Professional Documents

Culture Documents

Vdocuments - MX Onan Generator Operating Manual 981 01201

Uploaded by

Color XpressOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vdocuments - MX Onan Generator Operating Manual 981 01201

Uploaded by

Color XpressCopyright:

Available Formats

MDKC, MDKD

Diesel Series

Printed in U.S.A. 981-0120

7-95

IlrcXu~rSiUI T h l s symbol refers u a hazard or unsafe

practice vkhich can result n personal injury or pro

uct or p r a p r f y damage.

FUEL, E N G l N E OIL, AND FUMES ARE FLAMMABLE AND

X C L i G sxp osion, and persanal njuri mn esult from im-

p r cp e r p r a c k t c ,

Benrerir: and lead, found in SOtTm gasoline, have been

idwtifir d by s a m e state and federal agencies as causing

canciv o r rlapruducttw taxicity. \&hen cheskjn3, draining

or adding g-salina. take care not to ingest, breathzd the

f u m e ? , or r;anbd ga-rj'me.

I l ~ r j wgino G ~ S w n keen idcntified by soma sfate ar

fcidcral i g e n c i ~s causingcanc,r;ror reprdiuciivs fexic-

iPj. bVh.. rich.r,kinge)rckar,gingFJrlgine i\,fakemrenatto

ingcjlst, ;mathe h e fumes, or cantact u s d ail.

M a r s pwiorming any maintenancs on thi:. gerirratnr :d,

Do not 8l1ueltankswiththe engine r u n n i n g Do not S M O ~

disconnect its batteries to prevent accidental startir,g. 6

araund the generator set area, Wipe up any oil or gas not disconnect or cannect battery ab e: if fuel vzipor:? a r e

spills. Do not leave oily rags in engine compartment or on present. Ventilate the generator set compartment or bilgs

the gen vator set. Keep this and surrounding area c ean. thoroughly with the power exha uster.

nspect fuel system before operation and priodicaliy

while running. ELECTRICAL SHOCK W i L l CAUSE SEVERE

PERSONAL N J U R Y OR DEATH

Equip t l - ~ngine fuel supply with a pusitrm fuel shutoff. Do not make acljustmsrits in t h s control p a w l oronerigina

Lvith u n ? running. High voltagez E r e prcxmt. Work thaf

Always dtscmnectthe battery ground (-) lead first and re- must be dona vihils unit is r u n n i n g zhould b e d o n ? only by

connacl it last. Make s u r e you connect ?.he baflery cor- qualified t m i c t 3 permnnel standing on dry run'aces to i e -

rnclly, A direct short across the battery ierminai, Mn dum shmk hazard.

cause a n explosion. Do ot smoke & h k sesvichg batter-

iss Hyiriragengas given off during charging k var; axpta-

iw.

K ~ a p t h xtinguisher available in op near tiis tlng;ne

companmtint anel in other areas ihraughwt the vessel.

Usu the correct extinguisher for the area. For mosi types

of fires, an extinguisher rated ABC by the NFPA is avail-

able , ~ n jitahlo for sse cia ll types of firesexcept aka-

hd.

Do natworkon thisequipment when menhrlyar phy:ic-r;lly

HAUST GASES A R E DEADLY fatigued, csr after consuming any d m h o l o: drug lhst

a Provide adequafe ventilation, Equipthe bilge with apolviir nakss the aperation ef equipment urtzafu. F1

h e vessel. or publication of this document,

Copy and past these suggestions ]InpotenXIal haarc areas of t Redistribution

by any means, is strictly prohibited.

Table of Contents

SECTION TITLE PAGE

SAFETY PRECAUTIONS .......................... Inside Front Cover

1 INTRODUCTlON ............................................ 1-1

About This Manual ......................................... 1-1

How to Obtain Service ...................................... 1-1

2 SPECIFICATIONS ........................................... 2-1

Generator Details .......................................... 2-1

Engine Details ............................................. 2-1

3 OPERATION ............................................... 3-1

General .................................................. 3-1

Pre-Start Checks ........................................... 3-1

Control Panel ............................................. 3-2

Starting .................................................. 3- 3

Stopping ................................................. 3-3

Operating Recommendations ................................. 3-3

Troubleshooting ........................................... 3-4

4 MAINTENANCE .............................................. 4-1

General .................................................. 4-1

Periodic Maintenance Schedule ............................... 4-1

Set Inspection ............................................. 4- 2

Lubrication System ......................................... 4-3

Cooling System ............................................ 4- 4

Fuel System .............................................. 4-6

Battery ................................................... 4-8

AC Generator ............................................. 4-9

Out-of-Service Protection .................................... 4- 9

California

Proposition 65 Warning

I

iesel engine exhaust and some of its con stituents are known

to th e State of Califo rnia to cause cancer. bir th defects. and

other reprod uctive harm

i Redistribution or publication of this document,

by any means, is strictly prohibited.

. .

Redistribution or publication of this document,

by any means, is strictly prohibited.

Section 1 Introduction

ABOUT THIS MANUAL For the name of your local Cummins/Onan or

Onan-only distributor in the United States or C an-

This manual provides nformation for op erating and

ada, call -800-888-0NAN (This automated serv-

maintaining the genset. Study this m anual carefully

and observe all warnings and cautions. Using the ice utilizes touch-tone phones only). By entering

genset properly and following a regular mainte- your are a code and the first three digits of your local

nance schedule will contribute to longer unit life, telephone number, YOU W i l l receive the name and

better performance, and safer operation. telephone number of the distributor nearest you.

HOW TO OBTAIN SERVICE For the name of your local Cummins-only distribu-

When the genset requires servicing, contact your tor, O r if YOU need more assistance, please call

nearest dealer or distributor. Factory-trained Parts Onan Corporation, 1-612-574-5000, 7:30 AM to

and Service representatives are ready to handle all 4:30PM, Central Standard Time, M onday through

your service needs. Friday.

If unable to locate a dealer or distributor, co nsult the

Yellow Pages. Typically, our distributors are listed When contacting your distributor, always supply

under: the com plete M odel Number and Serial Num ber as

GENERATORS-ELECTRIC, shown on the genset nameplate.

ENGINES-GASOLINE OR DIESEL, OR

RECREATIONAL VEHICLES-EQ UIPMENT,

PARTS AND SERVICE.

INCORRECT SERVICE OR REPLA CEMENT OF PARTS CA N RESULT IN

SEVERE PERSONAL INJURY, DEATH, AND/OR EQUIPMENT DAMAGE.

SERVICE PERSONNEL MUST BE QUALIFIED TO PERFORM ELECTRI-

CAL AND/OR MECHANICAL SERVICE.

1-1 Redistribution or publication of this document,

by any means, is strictly prohibited.

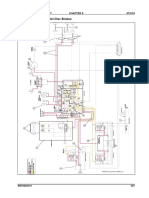

opnorwAC FUEL RETURN

CIRCUIT BREAKERS LINE Fl-m NG

INJECTION

M-1526-1

FIlTlNG FILTER

FIGURE 1-1, MDKC/MDKD GENERATOR SET COMPONENTS

1-2 Redistribution or publication of this document,

by any means, is strictly prohibited.

Section 2. Specifications

GENERATOR DETA ILS

Type ................................... Onan, Revolving Field, CP ole, Brushless

Standby Ratings:

60 Hz General Ma rine Rating, 8.0 MDKD-A, B, J, 1 phase . 8.0 kW, 8.0 kVA at 1.O PF

8.0 MDKD-L, 3-phase ..... 8.0 kW, 10.0 kVA at 0.8 PF

4.0 MDKC-A, B, J, 1 phase . 4.0 kW, 4.0 kVA at 1 .O PF

4.0 MDKC-L, 3-pha se ...... 4.0 kW, 5.0 kVA at 0.8 PF

50 Hz Gen eral Marine Rating, 6.5 MDKD-P, I-p ha se ...... 6.5 kW, 6.5 kVA at .O PF

6.5 MDKD-Z, 3-phase ...... 6.5 kW, 8.1 kVA at 0.8 PF

3.5 MDKC-P; I-phase ...... 3.5 kW, 3.5 kVA at 1.0 PF

3.5 MDK C-Z, 3-phase ...... 3.5 kW, 4.4 kVA at 0.8 PF

AC Voltage Reg ulation:

Electronic Regulation .................................................. e

Magnetic Regulation ................................................... +5%

ENGINE DETAILS

Engine Type ................................... Diesel, 3 Cylinder, Vertical In-Line

Engine Speed (r/min) ...............................................1800/1500

Fuel ........................................................... No.2 Diesel

Fuel Consumption, Average @ Full Load:

3.5 MDKC ............................................... 0.42 gph (1.57 Uh)

4.0 MDKC ............................................... 0.50 gph (1.89 Uh)

6.5 MDKD . . . . . . . . . . . . . . . . .. . . . . . . . .. . . . . . . .. . .. . . . . . . . . . .75 gph (3.12 Uh)

8.0 MDKD ............................................... 0.90 gph (3.75 Uh)

Fuel Pump Lift (Self-priming) ......................................... 4 ft (1.2 m)

Total Air Per M inute Required (Cooling and C ombustion):

3.5 MDKC . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . .. 150 ftVmin (4.2 mVmin)

4.0 MDKC ........................................... 170 ftVmin (4.8 mVmin)

6.5 MDKD ........................................... 160 ftVmin (4.5 m3/min)

8.0 MDKD ........................................... 180 ftVmin (5.1 m3/min)

Battery Charge Alternator M aximum Output (Regulated) ................. 10 Amperes

Battery Voltage (Nominal) ............................................. 12 Volts

Battery Recom mendation Minimum Cranking P erformance @ 0" F (-18 C) . 360 Ampere

Cooling System Capacity, Inc luding Heat Exchanger .................. quarts (2.8 L)

Oil Capa city With F ilter ............................................ 4 qt. (3.8 L)

2-1 Redistribution or publication of this document,

by any means, is strictly prohibited.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Section 3. Operation

EXHAUST GAS IS DEADLY

Exhaustgases con ain carbon monoxide, an odorless and colorlessgas.

Carbon monoxide is poisonous and can cause unconsciousness and

death. Symptoms of carbon monoxlde poisoning can include:

Dizziness Throbbing in Temples

Nausea Muscular Twitching

Headache Vomiting

Weakness and Sleepiness Inability to Think Coherently

IF YOU OR ANYONE ELSE EXPERIENCE ANY OF THESE SYMPTOMS,

GET OUT INTO THE FRESH IR IMMEDIATELY. If symptoms persist,

seek medical attention. Shut down the unit and do not operateuntil it has

been inspected and repaired.

Never sleep in the vessel wifh the genemfor set running unless the vehi-

cle interior is equipped with an operating canbon monoxide detector.

Protection against carbon monoxlde nhalafion also includes proper ex-

haust system installation and visual and audible inspection of the com-

plete exhaust system at the start of each generator set operation.

GENERAL The sudden release of hot pressur-

ized coolant can result in serious personal in-

This Section covers starting and O perating the gen- jury, Remove the expansion tankpressure cap

Set. Read through this entire Section befo re at- slowly fier fhe engine has cooled,

tempting to start the genset. It is essential for safe

operation that the operator b e com pletely familiar Fuel

with the genset.

Make sure the fuel tanks are full and the fuel system

is primed for operation (see Maintenance section).

PRE-START CHECKS

Exhaust

Before starting, be sure the following checks have

been made and the unit is ready for operation. Make sure the exhaust system components are

tightly connected and not corroded.

Refer to the Maintenance section for the proper

procedures. Sea Water Pump Priming

Lubrication Before beginning operation (initia l start-up) the sea

water pump should be primed. The priming water

Check the engine oil level. Keep the oil leve l near provides an impeller surface lubricant un til flotation

as possible to the dipstick full mark. Do not overtill. water is pulled into the pump.

Coolant To prime the pump, close the sea cock and rem ove

hose rom the water filter outlet. Fill hose and pump

The coolant level should be near the top of heat ex- with clean water. Replace hose and open sea

changer fill cap. Do not check while the coolant is cock. Check for pump operation on start-up by ob-

hot. sewing water discharge from exhaust outlet.

3-1 Redistribution or publication of this document,

by any means, is strictly prohibited.

CONTROL PANEL a sensor on the engine and h as a range of 100° to

250" F (40 o 121 C).

The following describes the function and op eration

of the genset controls. All instruments and control Oil Pressure Gauge (Optio nal):Shows engine lu-

switches are located on the face of the control bricating oil pressure. The gauge has a range of 0

panel as illustrated in Figure 3-1. to 100 psi (0 to 700 kPa) and is connected o an en-

gine sensor.

GaugedMeters and Switches Circuit B reakers

Start-Stop Switch:Starts and stops the genset lo- Fault Reset: A manual reset breaker that shuts

cally. When switch is released, the genset can be down the engine for low o il pressure, h igh coolant

operated from a remote switch connected to the temperature, high exhaust temperature and over-

control panel. speed.

Running Time Meter: Registers the to tal number Emergency Stop DC Con trol Breaker: A 15 am-

of hours that the un it has run. Useful for determin- pere breaker p roviding protection to the control box

ing need for periodic maintenance procedures. wiring and remote wiring from short circuits or over-

Time is cum ulative and cannot b e reset. load. Also. serves as an emergency stop switch.

Line Circuit Breakers (Opfio nal): Protects gen-

DC Voltmeter (Optional): Monitors B+ voltage erator from a short circuit or other overload. They

useful to determine battery condition and charge are mounted on the control box. Replacem ents

system operation. See Battery portion of Mainte- must m eet ABYC specs for proper protection.

nance section.

Field Breaker (Electron ic Regulators Only): A 3

Coolant Temp erature Gauge (Optio nal): Shows ampere breaker providing generator field protec-

engine coolant temperature. The gauge s wired to tion if the voltage regulator fails.

UNE CIRCUIT

BREAKER AND

FIELO BREAKER

(SI1I E OF CONTROL BOX)

RUNNNG

TIME \

METER START,STOP-PREIi E A T

SWlTCH

FAULT RESET DC CONTROL

BREAKER BREAKER

FIGURE 3-1. CONTROL BOX FRONT PANEL

3-2 Redistribution or publication of this document,

by any means, is strictly prohibited.

STARTING it will start. See Fuel System in the Mainte-

nance Section.

This section covers starting of the genset at the

control pa nel and the remote pane l (when used). Startin g at Remo te Panel

The same proced ures and cautions for starting at

Starting at Con trol Panel the genset control pan el apply for remote starting.

The following steps outline the correc t procedures Start-up Checks

for starting the genset at the generator control

panel. The DC Control Breaker must be n ON posi- Check optional gauges on the control box after the

tion. engine has started. Observe the oil pressu re

gauge immediately.

1. Press the Stop/Preheat switch position for 10

to 30 seconds depending upon temperature as Oil Pressu re Gauge:The oil pressure should be in

shown below in Table 1. Do not exceed 30 the range of 35 to 50 psi (241 to 345 kPa) when the

seconds. engine i s at operating temperature.

Preheat time longer than 3 DC Voltmeter; Norm al battery voltage during op-

seconds m ay damage glow p lugs. eration should be 14 to 15 volts (dependent upon

battery state-of-charge).

TABLE 1. PREHEAT TIME vs TEMPERATURE

Water Temperatur e Gauge: The water tempera-

IA m bi en t Temperature I

~

Preheat Time I ture should be in the range of 165' to195 F (74 o

Above 86 F (30' C) About 10 seconds 91 C) depending on the load and ambient tem-

perature.

Between 50° to 86' F About 15 seconds

(1 Oo to 30' C) STOPPING

2 to 50' F

Between 3 About 20 seconds Before Stopping

(00 o i o o C)

Run the genset at no load for three to five minutes

0 C)

Below 32' F ( About 30 seconds before stopping. This allows the lubrica ting oil and

engine coolant to carry heat away from the com-

bustion chamb er and bearings.

Failure to allow run ning time for en-

gine co oling withou t load can result in eng ine

damage. Make sure the generator set run s u n-

loaded for at least th ree minu tes.

To Stop; Press he S top/Preheat switch position at

the contro l panel, or at the rem ote station.

OPERATING RECOMMENDA TIONS

Break-In

can overheat and damage the s tarfer. Do Drain he crankcase oil after the first 35 hours of op-

not eng age starter for period s long er than eration on new gensets. Refer to the M aintenance

30 seconds without allowing two minutes Section of this manual orthe recommended proce-

for cooling. dures.

4. If the engine does not start on second try,

No-Load Operation

check the fuel supply and be sure the fu el sys-

tem has bee n primed. If the gense t runs out of Hold periods on no-load operation to a minimum

fuel, the fuel system may nee d priming before and avoid if possible. No-load opera tion allows

3-3 Redistribution or publication of this document,

by any means, is strictly prohibited.

combustion chamber temperatures to drop so low TROUBLESHOOTING

that the fuel does not burn completely. This results

in carbon dep osits which can clog injectors, cause

piston rings and valves to stick and ca n cause cylin- DC Control

der glazing. If it is necessary to run the e ngine for

long periods, con nect an electrical load to the gen- The DC control has a number of sensors that con-

erator. tinuously monitor the engine for abnormal condi-

tions such as low oil pressure, high coolant tem-

Exercise Period perature, high exhaust temperature and overspeed

To avoid excessive engine wear, exercise the gen- [option). If any one of these conditions occur, the

set at least once a week for a minimum of 30 min- fault breaker trips and stops the genset. See Figure

utes. Run the genset with a load applied to allow 3-2.

the e ngine to reach no rmal operating temperature.

Exercising will keep the engine parts lubricated, The following sections describe operation of the

maintain fuel prime, and prevent electrical relay fault systems and suggested items the operator

contacts from oxidizing. Top off the fuel tank after can check. If a m ajor problem s indicated, contact

each exercise period. an Onan Dealer or D istributor for help or service.

LOW OIL

PRESSURE

SWjTCH

W

OVERSPEED

SWITCH

(OPTION)

Esl445l-1

FIGURE 3-2. FAULT SENSOR L OCATION

3-4 Redistribution or publication of this document,

by any means, is strictly prohibited.

The control pan el Fault reset break erw ill rip for any Overspeed (Option): This switch (sensor is

one of the following fault conditions described mounted on the front of the e ngine crankshaft. It s

separately. The white breaker reset button pops factory adjusted o shut down 60 hertz units at 2200

out about 1/4 inch (6 mm) when a fault occurs. Lo- r/min B O /min, 50 hertz units at 1800 r/min 330 /

cate the problem and make the necessary correc- min.

tions be fore resetting breake r and starting the gen-

set. All fault shutdowns excep t high exhaust tem- AC Control

perature and overspeed option are delayed 5 ec-

onds to avoid nuisance tripping. The AC control may use two circuit breakers on the

control box depending upon purchased options.

Low Oil Pressure: Remove dipstick and check o il See Figure3-3. If either one trips, it results n loss of

level. If low, add oil to bring level up to full mark. generator AC power output. They function as fol-

Inspect engine exterior for leaks an d repair as nec- lows:

essary. The oil press ure switch actuates the fault

circuit if pressure drops below 9 psi (62 kPa). Field Breaker (Electron ic Regulator On ly): This

3-ampere breaker is located on the control side

High Coolant Temperature: Observe Coolant panel. It is in he regulator AC input circuit and pro-

Tem perature Gauge (op tion) for ind ication of tem - tects the generator field if the voltage regula tor ails

perature over 222' F (106 C). The coolant ther- and places abnormaldemands on it. If resetting h e

mostat switch closes at this temperature and actu- breaker returns power only m omentarily, then trips

ates the fault circuit. again, consult an Onan dealer or distributor for

service.

Check coolant level in the expansion tank alter al-

lowing the engine to cool down. Line Circuit Breakers: When supplied by Onan,

Check condition of the pump belt and that it has these breakers are m ounted on the control side

prope r tension. The sea water flow at the exhaust panel. They are connected in series with the load.

outlet should be about 3 gal/min (11 liter/min). Also

check the cooling system cleanliness (freedom

from contaminants, rust, sludge build-up, etc).

High Exhaust Temperature: The high exhaust

temperature switch is moun ted on the exhaust el-

bow and closes on tempera ture rise above 230' F

l l O o C). It will open again when temperature

reaches about 190' F (88' C) and functions to p ro-

tect exhaust system hoses.

inhalation of exhaus tgascan cause

serious p ersonal injury or death. Do not dis-

con nect or bypass the exhaust elbow switch.

Excessive heat will damage the exhaust hoses

and cause exhau st gas leakage. If exhaust

ho se is damaged, shu t off the generator set im -

REGUMTION ONLY)

mediately and do n ot o perate un til hos e i re-

paired, ES1405s-l

High exhaust elbow temperature is caused by in-

sufficient or lack of sea water flow. Sea water flow FIGURE 3-3. AC CONTROL B REAKERS

at exhaust outlet should b e about 3 gaVmin (11 liter/

min).

3-5 Redistribution or publication of this document,

by any means, is strictly prohibited.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Section 4. Maintenance

GENERAL ning time meter to keep an accurate log of all serv-

ice performed for warranty support. Perform all

Establish and adhere to a definite schedule for service at the time period indicated or after the

maintenanceand service. If he genset will be sub- number of operating hours indicated whichever

jected to extreme operation conditions, the service comes first. Use the schedule to determine the

intervals should be reduced accordingly as indi- maintenance required and then refer to the sec-

cated in Table 4-1. tions that follow for the correct service procedures.

Consult with an authorized Onan Dealer or Dis- J aWR ) ccid ental starting of he g enerator

tributor if the genset will be subjected to any ex- set can cause severe perso nal ln ju v or death.

treme operating conditions (high surrounding em- Disconnect the starting batfery (negative

perature , dusty air conditions, etc.), and determine lead f irs t) when doin g mainfenan ce or repair to

a suitable schedule of maintenance. Use the run- the engine, controls, or generator.

TABLE 4-1. PERIODIC MAINTENANC E SCHEDULE

1 Check for oil, fuel, cooling and exhaust system leaks. Check exhaust system audibly and visually

with genset running and repair any leaks immediately.

2- Perform after first 35 hours of operation on new gen set.

3 Perform more often n extremely dusty conditions.

4 Visually e belts or evidence of slippage.

4-1 Redistribution or publication of this document,

by any means, is strictly prohibited.

SET INSPECTION (aWARNING1Inhalation of exhau st gases can re-

sult in severe personal injury or death. inspect

During operation, be alert for mechanical problems exhaust system audibly and vlsuaiiy for leaks

that could create unsa fe or hazardous conditions. dai& Repair any leaks imm ediately.

The following sections cover several areas that

should be frequently inspected for continued safe Fuel System

operation. With the genset operating, insp ect the fue l supply

lines, return lines, filters, and fittings for leaks.

Engine Gauges Check flexible sections for cuts, cracks and abra-

sions so they are not rubbing against anything hat

Check the following while the gen set is operating. could cause breakage.

Oii Pressure Gauge (Option): The oil pressure Fuel leakage will create a f ire hazard

should be in the range of 35 to 50 psi (241 to 345 which can result In severe personal injury or

kPa) when the engine is a t op erating temperature. death If ign ited. While chec king for leaks, do

not sm oke or allow any spark, flame, pilot light

Note: 11 pressure readlngs sllghtiy lower than 35 or o ther ignltIon sourc e In th e area. if any leaks

psi may be acceptable, depending on operating co n- are detected, have them co rrected mm ediateiy.

ditions. Gen set shutdown for low oil pressure take s

place at 9 psi 163.4 kPa). Consult your Onan dis- DC Electrical System

tributor if in doubt about oil pressure readings.

With the genset off, check the terminals on the bat-

tery for clean and tight connections. Loose or cor-

Coolant Temperature Gauge (Option): The roded connections create resistance which can

water temp erature should be in he range of 165' to hinder starting. Clean and reconnect the battery

195' F (74' to 91 ) depending on the load and cables if loose. Always disconnect the negative

ambient temperature. battery cable first, and connect it last to reduce the

possibility of arcing.

DC Voltmeter (Option): Normal battery voltage

during operation should be 14 to 15 volts on a Ignition of exp loslv e battery gases

12-volt system. can cause severe personal injury. Do not

sm oke. Wear go ggles and pro tective, rubb er

Exhaust System glov es and apron when servicing batteries.

Mechanical

With the genset operating, inspect the entire ex-

haust system including the e xhaust m anifold, ex- With the gense t stopped, check for loos e belt and

haust elbow, mu ffler and exhaust pipe. Check sea fittings, leaking gaskets and hoses, o r any signs of

water pum p operation by observ ing sea water dis- mechanical damage. If any problem s are found,

charge from exhaust outlet-should be about 3 gal/ have hem corrected imm ediately. W ith the genset

min (11 liter/min). Visually and audibly check for running, listen for any unusual noises hat may indi-

leaks at all connections, welds, gaskets, and oints. cate mechanical problems and check the oil pres-

If any leaks are detected, have them corrected im- sure frequently. Investigate anything that indicate s

mediately. possible m echanical problems.

4-2 Redistribution or publication of this document,

by any means, is strictly prohibited.

LUBRICATION SYSTEM engine (see Figure 4-1). The dipstick is stamped

with FULL and ADD to indicated the level of oil in

The engine oil was drained from the crankcase the crankcase. For accurate readings, shut off the

prior to shipment. Before the in itial start, the lubri- engine and wait approximately 10 minutes before

cation system must be filled with oil of the recom- checking the oil level. This allows oil in the upper

mended classification and viscosity. Refer to the portion of the engine to drain back into the crank-

Specifications section for the lubricating oil capac- case.

ity.

Keep the oil level as near as possible to the FULL

Oil Recomm endations mark on the dipstick. Remove the oil fill cap and

add o il of the same quality and brand when neces-

Use oils with the American Petroleum Institute sary.

(API) classification SG/CD in viscosities per tem-

perature as shown in Table 4 -2 below. Do not operate fhe engine wlfh the

TABLE 4-2. OIL VISCOSITY VS TEMPERATURE oil levelbelo w fhe ADD m ark or abov e fhe FULL

mark. Overflliing can cause foaming or aera-

tion of the oil while operation below th e ADD

mark can cause loss of oii pressure.

OPTIONAL

/OIL FILL

0F-30-20-10 0 10 20 3 40 50 60 70 8 90100110120

0

/OC-34-29-23-18 -12 -7 -1 4 10 16 21 27 32 38 43 48

Anticlp ated A mbient Temperature

When selecting the oil viscosity, pick the viscosity

that i s right for the lowest temperature expected.

Oil hat is oo thick may result in a lack of lubrication

when the engine is started. Use a lower viscosity oil

as the am bient temperature reaches the lower end

of the scale.

Do not use synthetic oil or non-detergent oil, and do

not m ix different brands of oil.

7

OIL

1

OILFILL

7

DRAIN OIL

Engine Oil Level IPSTICK FILTER

VALVE

Check the engine oil level during engine shut-down M 1526

periods at the intervals specified in Table 4-1. The

oil dipstick and o il fill are located on the side of the FIGURE 4-1. ENGINE OIL

4-3 Redistribution or publication of this document,

by any means, is st rictly prohibited.

Oil and Filter Change F (-37' C) as m easuredwith an accurate hydrome-

ter.

Change the oil and filter at the intervals recom-

mended in Table 4-1. Use oil that meets the API The water us ed for engine coolant should be clean,

classification and appropriate SAE viscosity grade low in mineral content, and free of any corrosive

as indicated i n the previous section. chem icals such as chloride, sulfate, or acid. Use

distilled or soft water whenever available. Well

Engine 11 Changes Run the engine until thor- water often contains lime and other minerals which

oughly warm before draining the oil. Stop engine, eventually may clog the heat exchanger core or re -

open drain valve (Figure 4-1) and drain oil into a duce co oling efficiency.

container. When completely drained, close valve

and refill the crankcase with new oil. Filling the Cooling System

1 Hot crankcase ollc an causeburns f Verify that a ll drain cocks are closed and all hose

If is spllled or splashed on skin. Keep fing ers clamps secure. Remove the cooling system pres-

and hands clear when removing the oil drain sure cap and slowly fill the cooling system with the

plug and w ear protectlve clothin g. recommended coolant.

11 Fllter ChangesSpin off the oil filter and discard Gensets WIfh Coolan t Recovery TanksFill he re-

it. Thoroughly clean filter mounting surface. Apply covery tank with coolant mixture to the FULL mark.

a thin film of oil to filter gasket, and spin filter on by Operate the genset until normal operating tem-

hand un til gasket just touches the mounting pad. perature is maintained as observed on the tem-

Then turn an additional 3/4 turn. Do not over- perature gauge (option), o r about 15 minutes of op-

tighten. eration.. Shut down the genset and let cool. Add

coolant to recovery tank until coolant level stabi-

With oil in the crankcase, start the genset and lizes at the Full mark-this may require several op-

check for leakage around the filter gasket. Tighten eration cycles.

only as necessary to eliminate leaks.

Gensets Withou t Coolant Recovery Tank: Be-

COOLING SYSTEM fore the engine is started, remove the pressure cap

and m onitor the coolant level. As trapped air is ex-

The cooling system is drained prior to shipping and pelled from the system, th e coolant level will drop,

must be refilled before genset is operated. the and additional coolant should be added. Replace

cooling system capacity is listed in the Specifica- the pressure cap when the coolant level is stable.

tions section.

Confacf wifh hof coo lant can result

Coolant Requirements in serious burn s. Do not bleed hot, pressurized

coolant from a closed co oling system.

A satisfactory engine coolant inhibits corrosion and

protects against freezing. A 50/50 olution of ethyl- The high eng ine femp erafurecutoff

ene glycol anti-freeze and water is recommended will shut down th e engine in an overheat cond i-

for norm al operation and storage periods. Choose tion only if the coolanf level is sufficlently high

only a reliable brand of anti-freeze that contains a to physlcally contact the shutdown switch.

rust and corrosion inhibitor but does not contain a Loss of co olanf will allow engine to overheaf

stop-leak additive. wlthout profecflon of shutdo wn device, thereby

causing severe damage to the engine. If Is

Do not exceed a 50/50mixture of ethylene glycol therefor e m perative fhaf adequafe engin e coo l-

and water. A stronger mixtureof ethylene glycol will ant levels be m aintained fo r operational integ-

alter heat transfer properties of the coolant. A rify of the cooling sysfem and engine coo lant

50/50mixture will provide freeze protection to -34' overheat shu tdown p rotection.

4-4 Redistribution or publication of this document,

by any means, is strictly prohibited.

Flushing and Cleaning

For efficient operation, the cooling system should

be drained, flushed, a nd refilled with ne w coolant

once each year.

Confacf wit h hot co olanf can resulf

in serious burns. Do nof b leed hot, pressurized

coolant from a closed cooling sysfem. CYLINDER BLOCK

SEA WATER PLUG/ D W N VALVE

ZINC PENCIL

Drain he system completely. The heat exchanger

(or optiona l kee l cooler-see manufacturer’s litera-

ture) and the cylinder block drain must be opened.

See Figure 4-2. Remove the pressure cap to aid

the draining process.

Chemical Cleaning: Thoroughly clean the cooling

system if rust and scale have collected on the en- cs 34a

gine water jacket, or in the heat exchanger. Rust

and scale slow down heat absorptionand can block CAPTIVE WATER

the c oolant flow. Use a good cleaning compound DRAIN PLUG

and follow the supplier’s instructions.

Flushing: After cleaning, or b efore filling the sys - FIGURE 4 -2. LOCATION OF COOLA NT DRA IN/

tem w ith new coolant, drain the system and fill with ZINC PENCIL

clean water. Ope rate the genset for 10 minutes,

then drain the system completely. Re fill with the Pump Belt

recommended coolant.

r Access to the belt is made by removing the belt

Adding cold coolant to a warm en- guard rom the front of the genset. Before remo ving

’g in e can resulf In engine damage. the be lt guard, be sure the genset is disabled by re-

mov ing the battery cables-the neg ative (-) cable

first. Do not operate the genset without the be lt

Pressur e Cap guard in place.

Accidenfal starting o f he generafor

cap to increase he b oiling point of the coolant and set can cause sewere perso nal in jury or d eath.

allow higher ope rating em peratures. The pressure Sfop th e generator set and dis able by discon-

cap sh ould be replaced every two years, or sooner necfin g the starfing baffery cables (negative [ I

if it malfunctions. The cap is rated at 7 psi (48 kPa). cable first) when mainfenance or repairs are

made to fhe engine, controls, or generafor.

Sea Water Drain Ein c Pencil Belt tension is proper when a finger pressure of 22

pounds IO g) at middle of the belt deflects t about

The sea water side of the heat exchanger is pro- 0.4 inch IO mm).

tected from corrosion by a zinc pe ncil attached to

the sea water plug. See Figure 4-2. The pencil To adjust belt, loosen bolt that passes through

should be inspected about every two months and elongated slot in alternator mounting bracket and

replaced if deteriorated to less than 1/2 inch (13 slide alternator until proper ension s secured. See

mm) . Figure 4-3.

Redistribution or publication of this document,

by any means, is strictly prohibited.

lXiiGiM1 gnitio n of fuel can cause serious

perso nallnjury o r death by flre or explosion. D o

no tperm it any flame, clgarette,pliot light, spark

or other igniter near the fuel system.

Fuel Recomm endations

Use ASTM 2-D (no. 2 Diesel) or ASTM 1 D (No.

Diesel) fuel with a minimum cetane number of 45.

Number 2 diesel fuel gives the b est economy and

performance under most operating conditions.

Use number 1 diesel fuel when am bient tempera-

tures are below 32' F (0 C) and during long peri-

ods of light engine load.

Use low sulfur content uel having a cloud point of at

least 10 degrees below the lowest expected fuel

temperature. Cloud point is the temperature at

which wax crystals begin to form in d iesel fuel.

Fuel Handling Precautions

CSl230

Take appropriate precautions to prevent the en-

trance of dirt, water or o ther contaminants into the

fuel system. Filter or strain the fuel as the tank is

FIGURE 4 -3. PUMP BELT ADJUSTMENT

filled.

Siphon Break Valve Dirt or water In the system will

cause severe damage to both the injection

pump and the injection nozzles, i t is extremely

A siphon break valve is installed on gensets if the

exhaust injection elbow i s at or below load water

Important the fuel be k ept clean and water free.

line. When prop erly installed, it helps prevent sea To avoid condensation problems, keep fuel supply

water siphoning into the engine and compartme nt tanks as full as poss ible by filling up each time the

when the genset shuts down. genset is used. In cold weather, warm fuel return-'

ing from the injectors heats the fuel in the supply

The siphon break valve is normally trouble free. tank. If the fuel level s ow, the upper portion of the

However, when used in contaminated waters or tank tends to form condensation. In warm weather,

salt water for example, some corrosion may ap- both the fuel an d the tank will be warm during the

pear. The valve can be checked for free m ovement daytime. At night, cool air tends to lower the tem-

after unscrew ing he top cover. If he valve sticks or perature of the tank m ore rapidly han the tempera-

the seat shows wear, the valve must be replaced ture of the fuel. If the fuel level s low, the upper por-

tion of the tank wil l cool more rapidly and form con -

densation.

FUEL SYSTEM Condensation (water) can cause clogging of fu el fil-

ters as we ll as freezing problems. In addition, wa ter

Use only a good quality uel obtained from a reputa- mixing with the sulfur in the fuel forms ac id which

ble supplier. The quality of fuel used is mpo rtant n can corrode and damage e ngine parts.

obtaining dependable performance and satisfac-

Priming the Fuel System

tory engine life. Fuels must be clean, completely

distilled, well refined, and non-corrosive o fuel sys- The fuel system m ust be primed prior to initia l start-

tem parts. up or after engine has run out of fuel.

4-6 Redistribution or publication of this document,

by any means, is strictly prohibited.

High Pressure Fuel Sysfem: The injection Fuel Filter

pump,fuel injection lines and fuel injectors com-

prise the high pressure fuel system. See Figure The filter replacement nterval will vary according o

4-4. This part of the system is self-priming since the fuel quality and cleanliness. Using the wrong

any trapped air is forced out through the injection fuel, or dirty fuel, wil l shorten service life of the filter.

nozzles. D11i or wafer In the s ysfe m will

cause severe damage to b o t h the injection

Low Pressure Fuel System: The electric fuel pump and fhe njection nozzles. If is exfremely

pump, fuel filter and in jection pump inlet comp rise important fhe fuel be kepf clean and free of

the low pressure fuel system. To prime these com- wafer.

ponents, follow the same procedure as when the

fuel filter is replaced (follow ing section). Draining Wa er/SedimenfFrom Filter: Refer to

Table 1 for the recomm ended ime interval. Drain

Be sure to check fuel level in the tank, and that the about 1/4 cup of fuel as follows:

shut-off valve i s open.

1. Open the drain valve and bleed screw on the

fuel filter assembly (Figure4-5). Collect uel in

a su itable container and dispose of properly.

INJECTION PUMP

FUEL INLET 2. Tighten drain valve and b leed screw.

FUEL RETURN

UNE F l l I N G \ INJECTION UNE

CONNECTNG NUT

3. Bleed air from the filter housing by pe rforming

Steps 8 through 10 in the next paragraph.

Replacing Filter Element: Refer to Table 1 for the

recomm ended filter change interval. However, if

the engine shows signs of fuel starvation (reduced

power or surging), change the fuel filter. Use the

following procedure to replace.

1. Loosen he drain valve and bleed screws. Col-

lect fuel in a suitable container and dispose of

properly. remove the bleed plug. See Figure

4-5.

2. Remove filter element from the head with the

bow l connected.

3. Clean the bowl, O -ring and O-ring gland.

4. Lubricate he O -ring with clean diesel fuel and

place it in the bowl gland.

5. Spin the bo wl onto the new element. DO NOT

OVER-TIGHTEN.

6. Lubricate he element and gasket, and ill bowl

and filte r element with clean diesel fuel.

7. Spin the bow l and element assembly onto the

head a nd hand tighten.

-1526 8. Disconnect the starter solenoid lead at the

Faston terminal connector (this connector is

FUEL PUMP FUEL FILTER on the starter solenoid). This allows the fuel

pump operation without cran king the engine.

FIGURE4 4 INJECTION PUMP FUEL SYSTEM

9. Depress he Start switch until fuel purge sat he

bleed screw and bleed plug open ing.

4-7 Redistribution or publication of this document,

by any means, is strictly prohibited.

10. Replace he bleed plug and close bleed screw. Remove the battery from vessel for cleaning. Be

Reconnect the starter solenoid lead. sure the vent p lugs are tight to prevent cleaning so-

lution from entering the cells. After cleaning, flush

the outside of th e battery and the surrounding ar-

eas with clean water.

Keep the battery terminals clean and tight. After

making connections, coat the terminals with a light

application of non-conductive grease or petroleum

jelly to retard corrosion.

/ELEMENT

O-RING

AND GlAND

BOWL

DRAIN

-1529

FIGURE 4-5. FUEL FILTER ASSEMBLY

BATTERY

Check the condition of the starting battery at the in-

terval specified n Table 4-1. Always disconnect he

negative (-) cable from the b attery before working

on any part of the genset electrica l system. Disre-

gard the sections on Checking Specific Gravity and

Checking Electrolyte Level when u sing a mainte-

nance-free type battery. 51675

lgnltlon of exploslve batfery gases FIGURE 4-6. CLEANl,NGBAITERY

can cause severe personal Inju ry. Do no t

smoke. Wear gog gles and pro tective, rubb er Checking Specific Gravity

gloves and apro n when servicing b atteries. Use a battery hydrometer to check the specific

gravity of the electrolyte in each battery cell.

Cleaning the B attery

Battery electrolyte can cause se-

Keep the battery clean by wiping it with a damp vere eye dam age and burns to the skin. Wear

cloth whenever it appears dirty. Remove the bat- goggles, rubber gloves and a pro tecfive apron

tery cables (negative (-) cable first) if corrosion is when work ing with batteries.

present around the terminal connections. Wash

the terminals with an ammonia solution, o r a solu- Hold the hydrometer vertica l and take the reading.

tion consisting of 1/4 pound (about 100 grams) of Correct the reading by ad ding four gravity points

baking soda in 1 quart (about 1 liter) of water. See (0.004) for every five degrees the electrolyte tem-

Figure 4-6. perature s above 80' F (27' C), or subtracting four

4-8 Redistribution or publication of this document,

by any means, is strictly prohibited.

gravity points for every five degrees below 80 F

(27' C). A fully charged battery will have a cor-

recte d specific gravity of 1.260. Charge the ba ttery

if the reading is below 1.215.

Checking Electrolyte Level

Check the lev el of the electrolyte (acid and water

solution) in he b attery at least every 50 hours of op-

eration. Fill the battery cells to the bottom of the

filler neck. If cells are low on water, add distilled

water and recharge. If one cell is low, check case

for leads or for a b ad cell.

1 Do not add water in freezing

weather unless the englne w ill run long enough

(two to three hours) to provlde thorough mixing

of w afer and elecfro lyte.

Keep the battery case clean and dry. An accumu la-

tion of moisture will lead to battery discharge and E1223

fai Iu e.

FIGURE 4-7. GENERATOR END VIEW

AC GENERATOR Generator Bearing

There are no brushes, brush springs or collector Inspect he be aring or evidence of outer case rota-

rings on the generator, therefore t requires very lit- tion every 1000 hours of use. The bearing should

tle maintenance. Period ic inspections, to coincide be rep laced every five years. Dete rioration of the

I

with engine oil changes, w ill help provide good per- bearing grease due to oxidation makes this re-

formance. placement necessary. If the generator requires

i major repair or service, contact an authorizedOnan

I

I Accidental starilng of the generator dealer or distributor.

set can cause severe personal injur y or death.

Move th e Operation Seiector switch t o STOP OUT-OF-SERVICE PROTE CTION

and discon nect he startlng battery (negative[ I

lead flrst) before lnspectlng fhe rotating recfi- The inherent ubricatingqualities of No. 2 diesel uel

fler assembly. should protect he cylindersof a diesel engine for at

least 30 days when not in service. To pro tect an en-

Remove the gen erator end be ll cover and inspe ct gine that will be out of service for more than 30

the rotating rectifier assembly to make sure the di- days, proceed as follows:

odes are free of dust, dirt and grease (see Figure

4-7). Excessive oreign matter on these diodes and 1. Exercise the genset, as described in the O p-

heat sinks will cause diode overheatingand failure. eration section, until the en gine is at opera ting

Blow out the assembly periodically with filtered, temperature.

low-pressure air. 2. Shut down the genset and disconnect he bat-

tery cables (negative [-] cable first). Store the

1 Eircessive forelgn matter on diodes battery in a cool, dry place and c onnect to a

and heat sinks will cause overheating and pos- trickle charger once every 30 days to maintain

sible faiiur e. full charge.

4-9 Redistribution or publication of this document,

by any means, is strictly prohibited.

[aWARNINGI Battery electrolyte can cause Returning the Genset to Service

severe eye damage and burns to the skin.

Refer to the preceding paragraphs in this Mainte-

Wear gog gles, rubber gl oves and a protec-

nance section for specific service procedures.

tive apron when w orking w ith batteries.

Remove plug from the exhaust outlet, and

3. Drain the crankcase oil while still warm. Re-

open the seacock.

place oil filter. Re fill crankcase and attach a

tag ind icating viscosity of the oil used. 2. Clean an d check the battery. Measure the

electrolyte specific gravity with a hydrometer

4. Check the coolant level and add more coolant

(1.260 @ 80' F [ 2 7 O C]) and verify proper

if low. If freezing temp eratures are possible,

level. If the spe cific gravity is low, charge the

test strength of the co olant mixture.

battery u ntil correct value is obtained. If level s

The sea water cooling system m ust be drained low, add distilled water and charge until the

of water, or protected with a 50-50 anti-freeze specific gravity reading is correct.

mixture as follows:

(AWARNINGI Battery electrolyte can cause

severe eye damage and bur ns to th e skin.

A. Close sea cock and remove the sea water inlet

hose at filter. Wear gogg les, rubber gloves and a protec-

tive apron when w orking w ith batteries.

B. Place end hose in a bucket of anti-freeze mix- 3. Prime the fuel system.

ture and run engine until mixture is observed 4. Conn ect the starting battery, the negative (-)

coming out of the exhaust outlet.

cable last.

C. Replace inlet hose and tighten clamp. 5 Remove all loads before starting the ge nset.

6. After starting, app ly load of at least 50 percent

5. Plug exhaust outlets to prevent entrance of rated capacity.

moisture, bugs, dirt, etc.

7. Check all gauges for no rmal readings. Genset

6.Clean and wipe the entire genset. Coat parts is ready for operation.

susceptible to rust with a light coating of

grease o r oil.

4-10 Redistribution or publication of this document,

by any means, is strictly prohibited.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Qnan Carporation

1400 73rd Avenue N.E.

Minneapolis, M N 55432

1 ~ ~ ~ - ~ ~ ~ - ~ ~ ~ ~

612-574-5000nternational Use

Telex: 275 177

Fax: 612-514-8087

O n m is a rcq stered Irademark of Onan Corporation

Redistribution or publication of this document,

by any means, is strictly prohibited.

You might also like

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Onan KY Microlite 4000 Series Operator's Manual (09-1994)Document34 pagesOnan KY Microlite 4000 Series Operator's Manual (09-1994)HarryNo ratings yet

- Aaon Rtu RN - Iom - 150713Document124 pagesAaon Rtu RN - Iom - 150713lasNo ratings yet

- OBDII Codes PDFDocument238 pagesOBDII Codes PDFedhuam50% (6)

- Snorkel TB80 1997-05 Rev01Document304 pagesSnorkel TB80 1997-05 Rev01Lucho AlencastroNo ratings yet

- Cooltech 34700z ManualDocument20 pagesCooltech 34700z ManualWilliam Kibbe88% (8)

- 965-0628 Onan BGE NHE Emerald Plus Series RV Genset Installation Manual (10-1996)Document49 pages965-0628 Onan BGE NHE Emerald Plus Series RV Genset Installation Manual (10-1996)Robert RooseNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Denso Common Rail Injector Test DataDocument28 pagesDenso Common Rail Injector Test DataInkanata Sac94% (16)

- PCC 3200Document42 pagesPCC 3200AndresElejalde80% (5)

- Amort Hydril KDocument21 pagesAmort Hydril KFernando Aybar100% (1)

- ENGINE Nissan PDFDocument7 pagesENGINE Nissan PDFDanielNo ratings yet

- JLG 3394RT 4394RT Service Manual PDFDocument234 pagesJLG 3394RT 4394RT Service Manual PDFnelsonyNo ratings yet

- 928-0120 Onan EK EM Genset Operator's Manual (12-1995)Document32 pages928-0120 Onan EK EM Genset Operator's Manual (12-1995)Javier Pantoja100% (1)

- Motor YanmarDocument118 pagesMotor YanmarJhonny Marques100% (2)

- MAriner 20 25 HP Manual 11046910Document19 pagesMAriner 20 25 HP Manual 11046910Karl Ullman0% (1)

- Onan Generator Operating Manual 981-0120Document28 pagesOnan Generator Operating Manual 981-0120Alan Friend100% (3)

- Atb 60 ManualDocument332 pagesAtb 60 ManualMauro Antihual86% (7)

- B40D Bell Truck Hydraulic SystemDocument19 pagesB40D Bell Truck Hydraulic SystemMaimun maimun100% (1)

- VOITH Torque ConverterDocument22 pagesVOITH Torque ConverterLTE002100% (1)

- Volvo Penta Tamd63a 72j A Instruction Book PDFDocument124 pagesVolvo Penta Tamd63a 72j A Instruction Book PDFDavid Poma100% (1)

- Onan Pro 4000 Generator Operator's ManualDocument31 pagesOnan Pro 4000 Generator Operator's ManualMYMAINE1100% (1)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Victor-Reinz PKW Mitsubishi PDFDocument15 pagesVictor-Reinz PKW Mitsubishi PDFTommy CamposNo ratings yet

- TTLA0687Document68 pagesTTLA0687summoner001No ratings yet

- Service and Maintenance Manual: Models 3369LE 4069LE M3369 M4069Document146 pagesService and Maintenance Manual: Models 3369LE 4069LE M3369 M4069Vũ Đình HậuNo ratings yet

- CUMMINS ONAN GGHH DETECTOR CONTROL GENERATOR SETS Service Repair Manual PDFDocument12 pagesCUMMINS ONAN GGHH DETECTOR CONTROL GENERATOR SETS Service Repair Manual PDFfjjskemdmemNo ratings yet

- Engine Cranks But Does Not StartDocument5 pagesEngine Cranks But Does Not StartNay Soe100% (1)

- BRP ROTAX ACE 130 Manual ENDocument80 pagesBRP ROTAX ACE 130 Manual ENJohn Wales100% (1)

- Dinex Euro 6 CatalogueDocument108 pagesDinex Euro 6 CatalogueOsw GalatiNo ratings yet

- Snorkel Ab50jDocument226 pagesSnorkel Ab50jhugoamendozaNo ratings yet

- XPI Fuel System: en-GBDocument26 pagesXPI Fuel System: en-GBclaudio100% (2)

- Briggs & Stratton Generator 5500 Manual PDFDocument48 pagesBriggs & Stratton Generator 5500 Manual PDFEdilberto Hernandez100% (2)

- BGDservice ManualDocument107 pagesBGDservice ManualDaniel Wellner100% (2)

- Instruction Manual For Tanabe Main Air CompressorDocument86 pagesInstruction Manual For Tanabe Main Air Compressorprateek agarwal100% (6)

- Wisconsin Vg4d RepairDocument46 pagesWisconsin Vg4d RepairDan DelfinoNo ratings yet

- Rt540e CCS T4F SM CTRL527 01Document318 pagesRt540e CCS T4F SM CTRL527 01Cristyan GabrielNo ratings yet

- Motor Cursor 8 IvecoDocument45 pagesMotor Cursor 8 IvecoCarlos Paranhos100% (2)

- Operation & Service: Diesel Generator SetDocument52 pagesOperation & Service: Diesel Generator SetcarlosNo ratings yet

- Upfit Operator Manual: Cummins Npower 200Kw, Qsb6.7Document29 pagesUpfit Operator Manual: Cummins Npower 200Kw, Qsb6.7Jose Leandro Del Zar100% (1)

- Genset Ops Manual 69ug15 PDFDocument51 pagesGenset Ops Manual 69ug15 PDFAnonymous NYymdHgy100% (1)

- HDKAG Owners ManualDocument32 pagesHDKAG Owners ManualDan PoythressNo ratings yet

- DFFB Operator's Manual (2-2003)Document37 pagesDFFB Operator's Manual (2-2003)bert moragaNo ratings yet

- Model 69RG15: Operation & ServiceDocument48 pagesModel 69RG15: Operation & ServiceHerimandimby RavelomanantsoaNo ratings yet

- Operator Manual: RV Generator SetDocument48 pagesOperator Manual: RV Generator SetReynaldo CastilloNo ratings yet

- GPN012 KW 6 PDFDocument8 pagesGPN012 KW 6 PDFAnonymous RvcMu1mNo ratings yet

- Lista de Precios Atlas Shipping Enero 2021Document44 pagesLista de Precios Atlas Shipping Enero 2021Rolando CoelloNo ratings yet

- Onan Genset HDKCA HDKCB Operators ManualDocument39 pagesOnan Genset HDKCA HDKCB Operators ManualEli Marsee100% (1)

- Armstrong BCE3 Install 507120-01Document18 pagesArmstrong BCE3 Install 507120-01manchuricoNo ratings yet

- TB 42-50 MFG Between 01-1997 and 01-2001Document252 pagesTB 42-50 MFG Between 01-1997 and 01-2001kirk sutherlandNo ratings yet

- Pro126 PartsDocument314 pagesPro126 Partskirk sutherlandNo ratings yet

- 0981 0633Document25 pages0981 0633Sunilkumar KumarNo ratings yet

- Pancake Capacitor GeneratorDocument8 pagesPancake Capacitor GeneratorArmedy RuruNo ratings yet

- Kubota Diesel 3.6L Engine: MaintenanceDocument110 pagesKubota Diesel 3.6L Engine: MaintenanceLKNo ratings yet

- Onan Operations ManualDocument25 pagesOnan Operations ManualMike JacobsNo ratings yet

- Repair Parts Manual: Engine Powered Diesel Gasoline LPGDocument296 pagesRepair Parts Manual: Engine Powered Diesel Gasoline LPGmauricio carmona100% (1)

- JLG 530lrtDocument262 pagesJLG 530lrtcristoanto2001No ratings yet

- Air Compressor 3-Gallon 1.5 HP (Max Developed) 1 HP Running Oil LubricatedDocument11 pagesAir Compressor 3-Gallon 1.5 HP (Max Developed) 1 HP Running Oil LubricatedSIVARAMANJAGANATHANNo ratings yet

- PE-1 Series ManualDocument24 pagesPE-1 Series ManualGlenn IquinNo ratings yet

- Tracing SystemsDocument76 pagesTracing SystemsCliff BlackNo ratings yet

- Self Priming PumpDocument21 pagesSelf Priming Pumpgplese0100% (1)

- Command Pro: CV940-CV1000Document138 pagesCommand Pro: CV940-CV1000FredNo ratings yet

- AIRE Carrier48Tca04A12UsersManual310998.128173875Document107 pagesAIRE Carrier48Tca04A12UsersManual310998.128173875Elkin FernandezNo ratings yet

- Craftsman 580.327270Document20 pagesCraftsman 580.327270VVIINNCCEENo ratings yet

- UntitledDocument66 pagesUntitledzawmintun zpeNo ratings yet

- TK 60606-3-DM CANAIRE System Diagnostic's Manual Rev. 1 03-15 - ENDocument162 pagesTK 60606-3-DM CANAIRE System Diagnostic's Manual Rev. 1 03-15 - EN2ndpostaNo ratings yet

- Owner's Manual: XG Professional Series Portable GeneratorDocument56 pagesOwner's Manual: XG Professional Series Portable GeneratorjoaofavioNo ratings yet

- 18 CccfozDocument120 pages18 CccfozHalit YalçınkayaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- ATR - 600 Type Rating: System Questions 1Document3 pagesATR - 600 Type Rating: System Questions 1subhasishNo ratings yet

- 7 Marine Diesel Recommission Checklist: Value of The Maintenance LogDocument4 pages7 Marine Diesel Recommission Checklist: Value of The Maintenance LogRicky WrightNo ratings yet

- WIA WC30D Operator ManualDocument43 pagesWIA WC30D Operator Manualsoheil zamaniNo ratings yet

- PM B25B MkiiDocument327 pagesPM B25B Mkiiphilippe gravierNo ratings yet

- Cam Follower Inspection AE3Document1 pageCam Follower Inspection AE3boy qsiNo ratings yet

- Data Sheet: Diesel Generator 505Kw 50HZ/1500RPM Cummins Model: Kta19-G8Document7 pagesData Sheet: Diesel Generator 505Kw 50HZ/1500RPM Cummins Model: Kta19-G8Markus Sitanggang100% (1)

- Shell Lubricants Bangladesh - v1.1 PDFDocument118 pagesShell Lubricants Bangladesh - v1.1 PDFWaliur RahmanNo ratings yet

- DS C1250 D5a PDFDocument3 pagesDS C1250 D5a PDFVu TuongNo ratings yet

- Tata Nano SpecificationDocument4 pagesTata Nano SpecificationRishi SharmaNo ratings yet

- Major AlterationsDocument8 pagesMajor AlterationsCalvin LabialNo ratings yet

- Energies 15 05170 v2Document16 pagesEnergies 15 05170 v2Muhammad AsimNo ratings yet

- HD270 DumpDocument4 pagesHD270 DumpBui Thanh DanhNo ratings yet

- Diesel Engine 16V 2000 M61: MarineDocument2 pagesDiesel Engine 16V 2000 M61: MarinemnezamiNo ratings yet

- Dashboard - Actualiza SoloDocument199 pagesDashboard - Actualiza SoloMarkoOcampoEnriqueNo ratings yet

- Shree Cement LTDDocument45 pagesShree Cement LTDAbhishek SharmaNo ratings yet

- Cumins 6CTA 8.3l SPECSDocument5 pagesCumins 6CTA 8.3l SPECSAdriana María Huertas NietoNo ratings yet

- Next Generation Eaton Transmission Lube PS-386Document2 pagesNext Generation Eaton Transmission Lube PS-386Onando SaundersNo ratings yet

- 20th Exam P1 B PDFDocument11 pages20th Exam P1 B PDFAlbert SekarNo ratings yet

- 6134456745e30bb64872198 321t71504Document173 pages6134456745e30bb64872198 321t71504omarnoamanNo ratings yet