Professional Documents

Culture Documents

Installation Manual / / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory Parts

Uploaded by

Radovan JaicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Manual / / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory Parts

Uploaded by

Radovan JaicCopyright:

Available Formats

/ / / II.

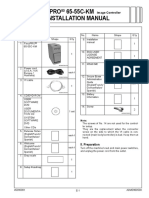

Installation space (unit: mm (inch))

bizhub 423 + PC-208 + FS-527 + SD-509

IV. Accessory parts

No. Name Qty

INSTALLATION MANUAL 1634

(64-5/16)

1. Users guide holder 1

658 976 2. Quick guide

Applied Machines: / / / 1

(25-7/8) (38-7/16) (Copy/Fax/Scan/Box operations)

3. Installation manual 1 set

<Important> 4. Users guide CD 1

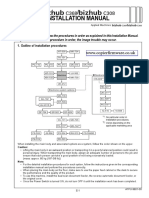

Be sure to correctly follow the procedures in order as explained in this Installation Manual. 5. CD-ROM 1 set

If you do not follow the procedure in order, the image trouble may occur. 6. Paper size label 1

7. Label (Legal restrictions on copying) *1 1

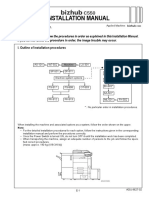

I. Outline of installation procedures

8. Chart *2 1

PC-109 PC-208 PC-409 DK-508 9. Seal A (Round) 2

Electronic system options 10. Seal B (Square) 2

AU-102 11. Cap A (Black) 2

EK-604*1 EK-605*1 12. Cap B (White) 2

WT-506 Machine 1187 13. Power cord *1 1

(46-3/4)

AU-201 UK-203*1 14. Power cord instruction *1 1

KH-101 293 834

(11-9/16) (32-13/16)

15. Control panel 1

SC-507*1

16. Screw (3 8 mm) 1

(16-1/4)

SP-501 DF-621*2 OC-509 17. Spacer *1

412

HD-516*2 1

18. Panel pen 1

FK-508 MK-726

Electronic system options 19. Developer 1

(61-1/4)

(32-1/8)

1553

20. Mylar 2

816

JS-603 *1

: No particular order in installation

procedures. *1

PK-517 FS-527 FS-529 JS-505 *2

Varies depending on the applicable marketing

(12-13/16)

: Whether the device is standard or area.

325

optional depends on each model *2

Supplied only when the ADF is standard.

SD-509 and marketing area.

A1UDIXC002DA

When installing the machine and associated options as a system, follow the order shown on the upper.

After unpacking, be sure to get rid of the

Caution: III. Pre-installation check items packaging materials and keep them out of

For the detailed installation procedures for each could result in personal injury. When transport-

1. Select a level and stable place for installing the the reach of children.

option, follow the instructions given in the corre- ing the machine, assign an adequate number of

sponding installation manual and perform the persons to the job and ensure that each person machine. Putting the head in the plastic bag

procedures correctly. (Optional devices must be can take a good position of not being exces- 2. Be sure to use a power source of the voltage and involves danger of suffocation.

installed after completing the main body instal- sively loaded. Machine mass: frequency indicated in the product specifications.

lation.) Approx. 78 kg (171-15/16 lb) Ensure that the current carrying capacity of the Note:

When placing the machine on the floor, make (423/ADF-standard 363 machines) power outlet is at least equal to the current listed This manual provides the illustrations of the acces-

sure to use the paper feed cabinet or the desk Approx. 66 kg (145-1/2 lb) in the product specifications. sory parts and machine that may be slightly differ-

to secure the performance and the quality of (363 machines without ADF/283/223) 3. Power the machine directly from a dedicated ent in shape from yours. In that case, instead of

the product. power outlet. (Do not use an extension cord.) the illustrations, use the appearance of your

To use this machine, install the reverse auto- 4. Do not plug or unplug the power cord with wet or machine to follow the installation procedure. This

matic document feeder (ADF) or the original dirty hands, otherwise you may get an electric does not cause any significant change or problem

cover.Even if you do not install the original shock. with the procedure.

cover, be sure to install the hinge covers sup- 5. Avoid a hot and humid environment, or a place

plied with the original cover. exposed to direct sunlight.

Once the Power Switch is turned ON, do not 6. Avoid a dusty location, or a place near volatile

turn OFF it until the installation work has been and flammable substances.

completed. 7. Avoid a poorly ventilated place.

Lifting the machine in an awkward position or

transporting it in a poorly balanced position A1UDIXC001DA

A1UD-9622-02

E-1

Downloaded from www.Manualslib.com manuals search engine

V. Removing the machine VI. Removing protective tape, packing and 2. Slide out the 1st drawer and remove protective 7. Remove the packing bracket.

tape from the inside of the drawer.

1. Unpack the packaging box and remove cushion- other shipping materials / Installing the

ing materials and plastic bags from the box. control panel

2. Hold onto the portions indicated in the illustration.

While keeping the machine level, take it out from 1. Remove the protective tapes and the protective

the box. materials.

Caution:

Machine mass:

Approx. 78 kg (171-15/16 lb)

(423/ADF-standard 363 machines)

Approx. 66 kg (145-1/2 lb)

(363 machines without ADF/283/223)

Make available collective manpower of an A1UDIXC042DB

appropriate size for transporting the machine. A0EDIXC012DA

When attaching the machine, as the reference 8. Install the supplied control panel.

fit the machine with the corner A and B of the 3. Slide out the 2nd drawer and remove protective Note:

paper feed cabinet. tape from the inside of the drawer. Insert the hook of the control panel into the posi-

A1UDIXC038DB tioning hole of the machine.

A1UDIXC003DA A0EDIXC013DA

A1UDIXC039DC

4. Open the right door and remove the protective

< In the case of the 423/363 tape.

machine equipped with ADF > 5. Push the lever in the direction of the arrow and

remove the spacer from the transfer roller.

A1UDIXC004DA

9. Secure the control panel with a supplied screw.

A

B

A1V4IXC010DA

A1UDIXC040DB

A1UDIXC033DA

6. Close the right door.

A1UDIXC005DA

A1UDIXC041DB

E-2

Downloaded from www.Manualslib.com manuals search engine

10. Connect the machine connector to the control VII. Mounting the accessory parts 3. Install the spacer supplied with the machine. IX. Loading the developer

panel. Note:

1. Attach the supplied seals A and B. 1. Open the right door.

This step may not be performed depending on the

Note: 2. Remove the cover shown in the illustration. (One

applicable marketing area.

If you install the finisher (FS-527) or the job sepa- screw)

rator (JS-505) immediately after the installation of Note:

the machine, you do not have to attach the seals After removing the screw, slightly raise the cover

B. and pull it toward you.

A0EDIXC010DA

Seal A

11. Remove the protective sheet. A1UDIXE034DA

Seal B 4. Set the panel pen in the pen holder at the control

panel.

A1UDIXC044DA

2. Attach the supplied caps A and B.

A0EDIXC011DB

A0P0IXC055DA

A1UDIXC058DA

A1UDIXC045DA 3. Disconnect the connector.

VIII. Installing the users guide holder

Install the users guide holder.

A1UDIXC008DA

A1UDIXC006DA

E-3

Downloaded from www.Manualslib.com manuals search engine

4. Remove the imaging unit (IU). 8. Remove the toner supply port. 11. Ready a packet of developer and cut off one cor- 14. Reinstall the toner supply port.

ner of the aluminum packet with scissors. Note:

Make sure of the correct mounting position and

direction.

A1UDIXC009DA 4040IXC078DA

4030U012AA

5. Remove screws that secure the drum unit in posi- 9. Remove the supplied sheets of mylar from the

tion. (Two silver screws each on the right and left paper backing. 12. While turning the gear in the direction of the 4040IXC077DA

sides) arrow, pour the packet of developer evenly into

6. Slightly opening the lower part (the shadowed the developer chamber. 15. Reinstall the developing unit cover, ensuring that

portion) on both sides of the drum unit, take out Note: its tabs are fitted properly into the slits. (Three

the drum unit. Turn the magnet roller in the direction of its nor- screws)

Note: mal rotation, and not the backward.

Do not touch or scratch the photo conductor. Not touching the gear of A side. Tighten this screw first

Cover the drum unit, which has been removed, Be sure not to let developer get inside the col-

with a protective cloth or similar tool. lar.

Drum unit

A1UDIXC048DB Magnet roller A

10. Attach the mylar sheets. (Two places)

Note:

Make sure that the collar is completely covered 4030U015AC

with the mylar sheet.

Developing unit 16. Align the shaft of the developing unit with the

inner guide of the drum unit.

A1UDIXC010DA 17. Slide the drum unit along the guide to check that

the positioning pin is properly aligned with the

7. Remove the developing unit cover. (Three mating hole.

screws)

Collar Collar

4040IXC209DA

13. Remove the mylar sheets that were attached in

step 10. (Two places)

Note:

Discard the removed mylar sheets.

A1UDIXC011DA

Collar

4040IXC208DA

E-4

Downloaded from www.Manualslib.com manuals search engine

18. Screw the drum unit in position. (Two silver 21. Install the cover shown in the illustration. (One XI. Clearing the counters XIII. Installing the toner bottle

screws each on the right and left sides) screw)

1. Turn ON the Main Power Switch and then Sub Note:

Note: Note:

Power Switch. The toner bottle is not shipped with the machine.

Use care not to touch or scratch the photo conduc- Make sure that the hole of the cover is aligned with

tor. the positioning pin of the machine. Note: Purchase one that is separately available.

Though the control panel displays the message 1. From a height of about 10 cm, tap the toner bottle

Positioning pin that informs you that the right door is open, ignore against a table or other hard object four to five

the message and perform the following steps. times. Then turn it upside down and repeat the

Hole

Guide 2. Display the Service Mode screen. (For details of same procedure.

how to display the Service Mode, see the service Note:

Positioning pin manual.) Toner can be caked in the toner bottle. Be sure to

Shaft 3. Touch Counter. perform this procedure.

Guide 4. Touch Life.

5. Touch 2.

6. Using the Clear key, clear Drum Unit Rotation

Shaft Time.

7. Using the Clear key, clear Developing Unit Rota-

A1UDIXC012DA A1UDIXC007DB tion Time.

8. Using the Clear key, clear Developer Use Time.

19. Install the imaging unit (IU) in position. Note: 9. Touch END.

After setting the IU in place, do not close the

right door.

After setting the IU in place, promptly plug the XII. TCR sensor adjustment

power cord into an outlet and clear the counters

within 1 minute. 1. Close the right door. 1166O228AA

2. Make sure that the Service Mode screen is dis-

played. 2. Shake the toner bottle well about five times in the

Hole

3. Touch Imaging Process Adjustment. vertical direction. Then, turn it over and repeat

X. Connecting the power cord 4. Touch TCR Sensor Adjust. the same procedure.

1. Connect the power cord. 5. Touch Black, and press the start key.

Note: Note:

This step may not be performed depending on the After pressing the start key, wait about one minute

A1UDIXC013DA

applicable marketing area. as it is.

* When the start key lights up blue, go to step 6.

20. Connect the connector. 6. Touch END.

7. Touch Exit on the Service Mode screen.

1166O095AA

3. To move toner to the toner supply port side in the

bottle, drop the toner bottle with the supply port

A1UDIXE035DA side down onto a table or other hard surface from

the height of about 10 cm several times.

A1UDIXC014DA

2. Plug the power cord into the power outlet.

A1UDIXC049DA

C4004U139CA

E-5

Downloaded from www.Manualslib.com manuals search engine

4. Open the front door and slide the toner hopper 8. Gently peel off the seal toward you from the bot- XIV. Performing Non-Image Area Erase XV. Adjusting touch panel

out of the machine. tle.

Note:

Check 1. Press the accessibility key.

2. Touch Touch Panel Adjustment.

Perform this procedure slowly, as toner can burst Note:

3. Using the panel pen, lightly touch the center of

out when the seal is peeled off. Perform the below at the site where customer

the + markers at four places on the touch panel.

uses the machine.

(Any specific marker can be the first one.)

1. Make sure that the Service Mode screen is dis- Note:

played. Pressing the touch panel hard may cause dam-

2. Select the Non-Image Area Erase Check function age.

as follows:

* When all the markers at four places have been

Machine Non-Image Area Erase Check. touched, the start key turns blue and lights up

Note: steadily blue.

Open fully the original cover / reverse automatic

4. Press the start key.

document feeder.

A1UDIXC015DA

5. Touch Close.

(When the OC-509/DF-621 is installed.)

5. Remove the protective tape. Do NOT place a document on the document

A1UDIXC017DA

glass.

Clean the document glass if dirty. XVI. Setting gradation adjust.

9. Slide the toner hopper back into the machine until Note:

it clicks into position. Then, close the front door. Before starting the gradation adjustment, install

the optional reverse automatic document feeder or

the original cover.

1. Set that A3 or Ledger paper is loaded in

the tray.

Note:

If the A3 or Ledger paper is not readily

available, use A4 or Letter paper.

A1UDIXC037DA

2. Display the Service Mode screen.

(For details of how to display the Service Mode

6. Open the toner holder and mount the toner bottle. A0P0IXC091DA

screen, see the service manual.)

Note: 3. Touch Imaging Process Adjustment.

Place the toner bottle so that its seal surface faces 3. Press the Start key.

A1UDIXC018DA

4. Make sure that Result is OK. 4. Touch Gradation Adjust.

upward.

Note:

7. Close the toner holder.

If Result is NG1 or NG2, review the place and

Place the surface to which direction of installation, or take measures to block

the seal is adhered upward. the light source (by covering it, etc.), then perform

installation checking again.

(If a fluorescent light or other bright light sources

exist right above the machine, the light source can

hinder installation checking and cause operation

errors in the Non-Image Area Erase Check. For

detailed information, see the service manual.)

5. Touch OK.

6. Touch Exit on the Service Mode screen.

Toner holder

A1UDIXC016DA

E-6

Downloaded from www.Manualslib.com manuals search engine

<If A3 or Ledger paper is set in step 1> 11. Touch Gradation Adjustment, select A3 / <If A4 or Letter paper is set in step 1> 11. Touch Gradation Adjustment, select A4 /

5. Touch Max Density Adjustment, select A3 / 1117 , and press the start key.

5. Touch Max Density Adjustment, select A4 / 811 , and press the start key.

1117 , and press the start key. A test pattern will then be produced on the

A test pattern will then be produced on the A3 A3 or Ledger paper. 811 , and press the start key. A test pattern will then be produced on the A4

or Ledger paper. 12. Place the test pattern face down on the original A test pattern will then be produced on the two or Letter paper.

6. Place the test pattern face down on the original glass. A4 or Letter papers. 12. Place the test pattern face down on the original

glass. 6. Place the test pattern face down on the original glass.

glass.

A1UDIXC021DB

A1UDIXC019DA A1UDIXC023DB

13. Place about ten sheets of A3 or Ledger A1UDIXC022DA

7. Place about ten sheets of A3 or Ledger paper on the test pattern placed on the original 13. Place about ten sheets of A3 or Ledger

paper on the test pattern placed on the original glass. 7. Place about ten sheets of A3 or Ledger paper on the test pattern placed on the original

glass. Lower the cover. paper on the test pattern placed on the original glass.

Lower the cover. glass. Lower the cover.

Lower the cover.

A1UDIXC020DA

A1UDIXC020DA A1UDIXC020DA

14. Press the start key. A1UDIXC020DA

8. Press the start key. The machine will start reading the test pattern. 14. Press the start key.

The machine will start reading the test pattern. 15. When the machine completes reading the test 8. Press the start key. The machine will start reading the test pattern.

9. When the machine completes reading the test pattern, the Gradation Adjust screen will reap- The machine will start reading the test pattern. 15. When the machine completes reading the test

pattern, the Gradation Adjust screen will reap- pear. 9. When the machine completes reading the test pattern, the Gradation Adjust screen will reap-

pear. 16. Repeat steps from 11 through 14 to let the pattern, the Gradation Adjust screen will reap- pear.

10. Confirm that OK is displayed for Max Density machine read the test pattern two times. pear. 16. Repeat steps from 11 through 14 to let the

Adjustment on the right top of the screen. 17. Touch END. 10. Confirm that OK is displayed for Max Density machine read the test pattern two times.

18. Touch Exit on the Service Mode screen. Adjustment on the right top of the screen. 17. Touch END.

18. Touch Exit on the Service Mode screen.

E-7

Downloaded from www.Manualslib.com manuals search engine

XVII. Magnification adjustment 4. Display the Service Mode screen. XIX. Adjusting the document stop position 5. Check whether the difference in the width B

(For details of how to display the Service Mode between the chart and the copy sample is within

<Magnification in the feeding direction> screen, see the service manual.) <Sub Scanning Direction 1-side/ Sub Scanning the specified range.

Note: 5. Touch ADF. Direction 2-side> Difference in the width B = B of the copy sample

For the 423 machine or the 363 machine that 6. Touch Feed Zoom. Note: B of the chart

comes with the ADF as standard, perform this 7. Touch Orig. Feed Zoom Ad. For the 423 machine or the 363 machine that Specifications: 0 2.0 mm

adjustment during their installation if necessary. 8. Specify a value using the -/+ key. comes with the ADF as standard, perform this * If the difference in the width B does not fall within

For the 363 machine that does not have the ADF Adjustable range: -2.00 % to +2.00 % adjustment during their installation if necessary. the specified range, perform the following

as standard or the 283/223 machines, follow the (0.1% per step) For the 363 machine that does not have the ADF adjustment.

ADF installation manual and perform the adjust- If the difference in the width C is greater than the as standard or the 283/223 machines, follow the

ment during the ADF installation. specifications, use the (minus) key. ADF installation manual and perform the adjust-

1. Place the chart in the document feeding tray If the difference in the width C is smaller than the ment during the ADF installation.

(with the side having an arrow facing up). specifications, use the + (plus) key. 1. Place the chart in the document feeding tray (with

9. Touch END. the side having an arrow facing up).

10. Touch Exit on the Service Mode screen.

11. Make copies again and check the difference in

the width C.

XVIII. Mixed original size adjustment

Note: A1DMIXC017DA

For the 423 machine or the 363 machine that

comes with the ADF as standard, perform this 6. Display the Service Mode screen.

adjustment during their installation if necessary. (For details of how to display the Service Mode

A01HIXC011DC For the 363 machine that does not have the ADF screen, see the service manual.)

as standard or the 283/223 machines, follow the A01HIXC011DC 7. Touch ADF.

2. Make full size copies. ADF installation manual and perform the adjust- 8. Touch Original Stop Position.

3. Check whether the difference in the width C ment during the ADF installation. 2. Make full size copies. 9. Touch Sub Scanning Direction 1-Side or Sub

between the chart and the copy sample is within 1. Display the Service Mode screen. 3. Place the chart in the document feeding tray Scanning Direction 2-Side.

the specified range. (For details of how to display the Service Mode (Make sure that the blank surface of the chart 10. While looking at the copy sample, enter a value

Difference in the width C = C of the copy sample screen, see the service manual.) faces up). using the ten-key pad. (To switch the signs,

C of the chart 2. Touch ADF. press the +/- key.)

Specifications: 0 1.0 mm 3. Touch Mixed original size adjustment. Adjustable range: -4.0 mm to +4.0 mm

* If the difference in the width C does not fall within 4. Place the chart in the document feeding tray (0.1 mm per step)

the specified range, perform the following (lengthwise). If the difference in the width B is greater than the

adjustment. specifications, enter a positive (+) value.

If the difference in the width B is smaller than the

specifications, enter a negative (-) value.

11. Touch END.

12. Touch Exit on the Service Mode screen.

13. Make copies again and check the difference in

the width B.

A1DMIXC005DA

4. Make full size copies.

* Make copies in duplex mode.

A0P0IXC075DA

A1DMIXC018DA

5. Press the Start key.

6. Check that Adjustment Result is OK.

7. Touch END.

8. Touch Exit on the Service Mode screen.

E-8

Downloaded from www.Manualslib.com manuals search engine

<Main Scanning (Front)/ Main Scanning (Back)> 18. Check whether the difference in the width A XX. Date/Time setting XXII. Serial number input

Note: between the chart and the copy sample is within

the specified range. 1. Make sure that the Service Mode screen is dis- Note:

For the 423 machine or the 363 machine that

Difference in the width A = A of the copy sample played. Serial number input is needed only for optional

comes with the ADF as standard, perform this

A of the chart 2. Display the Date & Time Setting screen. devices that will be installed later.

adjustment during their installation if necessary.

Specifications: 0 2.0 mm (To display the Date & Time Setting screen, press 1. Select the Serial Number Input function as fol-

For the 363 machine that does not have the ADF

* If the difference in the width A does not fall within Stop 1 1 4 4 Clear on the control lows: System 1 Serial Number.

as standard or the 283/223 machines, follow the

the specified range, perform the following panel.) 2. Touch the item you want to enter and input the

ADF installation manual and perform the adjust-

adjustment. 3. Press the clear key. serial number.

ment during the ADF installation.

4. Enter the data for the year, month, day, and time- 3. Touch END.

14. Place the chart in the document feeding tray of-day from the 10-key pad.

(with the side having an arrow facing up). 4. For other devices, enter their serial number in the

5. Touch Entry. same way.

Note: 5. Touch END.

Touching the Entry key returns the figures in the

Date & Time Setting screen to 0 and Date & Time

Setting has been completed.

6. Touch END.

XXIII. Unit change

7. Touch Exit on the Service Mode screen. Note:

8. Select the Date/Time Setting function as follows: This function allows the user to select the type of

Utility/Counter Administrator Settings Enter message that will appear when the replacement

the Administrator Password (Default setting: time arrives for each of the different units.

A1DMIXC016DA 12345678) System Settings Date/Time Set- 1. Select the Unit Change function as follows:

tings. System 2 Unit Change.

19. Display the Service Mode screen. 9. Select the item you want to set and press the

A01HIXC011DC 2. Select the appropriate message type for each

(For details of how to display the Service Mode clear key. unit.

15. Make full size copies. screen, see the service manual.) 10. Enter the data for the year, month, day, and 3. Touch END.

16. Place the chart in the document feeding tray 20. Touch ADF. time-of-day from the 10-key pad.

(Make sure that the blank surface of the chart 21. Touch Original Stop Position. 11. Touch OK.

faces up). 22. Touch Main Scanning (Front) or Main Scan- 12. Touch Close three times.

ning (Back). XXIV. List output

23. While looking at the copy sample, enter a value

1. Load the tray 1 with A4 or Letter paper.

using the ten-key pad. (To switch the signs,

press the +/- key.) XXI. Install date 2. Touch List Output.

3. Check that Machine Management List is

Adjustable range: -3.0 mm to +3.0 mm 1. Display the Service Mode screen.

selected and press the start key.

(0.1 mm per step) (For details of how to display the Service Mode

The list will be output.

If the difference in the width A is greater than the screen, see the service manual.)

4. Output Adjustments List in the same way.

specifications, enter a positive (+) value. 2. Select the Install Date function as follows:

5. Touch 2.

If the difference in the width A is smaller than the System 1 Install Date.

6. Check that Service Parameter is selected and

specifications, enter a negative (-) value. 3. Press the clear key.

press the start key.

24. Touch END. 4. Enter the data for the year, month, and day from

The list will be output.

25. Touch Exit on the Service Mode screen. the 10-key pad.

7. Touch END.

26. Make copies again and check the difference in 5. Touch Entry.

A1DMIXC005DA

the width A. Note:

Note:

If installing paper feed options is unnecessary,

17. Make full size copies. Touching the Entry key returns the figures in the

touch "Exit" on the Service Mode Screen.

* Make copies in duplex mode. Install Date screen to 0 and Install Date has been

completed.

6. Touch END.

E-9

Downloaded from www.Manualslib.com manuals search engine

XXV. Affixing the paper size label XXVII. Adjusting registration of paper 10. If the measured width A falls outside the speci- 9. Measure width A of the test pattern on the back-

fied range, enter the correction value using the side of the test print produced and check that it

Affix the paper size label. source options falls within the specified range.

or key.

<1 way paper feed cabinet, large capacity cabinet> 11. Produce another test print and check to see if Specifications: 3.0 mm 2.0 mm

1. Display the Service Mode screen. width A falls within the specified range.

(For details of how to display the Service Mode 12. Touch END.

screen, see the service manual.) 13. Touch Exit on the Service Mode screen.

2. Select the function to be used as follows: A

Machine Printer Area Printer Image Center- Paper exit

ing Side 1 3rd. <2 way paper feed cabinet> direction

3. Press the start key. 1. Display the Service Mode screen.

A test print will be produced. (For details of how to display the Service Mode

4. Measure width A of the test pattern on the back- screen, see the service manual.)

side of the test print produced and check that it 2. Select the function to be used as follows:

falls within the specified range. Machine Printer Area Printer Image Center-

Paper size label A1UDIXC024DA

Specifications: 3.0 mm 1.0 mm ing Side 1 3rd.

3. Press the start key. 4061IXC152DA

For loading the paper as well as setting the paper

A test print will be produced.

type, refer to the users guide. 10. If the measured width A falls outside the speci-

4. Measure width A of the test pattern on the back-

* Affix the paper size labels under the labels that A fied range, enter the correction value using the

side of the test print produced and check that it

show the number of the drawers.

Paper exit falls within the specified range. or key.

direction Specifications: 3.0 mm 1.0 mm 11. Produce another test print and check to see if

width A falls within the specified range.

XXVI. Affixing the label (Legal restrictions * Perform the same adjustment procedure also for

on copying) A

the 4th.

Affix the label (Legal restrictions on copying) to the 12. Touch END.

Paper exit 13. Touch Exit on the Service Mode screen.

position shown below. direction

Note: 4061IXC152DA

This step may not be performed depending on the

applicable marketing area. 5. If the measured width A falls outside the specified XXVIII. Check through test print

range, enter the correction value using the Make operation checks using Setting Information

or key. Print.

Label 6. Produce another test print and check to see if 1. Select the function to be used as follows:

width A falls within the specified range. 4061IXC152DA

Utility/Counter User Settings Printer Set-

7. Select the function to be used as follows: tings Print Reports.

Prt. Image Center. Side 2 (Dup) 3rd. 5. If the measured width A falls outside the specified

The types of the test prints that can be printed will

8. Press the start key. range, enter the correction value using the be displayed.

A test print will be produced. or key. 2. Touch Configuration Page.

9. Measure width A of the test pattern on the back- 6. Produce another test print and check to see if 3. Touch A4 size and press the start key.

side of the test print produced and check that it width A falls within the specified range. Check that the machine produces the corre-

falls within the specified range. 7. Select the function to be used as follows: sponding printed page.

Specifications: 3.0 mm 2.0 mm Prt. Image Center. Side 2 (Dup) 3rd. 4. Touch Cancel and then touch Close four

A1UDIXE036DA

8. Press the start key. times.

A test print will be produced.

A

Paper exit

direction

4061IXC152DA

E-10

Downloaded from www.Manualslib.com manuals search engine

XXIX. Connecting cables

1. Connect the network cable to the machine and

XXX. Network setting

Make the TCP/IP address setting for the network.

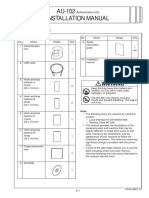

OC-509 Original Cover

route the cable as shown in the illustration. Note:

Consult the network administrator for the setting

INSTALLATION MANUAL

value to be entered and make settings as

required.

1. Select the function to be used as follows:

Utility/Counter Administrator Settings Enter

the Administrator Password Network Settings I. Accessory parts II. Installation procedures

TCP/IP Settings IPv4 Settings.

2. Touch Manual Input of IP Address Setting No. Name Shape Qty 1. Remove the two knockouts using nippers or a

Method and make the following settings. similar tool.

1. Original cover

IP Address: IP address of the controller

Subnet Mask: Subnet mask of the network, to

which the machine is connected 1

A1UDIXC025DA

Default Gateway: IP address of the default gate-

way

2. Connect the networking equipment (HUB) using 3. Touch OK. 4599U001AA

the network cable. 4. Turn OFF and ON the Main Power Switch. 2. Hinge cover A

Note: 5. Select the function to be used as follows: (right) *

The following shows the recommended network Utility/Counter Administrator Settings Enter

cables that correspond to each communication 1

the Administrator Password Network Settings

speed. Forward Detail Settings PING Confirma-

10BaseT/100BaseTX: Category 5 tion, and make the operation check of TCP/IP. A0EDIXC028DA

1000BaseT: Category 5E, Category 6

3. Hinge cover A

Networkport (left) *

A1UDIXC032DA

LED1 1

2. Attach the supplied hinge cover B (right) and

A0EDIXC029DA

hinge cover B (left).

(Four screws supplied with the original cover)

LED2 4. Hinge cover B

(right)

1

A1UDIXC027DA

A1UDIXC026DA

5. Hinge cover B

(left)

3. Check LEDs for lighting conditions.

LED1: 1

Should light up steadily if the link network con-

nection has been made.

LED2: A1UDIXC028DA

A1UDIXC029DA

Should blink according to the communications 6. Screw

status of the ACT network. (3 8 mm) 4

3. Install the original cover.

9646

* This part is not used with the original cover.

After unpacking, be sure to get rid of the

packaging materials and keep them out of

the reach of children.

Putting the head in the plastic bag

involves danger of suffocation.

A02EIXC038DA

E-11

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- A1ud 9622 01eDocument11 pagesA1ud 9622 01eOswaldo GuzmanNo ratings yet

- Installation Manual / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory PartsDocument8 pagesInstallation Manual / /: II. Installation Space (Unit: MM (Inch) ) IV. Accessory PartsAlexNo ratings yet

- Installation manual for bizhub C360 multifunction printerDocument8 pagesInstallation manual for bizhub C360 multifunction printerAlexNo ratings yet

- Installation ManualDocument26 pagesInstallation ManualhashemNo ratings yet

- Bizhub c200 InstalacionDocument14 pagesBizhub c200 InstalacioncopiartekNo ratings yet

- Manual Instalare Nou - A0P0 9951 02EDocument23 pagesManual Instalare Nou - A0P0 9951 02EHritcu IulianNo ratings yet

- Installation ManualDocument18 pagesInstallation ManualhashemNo ratings yet

- Installation Manual / /: I. Outline of Installation Procedures For Bizhub 362/ Bizhub 282/ Bizhub 222Document36 pagesInstallation Manual / /: I. Outline of Installation Procedures For Bizhub 362/ Bizhub 282/ Bizhub 222Radovan JaicNo ratings yet

- Installation Manual HighlightsDocument12 pagesInstallation Manual HighlightsAlin DoafidriNo ratings yet

- OKIMAT IPS - OKIMAT IPSe - OKIMAT EPS. Installation Instructions. (Translation of The Original Installation Instructions)Document36 pagesOKIMAT IPS - OKIMAT IPSe - OKIMAT EPS. Installation Instructions. (Translation of The Original Installation Instructions)RAMON CANDIDONo ratings yet

- Lu-202Xlm Installation Manual: 1.confirmation Prior To InstallationDocument12 pagesLu-202Xlm Installation Manual: 1.confirmation Prior To InstallationthiagoxsantosNo ratings yet

- Samsung Dvd-V3650 Chassis Diva Training ManualDocument202 pagesSamsung Dvd-V3650 Chassis Diva Training ManualPaulo Henrique SNo ratings yet

- Octave Ultrasonic Installation - GuideDocument16 pagesOctave Ultrasonic Installation - GuideCHRISTIAN JOSE BARRETO ROJASNo ratings yet

- FK-506 ImDocument9 pagesFK-506 ImionutkokNo ratings yet

- Thermaltake v21Document12 pagesThermaltake v21Chain CleanerProNo ratings yet

- KDL-32R413 Chassis Itc3Document21 pagesKDL-32R413 Chassis Itc3nnovik1No ratings yet

- Instruction Manual: AMO-NP-15167-01Document12 pagesInstruction Manual: AMO-NP-15167-01gary omanaNo ratings yet

- DVDP191 - Et SB Ex Si - 1257499059Document76 pagesDVDP191 - Et SB Ex Si - 1257499059Paulo Alexandre0% (1)

- 0060200.installation Manual 546560Document36 pages0060200.installation Manual 546560Tríade MusicNo ratings yet

- FieryPro80 Install ManualDocument3 pagesFieryPro80 Install ManualLucas MonteiroNo ratings yet

- KV-S2065L KV-S2065W: High Speed ScannerDocument157 pagesKV-S2065L KV-S2065W: High Speed ScannerGroza Alexandru ClaudiuNo ratings yet

- Service: ManualDocument76 pagesService: ManualJuan GutierrezNo ratings yet

- Manual Omega (ENG)Document46 pagesManual Omega (ENG)Eduardo Pereira0% (1)

- CIU - Communication Interface Unit: Installation and Operating InstructionsDocument10 pagesCIU - Communication Interface Unit: Installation and Operating InstructionszporvkasNo ratings yet

- Install PI-502 Post Inserter to Applied MachinesDocument8 pagesInstall PI-502 Post Inserter to Applied MachinesPitNo ratings yet

- Bizhubc368 C308 C258InstallInstrDocument13 pagesBizhubc368 C308 C258InstallInstrBizhub Konica MinoltaNo ratings yet

- StupDocument29 pagesStupNour BenNo ratings yet

- Service Instructions FOR Radar RDR 2000 With Moving Map Installation and Gns 530 (GPS) InstallationDocument42 pagesService Instructions FOR Radar RDR 2000 With Moving Map Installation and Gns 530 (GPS) InstallationjohnnysNo ratings yet

- PK-520 Installation Manual: 1. Accessory PartsDocument5 pagesPK-520 Installation Manual: 1. Accessory PartsАлексей ШешуковNo ratings yet

- User's Manual Benutzerhandbuch Mode d'emploi Manual del usuario Manuale dell'utente 安裝說明書 用戶手冊 ユーザーズマニュアル Руководство пользователяDocument19 pagesUser's Manual Benutzerhandbuch Mode d'emploi Manual del usuario Manuale dell'utente 安裝說明書 用戶手冊 ユーザーズマニュアル Руководство пользователяMarcelo OliveiraNo ratings yet

- AU-102bizhub287 227InstallInstrDocument7 pagesAU-102bizhub287 227InstallInstrRICHARD ALBERTO NARVA ORTIZNo ratings yet

- LT-LT-: Satellite TracerDocument70 pagesLT-LT-: Satellite TracerMarly SalasNo ratings yet

- Service Manual (Unique) : History Information For The Following ManualDocument27 pagesService Manual (Unique) : History Information For The Following ManualClubedoTecnicoNo ratings yet

- 3194E - 133-811 - DOC032 Digital RepeaterDocument28 pages3194E - 133-811 - DOC032 Digital RepeaterРинат СулеймановNo ratings yet

- Technical Repair Manual N45 N67 ENU 426Document426 pagesTechnical Repair Manual N45 N67 ENU 426Вячелав Егоров100% (1)

- Installation Manual ProceduresDocument13 pagesInstallation Manual Proceduresمصعب الغريبNo ratings yet

- Quick Guide: TroubleshootingDocument2 pagesQuick Guide: TroubleshootingHassan AlsafiNo ratings yet

- CAT Operation Manual Rev. A Created On 2008/09/10Document27 pagesCAT Operation Manual Rev. A Created On 2008/09/10Alexandre MorgadoNo ratings yet

- MAYA1010 User Guide for 24-Bit PCI Audio InterfaceDocument30 pagesMAYA1010 User Guide for 24-Bit PCI Audio InterfaceJKowalskiNo ratings yet

- Schematic Diagram SummaryDocument42 pagesSchematic Diagram SummaryStevenson QuinteroNo ratings yet

- CompellorDocument41 pagesCompellorAbdalhakeem Al turkyNo ratings yet

- 4hk1 - Engine Manual - TM PDFDocument353 pages4hk1 - Engine Manual - TM PDFFrancisco Beiza93% (29)

- CoverDocument2 pagesCoverRisoSilvaNo ratings yet

- 28 Amp/Hour Battery: InstallationDocument6 pages28 Amp/Hour Battery: Installationgood dayNo ratings yet

- ) NO. TMS02/010E: Technical Report (ManualDocument38 pages) NO. TMS02/010E: Technical Report (ManualXavier TorrasNo ratings yet

- Gear Boxes MaintenanceDocument8 pagesGear Boxes Maintenancekostis57No ratings yet

- ... For A Smooth Operation: WWW - Ecoroll.de Mail@ecoroll - deDocument23 pages... For A Smooth Operation: WWW - Ecoroll.de Mail@ecoroll - derodrigo.firstNo ratings yet

- Philips+Chassis+TPM15 7LDocument66 pagesPhilips+Chassis+TPM15 7LEveraldoNo ratings yet

- 7a23c2064facc64b7e8c74691a5667a8c5fc20ea301498463c9258eaaf7dd84f_optimDocument40 pages7a23c2064facc64b7e8c74691a5667a8c5fc20ea301498463c9258eaaf7dd84f_optimJekonia JakobNo ratings yet

- Installation Manual: 1. Mounting !Document2 pagesInstallation Manual: 1. Mounting !Thukhoadaihocla TaNo ratings yet

- Manual for Operation and Maintenance of Vibrating Screen PVDocument13 pagesManual for Operation and Maintenance of Vibrating Screen PVErick OttoNo ratings yet

- AS 53102 Visual KV SG 96M0364 GB WW 0079-3Document444 pagesAS 53102 Visual KV SG 96M0364 GB WW 0079-3vNo ratings yet

- Chartek 7 Application Manual (Rev10) 2017-05-19Document64 pagesChartek 7 Application Manual (Rev10) 2017-05-19suriya100% (6)

- Install MK-738/FK-512 Mount and Fax KitDocument6 pagesInstall MK-738/FK-512 Mount and Fax KitmfialloNo ratings yet

- AKD Installation Manual en (REV AA)Document216 pagesAKD Installation Manual en (REV AA)Royal Enfield ApprenticeNo ratings yet

- MT607i MT610i: Installation InstructionDocument2 pagesMT607i MT610i: Installation InstructionIvanNo ratings yet

- Ru-510 e A4fc955099Document20 pagesRu-510 e A4fc955099pjte39No ratings yet

- Fiber Distributed Data Interface [FDDI] Technology ReportFrom EverandFiber Distributed Data Interface [FDDI] Technology ReportRating: 5 out of 5 stars5/5 (1)

- Cisco Intelligent WANDocument878 pagesCisco Intelligent WANHernán Conrado Krause LeytonNo ratings yet

- The Complete Home Decorating Idea Book - Kathleen S. Stoehr PDFDocument401 pagesThe Complete Home Decorating Idea Book - Kathleen S. Stoehr PDFCristian OvanisofNo ratings yet

- CreateSpace Java Mar 2016 ISBN 1530669170 PDFDocument107 pagesCreateSpace Java Mar 2016 ISBN 1530669170 PDFDávid Attila SzékelyNo ratings yet

- A Beginner's Guide To Learning The Basics of Java Programming 2015Document144 pagesA Beginner's Guide To Learning The Basics of Java Programming 2015gabitaNo ratings yet

- Java - Java Programming For Beginners - A Simple Start To Java ProgrammingDocument221 pagesJava - Java Programming For Beginners - A Simple Start To Java ProgrammingBASIC100% (1)

- 04 Intellij Idea Tutorial InternalDocument394 pages04 Intellij Idea Tutorial InternalGocht GuerreroNo ratings yet

- Intellij Idea HelpDocument3,016 pagesIntellij Idea HelpRadovan JaicNo ratings yet

- A Beginner's Guide To Learning The Basics of Java Programming 2015Document144 pagesA Beginner's Guide To Learning The Basics of Java Programming 2015gabitaNo ratings yet

- IntelliJ IDEA Handbook PDFDocument73 pagesIntelliJ IDEA Handbook PDFAca Chch100% (1)

- JAVA - Felix Alvaro PDFDocument104 pagesJAVA - Felix Alvaro PDFincaNo ratings yet

- 100 Java Programs With Output Useful Collection of Java Programs - Aniket PataskarDocument112 pages100 Java Programs With Output Useful Collection of Java Programs - Aniket Pataskarnandhuln86% (64)

- A Beginner's Guide To Learning The Basics of Java Programming 2015Document144 pagesA Beginner's Guide To Learning The Basics of Java Programming 2015gabitaNo ratings yet

- NET For Visual FoxPro DevelopersDocument553 pagesNET For Visual FoxPro DevelopersEduardNo ratings yet

- JAVA - Felix Alvaro PDFDocument104 pagesJAVA - Felix Alvaro PDFincaNo ratings yet

- Visual Foxpro Client-Server Handbook - ContentsDocument52 pagesVisual Foxpro Client-Server Handbook - Contentsdesignwebargentina100% (1)

- Visual FoxproDocument20 pagesVisual Foxprovalentina orejuelaNo ratings yet

- Basics of Visual FoxPro ProgrammingDocument51 pagesBasics of Visual FoxPro ProgrammingRadovan JaicNo ratings yet

- What's New in Visual FoxPro 7.0 (PDFDrive)Document281 pagesWhat's New in Visual FoxPro 7.0 (PDFDrive)georgedragosNo ratings yet

- Special Edition Mastering Visual FoxPro 6Document864 pagesSpecial Edition Mastering Visual FoxPro 6jessie_rasonable_ortiz71% (7)

- (249326ea 35c3 4322 Baed 44c0beb2797e) ObjectPascalHandbook SydneyVersion CompleteDocument571 pages(249326ea 35c3 4322 Baed 44c0beb2797e) ObjectPascalHandbook SydneyVersion CompleteRadovan JaicNo ratings yet

- Certification Guide V FPDocument187 pagesCertification Guide V FPFausto ZarriaNo ratings yet

- DelphiDocument126 pagesDelphiRadovan JaicNo ratings yet

- Client Server Applications With Visual FoxPro and SQL Server PDFDocument263 pagesClient Server Applications With Visual FoxPro and SQL Server PDFWalter R. Ojeda Valiente100% (1)

- (249326ea 35c3 4322 Baed 44c0beb2797e) ObjectPascalHandbook SydneyVersion CompleteDocument571 pages(249326ea 35c3 4322 Baed 44c0beb2797e) ObjectPascalHandbook SydneyVersion CompleteRadovan JaicNo ratings yet

- The Delphi IDE Open Tools API Version 1.1 PDFDocument160 pagesThe Delphi IDE Open Tools API Version 1.1 PDFazouzNo ratings yet

- Lauren Blakely-Mister O PDFDocument343 pagesLauren Blakely-Mister O PDFMariana BUJNITA81% (27)

- (249326ea 35c3 4322 Baed 44c0beb2797e) ObjectPascalHandbook SydneyVersion CompleteDocument571 pages(249326ea 35c3 4322 Baed 44c0beb2797e) ObjectPascalHandbook SydneyVersion CompleteRadovan JaicNo ratings yet

- DelphiDocument126 pagesDelphiRadovan JaicNo ratings yet

- The Delphi IDE Open Tools API Version 1.1 PDFDocument160 pagesThe Delphi IDE Open Tools API Version 1.1 PDFazouzNo ratings yet

- Ovrhtp-400 DGTDocument4 pagesOvrhtp-400 DGTJGRNo ratings yet

- Daily instrument check sheetDocument8 pagesDaily instrument check sheetRaju RaiNo ratings yet

- Building Creative Thinking in Science TeachersDocument15 pagesBuilding Creative Thinking in Science TeachersJudarlyn Madria100% (1)

- CN Manu Sg303745557590a41 e 1000164105-03Document60 pagesCN Manu Sg303745557590a41 e 1000164105-03heruono sitorusNo ratings yet

- Material Handling (Conveyors, Cranes and Lifts)Document34 pagesMaterial Handling (Conveyors, Cranes and Lifts)abdallah hosinNo ratings yet

- 1.1 APS Powder Insert: Parts List PL 40993 EN 13Document16 pages1.1 APS Powder Insert: Parts List PL 40993 EN 13Alexandre VecaNo ratings yet

- Hascevher Catalog 2019Document64 pagesHascevher Catalog 2019AntonNo ratings yet

- Consumable Rates (USA)Document184 pagesConsumable Rates (USA)Vineet 01No ratings yet

- Shapers, Planner and SlottersDocument121 pagesShapers, Planner and SlottersReyven ReconNo ratings yet

- Amazon Standard Ambient Mini-VRF 20190130Document106 pagesAmazon Standard Ambient Mini-VRF 20190130saqib ismailNo ratings yet

- Technical Bulletin: Probe Shield Accessory For DELTA-50 (50kV Analyzer)Document4 pagesTechnical Bulletin: Probe Shield Accessory For DELTA-50 (50kV Analyzer)Ayleen nuñezNo ratings yet

- TC5X Configuration & Accessories GuideDocument17 pagesTC5X Configuration & Accessories GuideYesica SantamariaNo ratings yet

- Fitting and Machinig 7.6Document48 pagesFitting and Machinig 7.6Grayden Cozithinkmybrothersgay RichterNo ratings yet

- BeneFusion SP1&SP3 Syringe Pump Parts - V1.0 - EN PDFDocument8 pagesBeneFusion SP1&SP3 Syringe Pump Parts - V1.0 - EN PDFTheodor LuchkinNo ratings yet

- Pneumatic Connections: Figure 1: Tru-Balance Box-Type 300/400 Series Sifter Pneumatic SchematicDocument2 pagesPneumatic Connections: Figure 1: Tru-Balance Box-Type 300/400 Series Sifter Pneumatic SchematicmiguelNo ratings yet

- 1) The Bottle Opener Is An Example Of: Force, Work and EnergyDocument4 pages1) The Bottle Opener Is An Example Of: Force, Work and EnergyVinothini SreedharNo ratings yet

- RX Fume Hoods DatasheetDocument29 pagesRX Fume Hoods DatasheetMihai TanaseNo ratings yet

- US2394521 Lynn PatentDocument4 pagesUS2394521 Lynn PatentFulcrum386No ratings yet

- Adidas Original Ecuador 1Document33 pagesAdidas Original Ecuador 1kelvinmd2009No ratings yet

- PSG Wise Valid Permanent Vendor List PDFDocument17 pagesPSG Wise Valid Permanent Vendor List PDFsanjaydrdoNo ratings yet

- 55 XCDocument1 page55 XCDigvijay DuttaNo ratings yet

- Types and Applications of Common HVAC SystemsDocument39 pagesTypes and Applications of Common HVAC SystemsNur Atiqah NabilaNo ratings yet

- Script For PC BuildingDocument4 pagesScript For PC BuildingKC Glenn DavidNo ratings yet

- wc5890 Service ManualDocument2,010 pageswc5890 Service ManualCopiadoras IncodepNo ratings yet

- Cat 3412Document4 pagesCat 3412hoseinNo ratings yet

- Hitech Procedure: Lathe How To Check Skip Signal On A Lambda10LDocument11 pagesHitech Procedure: Lathe How To Check Skip Signal On A Lambda10LKalle HahneNo ratings yet

- Pin Out BCM SANTA FE CMDocument9 pagesPin Out BCM SANTA FE CMfbordilloNo ratings yet

- Reverse Current Advice PV SystemsDocument3 pagesReverse Current Advice PV Systemsamitraut2011No ratings yet

- Checking and Charging Brake System ComponentsDocument3 pagesChecking and Charging Brake System ComponentsЖеня СавченкоNo ratings yet

- Critical Die Quality InspectionDocument2 pagesCritical Die Quality InspectionDanu MamlukatNo ratings yet

![Fiber Distributed Data Interface [FDDI] Technology Report](https://imgv2-1-f.scribdassets.com/img/word_document/282658933/149x198/df3dc47c73/1699545009?v=1)