Professional Documents

Culture Documents

Fig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600

Uploaded by

Manuel CampoyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600

Uploaded by

Manuel CampoyCopyright:

Available Formats

STRAINERS P

PN16

OP

Fig. 822 & 922 DN50-DN300

Fig. 810 & 910 DN350-DN600 VOCS

STR

Y-Type Strainers

FEATURES & BENEFITS MATERIAL SPECIFICATION

• Helps to protect the system by trapping NRV

Part Size Material

foreign matter FORV

• Drain plug in cap as standard Body DN50 - DN300 Ductile Iron BS EN 1563 EN-GJS-450-10

Body DN350 - DN400 Cast Iron EN-JL1040

• Stainless steel screen

Body DN450 - DN600 Ductile Iron BS EN 1563 EN-GJS-500-7

• Test points can be fitted for system

Cover DN50 - DN300 Ductile Iron BS EN 1563 EN-GJS-450-10

diagnostics FC

Cover DN350 - DN400 Cast Iron EN-JL1040

• ANSI versions are also available to Class 125 -

Cover DN450 - DN600 Ductile Iron BS EN 1563 EN-GJS-500-7

Fig. 822ANSI & Fig. 922ANSI,

Screen DN50 - DN600 Stainless Steel 304

Fig. 810ANSI & Fig. 910ANSI TP

Stud DN50 - DN600 Steel

Nut DN50 - DN600

FOCS Steel

Washer DN50 - DN600 Steel

Drain Plug DN50 - DN600 Malleable Iron

4PMV

Gasket DN50 - DN300 Fibre (Asbestos Free) Klingersil C4430

Gasket DN350 - DN600 Graphite

Body Plug DN50 - DN300 Malleable Iron

Body Plug DN350 - DN600 Cast Iron EN-JL1040 DPCV

CFC

CV

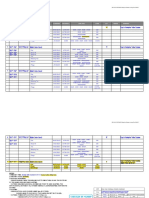

DIMENSIONAL DRAWING PRESSURE/ SPECIFICATION

TEMPERATURE RATING Bolted cover.

A

13 bar at 220ºC Figure 910 & 922 supplied complete

16 bar from -10 to 120ºC DOC with two Figure 631 test points.

MAV

Note: 910 restricted to 135°C Flanges to BS EN 1092-2 PN16 or

ANSI B16.1 Class 125.

TEST PRESSURES

B

(HYDRAULIC)

C

TRV

C = Withdrawal Shell: 24 bar

distance for the

strainer screen

DIMENSIONS & WEIGHTS

Nom Fig. 822/922 Fig. 810/910

Size mm 50 65 80 100 125 150 200 250 300 350 400 450 500 600

18

A mm 230 290 310 350 400 480 600 730 850 960 1079 1168 1275 1450

16

B mm 140 160 178 198 270 297 364 471 605 755 840 910 968 1160

C mm 197 227 256 293 362 407 513 726 946 1150 1306 1434 1550 1858 14

Cover Plug inch 1/2" 1" 1" 11/2" 2" 2" 2" 2" 2" 3/4" 11/2" 11/2" 11/2" 11/2" 12

Pressure bar

Weight kg 10 14 18 24 37 50 89 140 211 342 420 628 780 1080

10

Flow kv 58 89 127 180 268 356 630 901 1247 2401 2969 * * *

*Please contact Hattersley for details 8

m

SCREEN DATA

Stea

6

ted

Nom Fig. 822/922 Fig. 810/910 4

tura

Size mm 50 65 80 100 125 150 200 250 300 350 400 450 500 600

Sa

2

Hole Dia mm 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 3 3 3 3 3

0

Free Flow % 32 32 32 32 32 32 32 32 32 40 40 40 40 40 0 40 80 120 160 200 240

Area/cm2 Temperature ˚C

131119

Every effort has been made to ensure that the information contained in this publication is accurate at the time of publishing. Hattersley Ltd assumes no responsibility or

liability for typographical errors or omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

126 Technical Helpline UK: 0845 604 1790 MEA: +971 4 816 5800

Email UK: tech-enquiries@hattersley.com

MEA: mena-techenquiries@hattersley.com

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- AC10 Duo Check Wafer Valve: DN50-DN1000Document2 pagesAC10 Duo Check Wafer Valve: DN50-DN1000Akshat JainNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Krombach Crane ProductsDocument2 pagesKrombach Crane ProductsLuka BornaNo ratings yet

- Fig 950 950GDocument1 pageFig 950 950GAsmaaNo ratings yet

- Butterfly Valve DesponiaDocument8 pagesButterfly Valve Desponiadk_moehammedNo ratings yet

- Catalog Ava Tiger FitDocument1 pageCatalog Ava Tiger Fitazlen494No ratings yet

- Bellow sealed globe valves specificationsDocument1 pageBellow sealed globe valves specificationsjoaquin torrano veraNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Pipe & FittingDocument28 pagesPipe & Fittinghelman novrandoNo ratings yet

- Fig 907 Resilient Seated Gate Valve FlangedDocument1 pageFig 907 Resilient Seated Gate Valve FlangedSebastian Andres Quilodran BaquedanoNo ratings yet

- Pipe Re-Routing For 11kva Building CH-4Document2 pagesPipe Re-Routing For 11kva Building CH-4BALJIT singhNo ratings yet

- C 2018-07-10 ME H. Pelders S M. Ummelen ME PCL R. Menon/hpe 1 of 2Document2 pagesC 2018-07-10 ME H. Pelders S M. Ummelen ME PCL R. Menon/hpe 1 of 2mokie305No ratings yet

- BS-HWC4_Butterfly valveDocument10 pagesBS-HWC4_Butterfly valvesidparikh254No ratings yet

- Swing Check ValveDocument2 pagesSwing Check ValveHardik ShahNo ratings yet

- 53 50-001 AVK017 Eng v1-0Document2 pages53 50-001 AVK017 Eng v1-0kad-7No ratings yet

- Ductile Iron Fully-Lugged PN16: Features & BenefitsDocument1 pageDuctile Iron Fully-Lugged PN16: Features & BenefitsRonaldNo ratings yet

- Technical Specifications for KLINGER 2-Piece Ball ValvesDocument4 pagesTechnical Specifications for KLINGER 2-Piece Ball ValvesFood andfoodNo ratings yet

- NO Drawing No. Drawing Title Specification Standard Materials Nom. Size Conn. QTY Maker RemarksDocument17 pagesNO Drawing No. Drawing Title Specification Standard Materials Nom. Size Conn. QTY Maker RemarksDung Do ThanhNo ratings yet

- Thermodynamic steam trap performance and specificationsDocument2 pagesThermodynamic steam trap performance and specificationshamid vahedil larijaniNo ratings yet

- Double Check Valve DC: Technical DataDocument2 pagesDouble Check Valve DC: Technical DataAthanasoulis KostasNo ratings yet

- P 143 MPR Apx IDocument28 pagesP 143 MPR Apx ILakshmanan VenkateswaranNo ratings yet

- Katalog GALA - Gate Valve OSNYDocument1 pageKatalog GALA - Gate Valve OSNYaditNo ratings yet

- Documentatie Hora 1 3 Robineti Control Actionare Pneumatica Sialco Reprezentanta Hora RomaniaDocument14 pagesDocumentatie Hora 1 3 Robineti Control Actionare Pneumatica Sialco Reprezentanta Hora RomaniaMugeshNo ratings yet

- Butterfly Valve Wafer TypeDocument2 pagesButterfly Valve Wafer TypeHardik ShahNo ratings yet

- Abb Flowmeter Selection ChartDocument3 pagesAbb Flowmeter Selection ChartEepen JohnNo ratings yet

- Web+Presentation+12+July+2016 EA+-+Scott+MunterDocument44 pagesWeb+Presentation+12+July+2016 EA+-+Scott+MunterDesika RaniNo ratings yet

- Fig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150Document1 pageFig. 980 ANSI Ductile Iron Fully Lugged Butterfly Valve Class 150kikokiko KarimNo ratings yet

- DWS2510.03 Spherical ValvesDocument5 pagesDWS2510.03 Spherical ValvesCorneNo ratings yet

- VA1-BSWS-00100-M-M3-SPC-0011 Rev B Piping Material%2Document7 pagesVA1-BSWS-00100-M-M3-SPC-0011 Rev B Piping Material%2Tam Huynh ThanhNo ratings yet

- Ti Be PDFDocument30 pagesTi Be PDFPascual Ronald PatrickNo ratings yet

- Fig 1432-1432L-1432C-1432LC Hatt DS 0922Document1 pageFig 1432-1432L-1432C-1432LC Hatt DS 0922Dan HawthorneNo ratings yet

- HOBAS Gravity Pipe SystemsDocument42 pagesHOBAS Gravity Pipe SystemsMarkoNo ratings yet

- Resilient Seated Gate Valve Product Data SheetDocument2 pagesResilient Seated Gate Valve Product Data SheetEm Es WeNo ratings yet

- ARCA Info Catalogue GBDocument146 pagesARCA Info Catalogue GBcvfNo ratings yet

- Lieferprogramm EnglDocument3 pagesLieferprogramm EnglcvfNo ratings yet

- Iron Wafer Type Check Valve: Kitz Cast Iron ValvesDocument1 pageIron Wafer Type Check Valve: Kitz Cast Iron ValvesAndy SetyawanNo ratings yet

- MAKO Piping Library Catalogue - Rev CDocument28 pagesMAKO Piping Library Catalogue - Rev Celmfp7774676No ratings yet

- Shin Nan Catalogue PDFDocument38 pagesShin Nan Catalogue PDFElan ChezhiyanNo ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Temp. Control ValveDocument7 pagesTemp. Control Valvesaurabh kumarNo ratings yet

- MSS SP-67 Wafer Butterfly Valve SpecificationDocument1 pageMSS SP-67 Wafer Butterfly Valve Specificationlaura giraldoNo ratings yet

- 法兰标准体系Document125 pages法兰标准体系Forest MoNo ratings yet

- Vit GLBCTR PDFDocument6 pagesVit GLBCTR PDFtonnyhawk24No ratings yet

- 02 - Stobu PN16-40Document1 page02 - Stobu PN16-40Cherbee FerrerNo ratings yet

- Catalog - Ava - Air ValveDocument1 pageCatalog - Ava - Air Valveazlen494No ratings yet

- Catalog Ava Air Valve Dok DoakDocument1 pageCatalog Ava Air Valve Dok Doakazlen494No ratings yet

- ISO Flange Connection ElementsDocument8 pagesISO Flange Connection ElementsmihaiNo ratings yet

- Butterfly ValveDocument6 pagesButterfly ValveRomisamomNo ratings yet

- Lieferprogramm Engl 1398326758Document3 pagesLieferprogramm Engl 1398326758ChanNo ratings yet

- Tozen Valve CatalogueDocument45 pagesTozen Valve CatalogueMyo Kyaw Kyaw100% (1)

- Lift Check Valve: Straight, Flanged EndsDocument1 pageLift Check Valve: Straight, Flanged Endsadvantage025No ratings yet

- Sp-20-015-Rfq023-Fitting-For-Rubber-Lining-R1-200617 CheckedDocument18 pagesSp-20-015-Rfq023-Fitting-For-Rubber-Lining-R1-200617 CheckedDung Do ThanhNo ratings yet

- Fig.731 Cast Iron: Features & Benefits Material SpecificationDocument1 pageFig.731 Cast Iron: Features & Benefits Material SpecificationKarim Galal IsmailNo ratings yet

- Page 31 34Document4 pagesPage 31 34ISHAN VERMANo ratings yet

- Tecnidro - FirefightingDocument4 pagesTecnidro - FirefightinggtecnidroNo ratings yet

- CLASS 11180: DEP 31.38.01.12-Gen Class 11180, Rev. F Page 1 of 14Document14 pagesCLASS 11180: DEP 31.38.01.12-Gen Class 11180, Rev. F Page 1 of 14SaguesoNo ratings yet

- Dm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Document1 pageDm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Hasan V SNo ratings yet

- DS Datasheet ERHARD Non Slam Nozzle Check Valve enDocument6 pagesDS Datasheet ERHARD Non Slam Nozzle Check Valve entangouzeNo ratings yet

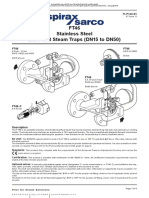

- FT46 Stainless Steel Ball Float Steam Traps (DN15 To DN50) : Air VentDocument6 pagesFT46 Stainless Steel Ball Float Steam Traps (DN15 To DN50) : Air Ventmember1000No ratings yet

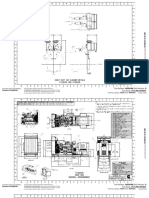

- Cummins Heavy Duty Air Cleaner DetailsDocument6 pagesCummins Heavy Duty Air Cleaner Detailsacere18No ratings yet

- Questions Cessna 525Document42 pagesQuestions Cessna 525Alan Mara100% (2)

- MT Duct 40/33 Hdpe: 2009 3020 5021 6001 5015 4005 TranDocument2 pagesMT Duct 40/33 Hdpe: 2009 3020 5021 6001 5015 4005 TranDerrick Kojo SenyoNo ratings yet

- Material ModelsDocument183 pagesMaterial Modelsmahesh84psgNo ratings yet

- Effects of Bearing Currents on Motor BearingsDocument17 pagesEffects of Bearing Currents on Motor BearingsHarris AnchesNo ratings yet

- Austria's Largest Pumped Storage Power Plant Kopswerk IIDocument4 pagesAustria's Largest Pumped Storage Power Plant Kopswerk IIjoaoaugusto79No ratings yet

- Statical Calculation of 50m TowerDocument25 pagesStatical Calculation of 50m TowerAntenasmNo ratings yet

- Quick Change Connectors: JK 201 Nipples (Special Mold Plug)Document2 pagesQuick Change Connectors: JK 201 Nipples (Special Mold Plug)Anilabc VermaxyzNo ratings yet

- AD 310 - Staircases With Flat StringersDocument1 pageAD 310 - Staircases With Flat Stringerssymon ellimacNo ratings yet

- Field Assembly HD787!7!7001 UpDocument200 pagesField Assembly HD787!7!7001 Upjosecall100% (1)

- Flat Belt Design ProceduresDocument40 pagesFlat Belt Design Proceduresjonnel batuigasNo ratings yet

- DTH Drilling MachineDocument8 pagesDTH Drilling MachineREL PromoNo ratings yet

- GBT 9222-2008Document149 pagesGBT 9222-2008ecsuperal100% (2)

- DIMISADocument273 pagesDIMISATACUPETO100% (1)

- Weinberg - Lectures On QM SolnsDocument112 pagesWeinberg - Lectures On QM SolnsSean McClure100% (3)

- Composites Data SheetDocument2 pagesComposites Data Sheetvlade naumovskiNo ratings yet

- VB9HZ7 GDocument2 pagesVB9HZ7 GConstantin294No ratings yet

- Yb08 2Document26 pagesYb08 2eemylNo ratings yet

- Motor Control Systems Analysis Design and Optimization StrategiDocument75 pagesMotor Control Systems Analysis Design and Optimization Strategipeter vanderNo ratings yet

- MS 9001 eDocument58 pagesMS 9001 eAlexey Marchenko100% (2)

- Tower Drawing 100 FeetDocument3 pagesTower Drawing 100 FeetMian M Khurram100% (3)

- 101MFLSTDocument1 page101MFLSTsky emelyNo ratings yet

- SF10 and SF16Document22 pagesSF10 and SF16Shanil BussooaNo ratings yet

- Chapter 8. Internal Flow (Bounded, Forced)Document31 pagesChapter 8. Internal Flow (Bounded, Forced)wadec24No ratings yet

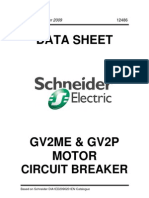

- Schneider GV2 Motor Circuit BreakerDocument19 pagesSchneider GV2 Motor Circuit BreakeruuraydinNo ratings yet

- Ultrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Document26 pagesUltrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Taufik SantosoNo ratings yet

- GRFP01 Gr11 Ch01toCh06Document126 pagesGRFP01 Gr11 Ch01toCh06AidanNo ratings yet

- 1-Ideal Gas LectureDocument60 pages1-Ideal Gas LecturemahmoudNo ratings yet

- TeSys motor starters coordination standardsDocument6 pagesTeSys motor starters coordination standardsAhmedNo ratings yet

- Multiple Riser Configurations Top-Tensioned Risers Hybrid Riser SystemDocument103 pagesMultiple Riser Configurations Top-Tensioned Risers Hybrid Riser Systemsaeed ghafoori100% (4)