratings yet

- Space Engineers Ship CalculatorDocument7 pagesSpace Engineers Ship Calculatorblackwolfz555No ratings yet

- Spin PLanDocument3 pagesSpin PLanntunewspoint100% (4)

- Final Estimate 14.09.2022Document24 pagesFinal Estimate 14.09.2022KumudNo ratings yet

- Monthly Fuel ConsumptionDocument3 pagesMonthly Fuel ConsumptionPrem KumarNo ratings yet

- BepacityDocument7 pagesBepacitySurianshah shahNo ratings yet

- Tumble Dry Project Financial ReportDocument3 pagesTumble Dry Project Financial ReportAkash SanganiNo ratings yet

- Case 1Document4 pagesCase 1imi.imtenanNo ratings yet

- Kagaoan Bill of QuantitiesDocument10 pagesKagaoan Bill of QuantitiesMichael EncarnacionNo ratings yet

- EpsfDocument1 pageEpsfandry hardianNo ratings yet

- Anchor Bolt: S. No. Bolt Description Qty. AB Dia. (D) Verticle Length (H) Thread (T)Document31 pagesAnchor Bolt: S. No. Bolt Description Qty. AB Dia. (D) Verticle Length (H) Thread (T)Sudhanshu PalNo ratings yet

- Design ChartDocument2 pagesDesign ChartFrederick TanNo ratings yet

- Diagrama de InteraccionDocument10 pagesDiagrama de InteraccionErick Mamani ZuñigaNo ratings yet

- Derivation of Primary Side MKDocument2 pagesDerivation of Primary Side MKjagdeep mulaniNo ratings yet

- J1+ Practice SetDocument15 pagesJ1+ Practice Setpavan h ghogareNo ratings yet

- Generación W/Time: Gaussiana PVDocument2 pagesGeneración W/Time: Gaussiana PVCarlos Terraza OyagaNo ratings yet

- Final ExamDocument51 pagesFinal ExambhavikrathodhiNo ratings yet

- POE Problemset5Document4 pagesPOE Problemset5Duc Chinh LuongNo ratings yet

- Practica 8 Ensayo de CorteDocument1 pagePractica 8 Ensayo de CorteJuancho TusinNo ratings yet

- SL - No Name of Assst No Rate AmountDocument21 pagesSL - No Name of Assst No Rate Amountlegalsg75No ratings yet

- OUT TSP RW1 RW2 RW3 RW4 RW5 RW6 RW7 RW8 CW1 CW2 CW3 CW4 CW5Document5 pagesOUT TSP RW1 RW2 RW3 RW4 RW5 RW6 RW7 RW8 CW1 CW2 CW3 CW4 CW5Ricardo Andres AristizabalNo ratings yet

- Experimental & 1D FEA Temp ComparisonDocument4 pagesExperimental & 1D FEA Temp ComparisonGaurav GayakeNo ratings yet

- Proposed Bongalow 360 SQMDocument1 pageProposed Bongalow 360 SQMJuneld Ian RamosNo ratings yet

- Demand Schedule: Concept of ElasticityDocument8 pagesDemand Schedule: Concept of Elasticityjossa pokkoNo ratings yet

- Budget 2021-2022Document16 pagesBudget 2021-2022Dasari VenkateshNo ratings yet

- Excel Formulas ApplicationDocument8 pagesExcel Formulas ApplicationAkash RajputNo ratings yet

- Session 11Document5 pagesSession 11samay gargNo ratings yet

- Aggregate Planning FinalDocument12 pagesAggregate Planning FinalDewashish RaiNo ratings yet

- New Model1Document5 pagesNew Model1oscaracostaNo ratings yet

- Analysis: Calculation of Total Sales of The ProjectDocument7 pagesAnalysis: Calculation of Total Sales of The ProjectShailesh Kumar BaldodiaNo ratings yet

- DIN Metric Flange Dimensions GuideDocument5 pagesDIN Metric Flange Dimensions GuideSara MahmoudNo ratings yet

- RCC Ladder Qty1Document25 pagesRCC Ladder Qty1Kannan GnanaprakasamNo ratings yet

- KE Units CompDocument7 pagesKE Units CompKhanNo ratings yet

- Documento 1685401803784Document3 pagesDocumento 1685401803784Kim HeeNo ratings yet

- Número 1 0 0 0 2 0 0 0 3 0 0 0 4 0 0 0 5 0 0 0 6 0 0 0 7 0 0 0 8 0 0 0 9 0 0 0 10 0 0 0 11 0 0 0 12 0 0 0Document6 pagesNúmero 1 0 0 0 2 0 0 0 3 0 0 0 4 0 0 0 5 0 0 0 6 0 0 0 7 0 0 0 8 0 0 0 9 0 0 0 10 0 0 0 11 0 0 0 12 0 0 0SEbastian FresnedaNo ratings yet

- Mr. Mcclintock Can Analyse The Following Factors To Decide Whether or Not To Adopt Level Production PlanDocument10 pagesMr. Mcclintock Can Analyse The Following Factors To Decide Whether or Not To Adopt Level Production Plansanket vermaNo ratings yet

- Variable Costs R/tonneDocument3 pagesVariable Costs R/tonneChemEngGirl89No ratings yet

- Alok GDocument1 pageAlok GmithileshsutharpcNo ratings yet

- Consolidation RizwanDocument14 pagesConsolidation RizwanNouman KhalidNo ratings yet

- Etude FinanciereDocument28 pagesEtude Financieresalma elkeltoumiNo ratings yet

- Aggregate Planning - Chapter 5Document36 pagesAggregate Planning - Chapter 5EKREM ÇAMURLUNo ratings yet

- MRP BasicsDocument13 pagesMRP BasicsEKREM ÇAMURLUNo ratings yet

- Case Study INDE342 SPRING 2020-2021Document3 pagesCase Study INDE342 SPRING 2020-2021EKREM ÇAMURLUNo ratings yet

- q3 GamsDocument2 pagesq3 GamsEKREM ÇAMURLUNo ratings yet

- SolutionssDocument7 pagesSolutionssEKREM ÇAMURLUNo ratings yet

- Ise 362 HomeworkDocument3 pagesIse 362 HomeworkEKREM ÇAMURLUNo ratings yet

- Ie 409 Project Management and Scheduling Individual ProjectDocument11 pagesIe 409 Project Management and Scheduling Individual ProjectEKREM ÇAMURLUNo ratings yet

- Nonlinear Programming: Operations Research: Applications and Algorithms 4th EditionDocument45 pagesNonlinear Programming: Operations Research: Applications and Algorithms 4th EditionEKREM ÇAMURLUNo ratings yet

- QMT 3001 Business Forecasting Group ProjectDocument30 pagesQMT 3001 Business Forecasting Group ProjectEKREM ÇAMURLUNo ratings yet

- Makerspace@TheTechCookbook BetaSamplerDocument67 pagesMakerspace@TheTechCookbook BetaSamplerLindsay Balfour100% (5)

- 4-Way Reversing ValvesDocument3 pages4-Way Reversing ValvesAbdulSattarNo ratings yet

- Wireshark Dump and Traffic AnalysisDocument79 pagesWireshark Dump and Traffic AnalysisSudipta DasNo ratings yet

- Reinforced Concrete StandardsDocument1 pageReinforced Concrete StandardsAkshay ThakurNo ratings yet

- Baker, BachourDocument178 pagesBaker, BachourHoward BrandonNo ratings yet

- Basic Rotor Aerodynamics: 1D MomentumDocument6 pagesBasic Rotor Aerodynamics: 1D MomentumJagabar SathikNo ratings yet

- Denis Wick PDFDocument2 pagesDenis Wick PDFvicentikooNo ratings yet

- Object Cloning Best PracticesDocument15 pagesObject Cloning Best PracticeswaltNo ratings yet

- Basic Electrnic ComponenetsDocument73 pagesBasic Electrnic ComponenetsПавел ДимитровNo ratings yet

- Workbook View Point 1Document105 pagesWorkbook View Point 1Juandacho Reina100% (1)

- Aion Aurora Ross Compressor DocumentationDocument7 pagesAion Aurora Ross Compressor DocumentationLucas Fabian Muñoz VasquezNo ratings yet

- Fluid Mechanics Revised ManualDocument57 pagesFluid Mechanics Revised ManualQuenNo ratings yet

- Parts List of Engine Assy of FMX 440 (PC-24) - TP-836Document1 pageParts List of Engine Assy of FMX 440 (PC-24) - TP-836Cws0% (1)

- E380Document88 pagesE380Luis JaramilloNo ratings yet

- FinalMissionReportdefversion Jakarta Coastal Area by NLDocument33 pagesFinalMissionReportdefversion Jakarta Coastal Area by NLLiya DjajadisastraNo ratings yet

- Draager PAC500Document200 pagesDraager PAC500Arnaldo AravenaNo ratings yet

- OneSteel Hot Rolled PropertiesDocument22 pagesOneSteel Hot Rolled PropertiesRajeev SharanNo ratings yet

- DGP CatalogDocument75 pagesDGP Catalogsenthilmurugan_k3289No ratings yet

- Design Standards For Offshore Wind Farms-ABSDocument224 pagesDesign Standards For Offshore Wind Farms-ABSAsid ZullahNo ratings yet

- Conductivity in Power PlantsDocument4 pagesConductivity in Power PlantsdsoNo ratings yet

- Ccna NotesDocument127 pagesCcna NotesRajumallepoola93% (14)

- PDN ConnectivityDocument1 pagePDN Connectivityjohncena90No ratings yet

- Master Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationDocument296 pagesMaster Minimum Equipment List: U.S. Department of Transportation Federal Aviation AdministrationZainal AbidinNo ratings yet

- Jonathan Ma ResumeDocument1 pageJonathan Ma Resumesumit kulyalNo ratings yet

- Microsoft Word - FAQ-For Supervision ProjectsDocument16 pagesMicrosoft Word - FAQ-For Supervision ProjectsAman LawaniaNo ratings yet

- BG Katalog Na BanknotiDocument133 pagesBG Katalog Na BanknotiGoroSoftNo ratings yet

- BSR330 Briefing IFP W1 - September 2019Document22 pagesBSR330 Briefing IFP W1 - September 2019Nur FatinahNo ratings yet

- APM100 Outdoor Power Supply System User Manual (V1.3)Document58 pagesAPM100 Outdoor Power Supply System User Manual (V1.3)Stephane70No ratings yet

- Ways in Responding To An Unplanned Events or Condition in Accordance With Established ProceduresDocument8 pagesWays in Responding To An Unplanned Events or Condition in Accordance With Established Proceduresapi-196541959100% (1)

- Eumeswil Ernst Jnger PDFDocument2 pagesEumeswil Ernst Jnger PDFSamantha0% (2)