Professional Documents

Culture Documents

Assessment of Site Selection For Aluminum Mining Industry in West Kalimantan Province

Assessment of Site Selection For Aluminum Mining Industry in West Kalimantan Province

Uploaded by

Dennis KusumaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assessment of Site Selection For Aluminum Mining Industry in West Kalimantan Province

Assessment of Site Selection For Aluminum Mining Industry in West Kalimantan Province

Uploaded by

Dennis KusumaCopyright:

Available Formats

1

Assessment of Site Selection for Aluminum Mining Industry in West Kalimantan Province

Assessment of Site Selection for Aluminum Mining Industry in West Kalimantan Province

Denis Kusuma Dinata1*, Chafid Fandeli2, Yohannes Sardjono1,2

1

Institut Teknologi Yogyakarta 55171, Indonesia

2

Center for Accelerator Science and Technology National Nuclear Energy, Yogyakarta, Indonesia

ARTICLE INFO ABSTRACT

Keywords: Aluminum is the most abundant metal mineral in the earth's crust.

Its existence in the bowels of the earth must be explored by

Aluminum mining industry

mining activities. As much as 90% of the world's bauxite

The assessment of site selection

reserves, which are the primary raw material for primary

Sustainable mining

aluminum, are concentrated as extensive sedimentary layers in the

tropics and sub-tropics, West Africa, Australia, South America,

and Southeast Asia. West Kalimantan Province is one of

Indonesia's tropical regions which has a total deposition of

bauxite resources of 2.07 billion tons, which is equivalent to

57.32% of the total bauxite resources in Indonesia. The issue that

must also be a concern at this time is the environmental problem

of the impact of natural resource exploration and how to create an

aluminum mining industry that is not only limited to economic

fulfillment but also environmentally sustainable. At present many

cases of mining in Indonesia contribute to local land, water, and

ecosystem damage. The assessment of the selection of the right

location to determine the clearance of the aluminum mining

industry in West Kalimantan in this paper will consider aspects of

ecology, water resources, population density, and post-mining

rehabilitation in order to achieve sustainable mining.

1. INTRODUCTION a large spread of bauxite deposits in the territory of

Indonesia. 2.07 billion tons of bauxite resources

Aluminum is a relatively young metal but is now the were recorded, equivalent to 57.32% of the total

most-shipped for various needs in the construction, bauxite resources in Indonesia [4].

transportation, packaging (cans, aerosols, foils, and The potential of bauxite resources in the mining and

carbon) and in electricity sectors. To fulfill this quarrying sectors can support economic growth in

demand, the practice of mining continues. Mining West Kalimantan, but it’s only contributed 5.6% of

represents an important source of income worldwide the economic sectors in 2016. This can be

[1]. Primary aluminum will grow next on the market maximized in line with the regulation "Law No. 4 of

for alumina and bauxite, which is also projected to 2009 concerning Mineral and Coal Mining," that

grow by 4%. Communities are getting richer, starting in 2014 raw minerals are prohibited from

increasing living standards and consumption levels being exported and must be processed domestically.

[2]. China currently represents more than 50% of the The main factors considered during the process of

demand for global primary aluminum and alumina selecting the location for the aluminum mining

production and this demand is expected to increase industry in West Kalimantan are generally financial,

until 2030 [3], due to reduced demand for local environmental, geological, land use and security

bauxite in China pushing the country. factors. These factors are combined together to

Indonesia is one of the metal industry's strategic avoid potential losses. Some of the environmental

sectors for aluminum in the form of bauxite ore. factors are soil, air, and water pollution, forest

Indonesia's total bauxite minerals resources are 3.61 destruction, etc. [5]. This paper will review the

tons and 1.26 billion tons of estimated reserves. assessment of aluminum production mine sites

West Kalimantan has a high potential for the which are focused on environmental factors, namely

development of the aluminum mining industry with ecology, water resources, population, and post-

mining land rehabilitation.

Corresponding author. Tel: +6287784414146

E-mail: d3niskusuma17@gmail.com

Assessment of Site Selection for Aluminum2Mining Industry in West Kalimantan Province

2. THEORETICAL BACKGROUND 5. Break down bauxite using methods such as ripping

with very large bulldozers, and in some cases drilling

2.1 Distribution of Bauxite Ore Minerals in and blasting;

Indonesia 6. After the bauxite becomes smoother, put it in a truck

Bauxite ore is formed in the tropics and or conveyor, it will need processing or stockpiling.

subtropics that allows rock weathering. Bauxite is Purification can be improved and is a relatively simple

formed from sedimentary rocks which have a process that includes increasing the grade of bauxite

relatively high Aluminum (Al) content, low iron through the disposal of unused material (waste) through

(Fe) levels and little or no contained Quartz (SiO2). filtration, destruction, washing and dewatering. This

Indonesia is one of the tropical countries that has a process produces higher-grade ore products and tailings

very large deposit of bauxite ore The Indonesian (mainly clay and fine sand);

bauxite mineral is mainly located in the Riau, 7. Transport the bauxite to alumina refineries; and

Bangka and Belitung Islands, West Kalimantan, a 8. After the transportation is complete, the affected area

small part in Central Kalimantan, Southeast is rehabilitated.

Sulawesi, Sumba and the Halmahera Islands [4]. 2.3 Geographical Conditions of West Kalimantan

It is known that the measured content of bauxite 2.3.1 Land and water

ore spread across Indonesia was 828,289,086 tons The Province of West Kalimantan has an area of ±

and the proven reserves were 330,359,053 tons in 14,730,700 ha, ± 8,389,600 ha of which is a forest area

2018, while the measured content of bauxite ore in consisting of natural reserve and conservation areas

Indonesia in 2016 was 602,248,630.18 tons and covering ± 1,621,046 ha, protected forest with an area of

proven reserves were 211,392,968 tons. This data ± 2,310,873 ha, production forest limited to ± 2,132,398

indicates that many bauxite ore minerals have not ha, ordinary production forest with an area of ±

yet been recorded [4]. 2,127,365 ha and conversion production forest with ±

The province of West Kalimantan includes the 197,918 ha [6]. The province of West Kalimantan also

largest distribution area of bauxite ore deposits, has many rivers, so it is nicknamed the Thousand River

with total bauxite resources of 2.07 billion tons, Province. The Kapuas River is the largest and longest

equivalent to 57.32% of the total bauxite resources river in Indonesia that passes through the Districts of

in Indonesia. The total bauxite reserves are 0.84 Kapuas Hulu, Sintang, Sanggau, Sekadau and Pontianak

billion tons, equivalent to 66.77% of the total with a length of 1,086 km. Kubu River is the shortest

national mineral reserves [4]. The spread of bauxite river at 38 Km in Kubu Raya Regency [7].

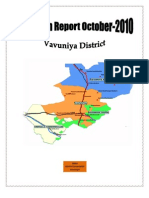

in West Kalimantan forms a Lateritic Belt covering 2.3.2 Population

9 regencies and cities, namely Singkawang City, Sustainable mining comprises many issues, such as

Bengkayang Regency, Pontianak Regency, Landak establishing transparent relationships with communities

Regency, Sanggau Regency, Sekadau Regency, as a fundamental metric for investment decisions [8].

Kubu Raya Regency, North Kayong Regency, Based on data from the population department, the

Ketapang Regency. Its spread extends from north record of the population of West Kalimantan in semester

to south on the west side of West Kalimantan 2 of 2018 was 5,422,814 people with an area of 146,807

Province [3]. Km2, the population density in West Kalimantan is

2.2 Exploration of Sustainable Bauxite Mining around 37 people per Km2. The highest population for

The exploration of bauxite minerals is generally each regency or city in West Kalimantan is Pontianak

extracted by open-pit mining, consisting of several City, Kubu Raya Regency, Sambas Regency, Ketapang

stages, witch are site preparation, mining, mineral Regency, Sanggau Regency, Sintang Regency, and

processing, transportation of raw materials to Landak Regency. 5 of the 7 regencies and cities with the

refineries, dan mine land cover or neglect. In highest population are traversed by lateritic belts which

sustainable bauxite mining, there are additional contain a lot of bauxite ore deposits.

stages to maintain ecological sustainability, namely 2.4 Alumina Process

relocating vegetation and land which still has the Bauxite is a source of aluminum metal after

potential to become a resource at the post-mining extraction by the Bayer process to produce alumina.

rehabilitation stage. The method used usually About 85% of bauxite is purified into alumina (or

depends on the location, and the steps that can be alumina chemicals), which is then melted into

taken are as follows [3]: aluminum, 8% produces alumina chemicals and 7% is

1. Clean the land from vegetation and save useful used for abrasive materials, refractories, propellants and

wood; in cement production [3]. Depending on the grade of ore,

2. Collect seeds, seedlings, and cuttings, which can it takes 4-6 tons of bauxite to be purified to 2 tons of

be used for revegetation; alumina, which is then melted into approximately 1 ton

3. Take the topsoil (and sometimes also the subsoil) of aluminum metal. Bauxite has a good quality in terms

to be used in rehabilitation, either by transferring of high alumina content and low reactive silica content,

land or by future use); which contains at least 40% alumina and <5% reactive

4. Take overburden (the layer between soil and silica [9]. The content of reactive silica in bauxite should

bauxite); be low because it will react with sodium hydroxide from

liquor (at least 1 mole of NaOH per mole of reactive

3

Assessment of Site Selection for Aluminum Mining Industry in West Kalimantan Province

silica). Alumina refining transforms bauxite ore to sodium aluminate. The sodium aluminate solution is

calcined alumina (Al2O3). This extraction method, used to make alumina [13]. In the process, washing

known as the Bayer process, has a progressive series of bauxite ore consumes a lot of water, so water

steps: crushing of the ore, digestion in sodium hydroxide management must be carried out carefully. West

solutions, clarification to remove solid waste materials, Kalimantan has 51 lakes and 8 large rivers which can be

precipitation of solid hydrated alumina, and calcination a great potential for water resources in the mining

to drive off water. The amount of reactive silica is one of process. Sustainable aspects must avoid, or at least

the major factors that determine the quality and price of minimize the amount of turbid water left by mining sites

ore [10]. through effective sediment control efforts [14].

Most bauxite mining companies in Indonesia have 3.3 Population

been already implementing methods of washing by wet

screening in trommel screen and vibrating screen after The distribution of the bauxite extends from north to

crushing the ore. Yield of the washed bauxite is between south on the west side of Kalimantan in West

40-50%. The rest (50-60%) is rejected as tailing. (In Kalimantan province. Fig.1 shows the Lateritic Belt

India, more than 40% of the bauxite ore is rejected as region that is rich in sediment deposits from bauxite ore

low-grade tailing. In terms of energy utilization, this through densely populated districts/cities include

process is inefficient and wasteful due to high water Pontianak City, Kubu Raya District, Ketapang Regency,

consumable [9]. Sanggau Regency, and Landak Regency [4].

3. DISCUSSION

During the process of opening and developing mining

industry projects, whatever decisions are made take into

account a number of considerations, likewise in the

assessment of the choice of the location where the

business will operate. A comprehensive approach to

consider environmental carrying capacity and post-

mining rehabilitation involves the analysis of these

drivers to be balanced to achieve a sustainable mining

industry.

3.1 Ecological capability of the region

Generally, environmental elements consist of abiotic and

biotic, and the relationship of both is very significant.

Mining interactions are closely related to land and forest

areas. Opencast mining causes much greater degradation

to land than underground mining [11]. Fig. 1 Lateritic Belt in West Kalimantan

The ecological footprint of bauxite mines (especially At the same time mining activity can bring positive

open-pit mining) and the fact that these mines are things to the local community, provide business

generally found in tropical and sub-tropical regions opportunities and create jobs directly or indirectly. Land

means that aluminum ore deposits often overlap or are acquisition and population displacement are rare issues

close to areas of high conservation value [3]. in bauxite mining, in fact, the economic movement is a

The use of forest areas for development purposes outside major issue for companies concerns, especially those

forestry activities can only be done for activities that who depend on the land. Therefore, planning must start

have inevitable strategic objectives [12]. West early. Companies must really engage with affected

Kalimantan is a strategic economic area with 4,457,681 communities to review and mitigate the important

ha of the aluminum mining industry with a cultivation impacts of land-use change and the possibility of

forest area. Such forest exploitation activities must have transferring communities to jointly develop resettlement

effective mitigation to reduce contributions to action plans with local governments [3].

biodiversity, which is the key to sustainability [3]. 3.4 Rehabilitation of Mining Areas

3.2 Water Resources The continuing mining activities unavoidably result in

the loss of original soils and a large volume of the

Water is also an important component in all bauxite tailings dam, which will inevitably change the landscape

mining activities [3]. Indonesia will be counted as a of the local environment. Although open-pit mining and

bauxite-producing country after owning a CGA underground mining damage the land in different ways,

processing plant owned by PT ICA and SGA owned by the damage to the surface landscape by open-pit mining

PT ANTAM. The existence of these two factories helped is greater than that of underground mining, which can

Indonesia to diminish loss because of exporting raw cause irreversible changes in the mining area, even

bauxite. In the manufacture of alumina, there is a Bayer turning mountains into artificial lakes [15]. All these

process which produces a solution of red mud and issues stress the need to consider how land reclamation

Assessment of Site Selection for Aluminum4Mining Industry in West Kalimantan Province

can be performed in conjunction with the creation of how to mitigate against the red mud

sustainable livelihood opportunities for communities footprint in ghana,” J. Urban Environ. Eng.,

living in surrounding areas[16]. the reclamation can be vol. 6, no. 2, pp. 48–56, 2012.

started by returning topsoil that has been separated in the [6] R. of I. Ministry of Forestry, “Keputusan

sustainable mining stage which contains a lot of organic Menteri Kehutanan Republik Indonesia

elements that can be combined with revegetation from

Nomor 733/menhut-II/2014 Tentang

seeds that had been removed previously [17].

Kawasan Hutan dan Konservasi Perairan

Provinsi Kalimantan Barat,” 2014.

5. CONCLUSION

[7] P. P. Daerah and P. K. Barat,

In terms of the resources and potential “Penyelenggaraan pemerintahan daerah

possessed by West Kalimantan, the aluminum (lppd) provinsi kalimantan barat akhir tahun

mining industry can make it a center of excellence anggaran 2017,” 2017.

based on bauxite minerals. Therefore West [8] K. Zharan and J. C. Bongaerts, “Decision-

Kalimantan is considered to have very high making on the integration of renewable

potential in the national mining industry. Mining energy in the mining industry: A case

practices continue to prioritize seeing ecological studies analysis, a cost analysis and a

potential in the province of West Kalimantan that is SWOT analysis,” J. Sustain. Min., vol. 16,

rich and has a reduced impact on the environment. no. 4, pp. 162–170, 2017.

In realizing this, the support of all parties and [9] “Upgrading of Tayan’S Crude Bauxite

relevant stakeholders starts from the government Using Rotary Drum Scrubber,” Indones.

with related regulations, the role of the community Min. J., vol. 17, no. 1, pp. 40–52, 2017.

as local residents, and the role of the company in [10] H. Kvande, “The aluminum smelting

supporting the realization of mining in the process,” J. Occup. Environ. Med., vol. 56,

aluminum industry that is economically sound and no. 5, pp. 2–4, 2014.

environmentally friendly. [11] A. O. Omotehinse and B. D. Ako, “The

environmental implications of the

ACKNOWLEDGMENT exploration and exploitation of solid

We sincerely thank to Prof. Ir. Yohannes Sardjono, minerals in Nigeria with a special focus on

APU and PSTA BATAN for providing the facilities Tin in Jos and Coal in Enugu,” J. Sustain.

needed for this study and to all staff members who Min., vol. 18, no. 1, pp. 18–24, 2019.

helped carry out this assessment. [12] KLHK, “Peraturan Menteri Lingkungan

Hidup dan Kehutanan Nomor

REFERENCES P.50/Menlhk/Setjen/Kum.1/6/2016 tentang

Pedoman Pinjam Pakai Kawasan Hutan,”

[1] C. R. Domínguez, I. V. Martínez, P. M. pp. 1–58, 2016.

Piñón Peña, and A. Rodríguez Ochoa, [13] H. Haryadi, “Analysis of the value – added

“Analysis and evaluation of risks in for Tayan bauxite ore and chemical grade

underground mining using the decision alumina,” Indones. Min. J., vol. 19, no. 3,

matrix risk-assessment (DMRA) technique, pp. 167–178, 2017.

in Guanajuato, Mexico,” J. Sustain. Min., [14] K. Lingkungan et al., “lINGKUNGAN

vol. 18, no. 1, pp. 52–59, 2019. HIDUP iNDONESIA lINGKUNGAN

[2] D. Paraskevas, A. Van De Voorde, K. HIDUP iNDONESIA,” Bul. tataruang

Kellens, W. Dewulf, and J. R. Duflou, BKPRN, vol. 91, no. 1, pp. 186–189, 2017.

“Current Status, Future Expectations and [15] L. Dong, X. Tong, X. Li, J. Zhou, S. Wang,

Mitigation Potential Scenarios for China’s and B. Liu, “Some developments and new

Primary Aluminium Industry,” Procedia insights of environmental problems and

CIRP, vol. 48, pp. 295–300, 2016. deep mining strategy for cleaner production

[3] E. Pertama, “Panduan Penambangan Bauksit in mines,” J. Clean. Prod., vol. 210, pp.

Berkelanjutan,” 2018. 1562–1578, 2019.

[4] P. Data, D. A. N. Teknologi, K. Energi, D. [16] S. A. Narula, M. A. Magray, and A. Desore,

A. N. Sumber, and D. Mineral, Ministry of “A sustainable livelihood framework to

Energy and Mineral Resources, Indonesia, implement CSR project in coal mining

Affect of bauxite processing on economic sector,” J. Sustain. Min., vol. 16, no. 3, pp.

value of West Kalimantan region. . 83–93, 2017.

[5] S. K. Y. Gawu, E. E. Amissah, and J. S. [17] O. Morteza and R. Mahdi, “Mine Planning

Kuma, “The proposed alumina industry and and Equipment Selection,” no. 1999, 2014.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- (SPEECH) A Short Speech On Global WarmingDocument1 page(SPEECH) A Short Speech On Global WarmingMarius Villanueva100% (1)

- Organization Associated With Biodiversity Organization-Methodology For Execution IucnDocument45 pagesOrganization Associated With Biodiversity Organization-Methodology For Execution IucnmithunTNNo ratings yet

- A Guide To Riverfront DevelopmentDocument48 pagesA Guide To Riverfront DevelopmentAbhishek Kadian100% (1)

- Calculo Tasa de DeforestacionDocument9 pagesCalculo Tasa de DeforestacionFre Figueredo100% (1)

- Environmental Engineering M TECH SYLLABUS JNTUHDocument23 pagesEnvironmental Engineering M TECH SYLLABUS JNTUHnagasmsNo ratings yet

- Senator Maria Kalaw Katigbak Memorial School (SMKKMS) Laboratory Cooperative - Brgy. Marawoy, Lipa CityDocument5 pagesSenator Maria Kalaw Katigbak Memorial School (SMKKMS) Laboratory Cooperative - Brgy. Marawoy, Lipa CityRitch LibonNo ratings yet

- What Is National Forest PolicyDocument10 pagesWhat Is National Forest PolicyPinku ShawNo ratings yet

- Human EcologyDocument24 pagesHuman EcologyVictoriaNo ratings yet

- ATTENDANCE Refresher b-2Document5 pagesATTENDANCE Refresher b-2Krystel Kaye Mangmang CasinilloNo ratings yet

- Carrying Capacity and Limiting Factors ActivityDocument5 pagesCarrying Capacity and Limiting Factors ActivitySaraA.DelgadoNo ratings yet

- Evaluation Report On Western Ghats Development Programme in Tamil Nadu (A Joint Study)Document5 pagesEvaluation Report On Western Ghats Development Programme in Tamil Nadu (A Joint Study)anbujeNo ratings yet

- DRRS Oct 2010Document82 pagesDRRS Oct 2010ictgisNo ratings yet

- Earth Science For STEM Q1 MODULE 10 11 Week 5Document11 pagesEarth Science For STEM Q1 MODULE 10 11 Week 5Ghaniella B. JulianNo ratings yet

- Proposal of Activity May 3Document9 pagesProposal of Activity May 3Anne Corrinne BacolodNo ratings yet

- Town PlanningDocument40 pagesTown PlanningAyushi AgarwalNo ratings yet

- ZimbanjeX Pitch Incl Trial AskDocument14 pagesZimbanjeX Pitch Incl Trial AskTaf GongNo ratings yet

- What You Should Know After This Lab:: Intermediate Disturbance HypothesisDocument5 pagesWhat You Should Know After This Lab:: Intermediate Disturbance HypothesisAhmad ElaridNo ratings yet

- Consequences of Deforestation by Ritika AgarwalDocument19 pagesConsequences of Deforestation by Ritika AgarwalritikaNo ratings yet

- Final Essay (Foundation in English)Document2 pagesFinal Essay (Foundation in English)YOGA SHURUTHI A/P YESUDASS BP21160619No ratings yet

- Grassland - WikipediaDocument19 pagesGrassland - WikipediakamaalNo ratings yet

- Cairo University: Faculty of EngineeringDocument2 pagesCairo University: Faculty of Engineeringayman_awadallahNo ratings yet

- Environmental Impact Assessment: 1. Importance of Eia in Respect of Enviornmental ProtectionDocument12 pagesEnvironmental Impact Assessment: 1. Importance of Eia in Respect of Enviornmental ProtectionRotich VincentNo ratings yet

- MFA - LCA Tools in Waste ManagementDocument12 pagesMFA - LCA Tools in Waste ManagementAnkur DhirNo ratings yet

- Drought Vulnerability and Impacts of Climate Change On Livestock Production and Productivity in Different Agro Ecological Zones of EthiopiaDocument20 pagesDrought Vulnerability and Impacts of Climate Change On Livestock Production and Productivity in Different Agro Ecological Zones of Ethiopiaabyalew b.No ratings yet

- 2021 Ui Greenmetric World University RankingsDocument4 pages2021 Ui Greenmetric World University RankingsAhmed WasifNo ratings yet

- 4.2 Energy Sector: Meaning of Socio-Scientific IssuesDocument2 pages4.2 Energy Sector: Meaning of Socio-Scientific IssuestaufiqNo ratings yet

- JournalDocument11 pagesJournalKate Mariel ColarinaNo ratings yet

- Great Barrier Reef BibliographyDocument2 pagesGreat Barrier Reef Bibliographyapi-219485794No ratings yet

- Batangas State UniversityDocument36 pagesBatangas State UniversityMeynard MagsinoNo ratings yet

- Bùi Thùy Dương - 20029231Document17 pagesBùi Thùy Dương - 20029231Dương ThùyNo ratings yet