Professional Documents

Culture Documents

Yokogawa UT35-UT32A - Part4

Uploaded by

Fajar PrawiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yokogawa UT35-UT32A - Part4

Uploaded by

Fajar PrawiroCopyright:

Available Formats

6HWWLQ 7DU HW 6HWSRLQW 63 5.

6ZLWFKLQ EHWZHHQ 872 DQG 0 1

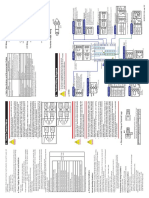

Operation UT35A, UT32A

OFF blinks. AUTO and MAN switching can be performed using any of the following: (1) A/M key,

Guide Digital Indicating Controller (Panel Mounting Type)

Operation Guide (2) Contact input, (3) Communication, and (4) User function key.

nal io

Funct ent Press the Up/Down arrow keys to display the required setpoint. The gure below shows a direct operation using the A/M key.

Operations cem

Enhan When AUTO and MAN switching function is assigned to the contact input, and the

6. contact input is ON, the switching by key operation cannot be performed.

«Standard Code Model» For details, see User’s Manual (IM 05P01D31-01EN).

Blinks during the change.

This operation guide describes key entries for operating the UT35A and UT32A.

Although the display of UT35A is used in this guide, UT32A can be operated similarly. The setting range is 1 to 4 (represent group numbers) or R.

For operations using external contact inputs, see “DI” of “6. Terminal Wiring Diagrams” To perform auto-tuning for the PID of group 1, set the parameter AT to 1.

in “Installation and Wiring.” 1. Show the SP Display (Operation Display).

To quit the auto-tuning, set the parameter to OFF.

If you cannot remember how to carry out an operation during setting, press the (This is an example of setting the target

MAN lamp is lit in MAN mode.

DISPLAY key or DISP key once. This brings you to the display (Operation Display) that setpoint to 150.0).

appears at power-on. Press the SET/ENTER key.

The scrolling guide is displayed on PV display in the Parameter Setting Display.

This guide can be turned on/off with the Fn key. 2. Press the SET/ENTER key to start the

last digit of the setpoint blinking. 7. The setpoint has been registered.

For details of the each function, refer to the electronic manual. Manuals can be This starts auto-tuning.

downloaded or viewed at the following URL. Blinking allows you to change the value.

The limiter can be set to the output during auto-tuning. Each time you press the key,

http://www.yokogawa.com/ns/ut/im/ For details, see User’s Manual (IM 05P01D31-01EN).

To set the setpoint, use the AUTO and MAN is switched alternately.

3.

Left/Right arrow keys to move During auto-tuning,

RQWHQWV between digits and the Up/Down • The MAN lamp blinks. When AUTO is switched into MAN, the control output value in AUTO mode is held.

arrow keys to increase and • The OUT symbol appears. The controller can be operated manually from the hold value.

1. Monitoring-purpose Operation Displays Available during Operation decrease the value. • The output values at 100.0% and If the manual preset output is set (MPON parameter ≠ OFF), the controller can be

2. Setting Target Setpoint (SP) 4. When the required value is displayed, 0% appear alternately. operated manually from the arbitrary output value (MPO1 to MPO5 parameters).

3. Performing/Canceling Auto-tuning press the SET/ENTER key to register

4. Selecting Target Setpoint Numbers (SPNO.) the setpoint. 8.

5. Switching between AUTO and MAN 6ZLWFKLQ EHWZHHQ 581 DQG 6723

6. Switching between RUN and STOP

7. Switching between REM (Remote) and LCL (Local) RUN and STOP switching can be performed using any of the following: (1) Contact

The MAN lamp goes off, which means that

8. Manipulating Control Output in Manual Mode input, (2) Parameter, (3) Communication, and (4) User function key.

the auto-tuning completed normally.

9. Troubleshooting The following shows an example of switching using the contact input.

(The switching function is assigned to DI2 contact for the factory default.)

0RQLWRULQ SXUSRVH 2SHUDWLRQ 'LVSOD V YDLODEOH GXULQ 2SHUDWLRQ For details of other switching methods and the display appearing when the operation

is started, see User’s Manual (IM 05P01D31-01EN).

■ 2SHUDWLRQ 'LVSOD 6ZLWFKLQ 'LD UDP IRU 6WDQGDUG DQG 3RVL When the controller is stopped, input and outputs are as follows:

3HUIRUPLQ DQFHOLQ XWR WXQLQ PV input Displays the PV value.

WLRQ 3URSRUWLRQDO 7 SHV 6HOHFWLQ 7DU HW 6HWSRLQW 1XPEHUV 6312

Auto-tuning should be performed after setting a target setpoint. Control output Displays the preset output value.

63 'LVSOD The preset output value is set for each PID group.

Displays the measured input value on PV display. Make sure that the controller is in automatic mode (AUTO) and in run mode (RUN) The following operating procedure shows an example of changing the target setpoint Alarm output H S F H I P

Displays the target setpoint (SP) on Setpoint display (SP can be changed). before auto-tuning. For setting to AUTO, see “5. Switching between AUTO and number (SPNO.) from 1 to 2. Each SP has its PID group. The PID group set for the

287 'LVSOD MAN,” and for setting to RUN, see “6. Switching between RUN and STOP.” parameter PIDN (PID number selection) is used.

'LVSOD LQ 6723 PRGH

Displays the measured input value on PV display. If the setpoint is known in advance or auto-tuning does not nd any appropriate PID Show the Operation Display.

Displays the control output value (OUT) on Setpoint display (OUT can be changed

1. “STOP” is displayed on Symbol display and "preset output value" is displayed on

constants, set the PID manually. For setting the PID manually, see User’s Manual (IM

in manual mode). Data display.

05P01D31-01EN).

Displays the valve’s feedback input value (at 0 to 100% valve opening) in Position 2.

S S F Display in STOP mode

'R QRW SHUIRUP DXWR WXQLQ IRU WKH IROORZLQ SURFHVVHV Hold down the PARAMETER key or PARA key for OFF: Operation RUN

7XQH 3,' PDQXDOO 3 seconds to display MODE menu.

3URFHVVHV ZLWK IDVW UHVSRQVH VXFK DV IORZ UDWH FRQWURO DQG SUHV

CAUTION VXUH FRQWURO

3URFHVVHV ZKLFK GR QRW DOORZ WKH RXWSXW WR EH WXUQHG RQ DQG RII

HYHQ WHPSRUDULO ON: Operation STOP

Press the SET/ENTER key.

3URFHVVHV ZKLFK SURKLELW VHYHUH RXWSXW FKDQ HV DW FRQWURO

YDOYHV RU RWKHU DFWXDWRUV

3URFHVVHV LQ ZKLFK SURGXFW TXDOLW FDQ EH DGYHUVHO DIIHFWHG LI

3.

In cases where the communication is

SP Display OUT Display 39 YDOXHV IOXFWXDWH EH RQG WKHLU DOORZDEOH UDQ HV specified, the parameter R.L Preset output (PO)

(SP can be changed.) (OUT can be changed.) (REMOTE/LOCAL switch) is displayed. Valve opening (0-100%) for

Position proportional type

Press the Down arrow key until the parameter SPNO.

■ 2SHUDWLRQ 'LVSOD 6ZLWFKLQ 'LD UDP IRU HDWLQ RROLQ 7 SH 1. Show the Operation Display. appears. STOP lamp is lit.

63 'LVSOD

Displays the measured input value on PV display. 4.

Displays the target setpoint (SP) on Setpoint display (SP can be changed). 2. The parameter SPNO. (SP number selection)

287 'LVSOD 'LVSOD LQ 6723 PRGH LQ HDWLQ FRROLQ FRQWURO

is displayed.

Displays the measured input value on PV display. “Cooling-side preset output value” is displayed on the left side of the “ST” symbol,

Hold down the PARAMETER key or PARA key for

Displays the control output values (C.H.) of heating and cooling sides on Setpoint and “Heating-side preset output value” is on the right side.

3 seconds to display MODE menu. Press the SET/ENTER key.

display (C.H. can be changed in manual mode).

Display in STOP mode

210

5. Change the setpoint using OFF: Operation RUN

the Up/Down arrow keys. 212

Press the SET/ENTER key. Blinks during the change.

3. Press the SET/ENTER key. 210

In cases where the communication is ON: Operation STOP

specified, the parameter R.L The setpoint has been registered. 212

(REMOTE/LOCAL switch) is displayed. 6.

SP Display Heating/cooling OUT Display Press the DISPLAY key or DISP key once

(SP can be changed.) (OUT can be changed.) to return to the Operation Display.

Press the Down arrow key until the parameter AT appears.

After showing the OUT Display, press the DISPLAY key or DISP key to show the fol- Heating-side preset output (PO)

lowing displays conditionally. For details, see User’s Manual (IM 05P01D31-01EN).

4. Cooling-side preset output (POc)

6WDQGDUG 3RVLWLRQ 3URSRUWLRQDO DQG HDWLQ RROLQ 7 SHV 7. STOP lamp is lit .

The parameter AT (auto-tuning switch) is displayed.

• SELECT Displays 1 to 5 (which appear when registered)

• Analog Input Display (display only) (factory default: non-display) SPNO. has been changed to 2.

• Position Proportional Computation Output Display (display only) (factory default: Press the SET/ENTER key.

non-display)

• PID Number Display (display only) (factory default: non-display)

Heater Break Alarm-1 Current Display (display only) (for heater break alarm option only)

Heater Break Alarm-2 Current Display (display only) (for heater break alarm option only) ,0 3 ' (1 SD H

6ZLWFKLQ EHWZHHQ 5(0 5HPRWH DQG / / /RFDO 0DQLSXODWLQ RQWURO 2XWSXW LQ 0DQXDO 0RGH ■ (UURUV DW 3RZHU 2Q

The errors shown below may occur in the fault diagnosis when the power is turned on. (For details of Setpoint display and input/output action when each error occurs, see User’s Manual (IM

Remote and local switching can be performed using any of the following: 05P01D31-01EN).)

(1) Contact input, (2) Parameter, (3) Communication, and (4) User function key. 39 GLVSOD

6HWSRLQW GLVSOD 6WDWXV LQGLFDWRU 3DUDPHWHU WKDW GLVSOD V HUURU

2SHUDWLRQ (UURU GHVFULSWLRQ DXVH DQG GLD QRVLV 5HPHG

2SHUDWLRQ 'LVSOD 2SHUDWLRQ 'LVSOD GHWDLOV

/ / /RFDO In manual mode, control output is manipulated by operating the keys (the value is 'LVSOD

Control is performed using the target setpoint set on the controller. changed using the Up/Down arrow keys, then outputted as it is). F II F II Faulty MCU RAM / MCU ROM MCU RAM / MCU ROM are failed.

Even if the SET/ENTER key is not pressed, the control output value changes ac- Contact us for repair.

5(0 5HPRWH cording to the displayed value. SYS - - - - - 6 HP H 6 HP F SH

Contact us for repair.

Control is performed using a setpoint via communication for the target setpoint. The In stop mode (when the STOP lamp is lit), control output cannot be manipulated.

following shows an example of switching from local to remote using the parameter. PAR 0004 User (parameter) default value User parameter is corrupted.

(for user default value error

(Only in cases where the communication is speci ed.) H Initialized to factory default value.

only) Check and recon gure the initialized

For details of other switching methods, see User’s Manual (IM 05P01D31-01EN). Up arrow key: increases control output.

PAR 0010 setting parameters. Error indication is

Down arrow key: decreases control output. Setup parameter (PA.ER) 6H S S PH H F SH

• The PID group for the local SP number is used as PID in remote mode. (for setup parameter error 6H S S PH H H H H H HS H H

Initialized to user default value.

ERR only) again.

PAR 0020 Operation parameter data is corrupted.

Operation parameter error

(for operation parameter error only) Initialized to user default value.

When the contact input is ON, operation cannot be performed using the parameter, F H FH I HP

communication, or key. When the contact input is OFF and the setting is switched SLOT 0015 Nonresponding hardware of hardware of extended function.

MAN lamp is lit. (0015: Error occurs to all

using the parameter, communication, or key, the last switching operation is per- Setup parameter (OP.ER) extended function (E1 to E4- Nonresponding communication between

hardware of E1 to E4-terminal Contact us for repair.

I PH terminal areas) hardware of extended function (E1 to E4-

In Position proportional control: areas.)

terminal areas).

Up arrow key; opens the valve.

Rightmost decimal point Initialized to calibrated default value because

Down arrow key; closes the valve. Calibration value error

Normal on PV display blinks. of corrupted factory default value.

Output; only while pressing a key. Normal indication Setup parameter (PA.ER)

1. Show the Operation Display. F Rightmost decimal point Contact us for repair.

OUT; valve opening (0-100%) Faulty FRAM Data writing (storing) to FRAM is impossible.

on Symbol display blinks.

Output manipulation in Position proportional control Normal Ladder program is corrupted.

2. Normal indication LADDER lamp blinks Setup parameter (LA.ER) Corrupted ladder program Download the ladder program again.

is not restricted from output limiters (OH, OL). F Operates without ladder program.

Normal 0.000 00000

Hold down the PARAMETER key or PARA key 0DQXDO RSHUDWLRQ LQ HDWLQ FRROLQ FRQWURO (Decimal point on the left of Setup parameter (OP.ER) User pro le error User pro le is corrupted. Download the user pro le again.

F

for 3 seconds to display MODE menu. the Symbol display blinks)

■ (UURUV GXULQ 2SHUDWLRQ

Heating-side control output The errors shown below may occur during operation. (For input/output action when each error occurs, see User’s Manual (IM 05P01D31-01EN).)

Press the SET/ENTER key. Symbol of heating side 39 GLVSOD

6HWSRLQW GLVSOD 6WDWXV LQGLFDWRU 3DUDPHWHU WKDW GLVSOD V

2SHUDWLRQ (UURU GHVFULSWLRQ DXVH DQG GLD QRVLV 5HPHG

Cooling-side control output 2SHUDWLRQ 'LVSOD 2SHUDWLRQ 'LVSOD HUURU GHWDLOV

'LVSOD

3. Symbol of cooling side Analog input terminal ADC error

AD.ERR Normal indication (Note) Setup parameter (AD1.E) Analog input terminal AD value error

The parameter R.L (REMOTE/LOCAL switch) •PV input Contact us for repair.

Target setpoint (SP) number

is displayed. RJC.E

(Displays RJC. Normal indication (Note) Universal input terminal RJC error Contact us for repair.

Setup parameter (AD1.E) Universal input terminal RJC error

Up arrow key: concurrently decreases cooling-side control output and increases E and PV •PV input Set the parameter RJC to OFF to erase

heating-side control output. alternately.) H F

Press the SET/ENTER key.

Down arrow key: concurrently increases cooling-side control output and decreases Check wiring and sensor.

Analog input terminal burnout error

Setup parameter (AD1.E) Analog input terminal sensor burnout Error indication is erased in normal

4. Change the operation mode using heating-side control output. •PV input

SH

the Up/Down arrow keys. (Either none of the heating-side and cooling-side outputs are presented, or both of B.OUT Normal indication (Note) Check wiring and sensor of connected

Blinks during the change. them are presented according to the dead band setting.) analog input terminals.

Setup parameter (PV1.E) PV input burnout error Burnout of analog input connected to PV

Error indication is erased in normal

Actual output (%) Actual output (%)

SH

100 100

Press the SET/ENTER key. PV input over-scale PV input is out of -5 to 105%. Also occurs

Cooling-side Heating-side OVER Check analog input value or ladder

Normal indication Setup parameter (PV1.E) PV input under-scale when the data out of range which is the

manipulated output manipulated output program.

5. Cooling-side Heating-side -OVER (PV values out of -5 to 105%) H F F H S

manipulated output manipulated output

Check wiring of feedback input resistor/

Normal Feedback input resistor/current

The REM lamp is lit. OUT - - - - - Setup parameter (AD2.E) Feedback input burnout current. Error indication is erased in

F burnout

P SH

-12.4 0 12.4 -12.4 0 12.4

Floating point computation for ladder

Control computation output Control computation output Ladder calculation over ow Check the ladder program.

calculation is in nite.

DB=24.8 Dead band: Operation parameter DB DB= -24.8 Computation does not end within the Change the control period or reduce

Load factor over 100% control period (load factor is 100% or the number of steps for the ladder

Manipulated output change Manipulated output change more). program.

when a dead band is positive (+) when a dead band is negative (-) Normal indication LADDER lamp blinks Setup parameter (LA.ER)

Load factor over 200% Computation does not end within the control Change the control period or reduce the

Normal

(Forced end) period (load factor is 200% or more). number of steps for the ladder program.

F

Download the ladder program again. If

Ladder program error Ladder program is corrupted. the error indication is still not erased,

7URXEOHVKRRWLQ there is a fault. Contact us for repair.

0.000 00000 Check that the target devices are

(Decimal point on the left of Setup parameter (OP.ER) Peer-to-peer communication error Peer-to-peer communication error F HF H F HF

■ Troubleshooting Flow the Symbol display blinks) Recovery at normal receipt.

■ 5HPHGLHV LI 3RZHU )DLOXUH 2FFXUV Auto-tuning does not end even when 24 Check the process. Hold down any key to

AT.E Normal indication Setup parameter (PV1.E) Auto-tuning time-out

If the Operation Display does not appear after turning on the controller’s power, check the procedures in the following owchart. GXULQ 2SHUDWLRQV hours have elapsed after the start of tuning. H H H H F

If a problem appears to be complicated, contact our sales representatives. Fully-closed valve position is equal to or larger

• Instantaneous power failure within 20 ms. Valve position automatic Check wiring and valve. Hold down any

VAT.E Normal indication Setup parameter (AD2.E) than the fully-open valve position after automatic

Is the controller adjustment error H H H HH F

A power failure is not detected. Normal valve position adjustment is performed.

defective? Framing parity error

SH F H

Yes Buffer over ow

• Power failure for less than about 5 seconds, 0.000 00000 Inter-character time-out Check the communication parameters.

Normal Communication error

No Key No No No or for about 5 seconds or more. (Decimal point on the left of Setup parameter (OP.ER) Checksum error (PC link communication with Recovery at normal receipt.

Completely Display I/O signal F (RS-485 communication)

operation Communication Affects the "settings" and "operation sta- the Symbol display blinks) checksum) Hold down any key to stop blinking.

inactive? failure? failure? failure? failure? CRC check error (Modbus/RTU)

* tus." LRC check error (Modbus/ASCII)

Yes Yes Yes Yes Yes

F o r d e ta ils , s e e U s er ' s Ma nu a l ( I M

05P01D31-01EN). Inconsistence of loop between coordinated Check the communication parameters.

Check wiring of the Check the key lock Turn off power, and Check the I/O specifications Check the specifications master and slaves Recovery at normal receipt. Change from remote

Normal 0.000 00000 Communication error to local mode to stop blinking.

power terminals. setting. then turn it on again. of the controller. of the controller. (Decimal point on the left of Setup parameter (OP.ER)

F (coordinated operation) When the mode is changed from remote to

the Symbol display blinks) Communication from coordinated master is local, SP tracking does not work even if it is

H SH I HF set to ON.

Check the Check the No With

supply voltage. specifications and polarity communi- Write down the settings of parameters for a 0.000 00000

of connected devices . cation? Normal

(Decimal point on the left of Setup parameter (OP.ER) User pro le error User pro le is corrupted. Download the user pro le again.

Yes repair request. F

the Symbol display blinks)

Normal Rightmost decimal point on

No Normal indication Setup parameter (PA.ER) Faulty FRAM Writing (storing) data to FRAM is impossible. Faulty. Contact us for repair.

No communication Check the communication- F Symbol display blinks.

Normal? capability related parameters. Faulty MCU / DCU

No Is the Unde ned Unde ned MCU / DCU is corrupted. Faulty. Contact us for repair.

Yes (ROM / RAM error, corrupted)

key locked?

Yes Note: When an error occurs in input shown in Analog input display (Operation display), Setpoint display shows the same symbol as the PV display.

Correct the error(s). Check the

communication wiring.

No * The LCD (a liquid crystal display) is used for

Correct? a display portion of this product.

The LCD has a characteristic that the display action Check the specifications

Yes of communication

Cancel the setting. becomes late at the low temperature. devices.

Additionally, the luminance and contrast degradation

are caused due to aged deterioration.

Contact us for repair. Problem solved. However, the control function is not affected. ,0 3 ' (1 SD H

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HW Differences Between Apg40 Apg43Document7 pagesHW Differences Between Apg40 Apg43sanjNo ratings yet

- Yokogawa UT35-UT32A - Part3Document2 pagesYokogawa UT35-UT32A - Part3Fajar PrawiroNo ratings yet

- Yokogawa UT35-UT32A - Part6Document2 pagesYokogawa UT35-UT32A - Part6Fajar PrawiroNo ratings yet

- Yokogawa UT35-UT32A - Part1Document2 pagesYokogawa UT35-UT32A - Part1Fajar PrawiroNo ratings yet

- FgmoDocument5 pagesFgmoSagar ThakerNo ratings yet

- Yokogawa UT35-UT32A - Part2Document2 pagesYokogawa UT35-UT32A - Part2Fajar PrawiroNo ratings yet

- Template HmteDocument44 pagesTemplate HmteFajar PrawiroNo ratings yet

- Etap12.6 New Feature ENG LowDocument1 pageEtap12.6 New Feature ENG LowFajar PrawiroNo ratings yet

- S Two-Control: 0.5 3 SS C Ontrol: 0.5Document2 pagesS Two-Control: 0.5 3 SS C Ontrol: 0.5Fajar PrawiroNo ratings yet

- Math Function C++Document1 pageMath Function C++Fajar PrawiroNo ratings yet

- Tambah/Insert Data: QrlabelDocument1 pageTambah/Insert Data: QrlabelFajar PrawiroNo ratings yet

- Generator StartupDocument2 pagesGenerator StartupFajar PrawiroNo ratings yet

- SymbolsDocument2 pagesSymbolsSiva RamNo ratings yet

- Electrical SymbolDocument1 pageElectrical Symbol5223043305No ratings yet

- SiskomDocument2 pagesSiskomFajar PrawiroNo ratings yet

- Rafal Lukawiecki Strategic Consultant Project Botticelli LTDDocument52 pagesRafal Lukawiecki Strategic Consultant Project Botticelli LTDPham TrungNo ratings yet

- ADV200 - Flying Shear For Roll Forming Machines Application: Instruction ManualDocument30 pagesADV200 - Flying Shear For Roll Forming Machines Application: Instruction ManualVladimirAgeevNo ratings yet

- Qnap Turbo Nas User Manual v4.0 EngDocument750 pagesQnap Turbo Nas User Manual v4.0 EngOrthogonal_FreqzNo ratings yet

- 1.1.6.a Componentidentification DigitalDocument7 pages1.1.6.a Componentidentification DigitalomNo ratings yet

- Hardware User'S Guide: Low-Power HDMI 1.4a TransmitterDocument46 pagesHardware User'S Guide: Low-Power HDMI 1.4a Transmitterรัศมีเจริญชัย ธีรเมธNo ratings yet

- 3G Huawei Capacity Optimization ProcessDocument45 pages3G Huawei Capacity Optimization ProcessAndres Gaytan100% (2)

- Design and Fabrication of A Password Protected Vehicle Security and Performance Monitoring SystemDocument6 pagesDesign and Fabrication of A Password Protected Vehicle Security and Performance Monitoring SystemRaheel FareedNo ratings yet

- Unisoc Latam: Logel User GuideDocument207 pagesUnisoc Latam: Logel User GuideANA CAROLINA VARGAS LOPEZNo ratings yet

- Vps SoftwareDocument46 pagesVps SoftwareHarmawan FebriantoNo ratings yet

- ANPR Access HD - Datasheet - EN - v5.0Document2 pagesANPR Access HD - Datasheet - EN - v5.0José Daniel Hernández SanchezNo ratings yet

- Network +Document19 pagesNetwork +Tolea TolNo ratings yet

- Microsoft Security Response Center (MSRC) Progress Report 2013Document27 pagesMicrosoft Security Response Center (MSRC) Progress Report 2013MSFTSIRNo ratings yet

- Mark Carlo Sanorjo Bscpe - 3B: Review Questions Fill in The BlanksDocument5 pagesMark Carlo Sanorjo Bscpe - 3B: Review Questions Fill in The Blanksmark carlo SanorjoNo ratings yet

- Hot PotatoesDocument4 pagesHot Potatoesapi-233558894100% (1)

- DTMF AsmDocument38 pagesDTMF AsmvancheNo ratings yet

- Cnav 3050Document2 pagesCnav 3050redvalorNo ratings yet

- Remedy For GPS Rollover in 2022: GP-80/90/150, GP-1650/1850, SC-50/110 and OthersDocument3 pagesRemedy For GPS Rollover in 2022: GP-80/90/150, GP-1650/1850, SC-50/110 and OthersVikas SinghNo ratings yet

- Business Analyst Job DescriptionDocument3 pagesBusiness Analyst Job DescriptionsoftpoolsNo ratings yet

- Commissioning ASHRAE Guideline 36 Sequences for VAV Air HandlersDocument30 pagesCommissioning ASHRAE Guideline 36 Sequences for VAV Air HandlersAouina ChokriNo ratings yet

- Data Compression (RCS087:) Dictionary-Based Coding Techniques-Static CodingDocument9 pagesData Compression (RCS087:) Dictionary-Based Coding Techniques-Static CodingFlask TutorialNo ratings yet

- Lebe0007-07 1Document550 pagesLebe0007-07 1Manu100% (1)

- ZMP - 2965288 - en - WS 2B ZB WHDocument3 pagesZMP - 2965288 - en - WS 2B ZB WHPonechor HomeNo ratings yet

- Syllabus - MAJDocument3 pagesSyllabus - MAJChristine RedondoNo ratings yet

- Terrain Analysis Package (TAP™) : TAP 7 Demo Quick Start GuideDocument18 pagesTerrain Analysis Package (TAP™) : TAP 7 Demo Quick Start Guidewalter.diaz.molinaNo ratings yet

- Architecting On AWS - Lab 3 - Creating A Virtual Private CloudDocument17 pagesArchitecting On AWS - Lab 3 - Creating A Virtual Private CloudDeysi RinconNo ratings yet

- Q1) What Is The % of BA in Team Size and Project Duration?Document13 pagesQ1) What Is The % of BA in Team Size and Project Duration?SURAJ RATHODNo ratings yet

- Open Edge Chassis OCP Contribution v1.4 PDFDocument37 pagesOpen Edge Chassis OCP Contribution v1.4 PDFVasanth SNo ratings yet

- Cloud ComputingDocument3 pagesCloud ComputingVidushi PandeyNo ratings yet

- Sending EmailDocument10 pagesSending EmailyprajuNo ratings yet