Professional Documents

Culture Documents

Servogem Ep: Description Application

Uploaded by

RAHULGUNDHER25Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Servogem Ep: Description Application

Uploaded by

RAHULGUNDHER25Copyright:

Available Formats

SERVOGEM EP

DESCRIPTION APPLICATION

Servogem EP greases are premium quality lithium soap

base products containing an extreme pressure Servogem EP greases are recommended for the

additive. These grades are specially formulated to lubrication of both plain and anti-friction bearings in a

meet the demand of an EP grease for boundary wide variety of application such as automotive and

lubrication conditions so as to prevent excessive wear, earth moving equipment, gear couplings, electric

localised welding or seizure often associated with such motors, mining equipment and general industrial

severs operating conditions. machinery.

Servogem EP greases possess excellent shear stability,

high load carrying capacity, high oxidation stability and PERFORMANCE STANDARDS

capability to provide protection against rust and

corrosion. Servogem EP 0, EP 1 & EP 2 & EP 3 meets IS:7623-

1993(EP Type).

PERFORMANCE BENEFITS Servogem EP 2 also meets IPSS:1-09-005.

Servogem EP greases are approved by the leading

Possess excellent dispensing properties at low and machinery manufacturers, such as:

high temperature, ensuring trouble free lubrication ACC-Vickers-Babcock Ltd., Durgapur

with centralise lubrication system BHEL, Hardwar/ Hyderabad

Protect machine elements from excessive wear Bharat Pumps & Compressors Ltd., Naini

Prevent welding and seizure of the moving parts Heavy Engineering Corporation Ltd., Ranchi

often caused by shock loading Hindustan Motors Ltd. (Earth Moving Equipment

Protect bearing elements against rust and Division), Trivellore

corrosion MECON, Ranchi

Resist water wash out thus assuring adequate BEML, Mysore,

lubrication over extended service intervals MEYA Transmissions, Pune

CHARACTERISTICS

NLGI GRADE 00 0 1 2 3

Colour Brown to Brown to Brown to Brown to Brown to

Dark Brown Dark Brown Dark Brown Dark Brown Dark Brown

Structure Smooth Smooth Smooth Smooth Smooth

Soap Type Lithium Lithium Lithium Lithium Lithium

Worked Penetration 400-430 355-385 310-340 265-295 220-250

Drop Point, C Min. 170 180 180 180 180

Water washout @ 80 Deg C 10 Max 10 Max 10 Max 10 Max 10 Max

Weld Load, Kg 225 225 225 280 280

Wear Scar Dia, mm, Max 0.6 0.6 0.6 0.6 0.6

Timken OK Load , Min 40 40 40 40 40

Jul-15

You might also like

- Credit Card DetailsDocument2 pagesCredit Card DetailsLazare Lazare100% (1)

- Hacking and Cracking TechniguesDocument16 pagesHacking and Cracking TechniguesEric MuiaNo ratings yet

- FSAE Damper Guide - Jim Kasprzak Kaz Tech TipDocument25 pagesFSAE Damper Guide - Jim Kasprzak Kaz Tech TipAlex BradleyNo ratings yet

- Dental Decks Radiology 2011-2012Document74 pagesDental Decks Radiology 2011-2012Prakarsh Dwivedi100% (3)

- High Performance LubricantsDocument20 pagesHigh Performance Lubricantsmaicol21n100% (2)

- Gear OilDocument26 pagesGear OilRohit Ramamurthy TevnanNo ratings yet

- OTC Project Corporate ITS MeetingDocument27 pagesOTC Project Corporate ITS MeetingrajinusaNo ratings yet

- Moly GreaseDocument2 pagesMoly GreaseDivyanshu SharmaNo ratings yet

- PVG32Document80 pagesPVG32Carlos PaezNo ratings yet

- Brochure-Metatech Thermal Spray PVT LTDDocument12 pagesBrochure-Metatech Thermal Spray PVT LTDbadesharamkNo ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- A o BrochureDocument20 pagesA o Brochuremax69442No ratings yet

- Green BuildingDocument67 pagesGreen Buildingdharmvir thakur100% (1)

- Servogem Ep: Description ApplicationDocument1 pageServogem Ep: Description ApplicationUdit JainNo ratings yet

- Gem EPDocument1 pageGem EPRAHULGUNDHER25No ratings yet

- Poweroil: Power Gem Ep00, Ep0, Ep1 & Ep2 Extreme Pressure GreasesDocument1 pagePoweroil: Power Gem Ep00, Ep0, Ep1 & Ep2 Extreme Pressure GreasesTechnicians SIMNo ratings yet

- MAK Lanthax EP GreaseDocument2 pagesMAK Lanthax EP GreaseshobhaNo ratings yet

- Servogem: Description ApplicationDocument1 pageServogem: Description ApplicationRAHULGUNDHER25No ratings yet

- ServocoatDocument1 pageServocoatbrpnaidu2157No ratings yet

- PETRONAS - Grease Li EP 0 - 10 10 2018Document3 pagesPETRONAS - Grease Li EP 0 - 10 10 2018Amira Shukor100% (1)

- Servo WayDocument1 pageServo Waybankim chauhanNo ratings yet

- Balmerol Liprex Ep SeriesDocument2 pagesBalmerol Liprex Ep SeriesManish MaharjanNo ratings yet

- DANA LITHIUM BASE EP GREASE PDS - by DANA LUBRICANTS UAEDocument1 pageDANA LITHIUM BASE EP GREASE PDS - by DANA LUBRICANTS UAEankurdanaNo ratings yet

- WL Ep2 Ep3 Grease PDSDocument1 pageWL Ep2 Ep3 Grease PDSAung Myat ThuNo ratings yet

- Brochure - Genuine Oil SPECIFICATIONS OILDocument14 pagesBrochure - Genuine Oil SPECIFICATIONS OILBouslimi SouhaibNo ratings yet

- Grease and ApplicationsDocument21 pagesGrease and ApplicationsDinesh babuNo ratings yet

- Bearing Lubrication: Grease Quantity 0.05 X D X B GmsDocument2 pagesBearing Lubrication: Grease Quantity 0.05 X D X B GmsMH M100% (1)

- Servo Product Data - Industrial GradesDocument23 pagesServo Product Data - Industrial GradesUtkarsh100% (1)

- Gem EPDocument1 pageGem EPAnanda Shankar SahuNo ratings yet

- Eni Grease MSX 2-460Document2 pagesEni Grease MSX 2-460ranjanguptNo ratings yet

- Servo Coat 120Document1 pageServo Coat 120BhaveshBalasNo ratings yet

- Servo Mesh Oil GradesDocument1 pageServo Mesh Oil Gradessrinu rao bandaruNo ratings yet

- Benefits:: A Sheer Stable EP Fortified Water Resistant Grease For High Load ApplicationsDocument1 pageBenefits:: A Sheer Stable EP Fortified Water Resistant Grease For High Load ApplicationsRahul JainNo ratings yet

- Servo System 32 46 68Document1 pageServo System 32 46 68ramu naik malothNo ratings yet

- Urania Turbo CF 4 PDFDocument1 pageUrania Turbo CF 4 PDFNik Mohd FikriNo ratings yet

- Industrial Gearbox Oils: Parthan EpDocument20 pagesIndustrial Gearbox Oils: Parthan EpChetan PrajapatiNo ratings yet

- Spheerol Epl GreaseDocument2 pagesSpheerol Epl GreaseRaja YadavNo ratings yet

- Parthan Ep: Industrial Gearbox OilsDocument1 pageParthan Ep: Industrial Gearbox OilsHesham MahdyNo ratings yet

- Bechem Oil EP 68 1000Document1 pageBechem Oil EP 68 1000zaidan hadi100% (1)

- Mak Lanthax Ep GreaseDocument2 pagesMak Lanthax Ep GreaseTaqudas AhmedNo ratings yet

- Eni I-Sigma Universal 15W-40: Characteristics (Typical Figures) SAE Grade 15W-40Document1 pageEni I-Sigma Universal 15W-40: Characteristics (Typical Figures) SAE Grade 15W-40Muhammad RipandiNo ratings yet

- Servogrease WR 1 (B)Document1 pageServogrease WR 1 (B)Udit JainNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- Alphasyn Ep 220Document2 pagesAlphasyn Ep 220Atika AtikaNo ratings yet

- Ichiro Lithium Ep GreaseDocument1 pageIchiro Lithium Ep GreasednoaisapsNo ratings yet

- Titanus EpDocument1 pageTitanus EpTAREK HAMADNo ratings yet

- Tds G. Beslux Tribopaste L-2-3 S (26.03.09)Document1 pageTds G. Beslux Tribopaste L-2-3 S (26.03.09)Iulian BarbuNo ratings yet

- Servo Product Data - Automotive Grades PDFDocument45 pagesServo Product Data - Automotive Grades PDFkaushikNo ratings yet

- GeneralEquipment MachineryGreasesDocument1 pageGeneralEquipment MachineryGreasesramakrishnagangavaraNo ratings yet

- TDS - Power Metcut S-PlusDocument1 pageTDS - Power Metcut S-PlusVaidya Mahesh ManoharNo ratings yet

- SG-1330-680 TDSDocument2 pagesSG-1330-680 TDSRajneesh RallanNo ratings yet

- Chevron Multifak EP GreaseDocument1 pageChevron Multifak EP GreaseGeorgina SuleNo ratings yet

- Servo SM: Description ApplicationDocument1 pageServo SM: Description Applicationphucdc095041No ratings yet

- Cast Wheel in Indian Rlys-Present StatusDocument6 pagesCast Wheel in Indian Rlys-Present StatusDevarshi GaurNo ratings yet

- Characteristics (Typical Figures) Eni Blasia 68 100 150 220 320 460 680Document2 pagesCharacteristics (Typical Figures) Eni Blasia 68 100 150 220 320 460 680AMAZING AGNo ratings yet

- Ultratack Mill Grease SG 4001Document1 pageUltratack Mill Grease SG 4001arkpNo ratings yet

- GreaseDocument3 pagesGreaseWac GunarathnaNo ratings yet

- Meditran SMX Sae 15w-40-OkDocument2 pagesMeditran SMX Sae 15w-40-Okbilly radja pratamaNo ratings yet

- Servo Premium 20W-40: Description ApplicationDocument1 pageServo Premium 20W-40: Description ApplicationBALANo ratings yet

- MAK Hitemp Xtra SM GreaseDocument1 pageMAK Hitemp Xtra SM GreaseAnand PadhiyarNo ratings yet

- Foodmax Grease CAS S LSDocument2 pagesFoodmax Grease CAS S LSALFREDO CANTOS CORNEJONo ratings yet

- Lactuca 3000 Metal Working Fluid Cutting OilDocument2 pagesLactuca 3000 Metal Working Fluid Cutting OilAbhimanyaNo ratings yet

- Metal Forming Lubricants: Wire Drawing Cold Forming Sheet Metal Forming RollingDocument7 pagesMetal Forming Lubricants: Wire Drawing Cold Forming Sheet Metal Forming RollingNokiabhre WijayaNo ratings yet

- PETRONAS Urania Optimo 10W-40Document1 pagePETRONAS Urania Optimo 10W-40Hazrulnizam HassanNo ratings yet

- Servo Prime & LP: Description ApplicationDocument1 pageServo Prime & LP: Description ApplicationRAHULGUNDHER25No ratings yet

- Servohydrex: Description ApplicationDocument1 pageServohydrex: Description ApplicationRAHULGUNDHER25No ratings yet

- Servosystem HLPDocument1 pageServosystem HLPRAHULGUNDHER25No ratings yet

- Servogem Super HT: Description ApplicationDocument1 pageServogem Super HT: Description ApplicationRAHULGUNDHER25No ratings yet

- Servosyngear: Description ApplicationDocument1 pageServosyngear: Description ApplicationRAHULGUNDHER25No ratings yet

- Servosystem HLP Af: Description ApplicationDocument1 pageServosystem HLP Af: Description ApplicationRAHULGUNDHER25No ratings yet

- Servocut S: Description ApplicationDocument1 pageServocut S: Description ApplicationRAHULGUNDHER25No ratings yet

- JK48V100 LiFePO4 Battery SpecificationDocument1 pageJK48V100 LiFePO4 Battery SpecificationMaxime TerrettazNo ratings yet

- Leak Detection Compendium Pfeiffer VacuumDocument74 pagesLeak Detection Compendium Pfeiffer VacuumRAHUL CHAVANKENo ratings yet

- Floor Fryer: 40 Lb. Stainless Steel Liquid Propane or Natural GasDocument2 pagesFloor Fryer: 40 Lb. Stainless Steel Liquid Propane or Natural GasJose SavinonNo ratings yet

- WooCommerce Websites in India - CRMDocument35 pagesWooCommerce Websites in India - CRMPrakash NNo ratings yet

- Media and Information Literacy: I. Multiple Choice. Read The Questions Carefully and Encircle The Letter of Your ChoiceDocument4 pagesMedia and Information Literacy: I. Multiple Choice. Read The Questions Carefully and Encircle The Letter of Your ChoiceKelvin MallariNo ratings yet

- Ritchey 2006 CatalogDocument50 pagesRitchey 2006 CatalogAleksandar SaricNo ratings yet

- Datasheet TL072Document11 pagesDatasheet TL072Martín SayagoNo ratings yet

- Findings Iml601Document4 pagesFindings Iml601Zaitil Aqilah ZawaniNo ratings yet

- Kevin Dalimunthe PBC NewDocument31 pagesKevin Dalimunthe PBC Newapi-295590351No ratings yet

- SCM - The HR DisconnectDocument16 pagesSCM - The HR DisconnectsirfanalizaidiNo ratings yet

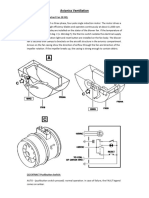

- Avionics VentilationDocument4 pagesAvionics Ventilationsa eedNo ratings yet

- Daily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateDocument1 pageDaily Progress Report For Site Engineer Format No: 00 Name of The Site Progress Date Report DateGokul KgsNo ratings yet

- Design EquationsDocument4 pagesDesign Equationsmurakami27No ratings yet

- Part 2 - The Stereo Listening Angle PDFDocument11 pagesPart 2 - The Stereo Listening Angle PDFRichard Hallum100% (1)

- Module WIFI TYWE3S User ManualDocument13 pagesModule WIFI TYWE3S User ManualPen TranNo ratings yet

- Management DecisionDocument23 pagesManagement DecisionHussain abbasNo ratings yet

- Cswip - Section 06-Wps and Welders QualificationDocument15 pagesCswip - Section 06-Wps and Welders QualificationNsidibe Michael Etim100% (1)

- Transformatory Germetizirovannye EI48x20.5-12VA Importer BelTerraTrans (Proizvoditel' Thai Lin Radio)Document4 pagesTransformatory Germetizirovannye EI48x20.5-12VA Importer BelTerraTrans (Proizvoditel' Thai Lin Radio)DontazavrNo ratings yet

- Amcrest NV4432-HS User Manual V3.6.1 PDFDocument222 pagesAmcrest NV4432-HS User Manual V3.6.1 PDFPhil MartinNo ratings yet

- I DenDocument34 pagesI DenGajendra SettyNo ratings yet

- Jetson Nano Tutorial To Setup VNCDocument2 pagesJetson Nano Tutorial To Setup VNCzabithNo ratings yet

- Design Freeze Monitoring - 17dec19Document74 pagesDesign Freeze Monitoring - 17dec19kramlester1982No ratings yet