Professional Documents

Culture Documents

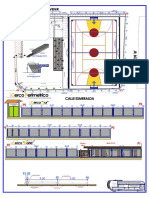

266.93m PRESSED PANEL TANK

Uploaded by

Insta PumpsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

266.93m PRESSED PANEL TANK

Uploaded by

Insta PumpsCopyright:

Available Formats

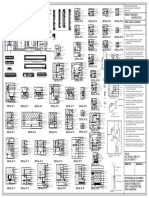

8.54x8.54x3.

66

8.54x8.54x3.66 8.54x8.54x3.66 266.93m3 PRESSED

266.93m3 PRESSED 266.93m3 PRESSED PANEL TANK

PANEL TANK PANEL TANK

HL6 HL14 HL13 HL20 HL21 HL13 HL13 HL13 HL14 HL6

HL17

HL16

HL2

HL1

HL13

HL2

HL1

HL1

HL1

HL13

HL1

HL6 HL14 HL13 HL13 HL13 HL13 HL6 HL6 HL14 HL13 HL20 HL21 HL13 HL13 HL13 HL14 HL6

HAND RAIL

LD9

HL2

CHS33.7*2.65

HL2

HL1

HL1

HL1

HL1

HL1

HL1

HL1

HL6 HL14 HL13 HL13 HL13 HL13 HL13 HL13 HL6 HL7 HL15 HL15 HL15 HL15 HL15 HL15 HL7

SAFETY_CHAIN LD9 HL7 HL15 HL15 HL15 HL15 HL15 HL15 HL15 HL7

Ø3 GALV-CHAIN LD10

7

LD

LD4 +12000

LD11 HB4 HB6

+12000

HB2 HB2 +11880 VB VB

LD3 3 3

ST1

+11880 4

VB VB VB

ST1

2480

1 2 1

LD6

VB 2 VB

VB 4

LD6

VB KICKER_STAY

2480

LD4 Detail C 3

VB SHS100*100*2.9

3

VB VB S250

9 1 +9900

LD3 LD11 HB11 HB5

+9900

HB10 HB1 VB VB

3 3

LD8

LD4 4

VB

1 VB

1600

8 2

VERTICAL_BRACING LD4 VB VB VB

4 VB

3

1600

VB

RSA75*75*6 S235JR 3

LD3 VB VB

9 1 +7920

LD11 HB11 4 HB5

+7920 VB

HB10 HB1 VB VB

3 3

HL10 HL18 4

1980

VB

1

VB

1 VB

HL11

HL4 8 2

1980

VB VB HL10 HL18 VB

HL22

HL3

3 VB

C4

C3

HL4 HL9 HL19 3

HL22

HL23

LANDING PLATFORM

12000

HORIZONTAL_BRACING RSC100*50 ~TYP VB VB

HL8 9 1 +5940

RSA75*75*6 S235JR LPT10 HB5 HB5

+5940

HB10 HB1 VB VB

3 3

LP 4

1980

LPT2

LPT2

LPT2

LPT2

LANDING_PLATFORM LD3 T2 VB

1

VB

1 VB

T3

8 2

LP

1980

RSC100*50 ~TYP VB VB 4 VB

VB 3 VB

3

LD4

LANDING_SUPPORT VB VB

9 1 +3960

C1

RSA70*70*6 ~TYP LD5 HB3 HB5

LD1

LD1

C3 +3960 Detail B COLUMN

LD3 HB10 HB1 VB VB

3 3 UC152*152*23

LD2

4 4

1980

VB VB VB VB S355JR

1 1

8 2

1980

LD4 VB VB

VB HB3 HB5

LD3 9 +1980

LD5 HB10 HB1

C3

+1980

C7

VB

C8

VB 3

COLUMN 3 B4 4

1980

VB

1 8

VB

1 V VB

UC152*152*23 VB

C2

2125

1980

S355JR VB

VB

C6

VB 3

C4

3

C1

VB VB COLUMN

C5

1 9 UC152*152*23 +0

1

C8

S355JR +0

3000 3000

C7

2 VERTICAL_BRACING A

RSA75*75*6 S235JR 1920 3000 3000

WITH SAFETY HOOPS

C3

B

3 1 2 3

C

3D VIEW

SCALE- 1:60 C B A VIEW ALONG GRID LINE - C

BRACINGS MARKS ARE SIMILAR AT GRID B, A

VIEW ALONG GRID LINE - 3 SCALE- 1:60

BRACINGS MARKS ARE SIMILAR AT GRID 2, 1

SCALE- 1:60

COLUMN VERTICAL_BRACING

VERTICAL_BRACING DIAGONAL_BRACING RSA75*75*6

UC152*152*23 RSA75*75*6 RSA50*50*4

S355JR S235JR

S235JR S235JR

PLATFORM

CORNER_GUSSET Secondary Beams - UB356 x 127 x 33 KG/M (S355)

PLT6*299.5 Main beams - UB406*178*54 KG/M (S355)

02 02 S275JR

GUSSET_PLATE TOWER

PLT6*190 Columns - UC 152*152*23 KG/M (S355)

C S275JR Vertical bracings - RSA 75*75*6 (S235)

HORIZONTAL_BRACING Horizontal ties - RSA 75*75*6 (S235)

RSA75*75*6 Diagonal bracings - RSA 50x50x4 (S235)

2 M16 8.8/8 x 35 S235JR VERTICAL_BRACING

RSA75*75*6 KICKERS

lg Bolts SHS 100*100*2.9 (S250)

S235JR

1 2 M16 8.8/8 x 35

VERTICAL_BRACING lg Bolts

RSA75*75*6

SECTION 02 - 02 Detail C

S235JR

SCALE: 1:15 SCALE:- 1:15

THIS DRAWING TO BE READ IN CONJUCTION

Detail B ~BRACE CONNECTION WITH DRAWING NO. STT1496/T-05 0 Issued for approval 24.06.2021

SCALE:- 1:15 Model :- STT1496-T-INSTAPUMPS LTD-SUPPLY OF 266.93m3 TANK AND 12m H*** Rev Revision Description Date

GENERAL NOTES: Drawing title

1)ALL WELDS 6 mm UNO

2)ALL DIMENSIONS ARE IN MM U.O.N.

CLIENT- INSTAPUMPS LTD

PAINT SPECIFICATION PROJECT- SUPPLY OF 266.93m3 TANK AND 12m HIGH TOWER

1) STEELWORK TO BE GENERAL ARRANGEMENT OF STEELWORK

Tekla Structures

WIRE-BRUSH CLEANED ADDRESS - MALABA

PRIOR TO PAINT APPLICATION

2) PAINT ONE SHOP COAT OF ZINC PHOSPHATE

PRIMER STLII RAL 7046 AFTER FABRICATION

PAINT ONE SHOP COAT OF SILVER ALUMINIUM

12M HIGH TOWER FOR 266.93m3 TANK

PAINT PRIOR TO DESPATCH

3) PAINT APPLICATION IS

BY HAND BRUSH OR ROLLER.

Prepared using Tekla Structures® (www.tekla.com)

You might also like

- Overture / All That Jazz: DrumsDocument2 pagesOverture / All That Jazz: DrumsRaf IrtNo ratings yet

- Avery 5160 Easy Peel Address LabelsDocument1 pageAvery 5160 Easy Peel Address LabelsTony MartinNo ratings yet

- Alana Top Pattern: Print OUT & KeepDocument17 pagesAlana Top Pattern: Print OUT & Keepngocthu tran100% (1)

- TunictechpackDocument10 pagesTunictechpackAmrutha RPNo ratings yet

- Math Workshop, Grade 3: A Framework for Guided Math and Independent PracticeFrom EverandMath Workshop, Grade 3: A Framework for Guided Math and Independent PracticeNo ratings yet

- Ig N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM CleDocument1 pageIg N e D: WMV Ral VSM Acp Ags Ral Cle WMV JCF FCM Clenestor159357No ratings yet

- Fidic Construction Contract 2ND Ed (2017 Red Book)Document225 pagesFidic Construction Contract 2ND Ed (2017 Red Book)Mohammed H Shehada88% (114)

- Band of BrothersDocument9 pagesBand of BrothersLaimonas MaseviciusNo ratings yet

- Waltz No. 2 ShostakovichDocument5 pagesWaltz No. 2 ShostakovichJoedi SantosNo ratings yet

- Types of Fashion Design and PatternmakingDocument6 pagesTypes of Fashion Design and PatternmakingcarixeNo ratings yet

- Pallet PalletDocument2 pagesPallet PalletRamanda Anugrah AfriantoNo ratings yet

- DX300LCA - SEND300A0001 779-ElDocument1 pageDX300LCA - SEND300A0001 779-ElMeterio Cao SuNo ratings yet

- Freight - ForwardingDocument105 pagesFreight - ForwardingRamalingam ChandrasekharanNo ratings yet

- 02 CAL Y ARENA 2022-10-05-Partitura y PartesDocument17 pages02 CAL Y ARENA 2022-10-05-Partitura y Parteskoldo quilchanoNo ratings yet

- Mosaic TRD1 Tests U7 1Document3 pagesMosaic TRD1 Tests U7 1juana67% (3)

- Plano Electrico 994kDocument6 pagesPlano Electrico 994kmarcol7050% (1)

- BC - L6 - Unit1 - StandardDocument4 pagesBC - L6 - Unit1 - StandardAnaNo ratings yet

- ABNT NBR 15784 - Produtos Químicos Utilziados No Tratamento de Água para Consumo Humano - ANTIGADocument39 pagesABNT NBR 15784 - Produtos Químicos Utilziados No Tratamento de Água para Consumo Humano - ANTIGAJaqueline FrancischettiNo ratings yet

- Il Barbiere Di Siviglia Atto I La Calunnia Un Venticello - Gioacchino RossiniDocument6 pagesIl Barbiere Di Siviglia Atto I La Calunnia Un Venticello - Gioacchino RossiniJulian CichettoNo ratings yet

- Nana FallaDocument2 pagesNana FallaMaría Hernández MiraveteNo ratings yet

- Ledge: SP SDDocument1 pageLedge: SP SDnikkoelbao96No ratings yet

- Plano de Comparacion A - 3.00 M: P Il S IT I IS TICDocument1 pagePlano de Comparacion A - 3.00 M: P Il S IT I IS TICRubenFloresNo ratings yet

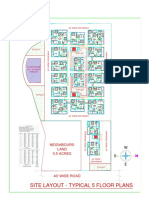

- Final Typical 5 Floors Site LayoutDocument1 pageFinal Typical 5 Floors Site LayoutBurela NaveenNo ratings yet

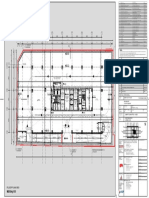

- GMP TD Ar FPL 11033Document1 pageGMP TD Ar FPL 11033Sammy NguyenNo ratings yet

- Kol Simcha QuatuorDocument3 pagesKol Simcha QuatuoradmNo ratings yet

- Agro Crops Peanut Crop ReportDocument3 pagesAgro Crops Peanut Crop ReportSrivatsan SeetharamanNo ratings yet

- Drawing Sanitary, PlumbingDocument1 pageDrawing Sanitary, Plumbingkhairil mohdNo ratings yet

- Notes: Subject-Building Construction Topic - Wall CladdingDocument1 pageNotes: Subject-Building Construction Topic - Wall CladdingPiyush SinglaNo ratings yet

- Sprinkler Elec SolarDocument1 pageSprinkler Elec SolarKomal amleshNo ratings yet

- SPB Acienda Mechanical Plans - For TenderDocument13 pagesSPB Acienda Mechanical Plans - For TenderRyan DizonNo ratings yet

- Formobile 24Document1 pageFormobile 24gaabriel.silva2001No ratings yet

- 05 Cerco PerimetricoDocument1 page05 Cerco PerimetricoEFRAIN JAUREGUI LLANCONo ratings yet

- Sao-Atan House FencingDocument2 pagesSao-Atan House FencingJun Michael Artates VelascoNo ratings yet

- Air 1Document1 pageAir 1saipNo ratings yet

- Gas Option 2 210504Document1 pageGas Option 2 210504Md ShahinNo ratings yet

- Notation Plan & Door Schedule of Main Kitchen-R00-O02m06-Acc-Xx-Xx-Sdw-Ar-12021Document1 pageNotation Plan & Door Schedule of Main Kitchen-R00-O02m06-Acc-Xx-Xx-Sdw-Ar-12021SUNDAR TNo ratings yet

- Alliance SLD-06 Final 2022-ModelDocument1 pageAlliance SLD-06 Final 2022-ModelskclengineeringNo ratings yet

- II. Andante AmorosoDocument4 pagesII. Andante AmorosoSarah DaisyNo ratings yet

- Septic Vault Cover Plan: LegendDocument1 pageSeptic Vault Cover Plan: LegendLizabeth Pillos MarquezNo ratings yet

- Basement Floor Layout Model PDFDocument1 pageBasement Floor Layout Model PDFGamanpreet AhujaNo ratings yet

- Layout Floor Finish LT 7Document1 pageLayout Floor Finish LT 7Tri Wulandari GintingNo ratings yet

- Sax Alto IIDocument1 pageSax Alto IIAngelo PalmisanoNo ratings yet

- Gallatin - FLR PPP Drwgs (Rev 11-16-22) CiDocument9 pagesGallatin - FLR PPP Drwgs (Rev 11-16-22) CiFelix ruiz RuizNo ratings yet

- FL, CLB, Pno 1Document1 pageFL, CLB, Pno 1Alvaro ClavelNo ratings yet

- Bachelor View KitchenDocument1 pageBachelor View KitchenAmrish TyagiNo ratings yet

- VH Ad 2 VHHH Aoc 4 (Typec)Document1 pageVH Ad 2 VHHH Aoc 4 (Typec)Loïc GIROUDNo ratings yet

- Apéndice C - Cortocircuito Trifásico Año 2019Document25 pagesApéndice C - Cortocircuito Trifásico Año 2019Daniel ValerioNo ratings yet

- As Built Drawing 15-07-2017 ModelDocument1 pageAs Built Drawing 15-07-2017 ModelShrutie PatilNo ratings yet

- ModifieddavidDocument1 pageModifieddavidSangmo landryNo ratings yet

- Feeling Good: AndanteDocument2 pagesFeeling Good: AndanteManuel OchoaNo ratings yet

- Water Tank Support Plan: Working DrawingDocument1 pageWater Tank Support Plan: Working DrawingKaruvapandiyanNo ratings yet

- Horetzky29 A4Document1 pageHoretzky29 A4infobitsNo ratings yet

- 00 - FA SchematicDocument1 page00 - FA SchematicManhNo ratings yet

- Arq-58 Obras Exteriores Patio CentralDocument1 pageArq-58 Obras Exteriores Patio CentraljogcNo ratings yet

- Circuito D246a Pap - 29 PDFDocument1 pageCircuito D246a Pap - 29 PDFNuno Castro PereiraNo ratings yet

- GroundfloorDocument1 pageGroundfloorKatherine ZoeNo ratings yet

- The 6 Shuffle Grooves That You Should KnowDocument2 pagesThe 6 Shuffle Grooves That You Should KnowpocerilloNo ratings yet

- The 6 Shuffle Grooves That You Should KnowDocument2 pagesThe 6 Shuffle Grooves That You Should KnowpocerilloNo ratings yet

- Proy. Restaurante IGDocument2 pagesProy. Restaurante IGIsrael RmzNo ratings yet

- G3606 Schematic RENR5966RENR5966-07 - SISDocument2 pagesG3606 Schematic RENR5966RENR5966-07 - SISsergioNo ratings yet

- DrumsetDocument2 pagesDrumsetGabriel Kyle DavidNo ratings yet

- 3 BHKDocument1 page3 BHKPratik ShindeNo ratings yet

- Anexo 17. DetallesDocument1 pageAnexo 17. DetallesMario Alexander Sinisterra BautistaNo ratings yet

- Plano Permisero - Petroil (2) - ModelDocument1 pagePlano Permisero - Petroil (2) - ModelEduardo GomezNo ratings yet

- Offshore Supply Vessel: ProfileDocument1 pageOffshore Supply Vessel: ProfileAswin Sathian100% (1)

- Amadeus - Level 01 - Kitchen LayoutDocument1 pageAmadeus - Level 01 - Kitchen LayoutJames prajwal.RNo ratings yet

- Denah Plumbing Pacuan Kuda PDFDocument4 pagesDenah Plumbing Pacuan Kuda PDFbenediktusNo ratings yet

- Level 3 Repair: 8-1. Components LayoutDocument50 pagesLevel 3 Repair: 8-1. Components LayoutAdriano Andreo JandreNo ratings yet

- Bautista - A4Document1 pageBautista - A4Wilfredo MinaNo ratings yet

- IS - 8110 - 2000 - Well Screens and Slotted Pipes SpecificationDocument19 pagesIS - 8110 - 2000 - Well Screens and Slotted Pipes SpecificationInsta PumpsNo ratings yet

- Apex Piping Catalogue 2020Document36 pagesApex Piping Catalogue 2020Insta PumpsNo ratings yet

- Bungoma Structure PlanDocument1 pageBungoma Structure PlanInsta PumpsNo ratings yet

- Nairobi Integarted Urban Development Master PlanDocument692 pagesNairobi Integarted Urban Development Master PlanInsta PumpsNo ratings yet

- Tononoka. Company Profile Product CatalogueDocument32 pagesTononoka. Company Profile Product CatalogueInsta PumpsNo ratings yet

- B&S Gauge Millimeters Inches: The Contenti Company, Pawtucket, RI 02861 USADocument1 pageB&S Gauge Millimeters Inches: The Contenti Company, Pawtucket, RI 02861 USAInsta PumpsNo ratings yet

- Min Max Slopes For Storm SewersDocument1 pageMin Max Slopes For Storm SewersInsta PumpsNo ratings yet

- Pillowcase Dress InstructionsDocument4 pagesPillowcase Dress InstructionsClaude ThomasNo ratings yet

- Filter Drum Cloth Replacement 40-2345Document6 pagesFilter Drum Cloth Replacement 40-2345Saadat BilalNo ratings yet

- Sports FestDocument9 pagesSports Festcris gerard trinidadNo ratings yet

- Delivery Order: Borwita Citra Prima, PT - Divisi 01 BDG0094101Document2 pagesDelivery Order: Borwita Citra Prima, PT - Divisi 01 BDG0094101Fiastuti KartikaNo ratings yet

- CD Changer To Head-Unit Compatibility Chart 2010v2Document4 pagesCD Changer To Head-Unit Compatibility Chart 2010v2rob.james14192No ratings yet

- In The Bedroom (Di Kamar Tidur) : English For Elementary School Second GradeDocument2 pagesIn The Bedroom (Di Kamar Tidur) : English For Elementary School Second GradeShiinta P AnggrainiNo ratings yet

- Lesson N°10 Clothes - Affirmative SentencesDocument3 pagesLesson N°10 Clothes - Affirmative SentencesTuxikito Visdey Mas TlvNo ratings yet

- Lecture No. 15-16 NewDocument23 pagesLecture No. 15-16 NewReaderNo ratings yet

- Transport TopicsDocument27 pagesTransport TopicsaskarqqqqNo ratings yet

- Lace Detail Ankle Boots With Track Soles - PULL&BEARDocument1 pageLace Detail Ankle Boots With Track Soles - PULL&BEARNini MatkavaNo ratings yet

- PriceListHirePurchase Normal 1Document55 pagesPriceListHirePurchase Normal 1Muhammad HajiNo ratings yet

- TransfersDocument5 pagesTransfersAmarjitSingh BhatiaNo ratings yet

- Fairy Skin Sunscreen - Google SearchDocument1 pageFairy Skin Sunscreen - Google SearchSHARON GABRIELNo ratings yet

- 07-Pipe FittingsDocument1 page07-Pipe Fittingssopan kharcheNo ratings yet

- Compro Logpin - 2023Document10 pagesCompro Logpin - 2023Yusuf Adi PuteraNo ratings yet

- ResumeDocument4 pagesResumeapi-310894929No ratings yet

- Customer List tIRUPURDocument3 pagesCustomer List tIRUPURmuthamilselvaneee43No ratings yet

- Report Daily Dan Monthly SPG NaturDocument62 pagesReport Daily Dan Monthly SPG NaturZidu JombangNo ratings yet

- Sony Muteki 7 2 Channel Surround Sound System ManualDocument3 pagesSony Muteki 7 2 Channel Surround Sound System ManualMarco Romasanta100% (2)

- 1 All India Depots Active Ready Furniture MRPDocument11 pages1 All India Depots Active Ready Furniture MRPwullendulaganagabhavaniNo ratings yet

- CK4 PersonaDocument24 pagesCK4 PersonaMendi GorencaNo ratings yet

- VocabularyDocument2 pagesVocabularyElenNo ratings yet