Professional Documents

Culture Documents

Installation Manual / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory Parts

Uploaded by

AlexOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory Parts

Uploaded by

AlexCopyright:

Available Formats

/ / II.

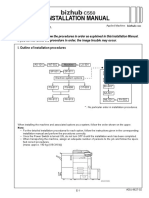

Installation space (unit: mm (inch))

bizhub C360 + DF-617 + PC-207 + FS-527

IV. Accessory parts

No. Name Q’ty

INSTALLATION MANUAL SD-509 + MK-713

1909

1. User’s guide holder 1

(75-3/16) 2. Quick guide

Applied Machines: / / 1

658 991 260 (Copy/Fax/Scan/Box operations) *

(25-7/8) (39) (10-1/4)

3. Installation manual 1 set

<Important> 4. User’s guide CD 1

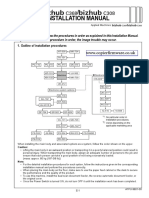

Be sure to correctly follow the procedures in order as explained in this Installation Manual. 5. CD-ROM 1 set

If you do not follow the procedure in order, the image trouble may occur. 6. Paper size label 1

7. Label (Legal restrictions on copying) * 1

I. Outline of installation procedures 8. Label (Super G3 label) 1

PC-107 PC-207 PC-408 DK-507 9. Cap A (Black) 2

✱ Electron system options 10. Cap B (White) 2

AU-101

WT-506 11. Power cord 1

EK-604*1 EK-605*1

AU-102 Machine MK-713 12. Power cord instruction * 1

13. Cord clamp 1

WT-507*2 UK-203 *1 1463.2

14. Waste toner box 1

AU-201 KH-101 (57-5/8)

321 1092.2 15. Control panel 1

VI-505*3 (12-5/8) (43)

16. Screw (3 × 6 mm) 1

SP-501 DF-617 OC-509

HD-515*4 17. Spacer 1

(19-1/2)

18. Panel pen 1

495.6

MK-720 FK-502

Electron system options

* Varies depending on the applicable marketing

(64-15/16)

JS-603 SC-507 area.

1649.6

(35-3/8)

Note:

899

PK-517 FS-527 FS-529 JS-505 IC-412*3 Keep the label (Super G3 label) at hand. It is nec-

essary for mounting the FAX Kit.

*1

(10-1/16)

SD-509 : No particular order in installation procedures.

255

*2

: Varies depending on the applicable marketing area.

*3 : Unable to be installed in C220.

*4 A0EDIXC042DA After unpacking, be sure to get rid of the

: For C220 only.

packaging materials and keep them out of

When installing the machine and associated options as a system, follow the order shown on the upper. the reach of children.

Note: Putting the head in the plastic bag

• For the detailed installation procedures for each could result in personal injury. When transport- III. Pre-installation check items

involves danger of suffocation.

option, follow the instructions given in the corre- ing the machine, assign an adequate number of 1. Select a level and stable place for installing the

sponding installation manual and perform the persons to the job and ensure that each person machine.

Note:

procedures correctly. (Optional devices must be can take a good position of not being exces- 2. Be sure to use a power source of the voltage and

This manual provides the illustrations of the acces-

installed after completing the main body instal- sively loaded. frequency indicated in the product specifications.

sory parts and machine that may be slightly differ-

lation.) (mass: approx. 98 kg (216-1/16 lb)) Ensure that the current carrying capacity of the

ent in shape from yours. In that case, instead of

• When placing the machine on the floor, make power outlet is at least equal to the current listed

the illustrations, use the appearance of your

sure to use the paper feed cabinet or the desk in the product specifications.

machine to follow the installation procedure. This

to secure the performance and the quality of 3. Power the machine directly from a dedicated

does not cause any significant change or problem

the product. power outlet. (Do not use an extension cord.)

with the procedure.

• To use this machine, install the reverse auto- 4. Do not plug or unplug the power cord with wet or

matic document feeder or the original cover. dirty hands, otherwise you may get an electric

Even if you do not install the original cover, be shock.

sure to install the hinge covers furnished with 5. Avoid a hot and humid environment, or a place

the original cover. exposed to direct sunlight.

• Once the Power Switch is turned ON, do not 6. Avoid a dusty location, or a place near volatile

turn OFF it until the installation work has been and flammable substances.

completed. 7. Avoid a poorly ventilated place.

• Lifting the machine in an awkward position or A0EDIXC041DA

transporting it in a poorly balanced position

A0ED-9601-00

E-1

Downloaded from www.Manualslib.com manuals search engine

V. Removing the machine VI. Removing protective tape, packing and 2. Open the right door and remove the protective 4. Install the furnished control panel.

sheet and packaging materials. Note:

1. Unpack and remove the machine package. other shipping materials / Installing the Note: Insert the hook of the control panel into the posi-

2. Remove the machine, holding it by the locations control panel After removing the packaging materials, make tioning hole of the machine.

on the left side and the handles on the right side

1. Remove the protective tapes and the protective sure that the transfer roller assy is secured in

as shown in the illustration and keeping it level.

materials. place. In the case of <NG>, press the transfer

Note: roller assy into place so that it is secured as shown

Machine mass: 98 kg/216-1/16 lb in <OK>.

• Make available collective manpower of an

appropriate size for transporting the machine.

• When attaching the machine, as the reference

fit the machine with the corner A and B of the

paper feed cabinet.

When holding the transportation handles,

be careful not to catch your fingers in the

machine.

A0EDIXC003DA

< OK > < NG >

A0EDIXC008DA

5. Secure the control panel with a furnished screw.

A0EDIXC006DB

A0EDIXE037DA 3. Remove the packing bracket.

A0XWMXC102MA

A0EDIXC009DA

6. Connect the machine connector to the control

panel.

A0EDIXC007DA

B A0EDIXC002DA

A0EDIXC010DA

E-2

Downloaded from www.Manualslib.com manuals search engine

7. Remove the protective sheet. 10. Open the front door and remove the protective 13. Slightly slide the drum unit (K) out and remove 2. Insert the toner cartridge into the machine.

tape. the protective tape. Note:

• Make sure that the color is same between

inserting port and the toner cartridge.

• Make sure that the blue label position of the

toner cartridge is matched with the one of the

machine side.

A0EDIXC011DA

8. Slide out the 1st drawer and remove protective

tape from the inside of the drawer.

A0EDIXC014DA A0EDIXC019DA

A0EDIXC021DA

11. Remove the protective materials from the four 14. Slide the drum unit (K) into the machine. 3. Push the toner cartridge all the way in and rotate

places. 15. Lock the drum unit (K) with the lever. it clockwise to lock it.

Note: Note:

Keep the protective materials. It is necessary for Make sure that the toner cartridge is pushed all the

transporting the machine.

VII. Installing the toner cartridge way in.

Note:

Since cartridge is not furnished with the machine,

A0EDIXC012DA purchase toner cartridge (of different colors) sepa-

rately.

9. Slide out the 2nd drawer and remove protective 1. Shake the toner cartridge up and down and left to

tape from the inside of the drawer. right 5 to 10 times respectively.

Note:

Shake the cartridge adequately. Otherwise, it may

cause trouble.

A0EDIXC015DA

A0EDIXC022DA

12. Release the lever of the drum unit (K). 4. Using the same procedure, install the toner car-

tridges for other colors of toner.

A0EDIXC013DA

A0EDIXC020DA

A0EDIXC017DA

E-3

Downloaded from www.Manualslib.com manuals search engine

VIII. Installing the waste toner box IX. Mounting the accessory parts XI. Installing the set guide for banner 2. Connect the power cord.

1. Remove the protective tape from the furnished 1. Attach the cap A and B furnished with the paper

waste toner box. machine. 1. Affix a furnished label to the set guide for banner

paper as shown in the illustration.

Note:

Select a label that fits onto the machine from the

furnished labels.

A0EDIXE038DA

3. Fit the cord clamp furnished with the machine

A0EDIXC024DA A0EDIXC026DA

over the power cord (one screw).

Note:

2. Install the waste toner box. 2. Set the panel pen in the pen holder at the control

Use the screw removed in step 1.

panel.

A0EDIXC033DA

2. Open the manual bypass tray and set the set

guide for banner paper.

A0EDIXC025DA

A0EDIXE039DA

A0P0IXC055DA

3. Close the front door.

4. Plug the power cord into the power outlet.

X. Installing the user’s guide holder/

spacer A02EIXC040DB

Install the user’s guide holder and the spacer.

XII. Connecting the power cord

1. Remove the screw at the rear of the machine.

A0EDIXC023DA

C4004U139CA

A0EDIXC027DA

A0EDIXE044DA

E-4

Downloaded from www.Manualslib.com manuals search engine

XIII. Toner supply 4. Touch “OK.” <If A3 or Ledger paper is set in step 1> 12. Touch “Copy”, select “A3 /11×17 ”, and

5. Touch “Exit” on the Service Mode screen. 6. Touch “Print”, select “A3 /11×17 ”, and press the start key.

1. Turn ON the Main Power Switch and then Sub 6. Turn OFF and ON the Main Power Switch. press the start key. A test pattern will then be produced on the

Power Switch.

Note: A test pattern will then be produced on the A3 A3 or Ledger paper.

2. Display the Service Mode screen.

When displayed the Service Mode screen, be sure or Ledger paper. 13. Place the test pattern face down on the original

(For details of how to display the Service Mode

to turn off the main power after exiting the Service 7. Place the test pattern face down on the original glass.

screen, see the service manual.)

Mode screen and wait for 10 seconds or more glass.

3. Touch “Imaging Process Adjustment.”

before turning on.

4. Touch “TCR Toner Supply.”

5. Touch "Cyan", "Magenta", "Yellow", and "Black",

and press the start key. XV. Adjusting touch panel

* When the start key lights up blue, go to step 6.

1. Press the accessibility key.

6. Touch “OK.”

2. Touch “Touch Panel Adjustment.”

3. Using the panel pen, lightly touch the center of

the + markers at four places on the touch panel.

XIV. Non-image area erase check (Any specific marker can be the first one.) Cyan

Note: Magenta

1. Select the Non-Image Area Erase Check function

as follows: Pressing the touch panel hard may cause dam-

age. A0P0IXC061DB

Machine → → Non-Image Area Erase Check.

* When all the markers at four places have been A0P0IXC058DB

Note: 14. Place about ten sheets of A3 or Ledger

touched, the start key turns blue and lights up

• Open fully the original cover / reverse automatic 8. Place about ten sheets of A3 or Ledger paper on the test pattern placed on the original

steadily blue.

document feeder. paper on the test pattern placed on the original glass.

4. Press the start key.

(When OC-509/DF-617 are installed previ- glass. Lower the cover.

5. Touch “Close.”

ously.) Lower the cover.

• Do NOT place a document on the document

glass.

• Clean the document glass if dirty. XVI. Setting gradation adjust.

Note:

Before starting the gradation adjustment, install

the optional reverse automatic document feeder or

the original cover.

1. Set that A3 or Ledger paper is loaded in

the tray.

Note:

If the A3 or Ledger paper is not readily A0P0IXC059DA

available, use A4 or Letter paper. A0P0IXC059DA

2. Display the Service Mode screen. 15. Press the start key.

(For details of how to display the Service Mode 9. Press the start key. The machine will start reading the test pattern.

A0P0IXC091DA

screen, see the service manual.) The machine will start reading the test pattern. 16. When the machine completes reading the test

3. Touch “Imaging Process Adjustment.” 10. When the machine completes reading the test pattern, the “Gradation Adjust” screen will reap-

2. Press the Start key. 4. Touch “Gradation Adjust.” pattern, the “Gradation Adjust” screen will reap- pear.

3. Make sure that “Result” is “OK.” 5. Touch “Stabilizer” and press the start key. pear. 17. Repeat steps from 12 through 15 to let the

Note: * When the start key lights up blue, go to step 6. 11. Repeat steps from 6 through 9 to let the machine read the test pattern two times (three

If “Result” is “NG1” or “NG2”, review the place and Note: machine read the test pattern two times (three times in total).

direction of installation, or take measures to block When a maintenance call occurs, see the service times in total). 18. Touch “END.”

the light source (by covering it, etc.), then perform manual.

installation checking again.

(If a fluorescent light or other bright light sources

exist right above the machine, the light source can

hinder installation checking and cause operation

errors in the Non-Image Area Erase Check. For

detailed information, see the service manual.)

E-5

Downloaded from www.Manualslib.com manuals search engine

<If A4 or Letter paper is set in step 1> 12. Touch “Copy”, select “A4 /8½×11 ”, and XVII. Date/Time setting XIX. Serial number input

6. Touch “Print”, select “A4 /8½×11 ”, and press the start key. 1. Make sure that the Service Mode screen is dis- Note:

press the start key. A test pattern will then be produced on the two played. Serial number input is needed only for optional

A test pattern will then be produced on the two A4 or Letter papers. 2. Display the Date & Time Setting screen. devices that will be installed later.

A4 or Letter papers. 13. Place the test pattern face down on the original (To display the Date & Time Setting screen, press 1. Select the Serial Number Input function as fol-

7. Place the test pattern face down on the original glass. Stop → 1 → 1 → 4 → 4 → Clear on the control lows: System 1 → Serial Number.

glass. panel.) 2. Touch the item you want to enter and input the

3. Press the clear key. serial number.

4. Enter the data for the year, month, day, and time- 3. Touch “END.”

of-day from the 10-key pad. 4. For other devices, enter their serial number in the

5. Touch “Entry.” same way.

Note: 5. Touch “END.”

Touching the Entry key returns the figures in the

Date & Time Setting screen to 0 and Date & Time

Setting has been completed.

XX. Unit change

Cyan 6. Touch “END.” Note:

Magenta

7. Touch “Exit” on the Service Mode screen. This function allows the user to select the type of

8. Select the Date/Time Setting function as follows: message that will appear when the replacement

A0P0IXC062DB

Utility/Counter → Administrator Settings → Enter time arrives for each of the different units.

A0P0IXC060DB the Administrator Password (Default setting: 1. Select the Unit Change function as follows:

14. Place about ten sheets of A3 or Ledger 12345678) → System Settings → Date/Time Set- System 2 → Unit Change.

8. Place about ten sheets of A3 or Ledger paper on the test pattern placed on the original tings. 2. Select the appropriate message type for each

paper on the test pattern placed on the original glass. 9. Select the item you want to set and press the unit.

glass. Lower the cover. clear key. 3. Touch “END.”

Lower the cover. 10. Enter the data for the year, month, day, and

time-of-day from the 10-key pad.

11. Touch “OK.”

12. Touch “Close” three times. XXI. List output

1. Load the tray 1 with A4 or Letter paper.

2. Touch “List Output.”

XVIII. Install date 3. Check that “Machine Management List” is

selected and press the start key.

1. Display the Service Mode screen. The list will be output.

(For details of how to display the Service Mode 4. Output “Adjustments List” in the same way.

screen, see the service manual.) 5. Touch “2.”

2. Select the Install Date function as follows: 6. Check that “Service Parameter” is selected and

A0P0IXC059DA System 1 → Install Date. press the start key.

A0P0IXC059DA 3. Press the clear key. The list will be output.

15. Press the start key. 4. Enter the data for the year, month, and day from 7. Touch “END.”

9. Press the start key. The machine will start reading the test pattern. the 10-key pad. 8. Touch “Exit” on the Service Mode screen.

The machine will start reading the test pattern. 16. When the machine completes reading the test 5. Touch “Entry.” 9. Turn OFF and ON the Main Power Switch.

10. When the machine completes reading the test pattern, the “Gradation Adjust” screen will reap- Note: Note:

pattern, the “Gradation Adjust” screen will reap- pear. Touching the Entry key returns the figures in the When displayed the Service Mode screen, be sure

pear. 17. Repeat steps from 12 through 15 to let the Install Date screen to 0 and Install Date has been to turn off the main power after exiting the Service

11. Repeat steps from 6 through 9 to let the machine read the test pattern two times (three completed. Mode screen and wait for 10 seconds or more

machine read the test pattern two times (three times in total). 6. Touch “END.” before turning on.

times in total). 18. Touch “END.”

E-6

Downloaded from www.Manualslib.com manuals search engine

XXII. Affixing the paper size label XXIV. Adjusting registration of paper 10. If the measured width A falls outside the speci- 9. Measure width A of the test pattern on the back-

fied range, enter the correction value using the side of the test print produced and check that it

Affix the paper size label. source options falls within the specified range.

or key.

<1 way paper feed cabinet, large capacity cabinet> 11. Produce another test print and check to see if Specifications: 3.0 mm ± 2.0 mm

1. Display the Service Mode screen. width A falls within the specified range.

(For details of how to display the Service Mode 12. Touch “END.”

screen, see the service manual.) 13. Touch “Exit” on the Service Mode screen.

2. Select the function to be used as follows: A

14. Turn OFF and ON the Main Power Switch.

Machine → Printer Area → Centering → 3rd. Note: Paper exit

3. Press the start key. When displayed the Service Mode screen, be sure direction

A test print will be produced. to turn off the main power after exiting the Service

4. Measure width A from the edge of the paper to Mode screen and wait for 10 seconds or more

the pattern printed on the test print and check that before turning on.

it falls within the specified range.

Paper size label Specifications: 3.0 mm ± 1.0 mm

A0EDIXC031DA

<2 way paper feed cabinet>

For loading the paper as well as setting the paper Paper exit 1. Display the Service Mode screen. 4061IXC152DA

type, refer to the user’s guide. direction (For details of how to display the Service Mode

screen, see the service manual.) 10. If the measured width A falls outside the speci-

2. Select the function to be used as follows: fied range, enter the correction value using the

Machine → Printer Area → Centering → 3rd. or key.

XXIII. Affixing the label (Legal restrictions 3. Press the start key. 11. Produce another test print and check to see if

on copying) A test print will be produced. width A falls within the specified range.

4. Measure width A from the edge of the paper to * Perform the same adjustment procedure also for

Affix the label (Legal restrictions on copying) to the the pattern printed on the test print and check that the “4th.”

position shown below. A it falls within the specified range. 12. Touch “END.”

Note: Specifications: 3.0 mm ± 1.0 mm 13. Touch “Exit” on the Service Mode screen.

This step may not be performed depending on the 4061IXC147DA

14. Turn OFF and ON the Main Power Switch.

applicable marketing area. Paper exit

5. If the measured width A falls outside the specified Note:

Label direction When displayed the Service Mode screen, be sure

range, enter the correction value using the

to turn off the main power after exiting the Service

or key. Mode screen and wait for 10 seconds or more

6. Produce another test print and check to see if before turning on.

width A falls within the specified range.

7. Select the function to be used as follows:

Centering (Duplex 2nd Side) → 3rd.

8. Press the start key. XXV. Check through test print

A test print will be produced. A

Make operation checks using “Setting Information

9. Measure width A of the test pattern on the back- Print.”

side of the test print produced and check that it 4061IXC147DA

1. Select the function to be used as follows:

falls within the specified range. Utility/Counter → User Settings → Printer Set-

A0EDIXE040DA

Specifications: 3.0 mm ± 2.0 mm 5. If the measured width A falls outside the specified

tings → Print Reports.

range, enter the correction value using the The types of the test prints that can be printed will

or key. be displayed.

6. Produce another test print and check to see if 2. Touch “Configuration Page.”

A

width A falls within the specified range. 3. Touch A4 size and press the start key.

Paper exit 7. Select the function to be used as follows: Check that the machine produces the corre-

direction Centering (Duplex 2nd Side) → 3rd. sponding printed page.

8. Press the start key. 4. Touch “Cancel” and then touch “Close” four

A test print will be produced. times.

4061IXC152DA

E-7

Downloaded from www.Manualslib.com manuals search engine

XXVI. Connecting cables

1. Remove the knockout from the cover located on

3. Connect the networking equipment (HUB) using

the network cable. OC-509 Original Cover

the right side of the machine with nippers as

shown in the illustration.

Note:

The following shows the recommended network

cables that correspond to each communication

INSTALLATION MANUAL

Note: speed.

Take this step only when the machine does not • 10BaseT/100BaseTX: Category 5

have the optional paper feed cabinet and the desk. • 1000BaseT: Category 5E, Category 6

Networkport

I. Accessory parts II. Installation procedures

LED1 1. Attach the furnished hinge cover (right) and hinge

No. Name Shape Q’ty

cover (left).

1. Original Cover (three screws furnished with the machine)

LED2 4599U001AA

2. Hinge Cover

A0EDIXC034DA (Right)

2. Connect the network cable to the machine and

A0EDIXC032DA

1

route the cable as shown in the illustration.

4. Check LEDs for lighting conditions.

Paper feed cabinet and desk installed LED1: A0EDIXC028DA

Should light up steadily if the link network con- 3. Hinge Cover

A0EDIXC030DA

nection has been made. (Left)

LED2:

1 2. Install the original cover.

Should blink according to the communications

status of the ACT network.

A0EDIXC029DA

4. Screw

XXVII. Network setting (3 × 6 mm) 3

Make the TCP/IP address setting for the network. 9646

Note:

Consult the network administrator for the setting

A0EDIXC035DA value to be entered and make settings as

required.

No paper feed cabinet and desk installed After unpacking, be sure to get rid of the

1. Select the function to be used as follows:

Utility/Counter → Administrator Settings → Enter packaging materials and keep them out of

A02EIXC038DA

the Administrator Password → Network Settings the reach of children.

→ TCP/IP Settings → IPv4 Settings. Putting the head in the plastic bag

2. Touch “Manual Input” of IP Address Setting involves danger of suffocation.

Method and make the following settings.

IP Address: IP address of the controller

Subnet Mask: Subnet mask of the network, to

which the machine is connected

Default Gateway: IP address of the default gate-

way

3. Touch “OK.”

4. Turn OFF and ON the Main Power Switch.

A0EDIXC036DA 5. Select the function to be used as follows:

Utility/Counter → Administrator Setting → Enter

the Administrator Password → Network Settings

→ Forward → Detail Settings → PING Confirma-

tion, and make the operation check of TCP/IP.

E-8

Downloaded from www.Manualslib.com manuals search engine

You might also like

- CE Password ResetDocument12 pagesCE Password ResetAlex100% (1)

- 4L60E SwapguideDocument3 pages4L60E Swapguideericproffitt100% (3)

- Universal Samsung Tool Pro User ManualDocument15 pagesUniversal Samsung Tool Pro User ManualLeon santillanNo ratings yet

- Manual Omega (ENG)Document46 pagesManual Omega (ENG)Eduardo Pereira0% (1)

- Installation Manual / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory PartsDocument8 pagesInstallation Manual / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory PartsAlexNo ratings yet

- Installation Manual / / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory PartsDocument11 pagesInstallation Manual / / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory PartsRadovan JaicNo ratings yet

- A1ud 9622 01eDocument11 pagesA1ud 9622 01eOswaldo GuzmanNo ratings yet

- Installation ManualDocument26 pagesInstallation ManualhashemNo ratings yet

- Bizhub c200 InstalacionDocument14 pagesBizhub c200 InstalacioncopiartekNo ratings yet

- Manual Instalare Nou - A0P0 9951 02EDocument23 pagesManual Instalare Nou - A0P0 9951 02EHritcu IulianNo ratings yet

- Installation ManualDocument18 pagesInstallation ManualhashemNo ratings yet

- Installation Manual / /: I. Outline of Installation Procedures For Bizhub 362/ Bizhub 282/ Bizhub 222Document36 pagesInstallation Manual / /: I. Outline of Installation Procedures For Bizhub 362/ Bizhub 282/ Bizhub 222Radovan JaicNo ratings yet

- Installation ManualDocument12 pagesInstallation ManualAlin DoafidriNo ratings yet

- Lu-202Xlm Installation Manual: 1.confirmation Prior To InstallationDocument12 pagesLu-202Xlm Installation Manual: 1.confirmation Prior To InstallationthiagoxsantosNo ratings yet

- Service: ManualDocument76 pagesService: ManualJuan GutierrezNo ratings yet

- Instruction Manual: AMO-NP-15167-01Document12 pagesInstruction Manual: AMO-NP-15167-01gary omanaNo ratings yet

- DVDP191 - Et SB Ex Si - 1257499059Document76 pagesDVDP191 - Et SB Ex Si - 1257499059Paulo Alexandre0% (1)

- FK-506 ImDocument9 pagesFK-506 ImionutkokNo ratings yet

- CoverDocument2 pagesCoverRisoSilvaNo ratings yet

- Installation Manual PI-502: I.Confirmation Prior To InstallationDocument8 pagesInstallation Manual PI-502: I.Confirmation Prior To InstallationPitNo ratings yet

- 0060200.installation Manual 546560Document36 pages0060200.installation Manual 546560Tríade MusicNo ratings yet

- Samsung Dvd-V3650 Chassis Diva Training ManualDocument202 pagesSamsung Dvd-V3650 Chassis Diva Training ManualPaulo Henrique SNo ratings yet

- OKIMAT IPS - OKIMAT IPSe - OKIMAT EPS. Installation Instructions. (Translation of The Original Installation Instructions)Document36 pagesOKIMAT IPS - OKIMAT IPSe - OKIMAT EPS. Installation Instructions. (Translation of The Original Installation Instructions)RAMON CANDIDONo ratings yet

- Thermaltake v21Document12 pagesThermaltake v21Chain CleanerProNo ratings yet

- LT-LT-: Satellite TracerDocument70 pagesLT-LT-: Satellite TracerMarly SalasNo ratings yet

- Bizhubc368 C308 C258InstallInstrDocument13 pagesBizhubc368 C308 C258InstallInstrBizhub Konica MinoltaNo ratings yet

- WA1200-3 - Manual de MontagemDocument198 pagesWA1200-3 - Manual de MontagemEduardo GabrielNo ratings yet

- Octave Ultrasonic Installation - GuideDocument16 pagesOctave Ultrasonic Installation - GuideCHRISTIAN JOSE BARRETO ROJASNo ratings yet

- Quick Guide: TroubleshootingDocument2 pagesQuick Guide: TroubleshootingHassan AlsafiNo ratings yet

- SCHEMATIC Persamaan Acer One Z1410 101200 REV-10Document33 pagesSCHEMATIC Persamaan Acer One Z1410 101200 REV-10De AdeNo ratings yet

- StupDocument29 pagesStupNour BenNo ratings yet

- Compal LA-5151P KAT00 Discrete VGA POITIER Montevina M96-M92 Dell Studio 1745 PDFDocument60 pagesCompal LA-5151P KAT00 Discrete VGA POITIER Montevina M96-M92 Dell Studio 1745 PDFMichael Davenport0% (1)

- PROFIBUS Fieldbus Coupler MVS3007Document114 pagesPROFIBUS Fieldbus Coupler MVS3007Diego MontanezNo ratings yet

- Mapit Mapit g2 Control Panel To Sfe IIDocument6 pagesMapit Mapit g2 Control Panel To Sfe IIJose SenderoNo ratings yet

- Greatwall E66 Fic Mr040t Rev0.4Document56 pagesGreatwall E66 Fic Mr040t Rev0.4dinnhowNo ratings yet

- FieryPro80 Install ManualDocument3 pagesFieryPro80 Install ManualLucas MonteiroNo ratings yet

- Dfu Optimix 960680 RevgDocument39 pagesDfu Optimix 960680 RevgXiomara GómezNo ratings yet

- User's Manual Benutzerhandbuch Mode d'emploi Manual del usuario Manuale dell'utente 安裝說明書 用戶手冊 ユーザーズマニュアル Руководство пользователяDocument19 pagesUser's Manual Benutzerhandbuch Mode d'emploi Manual del usuario Manuale dell'utente 安裝說明書 用戶手冊 ユーザーズマニュアル Руководство пользователяMarcelo OliveiraNo ratings yet

- SMD PackagesDocument5 pagesSMD Packagesamreshjha22No ratings yet

- KDL-32R413 Chassis Itc3Document21 pagesKDL-32R413 Chassis Itc3nnovik1No ratings yet

- Bizhub C258 C308 C368 InstallationDocument13 pagesBizhub C258 C308 C368 Installationمصعب الغريبNo ratings yet

- PK-520 Installation Manual: 1. Accessory PartsDocument5 pagesPK-520 Installation Manual: 1. Accessory PartsАлексей ШешуковNo ratings yet

- Ecs 730sa - RV 1.1Document36 pagesEcs 730sa - RV 1.1Carlos Henrique RibasNo ratings yet

- KV-S2065L KV-S2065W: High Speed ScannerDocument157 pagesKV-S2065L KV-S2065W: High Speed ScannerGroza Alexandru ClaudiuNo ratings yet

- Operation and Maintenance 1 PDFDocument452 pagesOperation and Maintenance 1 PDFstopless_dalian685No ratings yet

- FTP-628MCL101 50Document32 pagesFTP-628MCL101 50dcackovski.henryNo ratings yet

- MZ07 BrochureDocument4 pagesMZ07 BrochureXanti Zabala Da RosaNo ratings yet

- Systems Engineering (SE) & Project Management: Nick Clemens, PMPDocument37 pagesSystems Engineering (SE) & Project Management: Nick Clemens, PMPcasakaNo ratings yet

- Service Manual (Unique) : History Information For The Following ManualDocument27 pagesService Manual (Unique) : History Information For The Following ManualClubedoTecnicoNo ratings yet

- 6263 RM-207 / 6267 RM-210 Service Manual Level 1&2Document21 pages6263 RM-207 / 6267 RM-210 Service Manual Level 1&2Manisha JaiswalNo ratings yet

- Chapter 9 InstallationDocument26 pagesChapter 9 InstallationYesprianto YespriantoNo ratings yet

- Aloka TrainingDocument225 pagesAloka Trainingyujuncheng12No ratings yet

- Assembly Work InstrDocument6 pagesAssembly Work InstrAruna ChaparalaNo ratings yet

- OC 6000e System OverviewDocument33 pagesOC 6000e System OverviewKiên NguyễnNo ratings yet

- Gear Boxes MaintenanceDocument8 pagesGear Boxes Maintenancekostis57No ratings yet

- PM7 Mu GB 01Document15 pagesPM7 Mu GB 01Kaiser Iqbal100% (1)

- Samsung SV-DVD440Document31 pagesSamsung SV-DVD440videosonNo ratings yet

- ADP-100 GUI ConnectionDocument1 pageADP-100 GUI ConnectioncncyautomatizacionNo ratings yet

- Fiber Distributed Data Interface [FDDI] Technology ReportFrom EverandFiber Distributed Data Interface [FDDI] Technology ReportRating: 5 out of 5 stars5/5 (1)

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- ответ 06.10.2020г. - - - ZS-14088208 - 20Document1 pageответ 06.10.2020г. - - - ZS-14088208 - 20AlexNo ratings yet

- Wts AEM Automotive SMD Fuses 2016.12Document22 pagesWts AEM Automotive SMD Fuses 2016.12AlexNo ratings yet

- Bizhubc220 C280 C360InstallInstrDocument8 pagesBizhubc220 C280 C360InstallInstrJuan Martín Hernández VelascoNo ratings yet

- TIB362Plus - Level 5 Install Guide FWDocument27 pagesTIB362Plus - Level 5 Install Guide FWAlexNo ratings yet

- Installation Manual FS-503: I. Machine Combination ExamplesDocument19 pagesInstallation Manual FS-503: I. Machine Combination ExamplesAlexNo ratings yet

- D158/D159/D160/D161/D170 Service Manual: Downloaded From Manuals Search EngineDocument976 pagesD158/D159/D160/D161/D170 Service Manual: Downloaded From Manuals Search EngineAlexNo ratings yet

- Monochrome Digital Production Press: TechnologyDocument8 pagesMonochrome Digital Production Press: TechnologyAlexNo ratings yet

- Bizhub PRESS C7000 C6000 Centering and Skewing Adjustment Procedure (11 MAR 2011)Document12 pagesBizhub PRESS C7000 C6000 Centering and Skewing Adjustment Procedure (11 MAR 2011)AlexNo ratings yet

- Bizhub C754 C654 FW Update Procedure Using USB Memory StickDocument3 pagesBizhub C754 C654 FW Update Procedure Using USB Memory StickAlexNo ratings yet

- 1) Output 2 Sheets Each of Test Pattern No 53 With Dot1 Tone-130 For Y, M, C, R and GDocument2 pages1) Output 2 Sheets Each of Test Pattern No 53 With Dot1 Tone-130 For Y, M, C, R and GAlexNo ratings yet

- Ricoh 3035 - 3045 SMDocument497 pagesRicoh 3035 - 3045 SMJoseph AlbertNo ratings yet

- Final Exam Review Questions Funds of SecurityDocument65 pagesFinal Exam Review Questions Funds of Securityidk80% (5)

- Naruto - NagareboshiDocument2 pagesNaruto - NagareboshiOle HansenNo ratings yet

- 4 Litre Closed SamplersDocument3 pages4 Litre Closed Samplerslimhockkin3766No ratings yet

- 4 MivDocument19 pages4 Mivpavankumar001No ratings yet

- Internship Opportunities PDFDocument2 pagesInternship Opportunities PDFMD MoizNo ratings yet

- Ballastless TracksDocument20 pagesBallastless TracksYacoub Cheikh67% (3)

- Kinematic Analysis of 5 Dof Lynx ArmDocument6 pagesKinematic Analysis of 5 Dof Lynx ArmsathyaNo ratings yet

- On Phase ChangesDocument28 pagesOn Phase Changesapi-313517608No ratings yet

- UAV Compare & RecommendationDocument1 pageUAV Compare & RecommendationWafa PutraNo ratings yet

- En Mirage Classic Installation GuideDocument4 pagesEn Mirage Classic Installation GuideMykel VelasquezNo ratings yet

- Behringer FX2000-Product InfoDocument10 pagesBehringer FX2000-Product Infogotti45No ratings yet

- Bio GasDocument4 pagesBio GasRajko DakicNo ratings yet

- 01 - Motor Protection Circuit Breakers - 01 - 20 PDFDocument20 pages01 - Motor Protection Circuit Breakers - 01 - 20 PDFMostafa ShannaNo ratings yet

- Medium Voltage Application Guide en IECDocument224 pagesMedium Voltage Application Guide en IECJag Jagdish0% (1)

- List of Algorithms Interview QuestionsDocument9 pagesList of Algorithms Interview QuestionsSivaselvi RNo ratings yet

- Alcoa Lock Bolt PDFDocument8 pagesAlcoa Lock Bolt PDFMurugan PalanisamyNo ratings yet

- Coil PDFDocument2 pagesCoil PDFhandbookNo ratings yet

- Thermal Imaging Tech ResourceDocument20 pagesThermal Imaging Tech Resourceskimav86100% (1)

- BE Enus DP3441DP3441e DP3661e Series Portable Radios Quick Reference GuideDocument6 pagesBE Enus DP3441DP3441e DP3661e Series Portable Radios Quick Reference GuideEduardoNo ratings yet

- HIU Range Design GuideDocument24 pagesHIU Range Design Guidesachinsaklani23No ratings yet

- Aniuk SpecimenDocument10 pagesAniuk SpecimenMario ParraNo ratings yet

- Angoca Db2 Cheat Sheet For DevelopmentDocument3 pagesAngoca Db2 Cheat Sheet For DevelopmentTanveer AhmedNo ratings yet

- CCS Week 4 CBLMDocument6 pagesCCS Week 4 CBLMethel roseNo ratings yet

- Philips Accent LightingDocument37 pagesPhilips Accent LightingCecila Torrez BenitezNo ratings yet

- EV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)Document31 pagesEV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)TekkieNo ratings yet

- Lexium Motion Control 200401Document130 pagesLexium Motion Control 200401Mohamed Elsayed HasanNo ratings yet

- C8813 ÇDocument39 pagesC8813 ÇZawHtet Aung100% (1)

- Altman Fall Winter 2012 Product Showcase FlyerDocument32 pagesAltman Fall Winter 2012 Product Showcase FlyerИлия ГеоргиевNo ratings yet

- PCBA-WP543HV HW Manual Rev1.05Document21 pagesPCBA-WP543HV HW Manual Rev1.05Surapong Pongchaiprateep100% (1)

![Fiber Distributed Data Interface [FDDI] Technology Report](https://imgv2-2-f.scribdassets.com/img/word_document/282658933/149x198/df3dc47c73/1699545009?v=1)