Professional Documents

Culture Documents

Pile & Well Foundation - Manual

Pile & Well Foundation - Manual

Uploaded by

Arpan Saha0 ratings0% found this document useful (0 votes)

18 views17 pagesOriginal Title

Pile & Well Foundation_Manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views17 pagesPile & Well Foundation - Manual

Pile & Well Foundation - Manual

Uploaded by

Arpan SahaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 17

For Official use only

GOVERNMENT OF INDIA.

MINISTRY OF RAILWAYS.

(Railway Board)

INDIAN RAILWAY STANDARD

MANUAL ON THE DESIGN AND CONSTRUCTION

OF WELL AND PILE FOUNDATIONS (1985)

(WELL AND PILE FOUNDATION CODE)

ADOPTED - 1941

REPRINTED - 2004

ISSUED BY

RESEARCH DESIGNS AND STANDARDS ORGANISATION

LUCKNOW - 226011

IB

INTRODUCTION

This manual covers the design and construction of well foundation and pile foundations for

Railway bridges, which generally form part of the permanent foundations for long span bridges.

These foundations are commonly used for transferring heavy loads to deep strata in river bed

from piers and abutments of bridges.

This manual finalised by RDSO has been approved by the Bridge & structure Standards

Committee. The Chief Engineers may issue supplementary instructions from time to time to suit

local working conditions,

UB-ii

CONTENTS

1. WELL FOUNDATIONS

Depth of foundation.

Shape and cross-sections of well

Allowable bearing pressure and

Modulus of sub-grade reaction.

Loading.

Tilt and shift

Cutting edges.

Well curb.

Well steining

Bottom Plug. 4

Top Plug. 4

Well cap.

Pneumatic Sinking of Wells.

2. PILE FOUNDATIONS

Classification of piles.

Types of piles.

Spacing of piles,

Load carrying capacity of a pile.

Factor of Safety for pile foundations.

Pile grouping.

Settlement of pile foundations,

Load test.

Capacity of Pile against lateral loadings.

Roe ee

aaa

"1

"1

"

PAGE NO

MBit

MANUAL ON THE DESIGN AND CONSTRUCTION

OF WELL AND PILE FOUNDATIONS

DEEP FOUNDATIONS

1. WELL FOUNDATION

1.1. Depth Of Foundations The depth

of deep foundations below the high flood

level shall be determined as indicated in

clause 6.10.1. For substructures in sandy

strata the depth of foundations may be

determined from Fig 1 which is based on

Technical Paper No 153 PL: Xill. The

choice of type and shape of well foundation

will depend upon the soil, type, the size

and shape of pier or abutment, depth of

foundation and available _ construction

material. Where major obstructions such as

uneven rocky strata are likely to be

encountered, provision for pneumatic.

sinking may be made. Small obstructions

can be removed either with the help of

divers or by chiselling,

1.2. Shape And Cross-Section Of

Wells: The horizontal cross-section should

satisfy the following requirements:

(2) The dredge hole should be large

‘enough to permit dredging.

(b)__ The steining thickness should be

sufficient to enable sinking without

excessive kentledge and provide adequate

strength against forces acting on the

steining, both during sinking and service.

The well steining should also be designed

to withstand the earth pressures acting only

‘on two opposite sides or only on

diametrically opposite quadrants under

conditions of sand blowing. The effect of

heap of earth dumped near the well during

sinking shall also be taken into account.

(c) It should accommodate the base of

the substructure and not cause undue

‘obstruction to the flow of water.

(4) The overall size should be sufficient

to transmit the loads safely to the soil

without exceeding its allowable bearing

pressure.

FIG.1 DIAGRAM OF THE DEPTH OF BRIDGE PIERS IN,

WATER AND IN RIVE!

‘BED RESPECTIVELY.

i ,

se 7

He :

He

HH}! §

oD

Ae

IB. 1

Explanation Of The Diagram: The

intention of the diagram is to offer

something definite in place of the rather

fortuious method now centrally practiced.

OA-Represents highest known flood level

OB-Represents deepest ascertainable

scour.

OG-Represents depth to which foundation

should be sunk,

Note:

1. The diagram applies only to sandy

bottom. If the river bed is soft, a greater

depth is necessary. Piers are always

presumed to have enough stone around

them to prevent local pier formed swirls

from scooping pot-holes at pier base.

2. This diagram is based upon

Technical paper No 153 PI: XIII

(@) It shall allow rectification of the tit

and shift of the well without damaging the

well

‘The shapes normally used are circular,

double D. Dumb-bell, hexagonal or

‘octagonal, square, rectangular and any of

the above shapes with multiple dredge

holes.

1.3. Allowable Bearing Pressure And

Modulus Of Sub-Grade Reaction

13.4. The allowable bearing pressure

may be determined in cohesion less soils

on the basis of the penetration test results

as given in IS: 3955 and reproduced

below:

Q= 9.8 {5.4 NB + 16(100+N") D}

in Newton/m?

[Q=5.4 NPB + 16(100+N2) D in Kgim?

where,

= RaeARERSR RAFU RBI} Aer the wel

N = Number of blows per 30cm in the

standard penetration test.

B = smaller dimension of the well cross-

section in metre,

D = Depth of foundation below scour level

in metre

The capacity worked out by the above

formula is applicable only for safety

against shear failure. For well foundations,

settlement governs the allowable bearing

capacity in most cases. The permissible

value of settlement is generally keptwithin

25mm and the allowable bearing pressure

qs for such settlement can be obtained

approximately by the following equation:

qe=9.8 x (1+ 0.3/8 )° N for B > 1.2m -

Kim?

aor (14 0.3/8 7 N for B > 1.2m - in

tonne/m®]

g= N in tonne/m? (approximately irrespective of

B)

qe= 9.8 x 1.4.N for B< 1.2m —in KNim?

[ais 14N for $1.2 m-~in tonne’)

Where,

corrected standard penetration

resistance

(No of blows per 30 cm)

If larger settlement can be tolerated, the

allowable bearing pressure could be

increased accordingly. For clayey strata

settlement should be worked out for full

load based on consolidation test results.

For wells constructed in cohesion less

soils where full settlement due to dead

load will take place by the time

construction is completed and the

necessary adjustments in the final level

can be made before erection of girder,

dead load due to well and the substructure

can be ignored. In such cases, settlement

shall be evaluated only for superstructure,

live load and loss of friction in the well due

to scour.

4.32. The passive pressure and skin

friction shall be taken only for soil below

the level of scour. In seismic areas relief

due to skin friction should be ignored,

The average value of skin friction may be

scopted a po following equate,

F 981k, °z “oy tan2 in

oa 3

Nm?

Tost. so 2

FO K oz FE tan® inkgsm

A a2 A 3 8

Where,

F = Skin friction in Nim? (kg/m?)

Ko= Active earth pressure coefficient.

MB-2

© = Half of unconfined compressive

strength,

Angle of shearing resistance of soil

ubmerged weight of soil below scour

line.

Z = Depth of foundation level below bed

level

In the absence of any data, the following

values may be adopted; these are based

on observations made during sinking of

wells:

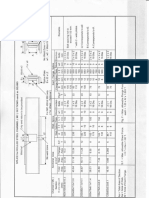

Value of | Value of

= friction | friction

Kum | Kgim

Sit& soltlay | 7.1610 | 73010

za73_ | 2930

Very siifday | 47.86t0 | 4880 to

19182 | 19590

Loose sand | 11.96 to | 12200

sas¢ | 3420

Dense sand | 33.64 10 | 342010

67.08 | 6840

Dense gravel 47.85t0 | 488010

9571 | 9760

1.3.3. Modulus of sub-grade reaction

may be adopted as per IS: 2950.

1.34 In case the well is found on rock,

its suitability to take load shall be found by

testing cores. If the rock bed is inclined, it

is advisable to seat the steining evenly on

the rock foundation,

14.4 Loading

1.4.1 Wells shall be designed to resist

the worst condition due to possible

combination of the following loads, as may

be applicable, with due regard to their

direction and point ofapplication.

(a) Vertical Loads:

i) Self.weight ofwell

ii) Buoyancy

ili) Dead load ofsuperstructure,

substructure,

iv) Live load, and

v) Kentledge during sinking operation

(>) HorizontalForces:

i) Braking and tractive effort of moving

vehicles.

ii) Forces on account of resistance of

bearings.

iil) Forces on account of water current or

waves.

iv) Centrifugal force, if the bridge is

situated on acurve.

v) Wind forces or seismic forces.

vi) Earth pressure.

vii) Other horizontal and uplift forces due

to provision of transmission line tower

(broken wire condition) ete.

1.5 Tilt And Shifts As far as possible

wells shall be sunk without any tilt and

shift. A tit of 1 in 100 and shift of D/40

subject to @ minimum of 150 mm shall be

taken into account in the design of well

foundation (D is the width or diameter of

well)

If greater tits and shifts occur, theireffects

fon bearing pressure on soil, steining

stresses, change in span etc. should be

examined individually.

1.6 Cutting Edges Cutting edge shall

be properly anchored to the well curb.

When there are two or more

compartments in a well the bottom of the

cutting edge of the intermediate walls may

be kept about 300 mm above the cutting

edge of the outer wall to prevent rocking.

4.7 Well Curb It should transmit the

superimposed load to the bottom plug

without getting overstressed and it should

offer minimum resistance to sinking. The

slope to the vertical of the inner faces of

the curb shall preferably be not more than

30 degrees. In sandy strata, it may be

Upto 45 degrees. An offset on the oulside

(about 50 mm) may be provided to ease

sinking. The curb shall invariably be of

reinforced concrete with a minimum

reinforcement of 72 kgm’ excluding bond

rods. In case blasting is anticipated, the

inner face of the curbs shall be protected

by steel plates or any other means to

sufficient height.

UB-3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter - 1 Preamble, Water Source & Availability and Selection of Water Intake LocationDocument157 pagesChapter - 1 Preamble, Water Source & Availability and Selection of Water Intake LocationArpan SahaNo ratings yet

- Specification Report Construction of Intake Well, WTP & Clear Water Sump For Ramappa-Godavari (Mangapeta Segment) in Mangapeta Mandal in Mulugu Constituency of Warangal DistrictDocument29 pagesSpecification Report Construction of Intake Well, WTP & Clear Water Sump For Ramappa-Godavari (Mangapeta Segment) in Mangapeta Mandal in Mulugu Constituency of Warangal DistrictArpan SahaNo ratings yet

- Intake Structure For Water Supply: Mathanakeerthi S Assistant Professor Civil Engineering Sns College of EngineeringDocument17 pagesIntake Structure For Water Supply: Mathanakeerthi S Assistant Professor Civil Engineering Sns College of EngineeringArpan SahaNo ratings yet

- Well Foundation DesignDocument4 pagesWell Foundation DesignArpan SahaNo ratings yet

- Disclosure To Promote The Right To InformationDocument34 pagesDisclosure To Promote The Right To InformationArpan SahaNo ratings yet

- Beam SketchDocument3 pagesBeam SketchArpan SahaNo ratings yet

- FDN - SketchDocument1 pageFDN - SketchArpan SahaNo ratings yet

- Design of Well Foundation - Design-of-Well-FoundationDocument6 pagesDesign of Well Foundation - Design-of-Well-FoundationArpan SahaNo ratings yet

- Beam DesignDocument21 pagesBeam DesignArpan SahaNo ratings yet

- Slab Design:: Two Way Concrete Floor SystemDocument3 pagesSlab Design:: Two Way Concrete Floor SystemArpan SahaNo ratings yet

- Effect of Prying Action Forces On Design Method of Rigid Bolted Connections With Circular End PlateDocument17 pagesEffect of Prying Action Forces On Design Method of Rigid Bolted Connections With Circular End PlateArpan SahaNo ratings yet

- Typical Slab DesignDocument3 pagesTypical Slab DesignArpan SahaNo ratings yet

- StandardDocument1 pageStandardArpan SahaNo ratings yet

- Particular Specifications: 1.0 GeneralDocument68 pagesParticular Specifications: 1.0 GeneralArpan SahaNo ratings yet

- Sikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater RepairsDocument3 pagesSikarep Microcrete-3 Uw: Antiwashout, Non-Shrink, High Strength Cementitious Micro Concrete For Underwater RepairsArpan SahaNo ratings yet