Professional Documents

Culture Documents

Determination of Mass Diffusivity of Sugars in Water

Uploaded by

marcoesteban97Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Determination of Mass Diffusivity of Sugars in Water

Uploaded by

marcoesteban97Copyright:

Available Formats

A Research Note

Determination of Mass Diffusivity of Simple Sugars in Water

by the Rotating Disk Method

G. R. ZIEGLER, A. L. BENADO, and S. S. H. RIZVI

ABSTRACT

The rotating disk method is shown to be an accuratemethod for de-

termining the mass diffusivity of solid food componentsin liquid

solutions. The diffusivities of sucroseand glucosein water were de-

termined to be 0.50 and 0.66 (m%ec X 109)at 25°C with activation

energiesof 36.3 and 31.6 Id/g-mol, respectively.

INTRODUCTION

THE DESIGN and analysis of mass transfer operations re-

quires knowledge of the diffusion coefficients of the compo-

nents under consideration. These diffusion coefficients are often

estimated from correlations, e.g. the Wilke-Chang for small

molecules or Stokes-Einstein form for macromolecules. Ap-

plication of these types of correlations to food systems may

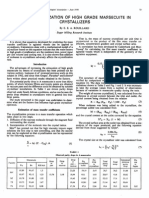

result in very crude estimates of diffusivity, since they do not Fig. l-Schematic of the rotating disk apparatus.

account for the effects of important parameters such as pH and

ionic strength on the interactions between the solute and sol-

vent. Experimental methods, especially those that allow the

determination of diffusivities of a solute in the particular sol-

vent of interest and at the appropriate temperature, are pref-

erable to empirical correlations. One such method is the rotating

disk, which has been used to measure the diffusivity of I-

naphthol in water (Boume and Tovstiga, 1985).

Theory

If a food component is (a) solid at the temperature of inter-

est, and (b) can be formed into the shape of a disk, then its

integral diffusivity in any solvent may be determined by ro-

tating that disk in the solvent and following its rate of weight

loss (or concentration gain in solution).

The rotating disk method involves following the dissolution

of a partially soluble substance from a disk of area A rotating

at an angular velocity w in a mass M of solution. If x’ is the

mass fraction of solute in solution at any time t’ and x* is the

same quantity at saturation, the mass transfer coefficient k of

a solute dissolving into the liquid may be macroscopically mea-

sured by following the mass fraction of solute in the solution

as a function of time (Boume and Tovstiga, 1985).

M$ = kA(x*-x’) (1)

which when integrated from x’ = 0 to x and t’ = 0 to t yields,

k = s In (1 - s) l/T (X103) OK-’

Fig. 2-Arrhenius plot showing the temperature dependence of

If molecular diffusion controls the dissolution rate, and if the the mass diffusivity of sucrose (0) and glucose (0) in water for

the temperature range 5-30°C.

Schmidt number (SC = k/pD where p. is the viscosity, p is

the density, and D the diffusion coefficient) is greater than

100, then the mass transfer coefficient from a rotating disk

follows the relation (Levich, 1962; Newman, 1973),

Authors Ziegler, Benado, and Rizvi are with the Institute of Food 0.6205 PD*‘~@*

Science, Co;nejl Univ., Ithaca, NY 14853.

k = d/6 (1 + 0.298 SC-‘/~ + 0.014515 SC-~~) (3)

Volume 52, No. 2, 1987-JOURNAL OF FOOD SCIENCE-501

MASS DlFFUSlVlTY OF SIMPLE SUGARS. .

where u = @p. Eq. (3) can be solved for D as, tion in the original sample was then determined by back calculation.

Experiments were conducted at 5”, lo”, 15”, 20”, 25’!$, and 30°C (2

-0.2980ku-‘/6 - (O.O888k%-If3 replicates at each temperature) as measured directly in the solvent

+ 2.482po’i2kv1’6 - &05804k%- “3)1’2 using a mercury thermometer. Physical properties of the solution were

D=[

0.02902kv 1/Z - 1.241p0”~

I3 (4) taken from the literature (Reid et al., 1977) as the physical properties

of pure water since sugar concentration never exceeded 4%. Equli-

Thus if the viscosity and density of the solution are known or brium concentrations were obtained from the International Critical

measured, and if the mass transfer coefficient is measured, the Tables of Numerical Data (Bates et al., 1927). Mass transfer areas

diffusivity of the component of interest in a solvent can be were calculated as the arithmetic mean of the surface area of the disk

before and after each experiment. From these data, all of the param-

computed. The purpose of this paper is to describe the rotating eters in Eq. (4) are known and the diffusion coefficients could be

disk method for determining mass diffusivity, and present a calculated.

simplified equation for the calculation of diffusivity from mass

transfer data using sucrose/water and glucose/water as model

food systems. RESULTS & DISCUSSION

VALUES of diffusivity at 25°C as determined b the rotating

MATERIALS & METHODS disk method were 0.50 and 0.66 (m21sec x 10B) for sucrose

and glucose in water, respectively, which compares favorably

Disk preparation

to reported values of 0.54 and 0.69 (m2/sec x 109) for the

Glucose disks were prepared by melting pure anhydrous glucose diffusivities of sucrose and glucose at infinite dilution in water

and pouring the molten mass into a 66 m diameter X 8 mm high at 25°C (Chandrasekaran and King, 1972). Arrhenius plots

mold. After pouring, the molds were hardened in a - 18°C freezer showing the temperature dependence of the mass diffusivities

and stored in a dessicator until used.

Sucrose disks were prepared by dissolving 50g of a mixture of 95%

are presented in Fig. 2. Activation energies calculated from

sucrose and 5% 42 DE corn syrup solids into approximately 25g water. the slopes in Fig. 2 are 36.3 and 31.6 kJ/g-mol for sucrose

The solution obtained was then boiled (sucrose decomposes if heated and glucose, respectively.

directly) until the temperature reached 16O”C, poured into the mold,

hardened in the freezer and stored as were the glucose disks. Corn

syrup solids were added to the sucrose disks to prevent crystal growth, SUMMARY

maintaining the sucrose in an amorphous form. This was necessary THE ROTATING DISK METHOD has been shown to be a

because for highly crystalline sucrose dissolution occurred at crystal

boundaries and entire crystals would then separate from the disk.

relatively simple and reliable technique for determining the

mass diffusivity of food components in liquids. The major

disadvantage of the methodology results from the requirement

Measurement procedure that the compounds of interest must be formed into disks of

The experimental apparatus is shown schematically in Fig. 1. Two

sufficient rigidity to physically endure the test procedure which

holes, equally spaced from the center, were drilled in the disks which is not possible for all food components.

were then bolted onto a specially modified steel nut and screwed onto

the end of the stirring shaft. The shaft was rotated at 500 rpm (mea-

sured by an electronic tachometer) using a MagneDrive II driven by REFERENCES

a belt attached to a variable speed motor (Autoclave Engineers, Erie, Bates, F., Phelps, F.P., and Synder, CF. 1927. Saccharinretry, the prop-

PA). erties of commercial sugars and their solutions. In “International Ciit-

ical Tables of Numerical Data. Physics, Chemistry and Technology,” Vol.

A jacketed stainless steel vessel was filled with a pm-weighed amount II, 1st ed, p 334. McGraw Hill, New York.

(approximately 600g) of water and maintained at the desired temper- Bourne, J.R. and Tovsti a, G. 1985. Measurement of the diffuaivity of l-

ature by means of a circulating ethylene glycol/water bath (Haake Naphthol in water wit.i a rotating disk. Chem. Eng. Comm. 36: 67.

Model A81). The vessel was raised using a lab jack, and a timer Chandrasekeran, S.K. and King, C.J. 19’72. Multicomponent di&aion and

vapor-liquid equilibria of dilute organic components in aqueous and sugar

started when the rotating disk was completely covered with fluid. The solutions. AIChE J. l&X3): 513.

test duration was 2 minutes, after which the vessel was lowered and Levich, V.G. 1962. “Physic0-Chemical Hydrodynamics,” ch. 2-3. Prentice-

a 20 mL sample of fluid was removed. This sample was placed in a Hall, Englewood Cliffs, NJ.

Newman, J.S. 1973. “Electrochemical Systems,” p. 309. Prentice-Hall, En-

tared beaker, weighed and concentrated by evaporating a portion of glewood Cliffs, NJ.

the water in a microwave oven until less than 2 mL remained. Sugar Reid, R.C., Prausnitz, J.M., and Sherwood, T.P. 1977. “The Properties of

concentration in the concentrated sample was measured using a Bausch Gases and Liquids.” McGraw Hill, New York.

and Lomb temperature compensated refractometer. Sugar concentra- MS received 10/26/86; accepted 12/17/86.

j ,\.

.1. ijr,

/

DETM OF TBA REACTIVE SUBSTANCES. . .From page 500

Sinnhuber, R.O. and Yu, T.C,, 1958, 2-Thiobarbituric acid method for the min, riboflavin and niacin content of beef steaks. Ph.D. dissertation,

measurement of rancidity m fishery roducts. 2. The quantitative de- Univ. of Kentucky, Lexington, KY.

termination of malonaldehyde. Food lpechnol. 12: 9. Tarladgis, B.G., Watts, B.M., Younathan, M.T., and Dugan, L.R. Jr. 1960.

Sinnhuber, R.O. Yu, T.C., and Yu, T.C. 1958. Characterization of the red A distillation method for quantitative determination of malonaldehyde

pigment formed in the 2-thiobarbituric acid determination of oxidative in rancid foods. J. Am. Oil Chem. Sot. 37: 44.

rancidity. Food Res 23: 626. MS received 6/27/86; revised 12/16/86; accepted 12/16/86.

Spillman, D.M. 1981. The effects of feeding regime, vacuum packaging

and agmg on the organoleptic quality, physical characteristics and thia-

502-JOURNAL OF FOOD SCIENCE-Volume 52, No. 2, 1987

You might also like

- The Use of Freezing-Point Depression For The Theoretical Dextrose Equivalent MeasurementDocument5 pagesThe Use of Freezing-Point Depression For The Theoretical Dextrose Equivalent Measurementgerpo123No ratings yet

- Thermal Characterization of Cornstarch Using DSCDocument7 pagesThermal Characterization of Cornstarch Using DSCAntonio MoncayoNo ratings yet

- Selman 2007Document14 pagesSelman 2007Ricardo Franco ArboledaNo ratings yet

- Binary Phase Diagram of WaterDocument10 pagesBinary Phase Diagram of WaterkmkmNo ratings yet

- Phase Equilibria of Alkali Nitrates in Glycerol-Water MixturesDocument8 pagesPhase Equilibria of Alkali Nitrates in Glycerol-Water MixturesAnita PuspitaNo ratings yet

- M3 ShortDescrDocument32 pagesM3 ShortDescrCẩm BìnhNo ratings yet

- Density and Viscosity of Brine An Overvi PDFDocument33 pagesDensity and Viscosity of Brine An Overvi PDFalpha ToolsNo ratings yet

- In With: Analysis Porous Cellulose Reverse Osmosis Acetate Membranes UsedDocument7 pagesIn With: Analysis Porous Cellulose Reverse Osmosis Acetate Membranes UsedjuanNo ratings yet

- 2003-The Christiansen Effect of Brightly Colored Colloidal Dispersion With An Amphiphilic PolymerDocument5 pages2003-The Christiansen Effect of Brightly Colored Colloidal Dispersion With An Amphiphilic PolymerAndrés Oswaldo Rivera HérnandezNo ratings yet

- 2007 SPE 107142 MS PCHightJamiolahmadyEtal PDFDocument10 pages2007 SPE 107142 MS PCHightJamiolahmadyEtal PDFcristinaNo ratings yet

- ES550-Geomorphology LAB 3: Weathering: NameDocument14 pagesES550-Geomorphology LAB 3: Weathering: NamePamela Nicole DomingoNo ratings yet

- Laboratory Results From Hydro-Mechanical Tests On A Water Unsaturated BentoniteDocument10 pagesLaboratory Results From Hydro-Mechanical Tests On A Water Unsaturated BentonitemazharNo ratings yet

- Modeling Volume Changes in Food Drying and Hydration: R.J. Aguerre, M. Tolaba and C. SuarezDocument6 pagesModeling Volume Changes in Food Drying and Hydration: R.J. Aguerre, M. Tolaba and C. SuarezgetsweetNo ratings yet

- AlaviDocument10 pagesAlavichetanudctNo ratings yet

- Phase Equilibria of Alkali Nitrates (NaNO3, KNO3, RbNO3, CsNO3) in Glycerol + H2O System at Various TemperaturesDocument8 pagesPhase Equilibria of Alkali Nitrates (NaNO3, KNO3, RbNO3, CsNO3) in Glycerol + H2O System at Various Temperaturesmisterno2No ratings yet

- Kinetics of Water Adsorption On Silica Fuji Davison RD: Microporous and Mesoporous Materials November 2006Document8 pagesKinetics of Water Adsorption On Silica Fuji Davison RD: Microporous and Mesoporous Materials November 2006Szymon JanuszNo ratings yet

- Biomaterial99 Monoolein ReviewDocument12 pagesBiomaterial99 Monoolein ReviewAlfonso Dominguez GonzalezNo ratings yet

- Reaction Kinetics in Conversion Process of Pineapple Leaves Into GlucoseDocument5 pagesReaction Kinetics in Conversion Process of Pineapple Leaves Into GlucoseArvin DalisayNo ratings yet

- Simal Et Al.,2001Document7 pagesSimal Et Al.,2001IrisCoraymaGuevaraSilvaNo ratings yet

- Ae - NaCl+Sucrose+Water SLEDocument9 pagesAe - NaCl+Sucrose+Water SLEayisha.maharramovaNo ratings yet

- Osmosis DehydrationDocument18 pagesOsmosis DehydrationGaluhFahmiNo ratings yet

- Mery Diaz (Unlocked by WWW - Freemypdf.com)Document67 pagesMery Diaz (Unlocked by WWW - Freemypdf.com)Pedraza Velandia JhonNo ratings yet

- Degree of GelatinisationDocument10 pagesDegree of Gelatinisationsagarkedare100% (1)

- Garasanin 2002Document7 pagesGarasanin 2002Hakan EKİNCİNo ratings yet

- Alginate Bead Fick's Law Soln ArticleDocument5 pagesAlginate Bead Fick's Law Soln Articleanon_455160285No ratings yet

- Liao Et Al. 2003Document6 pagesLiao Et Al. 2003reNo ratings yet

- Modelado de La Transferencia de Masa Durante La Deshidratación Osmótica de ManzanasDocument8 pagesModelado de La Transferencia de Masa Durante La Deshidratación Osmótica de ManzanasOliver Ch CNo ratings yet

- Transferencia de Masa en TomatesDocument5 pagesTransferencia de Masa en TomatesJulio Mauricio Vidaurre-RuizNo ratings yet

- Computer Simulation of Sugar Crystallization in Confectionery Products PDFDocument8 pagesComputer Simulation of Sugar Crystallization in Confectionery Products PDFFelipe RiveraNo ratings yet

- Alves, Maia, Vasconcelos - 2002 - Experimental and Modelling Study of Gas Dispersion in A Double Turbine Stirred TankDocument10 pagesAlves, Maia, Vasconcelos - 2002 - Experimental and Modelling Study of Gas Dispersion in A Double Turbine Stirred TankKita de AzevedoNo ratings yet

- Processes: Estimation of Ice Cream Mixture Viscosity During Batch Crystallization in A Scraped Surface Heat ExchangerDocument19 pagesProcesses: Estimation of Ice Cream Mixture Viscosity During Batch Crystallization in A Scraped Surface Heat ExchangerRafael KasperNo ratings yet

- Steen e Ken 1989Document20 pagesSteen e Ken 1989suryakantNo ratings yet

- Mass Transfer Into Dilute Polymeric Solutions: T. Wasan, M. A. Lynch, K. Chad, N. SrinivasanDocument7 pagesMass Transfer Into Dilute Polymeric Solutions: T. Wasan, M. A. Lynch, K. Chad, N. SrinivasanGustavo Gabriel JimenezNo ratings yet

- Research Article: Description of Guava Osmotic Dehydration Using A Three-Dimensional Analytical Diffusion ModelDocument8 pagesResearch Article: Description of Guava Osmotic Dehydration Using A Three-Dimensional Analytical Diffusion ModelNeida SanabriaNo ratings yet

- Bài Báo 17Document8 pagesBài Báo 17Lê Văn HòaNo ratings yet

- Convective Mixing in Homogeneous Porous Media FlowDocument9 pagesConvective Mixing in Homogeneous Porous Media FlowTing-Yu ChengNo ratings yet

- Norrish Equation Correlates Water Activity of Highly Concentrated SolutionsDocument6 pagesNorrish Equation Correlates Water Activity of Highly Concentrated SolutionsFrank GuzmanNo ratings yet

- Spherical Agglomeration During Crystallization of An Active Pharmaceutical IngredientDocument7 pagesSpherical Agglomeration During Crystallization of An Active Pharmaceutical IngredientMohamed AbdullaNo ratings yet

- 1978 - Rouillard - The Crystallization of HighDocument7 pages1978 - Rouillard - The Crystallization of Higheal3019No ratings yet

- Two-Stage Anaerobic Digestion ModelsDocument5 pagesTwo-Stage Anaerobic Digestion ModelsDaniel ChamorroNo ratings yet

- 05 Diffsep 07Document38 pages05 Diffsep 07whmonkeyNo ratings yet

- 05diffsep07 PDFDocument38 pages05diffsep07 PDFNaomi Lizzy FluegelNo ratings yet

- The Mathematical Modelling of The Rehydration Characteristics of FruitsDocument8 pagesThe Mathematical Modelling of The Rehydration Characteristics of FruitsPaulina BulsaraNo ratings yet

- 53-CG 244 730Document22 pages53-CG 244 730misulica80No ratings yet

- 0532 HTMLDocument6 pages0532 HTMLyuNo ratings yet

- Density and Viscosity of Aqueous Solution of K Cro /koh Mixed ElectrolytesDocument5 pagesDensity and Viscosity of Aqueous Solution of K Cro /koh Mixed ElectrolytesBimal Kumar NayakNo ratings yet

- Limitations in CelluloseDocument6 pagesLimitations in CelluloseShofiaNo ratings yet

- Moisture Sorption Isotherm Characteristics of Potatoes at Four TemperaturesDocument19 pagesMoisture Sorption Isotherm Characteristics of Potatoes at Four TemperaturesEduardo MafraNo ratings yet

- WijihuizenDocument10 pagesWijihuizenKhôi TrầnNo ratings yet

- Gupta and Larson 1979Document3 pagesGupta and Larson 1979tomppa21No ratings yet

- J. Chem. Thermodynamics: Kathrina R. Siongco, Rhoda B. Leron, Meng-Hui LiDocument8 pagesJ. Chem. Thermodynamics: Kathrina R. Siongco, Rhoda B. Leron, Meng-Hui LiMaryNo ratings yet

- Full Papers: Caking of Urea PrillsDocument5 pagesFull Papers: Caking of Urea PrillsDesi Rahma PrihandiniNo ratings yet

- Evaluation of natural gas dehydration in supersonic swirling separators applying the Discrete Particle MethodDocument6 pagesEvaluation of natural gas dehydration in supersonic swirling separators applying the Discrete Particle MethodNelson PalenciaNo ratings yet

- Article 1995 Separation of Liquid-Liquid Dispersions in A Deep-Layer Gravity Settler Part I. Experimental Study of The Separation ProcessDocument13 pagesArticle 1995 Separation of Liquid-Liquid Dispersions in A Deep-Layer Gravity Settler Part I. Experimental Study of The Separation ProcessMehdiMoosaviNo ratings yet

- Sorption Isotherms and Moisture Sorption Hysteresis of Intermediate Moisture Content BananaDocument7 pagesSorption Isotherms and Moisture Sorption Hysteresis of Intermediate Moisture Content BananaWilliam RaNo ratings yet

- Boenisch 2004 The Dissolution Rates of Natural Glasses As A FunctionDocument16 pagesBoenisch 2004 The Dissolution Rates of Natural Glasses As A FunctionVictor ValdiviaNo ratings yet

- Cellulose Acetates Biodegradation StudiesDocument10 pagesCellulose Acetates Biodegradation StudiesmostroyaNo ratings yet

- Wadsworth-2017-Topological Inversions in CoaleDocument6 pagesWadsworth-2017-Topological Inversions in Coale旭康 鲁No ratings yet

- Teriele1995 - Diffusion Coefficients at Infinite Dilution in WaterDocument3 pagesTeriele1995 - Diffusion Coefficients at Infinite Dilution in Watermarcoesteban97No ratings yet

- Diffusion Coefficient of Maltose in WaterDocument4 pagesDiffusion Coefficient of Maltose in Watermarcoesteban97No ratings yet

- Phase I Problem StatementDocument5 pagesPhase I Problem Statementmarcoesteban97No ratings yet

- Molecular Dynamics Simulation of Water Diffusion in ZeolitesDocument7 pagesMolecular Dynamics Simulation of Water Diffusion in Zeolitesmarcoesteban97No ratings yet

- Separation Science and Technology: To Cite This Article: R. A. Garcia-Delgado, L. M. Cotoruelo-Minguez & J. J. RodriguezDocument15 pagesSeparation Science and Technology: To Cite This Article: R. A. Garcia-Delgado, L. M. Cotoruelo-Minguez & J. J. Rodriguezmarcoesteban97No ratings yet

- Examples of Transport and System Models: Learning ObjectivesDocument70 pagesExamples of Transport and System Models: Learning Objectivesmarcoesteban97No ratings yet

- Fisher-Tropsch CatalysisDocument35 pagesFisher-Tropsch Catalysismarcoesteban97No ratings yet

- Techno-Economic Analysis 14butanedialproduction Single Step Bioconversion Process PDFDocument13 pagesTechno-Economic Analysis 14butanedialproduction Single Step Bioconversion Process PDFmarcoesteban97No ratings yet

- Examples of Transport and System Models: Learning ObjectivesDocument70 pagesExamples of Transport and System Models: Learning Objectivesmarcoesteban97No ratings yet

- Asphaltene Temperature PDFDocument9 pagesAsphaltene Temperature PDFmarcoesteban97No ratings yet

- Solutions To Haberman - App Partial Diff Eqs 4EDocument419 pagesSolutions To Haberman - App Partial Diff Eqs 4Emarcoesteban97No ratings yet

- Lingo Users ManualDocument592 pagesLingo Users ManualAnggera BayuNo ratings yet

- Petroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi BehbahaniDocument7 pagesPetroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi Behbahanimarcoesteban97No ratings yet

- Wellbore Temperature Profile PDFDocument8 pagesWellbore Temperature Profile PDFmarcoesteban97No ratings yet

- Catalog 02 Dual LineDocument50 pagesCatalog 02 Dual Lineminhtrieu999No ratings yet

- Capillary Conduction of Liquids Through Porous MediaDocument17 pagesCapillary Conduction of Liquids Through Porous MediaAsh KongNo ratings yet

- A New Mix Design Method For UHPC Based On Stepwise Optimization of Particle Packing DensityDocument8 pagesA New Mix Design Method For UHPC Based On Stepwise Optimization of Particle Packing DensityUDDOM CHHENGNo ratings yet

- Haake PDFDocument26 pagesHaake PDFSimão PintoNo ratings yet

- Microemulsion Formulation For Topical Delivery of Miconazole NitrateDocument8 pagesMicroemulsion Formulation For Topical Delivery of Miconazole NitrateNida Auliya RahmahNo ratings yet

- Saes H 002VDocument29 pagesSaes H 002Vmurtada adamNo ratings yet

- Journal of Herbal Medicine: Research PaperDocument5 pagesJournal of Herbal Medicine: Research PaperAnnaAlexNo ratings yet

- RHEOLOGY ASSIGNMENT INFLUENCES PHARMACEUTICAL PROCESSESDocument10 pagesRHEOLOGY ASSIGNMENT INFLUENCES PHARMACEUTICAL PROCESSESjosephine allen-lingoNo ratings yet

- Aerodynamic Drag of Engine-Cooling Airflow With External InterferenceDocument17 pagesAerodynamic Drag of Engine-Cooling Airflow With External InterferenceVyssion100% (2)

- Lecture 1 - Introduction & Fluid Properties PDFDocument24 pagesLecture 1 - Introduction & Fluid Properties PDFJohn Kenneth Basas MusicoNo ratings yet

- Engineering Science and Technology, An International JournalDocument9 pagesEngineering Science and Technology, An International JournalAli EmamiNo ratings yet

- Fine Ansys Fluent Simulation ReportDocument6 pagesFine Ansys Fluent Simulation ReportWanAminudinNo ratings yet

- Industrial OilDocument20 pagesIndustrial Oilguswerino24No ratings yet

- Chapter 1 FluidsDocument39 pagesChapter 1 FluidsnrhdyaaNo ratings yet

- Springer Series in Solid-State Sciences: Edited Manuel Cardona and Peter FuldeDocument189 pagesSpringer Series in Solid-State Sciences: Edited Manuel Cardona and Peter FuldeAbdelaziz EdNo ratings yet

- Hydraulic SimilitudeDocument46 pagesHydraulic SimilitudeAnas Ratth100% (1)

- QC Exam QuestionDocument30 pagesQC Exam QuestionMd. Ahedul IslamNo ratings yet

- Designer's data sheet for distillation column internalsDocument4 pagesDesigner's data sheet for distillation column internalsTarun BhatiaNo ratings yet

- Sound and Vibration Considerations of Some Materials For Automotive Engineering ApplicationsDocument14 pagesSound and Vibration Considerations of Some Materials For Automotive Engineering ApplicationshocdehieuNo ratings yet

- Roatational ViscometerDocument2 pagesRoatational ViscometerNooruddin SheikNo ratings yet

- Increase Oil Recovery with Polymer Flood ModelingDocument63 pagesIncrease Oil Recovery with Polymer Flood Modelingbillal_m_aslam100% (2)

- The Modeling of Chemical Reactors Chapter 7Document17 pagesThe Modeling of Chemical Reactors Chapter 7ManoakiNo ratings yet

- Thermic Fluid DTDocument5 pagesThermic Fluid DTKishorNo ratings yet

- Fluent TutorialDocument34 pagesFluent TutorialConstantinescu MateiNo ratings yet

- Oer BoosterDocument8 pagesOer Boosteredison58100% (1)

- Annudeep Dhiman, RHEOLOGICAL PROPERTIES & CORROSION CHARACTERISTICS OF PDFDocument78 pagesAnnudeep Dhiman, RHEOLOGICAL PROPERTIES & CORROSION CHARACTERISTICS OF PDFbharathpeNo ratings yet

- Flow Through A Pipe Elbow: Solved With COMSOL Multiphysics 5.0Document22 pagesFlow Through A Pipe Elbow: Solved With COMSOL Multiphysics 5.0sharkman2020No ratings yet

- r07220302 Mechanics of FluidsDocument8 pagesr07220302 Mechanics of FluidsandhracollegesNo ratings yet

- Ccai Engine ManDocument12 pagesCcai Engine ManginanjarNo ratings yet

- Classification and Selection of Industrial ValvesDocument76 pagesClassification and Selection of Industrial ValvesABVSAI100% (6)

- Is That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeFrom EverandIs That a Fact?: Frauds, Quacks, and the Real Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (3)

- Essential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilFrom EverandEssential Oil Chemistry Formulating Essential Oil Blends that Heal - Aldehyde - Ketone - Lactone: Healing with Essential OilRating: 5 out of 5 stars5/5 (1)

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincFrom EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincRating: 3.5 out of 5 stars3.5/5 (137)

- The Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsFrom EverandThe Disappearing Spoon: And Other True Tales of Madness, Love, and the History of the World from the Periodic Table of the ElementsRating: 4 out of 5 stars4/5 (146)

- Coating and Drying Defects: Troubleshooting Operating ProblemsFrom EverandCoating and Drying Defects: Troubleshooting Operating ProblemsRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsFrom EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsRating: 5 out of 5 stars5/5 (3)

- A Perfect Red: Empire, Espionage, and the Quest for the Color of DesireFrom EverandA Perfect Red: Empire, Espionage, and the Quest for the Color of DesireRating: 4 out of 5 stars4/5 (129)

- Science Goes Viral: Captivating Accounts of Science in Everyday LifeFrom EverandScience Goes Viral: Captivating Accounts of Science in Everyday LifeRating: 5 out of 5 stars5/5 (1)

- Organic Chemistry for Schools: Advanced Level and Senior High SchoolFrom EverandOrganic Chemistry for Schools: Advanced Level and Senior High SchoolNo ratings yet

- Meltdown: Nuclear disaster and the human cost of going criticalFrom EverandMeltdown: Nuclear disaster and the human cost of going criticalRating: 5 out of 5 stars5/5 (5)

- Guidelines for Asset Integrity ManagementFrom EverandGuidelines for Asset Integrity ManagementRating: 5 out of 5 stars5/5 (1)

- Chemistry for Breakfast: The Amazing Science of Everyday LifeFrom EverandChemistry for Breakfast: The Amazing Science of Everyday LifeRating: 4.5 out of 5 stars4.5/5 (90)

- Chemistry: a QuickStudy Laminated Reference GuideFrom EverandChemistry: a QuickStudy Laminated Reference GuideRating: 5 out of 5 stars5/5 (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Chemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)From EverandChemistry: 1001 Practice Problems For Dummies (+ Free Online Practice)No ratings yet

- The Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableFrom EverandThe Elements We Live By: How Iron Helps Us Breathe, Potassium Lets Us See, and Other Surprising Superpowers of the Periodic TableRating: 3.5 out of 5 stars3.5/5 (22)

- Transformer: The Deep Chemistry of Life and DeathFrom EverandTransformer: The Deep Chemistry of Life and DeathRating: 4.5 out of 5 stars4.5/5 (13)