Professional Documents

Culture Documents

Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 125

Uploaded by

Andi KaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 125

Uploaded by

Andi KaCopyright:

Available Formats

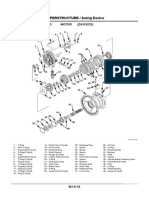

UPPERSTRUCTURE / Pump Device

13. Heat pump casing (51) to 50 to 80 °C (122 to 176 19. Install special tools (ST 2649), (ST 2650) over the

°F). spline parts of shafts (13) and (19).

CAUTION: Use special tool to insert the shaft NOTE: If the special tools are not available, wind

(19) assembly, because pump casing (51) has vinyl tape and etc. over spline part of the

been heated. shaft to protect the oil seal (49) from being

damaged.

14. Apply a film of hydraulic oil to the outside of bear-

ings (10), (12) installed on shaft (19), install shaft

(19) to pump casing (51) using the special tool.

If it is difficult to insert, tap in shaft (19) with a

ST 2650

guide bar, etc.

49

Special Tool

M8, Pitch 1.25

51

19 W157-02-04-022

ST 2649

IMPORTANT: Apply a film of grease to the inner

diameter of oil seals (49) (2 used).

Wooden Block Wooden

Block

20. Evenly tap oil seals (49) (2 used) onto shafts (13)

W178-02-04-012 and (19).

15. Install shaft (13) into pump casing (51), using the 21. Remove special tool (ST 2649), (ST 2650) from

same procedure as above step 14. shafts (13) and (19).

16. Wait for pump casing (51) cooling down to the 22. Install retaining rings (50) (2 used) to pump casing

temperature lower than 40 °C (104 °F). (51).

17. Install O-rings (23) (2 used) to stoppers (24) (2

used), and install them to pump casing (51).

: 19 mm

: 34.5 N⋅m (3.5 kgf⋅m, 25.3 Ibf⋅ft)

CAUTION: Pump casing weight: 65 kg (143 lb)

18. Attach a nylon sling to pump casing (51), lift it up

and position the regulator with the mounting sur-

face facing up.

W2-4-15

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Andi KaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 207Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 207Andi KaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 212Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 212Andi KaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 213Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 213Andi KaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 205Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 205Andi KaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 112Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 112Andi KaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 123Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 123Andi KaNo ratings yet

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 129Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 129Andi KaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- UNDERCARRIAGE / Travel Device: of Roller Bearing (30) On The Motor Side, So Don't Remove ItDocument1 pageUNDERCARRIAGE / Travel Device: of Roller Bearing (30) On The Motor Side, So Don't Remove ItAndi KaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 109Document1 pageManual de Taller Excavadora Hitachi Zx200 225 230 270 - 109Andi Ka100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Chapter 8 Solid State Relays ContactorsDocument74 pagesChapter 8 Solid State Relays ContactorsAndi KaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Class 69 Special Application Pressure Switches 4269SA: Hubbell Industrial Controls, IncDocument2 pagesClass 69 Special Application Pressure Switches 4269SA: Hubbell Industrial Controls, IncAndi KaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Dieselmax 55kW Engine SpecDocument4 pagesDieselmax 55kW Engine SpecSamir Khan100% (1)

- Understanding The Experiences of Grade-11 HumssDocument57 pagesUnderstanding The Experiences of Grade-11 HumssBLANCHE BUENONo ratings yet

- Neuro Reviewer 2Document33 pagesNeuro Reviewer 2joanneNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Fuji FCR 5000Document435 pagesFuji FCR 5000Lion Micheal OtitolaiyeNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Roth Conversion Strategies To ConsiderDocument5 pagesRoth Conversion Strategies To Considerkj4892No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Borang IshipDocument9 pagesBorang IshipUlfa RahayuNo ratings yet

- Solid Waste Management in SchoolsDocument32 pagesSolid Waste Management in SchoolsRusty TorioNo ratings yet

- AS 2122 HK1 DecuongHKI ANH7Document19 pagesAS 2122 HK1 DecuongHKI ANH7Nguyễn Lê KhánhNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Micro InsuranceDocument27 pagesMicro Insurancedrishya3No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Fluoroscopy Initial TestDocument3 pagesFluoroscopy Initial Testthepharaoh1234No ratings yet

- Hoja Técnica - Bomba 3 HP BerkeleyDocument4 pagesHoja Técnica - Bomba 3 HP BerkeleyRodrigo LimaNo ratings yet

- Final Revised Manuscript of ResearchDocument35 pagesFinal Revised Manuscript of ResearchKay Laguna100% (1)

- Aalco Metals LTD - Stainless Steel 201201L202204 - 97 PDFDocument3 pagesAalco Metals LTD - Stainless Steel 201201L202204 - 97 PDFNaman PrajapatiNo ratings yet

- SLL VS NLRCDocument11 pagesSLL VS NLRCJepski ScopeNo ratings yet

- 02 TBS Lightning Protection System PDFDocument448 pages02 TBS Lightning Protection System PDFgilbertomjcNo ratings yet

- Mind Body Relationship in PsychotherapyDocument8 pagesMind Body Relationship in Psychotherapymoyosore100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Assignment - Certificate of Pre & Primary Teacher TrainingDocument4 pagesAssignment - Certificate of Pre & Primary Teacher TrainingSuganya VimalNo ratings yet

- Anxiety Research Paper 10Document10 pagesAnxiety Research Paper 10api-582860150No ratings yet

- Sample - Global Pharmaceutical Contract Manufacturing Outsourcing (CMO) Market - Mordor IntelligenceDocument54 pagesSample - Global Pharmaceutical Contract Manufacturing Outsourcing (CMO) Market - Mordor IntelligenceSilke IgemannNo ratings yet

- Chapter 52 - Drugs Affecting The Urinary Tract and The BladderDocument12 pagesChapter 52 - Drugs Affecting The Urinary Tract and The BladderJonathonNo ratings yet

- Leica LS10 LS15 User ManualDocument106 pagesLeica LS10 LS15 User Manualabdelghafour adjNo ratings yet

- More Evidence Confirms Diet's Link To Mental Health: Could An Apple A Day Really Keep Depression and Anxiety Away?Document5 pagesMore Evidence Confirms Diet's Link To Mental Health: Could An Apple A Day Really Keep Depression and Anxiety Away?psychologyconceptsNo ratings yet

- US8236919Document4 pagesUS8236919Billy FowlerNo ratings yet

- Modelling The Transport of Crude Oil in Sandy Soil: Ejikeme Ugwoha, Victor Emeka Amah, Precious Ehis Agharese-AduDocument12 pagesModelling The Transport of Crude Oil in Sandy Soil: Ejikeme Ugwoha, Victor Emeka Amah, Precious Ehis Agharese-AdusfNo ratings yet

- Assignment Schumpeter CaseDocument1 pageAssignment Schumpeter CaseValentin Is0% (1)

- Crew Handbook v36 190809 PDFDocument311 pagesCrew Handbook v36 190809 PDFIanA100% (3)

- Fs Chapter I Vi ApprovalDocument119 pagesFs Chapter I Vi ApprovalPauline OrtegaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LUMBERPUNCTURDocument14 pagesLUMBERPUNCTURRahul VasavaNo ratings yet

- Early Production ContainmentDocument2 pagesEarly Production Containmenttravi9580% (5)

- Project Planning Template - Castillo JiselleDocument7 pagesProject Planning Template - Castillo Jiselleapi-692396370No ratings yet