Professional Documents

Culture Documents

Wear Resistant Steel: Product Description

Wear Resistant Steel: Product Description

Uploaded by

Filipe CordeiroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wear Resistant Steel: Product Description

Wear Resistant Steel: Product Description

Uploaded by

Filipe CordeiroCopyright:

Available Formats

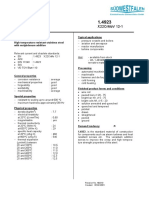

400

Wear resistant steel

1

Material data sheet, Edition April 2016

DILLIDUR 400 is a wear resistant steel with a nominal hardness of 400 HBW in delivery condition ex works.

DILLIDUR 400 is preferentially used by the customers where elevated resistance to wear is required together

with good workability and especially good weldability.

Examples of application: earth moving and loading machines, dredgers, skip cars, conveying plants, trucks,

cutting edges, knives and breakers, waste elimination and recycling plants.

Product description

Range of application

DILLIDUR 400 can be delivered in thicknesses from 6 mm (¼ in.)2 to 150 mm (6 in.)2, according to the

dimensional program. Other dimensions may be possible on request.

Chemical composition

For the ladle analysis, the following limiting values in % are applicable:

C Si Mn P S

0.20 0.70 1.80 0.025 0.010

Depending on thickness, the following alloying elements may be used singly or in combination:

Mo Ni Cu Cr V Nb B

0.50 0.80 0.30 1.50 0.08 0.05 0.005

The steel is fully killed and fine grain treated.

1

The current version of this material data sheet can be also found on http://www.dillinger.de.

2

The approximately converted values in brackets are for information only.

400 a product brand of Dillinger

1/6

Indicative values for the carbon equivalent:

Plate thickness [mm] 10 25 40 80 120

CEVa 0.45 0.49 0.56 0.63 0.67

CETb 0.30 0.32 0.35 0.36 0.37

a

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

b

CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40

Delivery condition

Controlled water quenched.

Mechanical properties in the delivery condition

Hardness

Brinell surface hardness at room temperature: 370 - 430 HBW

Tensile testing on transverse specimens at room temperature (indicative values for 20 mm

plate thickness)

Tensile strength: 1 200 MPa (175 ksi)3

Yield point: 800 MPa (116 ksi)3

Elongation: 12 % (Lo = 5.65So)

In spite of their high tensile properties, DILLIDUR steels are not intended for safety relevant components. For

this purpose high strength steels DILLIMAX are available.

Charpy-V impact test on longitudinal specimens (indicative values for 20 mm plate thickness)

Charpy impact energy: 30 J at -40 °C (-40 °F)3

Testing

Brinell surface hardness tested once per heat and 40 t.

3

The approximately converted values in brackets are for information only.

400 a product brand of Dillinger

2/6

Identification of plates

Unless otherwise agreed the marking is carried out via steel stamps with at least the following information:

steel grade (DILLIDUR 400)

heat number

number of mother plate and individual plate

the manufacturer’s symbol

inspector’s sign

Processing

The entire processing and application techniques are of fundamental importance to the reliability of the

products made from this steel. The user should ensure that his design, construction and processing methods are

aligned with the material, correspond to the state of the art that the fabricator has to comply with and are

suitable for the intended use. The customer is responsible for the selection of the material. The

recommendations in accordance with EN 1011-2 (Welding) and CEN/TR 10347 (Forming) as well as

recommendations regarding job safety in accordance with national rules should be observed while considering

the higher strength and hardenability.

Cold forming

DILLIDUR 400 can be cold formed by bending in spite of its high hardness and strength. It should be paid

attention to the fact that with increasing yield strength, the required forces for the forming operation also grow,

even if the plate thickness remains unchanged. The spring-back also increases. In order to avoid the risk of

cracking from the edges, flame cut or sheared edges should be ground in the area that is to be cold formed. It is

also advisable to round the plate edge slightly on the outside of the bend coming under tension stress during

bending.

During the processing, the necessary safety measures have to be taken, so that nobody will be exposed to a

danger by a possible fracture of the work piece during the forming process.

The following geometries can usually be achieved by cold forming without the formation of surface defects

(where t is the plate thickness):

Minimum bending radius Minimum die opening

Transverse direction 3t 10 t

Longitudinal direction 4t 12 t

400 a product brand of Dillinger

3/6

Hot forming

DILLIDUR 400 obtains its hardness by accelerated cooling from the austenitizing temperature. After hot

forming, the same hardness can only be obtained if the steel is quenched again after forming. It is to be

expected that the hardness achieved through such a treatment differs from that measured in the delivery

condition, because the cooling capacity available during plate manufacturing differs from that available at the

fabricator’s works.

The steel may be heated to about 250 °C (482 °F) without a substantial drop in hardness.

Flame cutting and welding

For flame cutting, the following minimum temperatures should be observed: 75 °C (170 °F) for plate

thicknesses from 30 up to 50 mm, 100 °C (212 °F) for plate thicknesses from 50 up to 100 mm and 150 °C

(302 °F) for thicker plates.

For manual arc welding, basic coated rods having a very low residual moisture should be used (if necessary,

drying according to the instruction of the manufacturer should be carried out).

Additionally the following recommendations are to be considered:

Up to a thickness of 20 mm the steel can normally be butt welded without preheating.

For more information about preheating of DILLIDUR 400, please refer to our technical information “THE

CONCEPT TO COMBAT WEAR AND TEAR – DILLIDUR”. A preheating over 250 °C (482 °F) must

however be avoided, because it could locally produce a hardness reduction in the base material (see

diagram).

Weld metals with low yield strength are preferred for tack, root and filler passes. If welds are exposed to

wear, only the final passes should be welded with consumables producing a hardness matching the parent

plate.

400 a product brand of Dillinger

4/6

Heat treatment

The following diagram shows the general changes in hardness or strength values in accordance with the heat

treatment temperature:

1 400

Indicative values for 20 mm plate

Hardness [HBW] resp. Rm and Rp0,2 [MPa]

thickness

1 200

Tensile strength

1 000

800

Yield strength

600

Nominal hardness in the delivery condition

400

Hardness

200

0

0 100 200 300 400 500 600

Tempering temperature [°C]

Machining

DILLIDUR 400 can be machined with HSS-drills and especially with HSS-Co-alloyed drills with a satisfactory

service life if the drill advance and cutting speed are correspondingly accommodated.

General technical delivery requirements

Unless otherwise agreed, the general technical requirements in accordance with EN 10021 are applicable.

Tolerances

Unless otherwise agreed, the tolerances are in accordance with EN 10029, with class A for thickness.

Surface quality

Unless otherwise agreed, the provisions in accordance with EN 10163-2, class A2 are applicable.

400 a product brand of Dillinger

5/6

General note

If special requirements, which are not covered in this material data sheet, are to be met by the steel due to its

intended use or processing, these requirements are to be agreed before placing the order.

The information in this data sheet is a product description. This data sheet is updated at irregular intervals. The

current version is relevant. The latest version is available from the mill or as download at www.dillinger.de.

For more information about application and processing of DILLIDUR 400, please refer to our technical

information “THE CONCEPT TO COMBAT WEAR AND TEAR – DILLIDUR”.

Contact

For your local representative AG der Dillinger Hüttenwerke

please contact our coordination office in Dillingen: P.O. Box 1580

66748 Dillingen/Saar, Germany

Telephone: +49 6831 47 2223

Telefax: +49 6831 47 3350

e-mail: info@dillinger.biz

http://www.dillinger.de

or visit our website:

http://www.dillinger.de/dh/kontakt/weltweit/index.shtml.en Telephone: +49 6831 47 3461

Telefax: +49 6831 47 3089

400 a product brand of Dillinger

6/6

You might also like

- Mohini Vidya Sadhana and Siddhi - Cleaned Up and RestoredDocument155 pagesMohini Vidya Sadhana and Siddhi - Cleaned Up and Restoredtejvan96% (27)

- Welding PositionsDocument116 pagesWelding PositionsASAPASAPASAPNo ratings yet

- Compressor Performance TestDocument13 pagesCompressor Performance Testdhanu_aqua100% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Welding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) SketchDocument1 pageWelding Procedure Specification (As Per AWS D1.3) : With Preheat & PWHT (Auto/Semi-Auto/Manual/Machine) Sketchoomoom0% (1)

- CB31Document12 pagesCB31Călin FlorianNo ratings yet

- MFJHamRadioCatalog 2020 PDFDocument133 pagesMFJHamRadioCatalog 2020 PDFLeslie Citrome100% (1)

- Hardox 450 PDFDocument2 pagesHardox 450 PDFAriel Toño Vaquera ZeballosNo ratings yet

- 107 - WELDOX - 700 - UK - Data Sheet PDFDocument2 pages107 - WELDOX - 700 - UK - Data Sheet PDFDaniel CringusNo ratings yet

- Structural FabricationDocument46 pagesStructural FabricationmithileshNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- AISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDocument2 pagesAISI 1024 Steel, 1024 Stainless Steel, 1024 Alloy Structural SteelDhileepan Kumarasamy67% (3)

- Strategic MNGTDocument18 pagesStrategic MNGTAnonymous wxHXrmuNo ratings yet

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 pagesWear Resistant Steel: Material Data Sheet, Edition April 2016Juan LeonNo ratings yet

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Document6 pagesWear Resistant Steel: Material Data Sheet, Edition April 2016Zoltán PálfyNo ratings yet

- Dilli Dur 500Document4 pagesDilli Dur 500Fernando Alonso Troncos MendivesNo ratings yet

- Dillidur 400 V: Water Quenched Wear Resistant SteelDocument4 pagesDillidur 400 V: Water Quenched Wear Resistant SteelCristobal A. Mir G.No ratings yet

- XAR 450 (WB 710) EnglischDocument3 pagesXAR 450 (WB 710) EnglischMario MoranNo ratings yet

- Raex 500Document4 pagesRaex 500Daniel MauricioNo ratings yet

- Domex 420 MCDocument2 pagesDomex 420 MCHugo RodriguezNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelBo WangNo ratings yet

- EN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationDocument5 pagesEN19 Alloy Steel - EN19 Forging - EN19 Flat - Saaj Steel CorporationNaiduNo ratings yet

- En 19Document1 pageEn 19Parvee K Nakwal100% (1)

- X210CR12 GradeDocument3 pagesX210CR12 GradekartsoftNo ratings yet

- Specification: Si MN P S 0.08 0.56 1.02 0.013 0.010Document2 pagesSpecification: Si MN P S 0.08 0.56 1.02 0.013 0.010Jennylyn DañoNo ratings yet

- UntitledDocument2 pagesUntitledGyurmoooNo ratings yet

- 1.4028 enDocument2 pages1.4028 ensandeep acharNo ratings yet

- 77e5-B005 (Hydraulic Cylinder)Document4 pages77e5-B005 (Hydraulic Cylinder)Sandeep JoshiNo ratings yet

- 1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,LrregularDocument3 pages1.6580, DIN 30CrNiMo8, AISI 4340 Round Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Forging,1.6580, DIN 30CrNiMo8, AISI 4340 Sheet,1.6580, DIN 30CrNiMo8, AISI 4340 Coil,1.6580, DIN 30CrNiMo8, AISI 4340 Flat Bar,1.6580, DIN 30CrNiMo8, AISI 4340 Pipe,Lrregularroberto_perraciniNo ratings yet

- 42crmo4 EnglishDocument3 pages42crmo4 Englisheduardomanar1224No ratings yet

- Hardox 450Document2 pagesHardox 450Brandon Vicuña GalánNo ratings yet

- En 19Document1 pageEn 19CharminNo ratings yet

- 421 - Domex 700 MCDocument2 pages421 - Domex 700 MClalamed21No ratings yet

- Xar PlusDocument3 pagesXar Plusmarcos crisostoNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Structural Steels: Chemical Composition Available DimensionDocument2 pagesStructural Steels: Chemical Composition Available Dimensionbruno.abuafNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKiranNo ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Bahra BusbarDocument4 pagesBahra BusbarSalmanNo ratings yet

- AÇOS VILLARES VF800-AT - InglesDocument2 pagesAÇOS VILLARES VF800-AT - InglesAmy Griffin100% (1)

- Jed-050m 008 eDocument5 pagesJed-050m 008 egsuoagNo ratings yet

- 32 Koenig 2013Document1 page32 Koenig 2013shashibagewadiNo ratings yet

- 708M40 Alloy Steel: Form of SupplyDocument3 pages708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNo ratings yet

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Document16 pagesVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNo ratings yet

- Impact: Wear Resistant SteelDocument6 pagesImpact: Wear Resistant SteelmazuckNo ratings yet

- Saben Silver Steel 1.2210: C Si MN CR Mo W V CoDocument1 pageSaben Silver Steel 1.2210: C Si MN CR Mo W V CoBernice JohnsonNo ratings yet

- Cold Rolling MillDocument4 pagesCold Rolling MillArslan BohioNo ratings yet

- Flexible Metalic Hose Braid & AssembliesDocument44 pagesFlexible Metalic Hose Braid & AssembliesiJordanScribdNo ratings yet

- X22CrMoV 12-1Document2 pagesX22CrMoV 12-1Prasad RvsNo ratings yet

- FRF Slabs: Rigid BoartdDocument16 pagesFRF Slabs: Rigid BoartdAmal RajNo ratings yet

- Westermann Table 8Document1 pageWestermann Table 8muhd.qasimNo ratings yet

- OCR12VMDocument4 pagesOCR12VMcvgfgNo ratings yet

- Aspac Royalloy enDocument7 pagesAspac Royalloy enNugroho Faris SudrajatNo ratings yet

- X65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Document2 pagesX65Cr13 C 0.58 - 0.70 CR 12.50 - 14.50 S Max. 0.015Jim SmithNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- 1.6523 20nicrmo2-2 - Aisi 8620Document3 pages1.6523 20nicrmo2-2 - Aisi 8620zhenyupanNo ratings yet

- Gb8417domex500mc PDFDocument2 pagesGb8417domex500mc PDFMario MereniNo ratings yet

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- Technical Data: ApplicationsDocument3 pagesTechnical Data: ApplicationssushmaxNo ratings yet

- En 24Document1 pageEn 24Puneet BNo ratings yet

- H13 Tool SteelDocument1 pageH13 Tool SteelPawanNo ratings yet

- பொது அறிவு உலகம் ஏப்ரல்2018Document100 pagesபொது அறிவு உலகம் ஏப்ரல்2018oomoomNo ratings yet

- KGP-Repair Welding Proc For BEI 221016Document5 pagesKGP-Repair Welding Proc For BEI 221016oomoomNo ratings yet

- KGP Flamme Stright For BEI 221016Document4 pagesKGP Flamme Stright For BEI 221016oomoomNo ratings yet

- KGP-Flamme Cutting Proce For BEI PDFDocument4 pagesKGP-Flamme Cutting Proce For BEI PDFoomoomNo ratings yet

- Datasheet For Steel Grades Structure Steel 15MnvDocument2 pagesDatasheet For Steel Grades Structure Steel 15MnvoomoomNo ratings yet

- Dillidur Technical Information 2007 PDFDocument56 pagesDillidur Technical Information 2007 PDFoomoomNo ratings yet

- O-Ring Tolerances: ACCORDING TO DIN ISO 3601-1:2013-11 (CLASS B)Document19 pagesO-Ring Tolerances: ACCORDING TO DIN ISO 3601-1:2013-11 (CLASS B)oomoomNo ratings yet

- RT InterpretationDocument10 pagesRT InterpretationoomoomNo ratings yet

- UNI 9200 - Break Mandrel Blind Rivets: Current Norm: DIN EN ISO 14589 Equivalent Norms: DIN 7337 ISO 15983 CSN 022391Document5 pagesUNI 9200 - Break Mandrel Blind Rivets: Current Norm: DIN EN ISO 14589 Equivalent Norms: DIN 7337 ISO 15983 CSN 022391oomoomNo ratings yet

- O-Rings: Your Advantages at A GlanceDocument2 pagesO-Rings: Your Advantages at A GlanceoomoomNo ratings yet

- DIN 910 - Screw Plugs With Collar and Outer Hexagon, Cylindrical ThreadDocument6 pagesDIN 910 - Screw Plugs With Collar and Outer Hexagon, Cylindrical ThreadoomoomNo ratings yet

- Plant Laboratory Test Requisition Form For Sub Contractors: (Please Tick ( ) Mark Which Ever Applicable)Document2 pagesPlant Laboratory Test Requisition Form For Sub Contractors: (Please Tick ( ) Mark Which Ever Applicable)oomoomNo ratings yet

- Shot LetterDocument2 pagesShot Letteroomoom100% (1)

- Pipes and CisternsDocument32 pagesPipes and CisternsoomoomNo ratings yet

- Scope of Pharmacy Education: A Concise Presentation byDocument26 pagesScope of Pharmacy Education: A Concise Presentation byDevendra PrajapatiNo ratings yet

- Vincent Virga - GaywyckDocument373 pagesVincent Virga - Gaywycknatsudragneel1967No ratings yet

- 04443720AA Masterpact NW User ManualDocument1 page04443720AA Masterpact NW User ManualdaywalkeryNo ratings yet

- Ingenierie Reseaux: Net - DesignDocument22 pagesIngenierie Reseaux: Net - Designit sonyNo ratings yet

- Annual Report 2010 PDFDocument400 pagesAnnual Report 2010 PDFVijay MishraNo ratings yet

- VEE Pro 7.5 User's Guide. 2005 PDFDocument657 pagesVEE Pro 7.5 User's Guide. 2005 PDFNidzaNo ratings yet

- Prices and Stocks Subject To Change Without Prior Notice, Please Check With Our Branches. .Document3 pagesPrices and Stocks Subject To Change Without Prior Notice, Please Check With Our Branches. .ihasakevinsNo ratings yet

- Conductor Parameters-SI UnitsDocument17 pagesConductor Parameters-SI UnitsMunesu Innocent Dizamuhupe0% (1)

- 72 Police-Body-Cameras US StudentDocument6 pages72 Police-Body-Cameras US StudentAline ChagasNo ratings yet

- English3am Modakirat Gen2-Unit3Document34 pagesEnglish3am Modakirat Gen2-Unit3aichaNo ratings yet

- SP6 - Financial Derivatives Specialist Principles: SyllabusDocument8 pagesSP6 - Financial Derivatives Specialist Principles: SyllabusRANJAN THOMASNo ratings yet

- Master Direction Draft On Information Technology Governance Risk ControlsDocument15 pagesMaster Direction Draft On Information Technology Governance Risk Controlsabee narayanNo ratings yet

- NIOS Class 12 Previous Year Question Papers Physics 2006Document5 pagesNIOS Class 12 Previous Year Question Papers Physics 2006Sanjeev dahiyaNo ratings yet

- Basic Geography: SUMMER - A.Y. 2019-2020Document117 pagesBasic Geography: SUMMER - A.Y. 2019-2020Freshie PascoNo ratings yet

- ASTM D1119 - 00 - Percent Ash Content of Engine Coolants and AntirustsDocument2 pagesASTM D1119 - 00 - Percent Ash Content of Engine Coolants and Antirustsphamthuyha100% (2)

- Defence and Security Short Courses Brochure PDFDocument20 pagesDefence and Security Short Courses Brochure PDFJunaed ZakirNo ratings yet

- SMM-139-6.4-Audio Visual Script TemplateDocument3 pagesSMM-139-6.4-Audio Visual Script Templatenandabi derickNo ratings yet

- Chap 2 Concept of IhrmDocument7 pagesChap 2 Concept of IhrmjagdishNo ratings yet

- Keywords For Syndk8 Form Danny Because Ilu 3 3 3Document491 pagesKeywords For Syndk8 Form Danny Because Ilu 3 3 3dan_abbamont3806100% (1)

- Exam Questions MS-100: Microsoft 365 Identity and ServicesDocument17 pagesExam Questions MS-100: Microsoft 365 Identity and ServicesdanielNo ratings yet

- Kumustahan Via Google Meet With Sir Cid Chief, Cornelio AquinoDocument2 pagesKumustahan Via Google Meet With Sir Cid Chief, Cornelio AquinoLeilani Grace ReyesNo ratings yet

- Helion Ventures Partners: Venture CapitalistDocument5 pagesHelion Ventures Partners: Venture CapitalistSantosh ArakeriNo ratings yet

- Shell ScriptDocument3 pagesShell ScriptRough MetalNo ratings yet

- East West University Presentation On Wal-Mart Course: MGT-600Document12 pagesEast West University Presentation On Wal-Mart Course: MGT-600Dipto KhanNo ratings yet

- Marrow UpdatesDocument9 pagesMarrow UpdatesVirat KohliNo ratings yet

- Mantra and Mind PDFDocument3 pagesMantra and Mind PDFgulanikar7694No ratings yet