Professional Documents

Culture Documents

Sap PC NTS

Uploaded by

Jit Ghosh0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

SAP PC NTS

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pagesSap PC NTS

Uploaded by

Jit GhoshCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 2

Material

Activity - Wielding, Assembly , Painting, QA

Work Center -- 1000 , 2000

Routing --

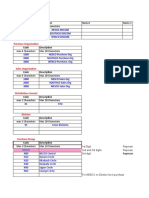

KP06 - Cost Element / Cost Center / Activity Type -- Cost Planning

100001 5.000.000 MFASM1

100005 3.000.000 MFPND1

100012 30.000.000 MFQAD1

130031 12.400.000 MFWLD1

KP26 - Activity type / Price Planning

MFASM1 1.500 H - Machine

MFPND1 2.700 H - Labour

MFQAD1 3.800 H - Labour

MFWLD1 2.000 H - Machine

KSPI - Plan Price Calculation

Cost calculation with Quantity Structure with BOM

Valuation Price for Material Component -- from MM

Activity Price- from Fixed / Variable Cost

Applied O/H

All the vallue needs to convert to standard Pricing

1. We have to create the following :

1. Costing Variants,

2. Cost Sheet

3. Costing Lot

4. Cost Component Structure

5. Costing Run - CK11n -

( Ref : Note 1658589 - Error CK694 in T-code CK11N and CK40N)

Whatever cost we calculate we will transfer to Material Cost

Working Note :

FG -- 1300000013, 1300000014

FG -- 19

SFG --1400000012

RM -- 13

RM -- 15

RM -- 17

Mat Doc no. 5000000050 -- Initial Stock Entry - Mat No : 1400000012

Planned Order -- 613

You can activate any number of statuses in a production order. It is possible for

a production order to be simultaneously "released", "pre-costed", "printed" and

"confirmed".

The Main system statuses which are in use at Netafim:

- CRTD = Created. This is the status given to each production order upon creation.

As long as a production order has not

been released, it cannot be printed or confirmed.

- REL = Released. Once a production order is created, it can be released for

production either automatically or manually.

- PCNF = Partially Confirmed. This status is given to an order once the first

confirmation had been received from the

shopfloor. This status will change automatically to CNF when a final confirmation

will be done.

- CNF = Confirmed. Confirmations of production progress and produced goods are

reported to SAP from the shop flor.

A final confirmation is given to an order when its production is complete.

- PDLV = Partially delivered. This status is given to production order that is

partially delivered.

- DLV = Delivered. This status is given to production order that is fully

delivered.

- TECO = Technically Complete. This status is given to production orders which had

been given both CNF status (final

production confirmation) as well as User Status of CHECK (see "User Status"

section). TECO is set automatically by a daily job running in the background.

- DLFL = Deletion Flag. This status indicates that the order had been marked for

deletion, but was not erased from the

information system.

Production Order Life Cycle

Material Master - MM01

2: BOM creation - CS01

3: Work Center creation - CR01

4: Routing creation -CA01

5: PIR Generation -MD61

6: MRP Run - for Total Planning - MD01

for Single-Item, Multi-Level - MD02

7: Evaluation through MRP list and Stock requirement list -

MRP List -MD05,

Stock Requirements List - MD04

8: Conversion of Planned order to Production order - With a

planned order -CO40

With material - CO01

9: Order management - Change >With material CO02

10: Confirmations- For order CO15

For Operation -For time ticket -CO11N

11: Goods issue - MB1A--261Movement type

12: Goods receipt - For Order MB31

13: TECO or Close Order- from Prod. Order Header menu

14. KGI2 - Overhead Calculation

15:Ko88 Order settlement

16:kkbc_ord costing report

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- S5 - RA T CodesDocument5 pagesS5 - RA T CodesJit GhoshNo ratings yet

- Voyager - S4HANA Conversion ProjectDocument4 pagesVoyager - S4HANA Conversion ProjectJit GhoshNo ratings yet

- Concur Customer Discovery QuestionnaireDocument17 pagesConcur Customer Discovery QuestionnaireJit GhoshNo ratings yet

- SAP RAR Period End Processing and Accounting EntriesDocument16 pagesSAP RAR Period End Processing and Accounting EntriesJit GhoshNo ratings yet

- COPA Activate Account BasedDocument2 pagesCOPA Activate Account BasedJit GhoshNo ratings yet

- XK99 Mass Vendor ChangeDocument4 pagesXK99 Mass Vendor ChangeJit GhoshNo ratings yet

- Concur Discovery Questions: Topic Item Country/Business UnitsDocument12 pagesConcur Discovery Questions: Topic Item Country/Business UnitsJit GhoshNo ratings yet

- Transaction Code CESU Business Process Master List - FICODocument4 pagesTransaction Code CESU Business Process Master List - FICOJit GhoshNo ratings yet

- S. No. Module Dev ID Development Type Frequency Explanation of Requirements Standard SAP Solution Input OutputDocument1 pageS. No. Module Dev ID Development Type Frequency Explanation of Requirements Standard SAP Solution Input OutputJit GhoshNo ratings yet

- Transaction Code CESU Business Process Master List - FICODocument4 pagesTransaction Code CESU Business Process Master List - FICOJit GhoshNo ratings yet

- Busness Process Mapping List Prject Name: JBVNL Module: FICO (Finance & Controlling)Document10 pagesBusness Process Mapping List Prject Name: JBVNL Module: FICO (Finance & Controlling)Jit GhoshNo ratings yet

- CESU Approval of Revised SAP Asset Management BBPDocument2 pagesCESU Approval of Revised SAP Asset Management BBPJit GhoshNo ratings yet

- Streamline Travel & Expense with ConcurDocument13 pagesStreamline Travel & Expense with ConcurJit GhoshNo ratings yet

- R-APDRP Project Business BlueprintDocument2 pagesR-APDRP Project Business BlueprintJit GhoshNo ratings yet

- SGR - ID - Wtihholding TaxDocument13 pagesSGR - ID - Wtihholding TaxJit GhoshNo ratings yet

- CESU - RAPDRP - FICO - CC Master DataDocument2 pagesCESU - RAPDRP - FICO - CC Master DataJit GhoshNo ratings yet

- L2 Training Guide for Flexible Real Estate ManagementDocument49 pagesL2 Training Guide for Flexible Real Estate Managementgagan3y83% (6)

- Asset Legacy Transfer Error - Accumulated Values For Activation Date Not Allowed in Transfer YearDocument2 pagesAsset Legacy Transfer Error - Accumulated Values For Activation Date Not Allowed in Transfer YearJit GhoshNo ratings yet

- Incorrect WTH TAN Calculation For DP and Invoice ProcessingDocument2 pagesIncorrect WTH TAN Calculation For DP and Invoice ProcessingJit GhoshNo ratings yet

- GL - Master Chart Of Accounts DataDocument49 pagesGL - Master Chart Of Accounts DataJit GhoshNo ratings yet

- S4hana CopaDocument10 pagesS4hana CopaGhosh2No ratings yet

- Miel Development List Abap Bi BoDocument5 pagesMiel Development List Abap Bi BoJit GhoshNo ratings yet

- 6b. CESU - RAPDRP - FICO - RICEFW - Flow ChartDocument3 pages6b. CESU - RAPDRP - FICO - RICEFW - Flow ChartJit GhoshNo ratings yet

- Reply-Wesco - FICO AMDocument165 pagesReply-Wesco - FICO AMJit GhoshNo ratings yet

- CESU Material Management and Plant Maintenance ProcessesDocument19 pagesCESU Material Management and Plant Maintenance ProcessesJit GhoshNo ratings yet

- 1000 Nesco Discom 2000 Southco Discom 3000 Wesco Discom: Code DescriptionDocument58 pages1000 Nesco Discom 2000 Southco Discom 3000 Wesco Discom: Code DescriptionGhosh2No ratings yet

- Busness Process Mapping List Prject Name: JBVNL Module: FICO (Finance & Controlling)Document10 pagesBusness Process Mapping List Prject Name: JBVNL Module: FICO (Finance & Controlling)Jit GhoshNo ratings yet

- SPPL March 2018 Document with Repeating EntriesDocument8 pagesSPPL March 2018 Document with Repeating EntriesGhosh2No ratings yet

- HSBCnet - MY MT940 File SpecificationDocument8 pagesHSBCnet - MY MT940 File SpecificationGhosh2No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SyllabusDocument11 pagesSyllabusraviNo ratings yet

- Ddoocp Ms March2012 FinalDocument11 pagesDdoocp Ms March2012 FinalSarge ChisangaNo ratings yet

- EZdrummer Operation Manual PDFDocument21 pagesEZdrummer Operation Manual PDFberangleblanc100% (1)

- Wireless Data Converter IDATA and Wireless DC Meter IDCMETER Quick GuideDocument8 pagesWireless Data Converter IDATA and Wireless DC Meter IDCMETER Quick GuidetaufiqNo ratings yet

- CR Lora 102 Lorawanr and NB IotDocument6 pagesCR Lora 102 Lorawanr and NB IotTim ShipleNo ratings yet

- Md. Nabil Zawad: LecturerDocument13 pagesMd. Nabil Zawad: LecturerMd TareqNo ratings yet

- Digital Transformation Week 2 NotesDocument3 pagesDigital Transformation Week 2 NotesJasmine AndersonNo ratings yet

- Operation Analytics and Investigating Metric Spike PROJECT 3RDDocument11 pagesOperation Analytics and Investigating Metric Spike PROJECT 3RDNiraj Ingole100% (1)

- Connecting OLE-Compatible Office Applications To The R - 3 SystemDocument6 pagesConnecting OLE-Compatible Office Applications To The R - 3 SystemChitturi PraveenNo ratings yet

- Ramdump Modem 2023-06-01 19-16-22 PropsDocument26 pagesRamdump Modem 2023-06-01 19-16-22 PropsOliver VelascNo ratings yet

- Swift MailerDocument63 pagesSwift Mailerdan3dssNo ratings yet

- Cloud Web HelpDocument306 pagesCloud Web HelpVăn HảiNo ratings yet

- GIDAR Analytics Canvas: Goals Information DataDocument4 pagesGIDAR Analytics Canvas: Goals Information DataAlfred AmihereNo ratings yet

- Java Micro-ProjectDocument26 pagesJava Micro-ProjectSaloni PatilNo ratings yet

- PREMIER EDUCATION SOCIETY’S TRINITY INTERNATIONAL SCHOOL (IGCSE – A LEVEL) MOCK – IIDocument7 pagesPREMIER EDUCATION SOCIETY’S TRINITY INTERNATIONAL SCHOOL (IGCSE – A LEVEL) MOCK – IIYashodhaNo ratings yet

- 1 - Unit 5 - Assignment Brief 1Document3 pages1 - Unit 5 - Assignment Brief 1Tran Quang Thang FGW DNNo ratings yet

- Item BarcodeDocument473 pagesItem BarcodemanjunathNo ratings yet

- VoIP to Mobile Gateway Connects IP PBX to GSMDocument2 pagesVoIP to Mobile Gateway Connects IP PBX to GSMPedro AlgarañazNo ratings yet

- Shashank CV Business Analyst 11+ ExpDocument3 pagesShashank CV Business Analyst 11+ ExpVibhu SaxenaNo ratings yet

- 82-Telecommunication Brochure PDFDocument18 pages82-Telecommunication Brochure PDFAlfredo Palacios EnriquezNo ratings yet

- Sensirion I2c Functional Description sfm3xxxDocument10 pagesSensirion I2c Functional Description sfm3xxxCesar GordilloNo ratings yet

- Arena AnimationDocument14 pagesArena AnimationKriti JainNo ratings yet

- Illustrated Parts & Service Map: HP Compaq 8300 Elite Business PC Ultra Slim DesktopDocument4 pagesIllustrated Parts & Service Map: HP Compaq 8300 Elite Business PC Ultra Slim DesktopFlorea SorinNo ratings yet

- Manual Primavera p6Document88 pagesManual Primavera p6Cristian MansillaNo ratings yet

- Job Responsibilities and Skills Required - Versa ExperienceDocument2 pagesJob Responsibilities and Skills Required - Versa ExperienceSureshNo ratings yet

- Catalogues and Specifications User GuideDocument218 pagesCatalogues and Specifications User GuideManny Mendoza100% (1)

- WESPER: Zero-Shot and Realtime Whisper To Normal Voice Conversion For Whisper-Based Speech InteractionsDocument13 pagesWESPER: Zero-Shot and Realtime Whisper To Normal Voice Conversion For Whisper-Based Speech Interactionsluksisnskks929299wNo ratings yet

- Getting Started GuideDocument102 pagesGetting Started GuideLin KenNo ratings yet

- Book Bank UML DiagramsDocument9 pagesBook Bank UML DiagramsVanithaNo ratings yet

- User ManualDocument35 pagesUser ManualAlex Aeron100% (1)