Professional Documents

Culture Documents

Flooding Characteristics and Separation Efficiencies of Pulsed Sieve-Pla Te Extraction

Uploaded by

ArunOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flooding Characteristics and Separation Efficiencies of Pulsed Sieve-Pla Te Extraction

Uploaded by

ArunCopyright:

Available Formats

I L. D. SMOOT, 6. W. MAR,' and A. L.

BABB

Department of Chemical Engineering, University of Washington, Seattle, Wash.

Flooding Characteristics and

Separation Efficiencies of Pulsed

Sieve-Plate Extraction Columns

Experimental Data Applied to Design of Extraction Columns

This article details equations and gives nomographs for calculating

flooding velocities and over-all transfer unit heights

P U L S E D sieve-plate solvent extraction marizes flooding and mass transfer physical barrier in prohibiting counter-

columns are widely used in radiochemical experimental data, including the range current flow of the two immiscible

separation processes. Although invented of pulsed column variables and systems phases. As pulsation is increased, a

by Van Dijck (27) in 1935> the pulsed studied, and the number of experiments region of stable operation is reached,

column was not used in the chemical utilized in this study. Flooding correla- followed by flooding at an upper limit

industry until its application to solvent tions have been presented by Beyer and of pulsation where mechanical agitation

extraction separations in the radio- Edwards ( 2 ) : Sege and Woodfield (79): becomes excessive and "emulsion" flood-

chemical field in the late 1940's. Be- Swift ( 2 3 ) , Pike and others (76), Crico ing occurs. This is characterized by

cause size and space are important (6), and Thornton (26). The most com- mixtures of fine and coarse dispersed

economical factors in the nuclear indus- prehensive study of flooding was made phase drops, the formation of large

try, the greater efficiency and smaller by Thornton (25: 26) and Logsdail and globs of dispersed phase by coalescence,

size of the pulsed columns greatly reduce Thornton (75), who developed an em- and periodic reversals of the continuous

the over-all cost of radiochemical separa- pirical correlation based on experimental phase in short sections of the column.

tions compared to conventional columns. flooding data for six liquid systems Geier (8) describes five regions of opera-

Other advantages are mechanical sim- (Table I). Correlating equations for tion. This study and the majority of

plicity: ease of operation, and flexibility mass transfer data have been presented previous flooding studies are concerned

( 2 3 ) . Wiegandt and Von Berg (29), by Swisher ( 2 4 ) ,Rubin and Lehman (78), with flooding in the upper region of

reviewed the functions and performance Crico (6): and Thornton (26). Thornton operation. Flooding is frequently ex-

of the apparatus. has also produced the most complete mass pressed in terms of the volume flow rate

For experimental studies, pulsed transfer correlation available in the of the continuous phase, Vc,plus the dis-

columns are constructed of either pre- literature. persed phase, V,. based on the cross

cision-bore tubing with an inserted sieve-

plate cartridge or short lengths of glass

This work correlates the experimental section of the empty column-Le., V, +

flooding and mass transfer data in the Vd:cubic feet per hour per square foot.

stacked between sieve plates and held in literature for sieve-plate pulsed columns Selection of Variables. The vari-

compression. A cartridge normally con- using dimensional analysis and multiple ables considered to affect the total flood-

sists of a central rod on which the sieve regression techniques. ing velocity in sieve-plate pulsed columns

plates and spacers are alternately strung are: f, pulse frequency; a, pulse ampli-

and positioned by nuts on both ends of tude; VC, superficial velocity of con-

the rod. Phase disengaging sections,

A Generalized Flooding Correlation

tinuous phase; V,, superficial velocity of

located at both ends of the column, are Flooding in pulsed columns may be dispersed phase; d, sieve hole diameter;

approximately 30% larger in diameter defined as the flow condition when the D,column diameter; 1, plate spacing;

than the column proper. Pulsation is fluid of one phase entering a t one end of E , fractional free space per plate; y,

provided by metal or Teflon bellows the column cannot leave a t the opposite interfacial tension; pc, p d 3 viscosities

driven by variable-speed drive units or end and must exit through the effluent of the continuous and dispersed phases,

reciprocating metering pumps. A typi- line intended for the second phase (79). respectively; pe, p d : densities of con-

cal laboratory column is described by I t can occur both above and below a tinuous and dispersed phases, respec-

Stephenson (22). region of stable operation. Flooding tively; and g, acceleration due to

A great many experimental studies owing to inadequate pulsation will gravity. Other variables are: pulse

have been conducted using pulsed sieve- occur when insufficient mechanical agita- wave form, plate material, clearance

plate extraction columns. Table I sum- tion is supplied to force the liquids between plates and column wall, and

l Present address, Boeing Airplane Co., through the perforated holes of the temperature. Data obtained from col-

Seattle: Wash. column plates. Thus, the plates act as a umns with plates of materials other than

VOL. 5 1 , NO. 9 SEPTEMBER 1959 1005

0 2- wv )+ P+ Pm m *W

x F r. 8

o m

O???? ? P .a

P

G

4?00?

2 6882

0

m

0 09%

4 m-"m 8 W

N

I

.m

r G?

J

0 0 0 0 0

00000

0

9

0

?

0 x 00

..

O 0

0

00

N

, 0

c

?J

n r. r. br. m

m m m m P P P. P.

? N m m ?

-3

4 4 4 4 44 4

w

VI

y.

0

-aJ

I)

.2

4

0

I- 3-

1 006 INDUSTRIAL AND ENGINEERING CHEMISTRY

E X T R A C T I O N COLUMNS

0

N

\ '

\ '

-

Pi \

r

P

!!

F

E

0

Z

al

I L.

0,

G

I

c(

/

I

I

,

/

VOL. 51, NO. 9 SEPTEMBER 1959 1007

brass or steel were not included in the

correlation. Only data obtained with Table II. Maximum and Minimum Values of Variables Used in Obtaining

sinusoidal pulse wave forms were used. Correlating Equations

Moreover, as runs were generally made Flooding Mass Transfer

a t room temperature, the effect of tem- Variable Min. Max. .Min. Max.

perature was neglected. It has been

a, ft./cycle 0.009 0.0416 0.018 0.098

demonstrated experimentally (23) that D,feet 0.167 1.00 0.1667 1.0

the effect of plate thickness can be d, feet 0.00167 0.0155 0.0052 0.0104

ignored. D,,sq. ft./hr. ... ... 6.92 X lo-& 9.86 Y 10-5

Several variables can be related by a f, cycles/hr. 870 18,000 7,200 30,600

theoretical equation defining the power

(HTU),,,feet ...

... ... 0.71 7.10

I , feet 0.0416 0.25 0.0417 0.1667

input to the column. Jealous and V,,ft./hr. 8 195 9.9 104.5

Johnson (10) first introduced a method v d , ft./hr. 4 255 12.5 94.9

for computing power requirements for a E 0.081 0.62 0.085 0.62

-1, lb./hr.* 0.288 x 106 1.20 x 106 4.06 X 105 9.72 X 10’

pulsed column and this approach was wC, lbJ(ft.1(hr.) 2.42 2.42 2.55 2.55

recently applied to pulsed column p d , lb./(ft.) (hr.) 1.41 3.19 1.36 1.81

correlations by Thornton (261, who p0 lb./cu. ft. 62.4 62.4 62.4 62.4

p d , Ib./cu. ft. 46.9 55.0 53.5 55.0

relates the frequency, amplitude, column

height, number of plates, and fractional

free area per plate in terms of one

variable, I/,,,the maximum power

found to be independent of the column represented by two hypothetical stagnant

absorbed per unit mass of fluid. For a

diameter. Equation 2 with the recom- liquid ‘:films,” one on either side of the

sine wave pulse:

mended constants represents the 665 interface. This “two-film concept” was

experimental points with an average first postulated by Whitman (28) in

deviation of 19.6%. This result can be 1923. Concentration gradients are said

made more useful by combining common to exist within the films which represent

where C, is the orifice coefficient. factors and supplying numerical values the driving force for mass transfer be-

for p c , pe, and g, which were constant: tween the interface and the bulk streams.

By combining the remaining variables, As it is very difficult to determine the

D,d, V C ,Vdj +/, g, AP: p d ,

P C , P C , and 7 V, + V d = 3.20 X interfacial concentration, the entire po-

into significant dimensionless groups A n

105 P’_-.

63 d0.m vcn0 1 1

. ~- tential for mass transfer is combined in

(77, 27), the following exponential func- y o . i u #,o.zn7 Pdo ao vdo.oic (3)

~~~

a n over-all driving force to be used in

tion is obtained : conjunction with over-all mass transfer

The accuracy of this equation has not coefficients. The coefficients are as-

been reduced by this manipulation. sumed to remain constant throughout the

This equation best illustrates the de- column, and all the resistance is assumed

pendence of the total flooding velocity to be concentrated in one phase or

on the principal variables. another, which is often the case

For rapid calculation of flooding veloc- I t would be difficult to correlate

where the majority of groups are identical

ities in experimental pulsed columns HTU’s on an ”over-all” basis unless the

to those derived by Thornton (26). where water is the continuous phase, a

While this function need not be exponen- resistance to mass transfer was concen-

nomograph based on Equation 3 is pre- trated principally in one phase, in which

tial in nature, it often represents experi-

sented in Figure 1. The flooding veloc- case the resistance in the second phase

mental data very closely. ities determined from the nomograph

Analysis of Experimental Data. A

could be neglected. For the systems

are within 20% on the average of the utilized in this study, it is assumed

total of 751 flooding experiments from experimental values. Table I1 sum-

five investigators were available in the that the major resistance to m a s transfer

marizes the range of pulsed column lies in the dispersed phase “film” with

literature, from which 665 experiments

variables to which this equation applies. negligible resistance in the continuous

of four investigators were utilized in the Application to D e s i g n . Once the

flooding correlation. In many instances phase. This assumption was verified

total flooding velocity has been predicted by analyzing the distribution of solute

the experimental data were not amen- for a given set of conditions using Equa-

able to correlation because physical between the two immiscible phases for

tions l and 2 or the flooding nomograph each system.

properties of complex systems (7, 9, 72, in Figure 1, the required column diam- Selection of Variables. Thc variables

73, 78, 79) were not available, or the eter can be calculated from the relation- thought to affect the ratr of mass rransfer

column was operated in a region other

ship : of the solute through the dispersed phase

than emulsion flooding (2) or had un-

usual constructional or operational char- film are VO,LTc, V d , D,d, I , P d , AP. Y, pd,

acteristics such as Teflon plates (72), and P d , where b’o = fa/€,a term which is

assumed to be proportional to the mean

packed columns ( 3 ) ,or pulse wave forms

where F is the fraction of the flooding velocity of the dispersed phase bubbles

other than sinusoidal (26).

Equation 2 was transformed logarith- velocity at which the column is to operate through the sieve plate perforations ( 7J).

mically, and multiple regression tech- and W is the design capacity of the T h e relationship among the selected

niques were applied to obtain the co- column in cubic feet per hour. dimensionless groups can be expressed as:

efficient and exponents from the data

with the aid of an IBM 650 digital Generalized Mass

computer. T h e recommended values Transfer Correlation

for use with Equation 2 are : When mass transfer of the solute from

the feed stream to the solvent occurs,

bo = 0.527 ba -0.207 ba = 0.81

bi = -0.014 bi 0.458 bi = -0.20 it is generally assumed that diffusion is The Reynolds number, Schmidt number,

bz = 0.63 b5 = 0 so rapid that equilibrium exists a t the and density group are based on the dis-

interface between the two phases and persed phase properties where the major

Total flooding velocity, V , + V , was that all resistance to diffusion can be resistance is assumed to exist. C; and

1 008 INDUSTRIAL AND ENGINEERING CHEMISTRY

E X T R A C T I O N COLUMNS

3

t-

I

v

VOL. 51, NO. 9 0 SEPTEMBER 1959 1009

pc are not considered to have an appreci- in part, are still uncertain. Thus, the Literature Cited

able effect on mass transfer in the dis- nomograph is most useful when systems

persed phase. with properties similar to the data (1) Belaga, M. W.,Bigelow, J. E., U. S.

Analysis of Experimental Data. Of Atomic Energy Comm., Rept. KT-133

analyzed in this study are to be investi- (1952).

the 696 data points which were available gated. However, Equation 5 should (2) Beyer, H. G., Edwards, R. B., Ibzd.,

in the unclassified literature, 285 were account for a wide range of systems, ISC-553 (1954).

applied to the mass transfer correlation. if the exponents were verified or altered (3) Chantry, W. A., Von Berg, R. I..,

Wiegandt, H. F., IND.ENG.CHEM.47,

T h e remainder of the data were excluded by more extensive data. T h e H T U 1153 (1955).

for the reasons cited in analysis of the values predicted using the nomograph (4) Chilton, T. H., Colburn, A. P., Ibid.,

flooding data. I n addition, only the data are within 20% of the experimental 27, 255 (1935).

for which mass was transferred from the values on the average. (5) Cohen, R. M., Beyer, G. H., U. S.

.4tomic Enrrgy Comm., Rept. ISC-294

dispersed phase to the continuous phase Application to Design. (HTU),,. (1953).

were utilized in obtaining the mass the over-all height of a transfer unit (6) Crico, 4 . , Genie chim. 73, 57 (1955).

transfer correlation. based on the continuous phase. can be !7) Ellison, C. V., U. S. Atomic Energy

Evaluating the coefficient and ex- calculated from Equation 5, or hy using Comm., Rept. ORNL-912 (1956).

( 8 , Geier, R . G., Ibid.. HW-49542-A

ponents for the mass transfer relation- the nomograph cf Figure 2, for any 11957).

ship in a manner identical to that used in given set of conditions. Sincc A’,,,,, (9) Griffith, W. L., Jasny, G. R., Tupper,

the flooding analysis, the following con- the number of over-all transfer units H. T., Ihid., KT-114 (19521.

stants, when applied to Equation 5, were based on the ccntinuous phase, can be (10) Jealous, A. C., Johnson, H. F.,

IND. E N G . CHEM. 47, 1159 (1955).

found to represent the mass transfer determined from equilibrium data (20) (11) Klinkenberg, A., Mooy, H. H.,

data with an average deviation of 16.4% : and a knoL51edge of the desired extraction Chem. Enp. P r q r . 44, 19 11948).

of the solute, the height of the column (12) Lane, A. F., U. S. Atomic Energy

C( = 0.20 C3 = 0.865 C6 = 0.317 Comm., Rept. UCRL-2983 (1955).

for a given set of conditions can be

CI = - 0 . 4 3 4 C( 0.096 CI = 4.57 (13) Lehman, H . R., Zbid., UCRL-1558

C? 1.04 CL = -0.636 calculated ( 4 ) from the equation: (1956).

(14) Li, W. H., Newton, W.li.,A.1.Ch.E.

This equation is strictly valid only for h = (HTU)dL.Vto c (7) Journal 3. 56 11957).

extraction in pulsed columns, where mass (15) Logsdail, D. H., Thornton, J. D.,

Alternatively, design Equation 6 can Trans. Inst. Chem. Engrs. (London) 35,

transfer occurs from the dispersed phase 331 (1957’1.

be used to investigate effects of important

to the aqueous continuous phase and (16) Pike, F. P., Nelli, J. R., Erickson,

independent variables on the height of a

where the major resistance to mass F. E., Arnold, D. S., Box, G. E. P.;

transfer unit. Hunter. S. J.. U . S. Atomic Enerw

transfer is in the dispersed phase. I t is V I

Comm.; Rept. ORO-140 (1954).

possible that similar correlaiions could 117) Ibid.. ORO-141 11954).

be applied to transfer of mass from the Acknowledgment i18j Rubin, B., Lehman, H. R., Thio‘.,

continuous phase to the dispersed phase UCRG718 (1950).

T h e authors thank IVayne Van Meter (19) Sege, G., Woodfield, F. I\’,, Zbid.,

or to the case where the major resistance and Satoru Tashiro for assistance with HW-31259 (1954).

is in the continuous phase. However, (20) Sherwood. T. K., Pipford. R. L.,

the calculations.

certain exponents would be expected to ’ “Absorption ‘and Extractyon,“ ’ 5th ed.,

be different for these cases. McGraw-Hill, New York, 1952.

Analysis of the range of variables for Nomenclature (21) Smoot, L. D., M.S. thesis, University

of Washington, Seattle, Wash., 1958,

the terms of Equation 5 shows that the a = pulse amplitude, feet,’cycle (22) Stephenson, R., Chern. Eng. P r o y .

physical properties of the liquid systems bo-bi constants

= 49, 340 (1953).

were very nearly constant as outlined in GO-c, =constants (23) Swift, W. H., U. S. Atomic Enerpv

Table 11. Thus, the exponents of CO = orifice coefficient = 0.60 Comm., Rept. HW-33953 119541.

D = column diameter, feet (24) Swisher, G. F., Dissertalion Abstr. 16,

(A ’ P (PU’P~DJ, ( A P / P ~ , and (Y ’

~ T

1421 (1956).

V C p J are not to be considered too d = diameter of plate hole, feet

125) Thornton. J. D.. Brit. Chem. Ener.

accurate. However, a qualitative anal-

D, = diffusivity of solute in dis- \-

3,247 11958j. ’

persed phase, sq. ft./hr.

ysis of these exponents reveals certain

trends which are thought to be correct. f

= (Vc +

Vd)operaiin&/(vc + y d ) f l o o d i n g

= pulse frequency, cyclesihr.

(26) Thornton, J. D., T r a n s . Inst. Chem.

Engrs. (London) 35, 316 (1953).

(27) Van Dijck, W. J. O., U. S. Patent

For instance, the HTU is proportional g = acceleration of gravity, ft.lhr.2 2,011,186 (1 935).

to the density difference of the immiscible k = column height, feet (28’1 Whitman. W. G.. Chem. ‘Met. Ener. 29,

Y .

phases, inversely proportional to the (HTU),,, = overall height of a transfer 127 (1925).

unit based on continuous (29) Wiegandt, H. F., Von Berg, R. L.,

diffusion coefficient of the solute in the Chem. Eng.61, No. 7, 149 (1954).

dispersed phase, and nearly independent phase, feet

of the interfacial tension. T h e exponent I = plate spacing, feet

N , = number of transfer units RECEIVED

for review July 23, 1958

for the ratio of viscosities is thought to ACCEPTED April 15, 1959

V = superficial velocity, ft./hr.

be unduly large and possibly represents Vo = fa/^, ft./hr.

only a constant in the equation. Equa- W = total column design capacity, Based on work performed at the Univer-

tion 5 with the recommended constants cu. ft./hr. sity of Washington for Atomic Energy Com-

can be simplified without reducing the t = plate thickness, ft. mission, Contract No. AT(45-1 t1053.

accuracy to give :

SUBSCRIPTS

(HTU),, =

c = continuous phase

d = dispersed phase

GREEKLETTERS

Synthetic Lubricant-

Such a n equation best illustrates the Correction

dependence of H T U on the major vari- e = fractional free space per plate

ables. $, = power function, sq. ft./hr.3 In the I/EC Special Feature on syn-

y = interfacial tension, lb./hr.2

T o provide a means of rapid calcula- thetic lubricants [IND. EKG.CHEM.51,

p = viscosity, lb./(ft.)(hr.)

tion of HTU values for sieve-plate p = density, lb./cu. ft. 49A-63A (May 1959)] the illustrations

pulsed columns, a nomograph based on Ap = density difference between con- on pages 50 A and 51 A should have been

Equation 5 is presented in Figure 2 . tinuous and dispersed phases, placed with the article by J. S. McClure

The optimum values for the exponents, lb./cu. ft. on page 57A.

1 01 0 INDUSTRIAL AND ENGINEERING CHEMISTRY

You might also like

- Lab Sheet H1 Sharp Crested Overshot WeirDocument3 pagesLab Sheet H1 Sharp Crested Overshot Weirwilson100% (1)

- Test Bank For Earth Science 14th Edition PDFDocument13 pagesTest Bank For Earth Science 14th Edition PDFBETHUEL P. ALQUIROZ100% (1)

- Lab Manual (Hydraulics Engineering)Document34 pagesLab Manual (Hydraulics Engineering)Shahid Kamran63% (8)

- CHP 8-3 Solubility and ConcentrationDocument6 pagesCHP 8-3 Solubility and ConcentrationMaridjan WiwahaNo ratings yet

- Two Coupled PendulumsDocument10 pagesTwo Coupled PendulumsBilal HaiderNo ratings yet

- Greve 2005Document12 pagesGreve 2005Emotional V.I.PNo ratings yet

- Mixer Theory 1Document5 pagesMixer Theory 1Anonymous CMS3dL1TNo ratings yet

- 2008 Kumar Dynamic Analysis of Conical Shells JSVDocument20 pages2008 Kumar Dynamic Analysis of Conical Shells JSVAnirudh SabooNo ratings yet

- Open-Water Thrust and Torque Predictions of A Ducted PropellerDocument12 pagesOpen-Water Thrust and Torque Predictions of A Ducted Propellersyclops3No ratings yet

- COB09-1054 Panel MethodsDocument9 pagesCOB09-1054 Panel MethodsAnonymous K48TgviNo ratings yet

- Numerical Investigation of Recirculation Zone Length Upstream of Round-Nosed BCWDocument6 pagesNumerical Investigation of Recirculation Zone Length Upstream of Round-Nosed BCWAlind HasanNo ratings yet

- Heat Effects in Adsorption Column DynamicsDocument7 pagesHeat Effects in Adsorption Column DynamicsJesús Miguel Jacinto NavaNo ratings yet

- Kármán Vortex Shedding Behind HydrofoilDocument14 pagesKármán Vortex Shedding Behind HydrofoilFolpoNo ratings yet

- Bubble Surface Area Flux Key to Characterizing FlotationDocument11 pagesBubble Surface Area Flux Key to Characterizing FlotationJose Luis Barrientos RiosNo ratings yet

- BBAA7 Shanghai 2012 Bridge Deck Flutter SimulationDocument8 pagesBBAA7 Shanghai 2012 Bridge Deck Flutter SimulationSaang Bum KimNo ratings yet

- Numerical Simulation of Turbulent Flow Over Surface Mounted Obstacles With Sharp Edges and CornersDocument19 pagesNumerical Simulation of Turbulent Flow Over Surface Mounted Obstacles With Sharp Edges and CornersHelen ChoiNo ratings yet

- Plynett@tamu - Edu,+4373 18378 1 CEDocument15 pagesPlynett@tamu - Edu,+4373 18378 1 CEANILANo ratings yet

- Sloane John H19650Document77 pagesSloane John H19650Ryan RafaelNo ratings yet

- CFD Study of Prospective 1st Stage Centrifugal Impeller DesignDocument6 pagesCFD Study of Prospective 1st Stage Centrifugal Impeller DesignSADULLAHNo ratings yet

- Drop Characteristics of Free-Falling Nappe for Aerated SpillwaysDocument6 pagesDrop Characteristics of Free-Falling Nappe for Aerated SpillwaysANo ratings yet

- Numerical Simulation of An Oscillating Cylinder in A Cross - Ow at Low Reynolds Number: Forced and Free OscillationsDocument21 pagesNumerical Simulation of An Oscillating Cylinder in A Cross - Ow at Low Reynolds Number: Forced and Free OscillationsManu K VasudevanNo ratings yet

- LAB REPORT - Discharge Over WeirsDocument9 pagesLAB REPORT - Discharge Over WeirsLuli LolNo ratings yet

- Effects of Model Scale in Estimating Pollutant Dispersion Near BuildingsDocument11 pagesEffects of Model Scale in Estimating Pollutant Dispersion Near BuildingsJoan DivesNo ratings yet

- 71 FeDocument17 pages71 FeEric21No ratings yet

- MATHEMATICAL MODELS FOR WAVESDocument11 pagesMATHEMATICAL MODELS FOR WAVESVincent Czar CabiliNo ratings yet

- Preliminary Calculations of Flow in Channel With Triangular and Rectangular ObstacleDocument10 pagesPreliminary Calculations of Flow in Channel With Triangular and Rectangular ObstacleHawraa ImadNo ratings yet

- Water-Entry and - Exit of A Horizontal Circular CylinderDocument8 pagesWater-Entry and - Exit of A Horizontal Circular CylinderSoledad AceitunoNo ratings yet

- Experiment 10Document3 pagesExperiment 102022me112No ratings yet

- Numerical Simulation of Flow Field Formed in Water Pump-SumpDocument12 pagesNumerical Simulation of Flow Field Formed in Water Pump-SumpAnonymous KSHLSkbiNo ratings yet

- An Experimental Study of The Source/drain Parasitic Resistance Effects in Amorphous Silicon Thin Film TransistorsDocument8 pagesAn Experimental Study of The Source/drain Parasitic Resistance Effects in Amorphous Silicon Thin Film TransistorsTianyu TangNo ratings yet

- Exam 10 1 2020Document8 pagesExam 10 1 2020Francisco MachadoNo ratings yet

- FP Eucass-358Document10 pagesFP Eucass-358vsjana10No ratings yet

- Flow Ovr WeirDocument9 pagesFlow Ovr WeirniasandiwaraNo ratings yet

- An Experimental Investigation of Hypersonic Flow Over Blunt Nosed Coneshypersonic Flow Over Blunt Nosed Cones at A Mach Number of 5.8 - 1956Document59 pagesAn Experimental Investigation of Hypersonic Flow Over Blunt Nosed Coneshypersonic Flow Over Blunt Nosed Cones at A Mach Number of 5.8 - 1956NeoNo ratings yet

- Carrier Lifetime Meassurement in PIN DiodesDocument5 pagesCarrier Lifetime Meassurement in PIN DiodesGuillermo VillarNo ratings yet

- Numerical Simulation of Vortex Shedding From An inDocument12 pagesNumerical Simulation of Vortex Shedding From An inShyla_SinhaNo ratings yet

- Lab3-Exercise Note OldDocument14 pagesLab3-Exercise Note OldHarsha HarNo ratings yet

- Stability of Cubes, Tetrapods and Accropode: January 1988Document11 pagesStability of Cubes, Tetrapods and Accropode: January 1988romeoremoNo ratings yet

- Computation of Perspective KRISO Containership Towing Tests With The Help of The Complex of Hydrodynamical Analysis FlowVisionDocument10 pagesComputation of Perspective KRISO Containership Towing Tests With The Help of The Complex of Hydrodynamical Analysis FlowVisionSADULLAHNo ratings yet

- The DAMOCLES Monte Carlo Device Simulation ProgramDocument6 pagesThe DAMOCLES Monte Carlo Device Simulation ProgramJorge OrtegaNo ratings yet

- Flow of Water by Notch and WeirsDocument15 pagesFlow of Water by Notch and WeirsAngelica Joyce BenitoNo ratings yet

- Flow Mapping of The Mercury FlowDocument4 pagesFlow Mapping of The Mercury FlowPrince Israel EboigbeNo ratings yet

- Simplified Analysis and Design of AbandonmentDocument20 pagesSimplified Analysis and Design of AbandonmentRUSSEL SAHDA MALAKANo ratings yet

- Zia Lecampion IJSS 2016 AcceptedManuscriptDocument43 pagesZia Lecampion IJSS 2016 AcceptedManuscriptoreNo ratings yet

- UR A NS Study of Air-Layer Drag Reduction in A High-Reynolds-Number Flat-Plate Turbulent Boundary LayerDocument9 pagesUR A NS Study of Air-Layer Drag Reduction in A High-Reynolds-Number Flat-Plate Turbulent Boundary Layerflowh_No ratings yet

- Flows and Open-Channel Flows: Srinivas ChippadaDocument229 pagesFlows and Open-Channel Flows: Srinivas ChippadashaymaaNo ratings yet

- Numerical Simulation of An Oscillating Cylinder in A Cross-Flow at Low Reynolds Number: Forced and Free OscillationsDocument22 pagesNumerical Simulation of An Oscillating Cylinder in A Cross-Flow at Low Reynolds Number: Forced and Free OscillationsManu K VasudevanNo ratings yet

- Nonlinear and Nonplanar Dynamics of Suspended Nanotube and Nanowire ResonatorsDocument6 pagesNonlinear and Nonplanar Dynamics of Suspended Nanotube and Nanowire Resonatorsteju1996coolNo ratings yet

- Numerical Investigation of Incompressible Flow Past Circular Tubes in Confined ChannelDocument14 pagesNumerical Investigation of Incompressible Flow Past Circular Tubes in Confined ChannelaadinathhariharNo ratings yet

- Numerical Simulation of Formation Process of KeyholeDocument6 pagesNumerical Simulation of Formation Process of KeyholeWilliam WilkenNo ratings yet

- Flow Environments of Aquatic BenthosDocument26 pagesFlow Environments of Aquatic BenthosAnggi Sumantri Simatupang 2204111517No ratings yet

- H.K. Moffatt - Rotation of A Liquid Metal Under The Action of A Rotating Magnetic FieldDocument19 pagesH.K. Moffatt - Rotation of A Liquid Metal Under The Action of A Rotating Magnetic FieldOsdfmNo ratings yet

- Urbanowicz Et Al - Modelling Water Hammer Viscoelastic Pipelines (2016)Document12 pagesUrbanowicz Et Al - Modelling Water Hammer Viscoelastic Pipelines (2016)Baja BajabajasziNo ratings yet

- NACA TN 3169 RoshkoDocument30 pagesNACA TN 3169 RoshkodickysilitongaNo ratings yet

- Amr 1016 377Document7 pagesAmr 1016 377mytgamesNo ratings yet

- 1 20 UrbanHydrology - RoutingDocument29 pages1 20 UrbanHydrology - RoutingNuman ShahNo ratings yet

- Hydrodynamics Effect PipeDocument4 pagesHydrodynamics Effect PipenuvanNo ratings yet

- 05762922Document7 pages05762922Master JuegosNo ratings yet

- Hydraulics Hydraulic Machine Lab ManualDocument33 pagesHydraulics Hydraulic Machine Lab ManualAlcazar HyundaiNo ratings yet

- Effects of Expanding Zone Parameters of Vacuum Dust Suction Mouth On Flow Simulation ResultsDocument6 pagesEffects of Expanding Zone Parameters of Vacuum Dust Suction Mouth On Flow Simulation ResultsMHK ZarkNo ratings yet

- Use of The Soltzmann Equation To Simulate Lattice-Gas AutomataDocument4 pagesUse of The Soltzmann Equation To Simulate Lattice-Gas Automatazhaojie qinNo ratings yet

- Three-Dimensional Numerical Analyses On Liquid-Metal Magnetohydrodynamic Flow Through Circular Pipe in Magnetic-Field Outlet-RegionDocument18 pagesThree-Dimensional Numerical Analyses On Liquid-Metal Magnetohydrodynamic Flow Through Circular Pipe in Magnetic-Field Outlet-RegionabdullaalakourNo ratings yet

- Modelling in Chemical EngineeringDocument6 pagesModelling in Chemical EngineeringMaria ClaudiaNo ratings yet

- 109CH0458 PDFDocument41 pages109CH0458 PDFoverdose500No ratings yet

- Gandhi 2007Document12 pagesGandhi 2007ArunNo ratings yet

- Gandhi 2007Document12 pagesGandhi 2007ArunNo ratings yet

- Performance Analysis of Shell and Tube Heat Exchanger Using Miscible SystemDocument5 pagesPerformance Analysis of Shell and Tube Heat Exchanger Using Miscible SystemKroya HunNo ratings yet

- Fundenmentals of Model Predective ControlDocument11 pagesFundenmentals of Model Predective ControlArunNo ratings yet

- Axial Dispersion in A Pulsed Plate ColumnDocument8 pagesAxial Dispersion in A Pulsed Plate ColumnArunNo ratings yet

- Hydrodynamic Performance of A Pulsed Solvent ExtractionDocument27 pagesHydrodynamic Performance of A Pulsed Solvent ExtractionArunNo ratings yet

- Effect of Baffle Spacing On Pressure Drop and Local Heat Transfer in Shell-And-Tube Heat Exchangers For Staggered Tube Arrangement PDFDocument9 pagesEffect of Baffle Spacing On Pressure Drop and Local Heat Transfer in Shell-And-Tube Heat Exchangers For Staggered Tube Arrangement PDFIgorToporskyNo ratings yet

- Application of Statistical Methods in Chemical EngineeringDocument11 pagesApplication of Statistical Methods in Chemical EngineeringArunNo ratings yet

- Drop Size Distributions in Liquid Pulsed ColumnsDocument7 pagesDrop Size Distributions in Liquid Pulsed ColumnsArunNo ratings yet

- Application of Statistical Methods in Chemical EngineeringDocument11 pagesApplication of Statistical Methods in Chemical EngineeringArunNo ratings yet

- Supporting Information Pulsed Sieve Plate Extraction ColumnsDocument4 pagesSupporting Information Pulsed Sieve Plate Extraction ColumnsArunNo ratings yet

- CFD simulation of flow and axial dispersion in external loop airlift reactorsDocument14 pagesCFD simulation of flow and axial dispersion in external loop airlift reactorsArunNo ratings yet

- Use of Neural Networks For Liquid-Liquid Extraction ColumnDocument10 pagesUse of Neural Networks For Liquid-Liquid Extraction ColumnArunNo ratings yet

- Supporting Information Pulsed Sieve Plate Extraction ColumnsDocument4 pagesSupporting Information Pulsed Sieve Plate Extraction ColumnsArunNo ratings yet

- Numerical Simulations of Sieve Plate Pulsed Column Using OpenfoamDocument1 pageNumerical Simulations of Sieve Plate Pulsed Column Using OpenfoamArunNo ratings yet

- Hydrodynamic Performance of A Pulsed Solvent ExtractionDocument27 pagesHydrodynamic Performance of A Pulsed Solvent ExtractionArunNo ratings yet

- Multivariable Control of A Pulsed Liquid-Liquid Extraction Column by Neural NetworksDocument9 pagesMultivariable Control of A Pulsed Liquid-Liquid Extraction Column by Neural NetworksArunNo ratings yet

- Measurement and CFD Simulation of Single-Phase Flow in Solvent Extraction Pulsed ColumnDocument9 pagesMeasurement and CFD Simulation of Single-Phase Flow in Solvent Extraction Pulsed ColumnArunNo ratings yet

- RSM and ANN Modeling of Hold Up, Slip, and Velocity of Pulsed Seive Plate ColumnDocument17 pagesRSM and ANN Modeling of Hold Up, Slip, and Velocity of Pulsed Seive Plate ColumnArunNo ratings yet

- Fluid Dynamics of Pulsed Sieve Plate Extraction ColumnsDocument12 pagesFluid Dynamics of Pulsed Sieve Plate Extraction ColumnsAnonymous q1gGEpNo ratings yet

- CFD Simulation of Liquid-Liquid Two-PhaseDocument15 pagesCFD Simulation of Liquid-Liquid Two-PhaseArunNo ratings yet

- Yadav Patwardhan 2009 PDFDocument11 pagesYadav Patwardhan 2009 PDFAnonymous q1gGEpNo ratings yet

- CFD Simulations of Pulsed Sieve Plate Column Single Phase FlowDocument12 pagesCFD Simulations of Pulsed Sieve Plate Column Single Phase FlowArunNo ratings yet

- 5.2 Residence Time Distribution of Droplets Within Discs and Doughnuts Pulsed Extraction Columns Via Lagrangian Experiments and SimulationsDocument14 pages5.2 Residence Time Distribution of Droplets Within Discs and Doughnuts Pulsed Extraction Columns Via Lagrangian Experiments and SimulationsArunNo ratings yet

- Computational Fluid Dynamics Modelling To Predict Axial Dispersion in PulsatileDocument26 pagesComputational Fluid Dynamics Modelling To Predict Axial Dispersion in PulsatileArunNo ratings yet

- Numerical Experimentation A Tool To Calculate Axial Dispersion Co-EfficentDocument16 pagesNumerical Experimentation A Tool To Calculate Axial Dispersion Co-EfficentArunNo ratings yet

- CFD Simulation of Two-Phase Flow in Pulsed SieveDocument15 pagesCFD Simulation of Two-Phase Flow in Pulsed SieveArunNo ratings yet

- Problem Set 1Document15 pagesProblem Set 1YanYan Carpio25% (4)

- Article1430240348 - Isehunwa Et AlDocument7 pagesArticle1430240348 - Isehunwa Et AlAbhishek DubeyNo ratings yet

- S4 Thermodynamics PQPDocument16 pagesS4 Thermodynamics PQPAltros mNo ratings yet

- Evaluate Analytical Data AccuracyDocument15 pagesEvaluate Analytical Data AccuracyGopinathNo ratings yet

- Paraffins-101: Shekhar Khandekar Global Flow Assurance ManagerDocument55 pagesParaffins-101: Shekhar Khandekar Global Flow Assurance ManagerSamuel OnyewuenyiNo ratings yet

- Me 45 Strength of MaterialsDocument243 pagesMe 45 Strength of MaterialsJhonny Perez Saldaña100% (1)

- Status of Medium - and Long-Chain Chlorinated ParaffinsDocument11 pagesStatus of Medium - and Long-Chain Chlorinated ParaffinsTravis HNo ratings yet

- Brittle Failure of Liberty Ships PDFDocument7 pagesBrittle Failure of Liberty Ships PDFvivek singhNo ratings yet

- A New Michelson-Morley ExperimentDocument8 pagesA New Michelson-Morley ExperimentEnric ToledoNo ratings yet

- Bio 1010 Midterm 2Document4 pagesBio 1010 Midterm 2api-265979570No ratings yet

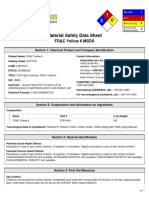

- FD&C Yellow 6 MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesFD&C Yellow 6 MSDS: Section 1: Chemical Product and Company Identificationzubair1951No ratings yet

- Horton's Infiltration TutorialDocument11 pagesHorton's Infiltration TutorialSamundra Lucifer100% (1)

- Lecture 6 Variational Principle PDFDocument77 pagesLecture 6 Variational Principle PDFJonNo ratings yet

- Oligodynamic Effect - Wikipedia PDFDocument29 pagesOligodynamic Effect - Wikipedia PDFkuldeep sainiNo ratings yet

- 759-Article Text-1948-1-10-20150627Document6 pages759-Article Text-1948-1-10-20150627hayet debbichNo ratings yet

- Report Standard Compaction TestDocument14 pagesReport Standard Compaction TestLuqman Yusof100% (1)

- Transport Processes and Carrier DesignDocument24 pagesTransport Processes and Carrier Designcgckamilshaikh50% (2)

- 2020-General Chemistry 1 Review WorksheetDocument4 pages2020-General Chemistry 1 Review WorksheetNgọc Thảo Vy NguyễnNo ratings yet

- Ald&Ketone IIDocument51 pagesAld&Ketone IIheraldas2421No ratings yet

- Applied Mechanics Problems & SolutionsDocument4 pagesApplied Mechanics Problems & SolutionsBuddhisagar BastolaNo ratings yet

- Material Balance in Unit OperationsDocument75 pagesMaterial Balance in Unit OperationsAcademicBMNo ratings yet

- BIOCHEMISTRY CHAPTER 1 INTRODUCTION With CONCEPT MAPDocument4 pagesBIOCHEMISTRY CHAPTER 1 INTRODUCTION With CONCEPT MAPKASHMIR R3No ratings yet

- Optical RecordingDocument17 pagesOptical RecordingArijit MitraNo ratings yet

- CBSE Class 12 Physics Current ElectricityDocument21 pagesCBSE Class 12 Physics Current ElectricityK_S_Krishna0001No ratings yet

- Simultaneous Oxygen-Reduction and Methanol-Oxidation Reactions at The Cathode of A DMFC: A Model-Based Electrochemical Impedance Spectroscopy StudyDocument7 pagesSimultaneous Oxygen-Reduction and Methanol-Oxidation Reactions at The Cathode of A DMFC: A Model-Based Electrochemical Impedance Spectroscopy StudyKaustubhNo ratings yet

- 2.7 Exercise 2 - Extraction of Aluminium and TitaniumDocument4 pages2.7 Exercise 2 - Extraction of Aluminium and TitaniumHo Yong WaiNo ratings yet

- The ElectroscopeDocument3 pagesThe ElectroscopeDanielle Danica Alcuizar BaguioNo ratings yet