Professional Documents

Culture Documents

Ccai Engine Man

Uploaded by

ginanjarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ccai Engine Man

Uploaded by

ginanjarCopyright:

Available Formats

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.

net/preview/8405142/page:9/

Войти / Регистрация FAQ Обратная связь Вопросы и предложения

Файловый архив студентов.

1178 вузов, 3261 предметов.

Вузы Предметы Пользователи Добавить файлы Заказать работу

Добавил: Leshy Скачиваний: 226

Опубликованный материал нарушает ваши авторские Добавлен: 14.07.2019

права? Сообщите нам.

Размер: 7.68 Mб

Вуз: Нижегородский Государственный

Технический Университет им. Р.Е. Алексеева Скачать ☆

Предмет: Судовые энергетические установки

Файл: 7 семестр (Бормотов А) /

1man_bw_l23_30_chn_23_30_instruktsiya_po_ekspluatatsii_1

/ MAN-BW L23-30 H Vol-1 (Instruction)+.pdf

< Предыдущая << < 1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17 18 > >> Следующая >

1 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

Description 504.26

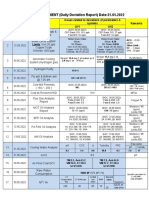

Page 1 (2) Nomogram for Determination of CCAI Edition 02

General

08028-0D/H5250/94.08.12

Fig 1 Nomogram for determination of CCAI.

01.34 - ES1

2 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

504.26 Description

Edition 02

Nomogram for Determination of CCAI Page 2 (2)

General

Example: Ignition quality is an important fuel parameter. The

reason why it does not appear in the international

Viscosity: 180 cSt at 50°C specificationsisthattherearenostandardizedtesting

Density: 990 kg/m³ at 15°C method is non-existent. Therefore, parameters

such as the Calculated Carbon Aromaticity Index

The combining straight line across density (990 kg/ (CCAI) are resorted to as an aid which is derived

m³) and viscosity (180 cSt) of a heavy fuel oil from determinable fuel parameters. According to

results in CCAI (859). From CCAI, conclusions may our experience, only a rough assessment of the

be derived with regard to the ignition qualities. ignition quality of the heavy fuel oil is possible with

the help of this method.

CCAI may be calculated with the aid of the

following formula: However, the CCAI has become so well-known in

widespread publications that, in spite of the

CCAI = D - 141 log (log (v + 0.85)) - 81 reservations mentioned above. We were compelled

to classify the respective MAN B&W Diesel A/S,

Holeby engines according to CCAI-rating, too.

01.34 - ES1

3 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

Description 504.27

Page 1 (4)

Analysis Data Edition 02

General

Comments on Analysis Data for Fuel Oils Asphaltenes also influences the lubricating

properties of the fuel oil and, in extreme cases, high

Carbon Residue asphalteness content may lead to fuel injection

pump sticking.

The carbon residue of a fuel oil indicates its

cokeforming tendency and can be used to Fuel oils with a high asphalteness content will have

determine the tendency to form deposits in the a tendency to form sludge, especially if the water

combustion chamber and gasways. The higher the content is also high. The asphaltenes content of a

carbon residue value, the higher the fouling fuel oil is influenced by pre-treatment. The heaviest

tendency. semi-solid asphaltenes, and asphaltenes bound to

water as sludge, can be separated by centrifuging.

Some changes in the combustion process,

requiring adjustment of the maximum pressure,

may also be attributed to a high carbon residue Diesel Index

content. The value is measured by standardized

tests, such as the Conradson or Ramsbottom tests Diesel index is a calculated value to determine the

which give similar results. ignition quality of a fuel oil. The ignition quality is

related to the hydrocarbon composition, paraffin

The non-vaporized residue from the carbonizing being of high quality, n-heptanes of moderate

test consists of carbonaceous material and quality and aromatics of low quality.

inorganic impurities and is expressed as

percentage weight of the fuel sample tested. With certain exceptions the properties of the aniline

Carbon residue and asphaltenes content generally point and the specific gravity reflect the

move in parallel, both in relation to the carbon-to- hydrocarbon composition of a fuel oil, and are

hydrogen ratio, with increasing values for a higher therefore used in the following simple formula as an

ratio. expression of ignition quality:

The carbon-to-hydrogen ratio and thus also the Diesel index = (aniline point °F x API gravity) x 0.01.

carbon residue depends on the source of the crude

oil and the type of refinery processing used. The aniline point is the lowest temperature at which

equal volumes of the fuel and aniline become just

The effect of carbon residue is impossible to miscible. The test relies on the fact that aromatic

counteract by pre-treatment of the fuel oil, as hydrocarbons mix completely with aniline at

centrifuging only influences solid inorganic comparatively low temperatures, whereas paraffins

contaminants and hard asphalts, which are only require considerably higher temperatures before

small amounts of the percentage weight called they are completely miscible.

carbon residue.

A high aniline point thus indicates a highly paraffinic

fuel, and consequently a fuel oil of good ignition

Asphaltenes quality. Similarly, a high API gravity number

denotes a low specific gravity and high paraffinicity,

Asphaltenes is defined as the part of a fuel oil and again a good ignition quality.

sample which is insoluble in heptane. The content

of asphalteness is expressed as percentage weight The diesel index provides a reasonable idea of the

of the fuel oil sample tested. ignition quality, but generally gives figures slightly

above the cetane number.

Asphaltenes, which is aromatic, slow-burning,

semisolid hydrocarbon compounds dispersed in the Fuel oils with poor ignition quality and a low diesel

fuel oil, has a similar effect on the combustion index might in particular cause problems in starting

process to the carbon residue, the main impact diesel engines and running at low load.

being fouling of gasways. The stability of the fuel oil

is related to the asphaltenes content.

4 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

02.16 - ES0 - G

504.27 Description

Edition 02

Analysis Data Page 2 (4)

General

In addition to starting difficulties, a prolonged Especially if the weight ratio of sodium to vanadium

ignition delay may give rise to alternations in the exceeds 1:3, ash with a very low melting point and

maximum pressure, leading to increased stiction temperature is formed, giving rise to high

mechanical or thermal load. temperature corrosion of exhaust valves and

deposit formation in turbochargers.

Furthermore, fuel oils with poor ignition quality may

cause retarded combustion and subsequent fouling It is possible to reduce the tendency for formation of

of gasways. detrimental vanadium-sodium ash by effective

centrifuging, which will remove sodium salts

together with water. If a very low content of sodium

Sulphur is ensured, a relatively high vanadium content

might be acceptable.

Sulphur is present in fuel oil, mainly as organic

compounds, the amount present being expressed as

percentage weight of an oil sample tested. If free Water

sulphur is present it may cause corrosion in the fuel

system. The main problem caused by sulphur is low The water content of fuel oil is measured by a

temperature corrosion. During combustion, sulphur standardized distillation test and is expressed as

oxides are produced in the form of gases. Since percentage volume of the sample tested. Water in

humidity is also present sulphur and sulphuric acid may the fuel oil may lead to several detrimental effects

be formed on components in the combustion chamber on the fuel oil system, and corrosion and cavitation

and in the gasways, where the temperature is below that of fuel injection pumps and fuel valves, and cause

of the dew point for sulphuric acid. fouling of exhaust systems and turbochargers.

The detrimental effect of sulphur in fuel oil is Due to its content of sodium, salt water in

counteracted by maintaining an adequate temperature combination with vanadium contributes to the

of the combustion chamber components and by using formation of low-melting corrosive ash, which

alkaline lubricating oil to neutralize the sulphuric acid attacks exhaust valves and turbochargers. When it

produced during combustion. disturbs the fuel atomization, water will lead to poor

combustion, resulting in higher heat load on the

combustion chamber components.

Vanadium and Sodium

It is possible to reduce the water content of a fuel

Vanadium and sodium are constituents of the ash oil primarily by centrifuging, and this should be

content. The amounts of these are measured by done to the widest possible extent in order to avoid

analyzing the residue from the combustion test used for the detrimental effects of water in the fuel oil.

determination of the ash content. The amount of

vanadium and sodium present is expressed in ppm,

parts per million, by weight in relation to the fuel oil Ash

sample being tested for ash content. Vanadium derives

from the crude oil itself and, being oil soluble, cannot be Ash content is a measure of the non-combustible

removed from the fuel oil by conventional pre-treatment. material present in the fuel oil. The ash content is

Sodium derives from the crude oil, and also from determined by a combustion test and it is

contamination with salt water during storage and expressed as a percentage weight residue from

transport of the fuel oil. Sodium is watersoluble and, complete combustion of the oil sample tested.

regardless of derivation, tends to combine with the water

present in the fuel oil. Ash-forming materials are present in the fuel oil as

natural components of crude oil and due to external

Owing to its water solubility, it is possible to remove contamination of the fuel oil.

or reduce the amount of sodium present in the fuel

oil. During combustion, corrosive ash is formed

from vanadium and sodium.

02.16 - ES0 - G

5 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

02.16 - ES0 - G

Description 504.27

Page 3 (4)

Analysis Data Edition 02

General

Ash-forming materials exist both as solid Viscosity of Marine Gas Oil (MGO) and Marine

contaminants and in soluble compounds. The solid Diesel Oil (MDO) are expressed in centistokes (cSt)

contaminants may lead to abrasive wear in the fuel at 40° C.

injection system. Ash formed during combustion

may lead to abrasive as well as corrosive wear of Viscosity is an important parameter in connection with

combustion chamber components and give rise to pumping, pre-treatment and injection of fuel oil, since the

formation of detrimental deposits. It is therefore possibility and efficiencyofthese processes to a large

essential, to the greatest possible extent, to reduce extent depend on adequate viscosity.

the amount of ash-forming materials by centrifuging.

Adjustmentofviscositytoadequatevaluesispossible

Solid contaminants such as sand, rust, certain by takingadvantageof theinterdependence between

metal oxides and catalyst fines can be removed by the temperature and viscosity index of the fuel oil.

centrifuging, and the same goes for water-soluble

salts such as sodium. The nominal viscosity of a fuel oil is the factor

determining the preheating temperatures necessary

Some of the components included in the ash content to obtain adequate viscosity for pumping,

have been found to be particularly harmful and are centrifuging and injection of the fuel oil, and thus

therefore stated individually in the analysis data. also the factor determining the capacity of the

preheating equipment in the fuel oil system.

Silicium and Aluminium Oxides

Density

Residual fuels produced by refineries using fluid

catalytic cracking may be contaminated by catalyst Density is defined as the mass of a unit volume and

particles in the form of silicium and aluminium is expressed in g/cm³ at a temperature of 15°C

oxides. Any catalyst particles are shown by the ash (59°F).

content value. Separate values for silicium oxide

content and aluminium oxide content are measured Specific gravity is the ratio of the mass of a given

by analyzing the ash content. volume of liquid at 60°F (15.6°C) and the mass of

an equal volume of water at the same temperature.

The amount of silicium and aluminium oxides is For a given liquid, the specific gravity will generally

expressed in ppm in relation to the weight of the give the same numerical value as the density.

original fuel oil sample being tested for ash content.

API gravity is an arbitrary scale calibrated in

As catalyst particles are very hard and abrasive, degrees and related to specific gravity by the

they can cause extreme mechanical wear of the fuel following formula:

injection system, cylinder liners and piston rings. 141.5

° API gravity = + 131.5

Catalyst particles, being solid and insoluble, can be specific gravity/50°F

removed from the fuel oil. The guidelines for

dimensioning the centrifuge size are based on the As the formula indicates, the API gravity is in

fact that approx. 1/3 of the catalyst particles in inverse proportion to density and specific gravity.

terms of weight is removed.

Density is an important parameter in the centrifuging

process, where separating water and water-dis-

Viscosity solved impurities from the fuel oil is based on the

difference in densities. If the density of the fuel oil

Basically viscosity is a measure of the internal approaches that of water, centrifuging thus becomes

friction or resistance of a liquid to flow. less effective, necessitating a reduced flow rate and

therefore increased centrifuge capacity.

02.16 - ES0 - G

6 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

504.27 Description

Edition 02

Analysis Data Page 4 (4)

General

The water separation ability of fuel oil is increased Pour Point

by preheating the fuel oil prior to centrifuging since

the densities of fuel oil and water change with the The pour point is the lowest temperature at which

temperature at different rates, thus making it an oil will flow or can be poured. The pour point is

possible to optimize density differences. measured under specific test conditions. Fuel oil

must be stored, handled and pumped at

To some extent the quality of a fuel oil can be temperatures above the pour point to avoid wax

judged by the density, since this is directly crystallization, which may result in precipitation in

proportional to the carbon-to-hydrogen ratio, which storage tanks, blocking of filters and pipe lines and

again is in direct proportion to aromativity, carbon prevention of pumpability. Normally, the pour point

residue and asphaltene content, but in reverse ratio of residual fuel oil does not create any problems,

to calorific value. since the temperature needed to reduce the

viscosity to pumpable levels will be adequately in

excess of the pour point.

Analysis Data for Fuel Oils

Carbon Residue % weight Flash Point

Asphaltenes % weight

Diesel Index The flash point of an oil is defined as the

Engine- FIA temperature at which it gives off sufficient vapour to

Relevant Ash % weight

Properties Sulphur % weight

create an inflammable mixture with air. This mixture

Water % volume will ignite or flash under the influence of an open

Vanadium ppm flame, but will not support combustion itself. The

Sodium ppm flash point of fuel oil is normally tested by the

Silicium Oxide ppm Pensky-Martens closedup method.

Aluminium Oxide ppm

Viscosity cSt/50°C In order to provide a sufficient margin of safety from

Installation- Density g/ml fire risk during storage, handling and transportation,

Relevant Flash Point °C fuel oils for shipboard use must meet the

Properties Pour Point °C

classification societies' requirements of flash point,

limited to a minimum of 60°C (140°F).

Table 2 Analysis data for fuels.

02.16ES0 - G

7 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

Description 504.30

Page 1 (2)

Fuel Oil Cleaning Edition 01

General

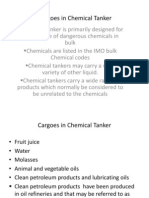

Purification Recommendations Especially for fuels above 180 cST/50°C (1500 sec.

RW/100°F) the highest possible temperature of

Fuel oils are always contaminated and should 98°C (208°F) should be maintained in the

therefore be cleaned thoroughly of solid as well as centrifuge oil preheater.

liquid contaminants before use. The solid

contaminants in the fuel are mainly rust, sand, dust The fuel is kept in the centrifuge for as long as

and possible by adjusting the flow rate through the

refinerycatalysts.Liquidcontaminantsaremainlywater, centrifuge so that it corresponds to the amount of

i.e. either fresh water or sea water. fuel required by the engine without excessive

recirculating. Consequently, the centrifuge should

The impurities can cause damage to fuel injection operate for 24 hours a day except during necessary

pumps and fuel valves, result in increased cylinder cleaning.

liner wear and cause the exhaust valve seats to

deteriorate. Increased fouling of gasways and Taking today's fuel qualities into consideration the

turbocharger blends may also result from the use of need to clean centrifuges ("shooting frequency")

inadequately cleaned fuel oils. should not be underestimated. Correct choice and

adjustmentoftheregulatingscrewsand/orthegravity

Effective cleaning can only be ensured by means of discs are of special importance for efficient water

a centrifuge. We recommend that the capacity of the removal. The centrifuge manual states the disc or

centrifuges installed be at least according to the screw adjustment which should be chosen on the

centrifuge maker's recommendations. To obtain basis of the specific gravity of the fuel.

optimum cleaning it is of the utmost importance to

operate the centrifuge with as low a viscosity of the Normal practice is to have at least two centrifuges

fuel oil as possible and to allow the fuel oil to remain available for fuel cleaning. Results from

in the centrifuge bowl for as long as possible. experimental work on centrifuges, treating today's

qualities of residual fuel, have shown that the best

cleaning effect, especially as regards removal of

catalyst fines, is achieved when the centrifuges are

Cleaning of HFO by Centrifuging operated in series, in purifier/clarifier mode.

Operating Single centrifuge as purifier.

Therefore series operation of centrifuges to ensure

options Two centrifuges in parallel. maximum safety is a fully accepted alternative to the

Two centrifuges in series.

previouslyrecommendedparalleloperation,provided the

operating capacity of each individual centrifuge can

Optimum Operating Configurations

handle the total amount of fuel required by the

engine,withoutexceedingtheflowraterecommended by

Water content Parallel operation

the centrifuge maker for the operating mode in question.

below 1 % Purifier / Purifier

Normal

conditions or

Density at 15°C Series operation

If the centrifuge capacity installed is on the low

below 0.991 Purifier + Clarifier

side, corresponding to the specific viscosity of the

fuel oil used, and if more than one centrifuge is

Water content available, parallel operation may be considered in

below 1 % Parallel operation order to obtain an even lower flow rate. However, in

view of the above results and recommendations

Extreme Density at 15°C Purifier / Purifier serious consideration should be given to installing

conditions below 0.991 new equipment in accordance with today's fuel

qualities and flow recommendations.

High content Series operation

of catalyst fines Purifier + Clarifier

Table 1. Cleaning of HFO.

97.40 - ES0

8 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

504.30 Description

Edition 01

Fuel Oil Cleaning Page 2 (2)

General

To determine centrifuging capacity we generally

advise to follow the recommendations of the Flow Rate

centrifuge maker, but the curves in fig. 1, can be Related to Rated Capacity of Centrifuge

used as a guideline. %

100

A homogenizer may be installed in the fuel oil 80

system as a supplement to the centrifuges in order 60

to homogenize possible water and sludge still 40

present in the fuel after centrifuging. 20

Separation Temperature

°F °C

212 100

194 90

176 80

158 70

140 60

122 50

104 40

100

15 25 45 75 130 cSt/80°C

Log scales 30 60 80 180 380 600 cST/50°C

200 400 600 1500 3500 6000 sec. RI/100°F

Fig. 1 Flow rate through centrifuge related to nominal

capacity of centrifuge.

97.40 - ES0

9 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

Description 504.40

Page 1 (5)

Freshwater System Treatment

Edition 02

General

Protection against Corrosion in Cleaning agents emulsified in water as well as slightly

Freshwater Cooling System alkaline cleaning agents can be used for the degreasing

process, whereas ready-mixed cleaning agents which

The engine fresh water must be carefully treated, involve the risk of fire must obviously not be used. For

maintained and monitored so as to avoid corrosion descaling with acid, especially products based on amino-

or the formation of deposits which can result in sulphonic acid, citric acid, and tartaric acid are

insufficient heat transfer, it is necessary to treat the recommendable, as these acids are usually obtainable

cooling water. MAN B&W recommend that this as solid substances, easily soluble in water, and do not

treatment is carried out according to the following emit poisonous vapours.

procedure:

The cleaning agents should not be directly

admixed, but should be dissolved in water and then

– Clean the cooling water system. added to the cooling water system.

– Fill up with deionized or distilled cooling Normally, cleaning can be executed without any

water (for example from the freshwater dismantling of the engine. We point out that the

generator) with corrosion inhibitor added. water should be circulated in the engine to achieve

the best possible result.

– Carry out regular checks of the cooling water

system and the condition of the cooling water. As cleaning can cause leaks to become apparent in

poorly assembled joints or partly defective gaskets,

inspection should be carried out during the cleaning

Observance of these precautions, and correct process. The acid content of the system oil should

venting of the system, will reduce service difficulties also be checked immediately after cleaning, and 24

caused by the cooling water to a minimum. hours afterwards.

Cleaning of the Cooling Water System Cooling Water - Inhibitors

Before starting the inhibition process, any existing The filling-up with cooling water and the admixture

deposits of lime or rust, or any oil sludge, should be of the inhibitor is to be carried out directly after the

removed in order to improve the heat transfer and cleaning in order to prevent formation of rust on the

to ensure uniform protection of the surface by cleaned surfaces.

means of the inhibitor.

Raw Water

The cleaning should comprise degreasing to

remove oil sludge, and descaling with acid The formation of lime stone on cylinder liners and in

afterwards to remove rust and lime deposits. cylinder heads may reduce the heat transfer, which

will result in unacceptably high temperatures in the

Ready-mixed cleaning agents, specially made for material.

cleaning the cooling water system, can be obtained from

companies specializing in cooling water treatment. Therefore, it is recommended that deionized or

These companies offer assistance and control of the distilled water (for example from the freshwater

treatment in all major ports. A number of these generator) is used as cooling water. However, on

companies are mentioned on the enclosed list. We point account of its lack of hardness, this water will be

out that the directions given by them should be closely relatively corrosive, and a corrosion inhibitor should

followed. It is of particular importance to flush the system

therefore always be added.

completely after cleaning.

00.11ES1

10 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

504.40 Description

Freshwater System Treatment Page 2 (5)

Edition 02

General

If deionized or distilled water cannot be obtained, Checking of the Cooling Water System

normal drinking water can be used in exceptional and the Cooling Water during Service

cases. If so, the total hardness of the water must

not exceed 9° dH (German hardness degrees). The If the cooling water is contaminated during service,

chloride, chlorine, sulphate, and silicate contents sludge or deposits may form. The condition of the

are also to be checked. These contents should not cooling water system should therefore be regularly

exceed the following values: checked, especially if deionized or distilled water is

not used. If deposits are found in the cooling

Chloride 50 ppm (50 mg/litre) spaces, these spaces or, if necessary, the entire

Chlorine 10 ppm (10 mg/litre) system should be cleaned.

Sulphate 100 ppm (100 mg/litre)

Silicate 150 ppm (150 mg/litre) According to experience, a zinc galvanized coating

in the freshwater cooling system is often very

There should be no sulphide and ammonia content. susceptible to corrosion, which results in heavy

Rain water must not be used, as it may be heavily formation of sludge, even if the cooling water is

contaminated. correctly inhibited. The initial descaling with acid

will, to a great extent, remove the galvanized

It should be noted that softening of water does not coating. Generally, therefore, we advise against the

reduce its sulphate and chloride contents. use of galvanized piping in the freshwater cooling

system.

11 dari 12 26/03/2021 08.54

MAN-BW L23-30 H Vol-1 (Instruction)+ - Стр 9 https://studfile.net/preview/8405142/page:9/

< Предыдущая << < 1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17 18 > >> Следующая >

Соседние файлы в папке 1man_bw_l23_30_chn_23_30_instruktsiya_po_ekspluatatsii_1

MAN-BW L23-30 (Instruction)+.PDF 138 # 21.69 Mб 14.07.2019

MAN-BW L23-30 H Vol-1 (Instruction)+.pdf 226 # 7.68 Mб 14.07.2019

MAN-BW L23-30h project-guide.pdf 72 # 4.66 Mб 14.07.2019

T23LH_4 (BW) (Analog of MAN-BW L23-30).PDF 62 # 9.04 Mб 14.07.2019

Помощь Обратная связь Вопросы и предложения Пользовательское соглашение Политика конфиденциальности

12 dari 12 26/03/2021 08.54

You might also like

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Nomogram For Determination of CCAI: Description Page 1 (2) Edition 02Document2 pagesNomogram For Determination of CCAI: Description Page 1 (2) Edition 02Atanasio PerezNo ratings yet

- Sewerage Design Calculation For CO4Document6 pagesSewerage Design Calculation For CO4Mohd RafiqNo ratings yet

- EEXIDocument5 pagesEEXIstyahadNo ratings yet

- StarLAN Technology ReportFrom EverandStarLAN Technology ReportRating: 3 out of 5 stars3/5 (1)

- CraneDocument37 pagesCraneAreeb AhmedNo ratings yet

- Closed Coke Slurry System Enhances Coking Operations Vermiere TriPlan DCU Mumbai 2016 PDFDocument33 pagesClosed Coke Slurry System Enhances Coking Operations Vermiere TriPlan DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- 1 s2.0 S2092678221000510 MainDocument15 pages1 s2.0 S2092678221000510 MainromaylopezismaelNo ratings yet

- Silika - DikonversiDocument30 pagesSilika - DikonversiMuhammad Yudi SaputraNo ratings yet

- 6 - Durable High-Power Density Fuel Cell Cathodes For HeavyDuty VehiclesDocument31 pages6 - Durable High-Power Density Fuel Cell Cathodes For HeavyDuty VehiclesFaseeh KKNo ratings yet

- Gac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDocument3 pagesGac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDipayan DasNo ratings yet

- MOL - Central Front End Compression Facility Project: PAGE: 1 of 13 Rev: 0 DATE: 11-Mar-2017Document13 pagesMOL - Central Front End Compression Facility Project: PAGE: 1 of 13 Rev: 0 DATE: 11-Mar-2017eke23No ratings yet

- Ilovepdf Merged PDFDocument60 pagesIlovepdf Merged PDFAtanu PaulNo ratings yet

- CT1 2022-23Document2 pagesCT1 2022-23Saurabh KumarNo ratings yet

- Sample Design Calculations For Vertical VesselsDocument14 pagesSample Design Calculations For Vertical VesselsFaris QoceyNo ratings yet

- Ballistic Properties of Scavenged Solid Rocket PropellantsDocument16 pagesBallistic Properties of Scavenged Solid Rocket PropellantsspetNo ratings yet

- Fem Analysis For Spherical TanksDocument28 pagesFem Analysis For Spherical TanksNilabhNo ratings yet

- LWB II Basic Data Gaa26800kjDocument16 pagesLWB II Basic Data Gaa26800kjAr666No ratings yet

- Manual Calculation Skid Enclosure - Belida WHP-B - Rev.2 PDFDocument9 pagesManual Calculation Skid Enclosure - Belida WHP-B - Rev.2 PDFLukman ChairkiandraNo ratings yet

- 34 2-DTNB Thiet Ke Che Tao MCC+EMCC - CTC01 - 090817 Revised 10.08.17Document158 pages34 2-DTNB Thiet Ke Che Tao MCC+EMCC - CTC01 - 090817 Revised 10.08.17Nguyen Hong QuyetNo ratings yet

- BLNG Ce 818010298560001Document66 pagesBLNG Ce 818010298560001Venkatesh PrasathNo ratings yet

- 2010 - MAN Project Guide 6S90MEDocument363 pages2010 - MAN Project Guide 6S90MEМаксим АгеевNo ratings yet

- Failure Analysis On Drilling Rigs SongDocument6 pagesFailure Analysis On Drilling Rigs SongKevin Roj MedNo ratings yet

- Manual Komatsu Tier3 Engines Ecot3 Emission Regulations Development Technology Electronic Control System Common RailDocument7 pagesManual Komatsu Tier3 Engines Ecot3 Emission Regulations Development Technology Electronic Control System Common RailPMV DeptNo ratings yet

- Deviation & Clarification List: Valdel Towell EngineeringDocument2 pagesDeviation & Clarification List: Valdel Towell EngineeringSiva baalanNo ratings yet

- Structural - Analysis - Skid A4401 PDFDocument94 pagesStructural - Analysis - Skid A4401 PDFMohammed Saleem Syed Khader100% (1)

- RASEL 631,1 70lt 43kg 42barDocument8 pagesRASEL 631,1 70lt 43kg 42barmilanNo ratings yet

- UPD ME W7 CI CL 4107 - RevCDocument124 pagesUPD ME W7 CI CL 4107 - RevCDidi Hadi RiantoNo ratings yet

- BC63KA-Retrofit Plan For BWTSDocument19 pagesBC63KA-Retrofit Plan For BWTSВиталий МакошибаNo ratings yet

- Mathieu 2012Document17 pagesMathieu 2012Bara Abdullah Azmi Al-BaihaqiNo ratings yet

- 2017 - Current Status and Future Development of Solvent-Based Carbon CaptureDocument10 pages2017 - Current Status and Future Development of Solvent-Based Carbon CaptureBruno BunyaNo ratings yet

- Service Letter SL2018-665/MET: SO Scrubber Retrofit On Two-Stroke Engines in ServiceDocument3 pagesService Letter SL2018-665/MET: SO Scrubber Retrofit On Two-Stroke Engines in ServiceWing On WongNo ratings yet

- Spec Draft DMSL FinalDocument28 pagesSpec Draft DMSL FinalSriram SubramanianNo ratings yet

- Design Guide For Slug Force Calculation ProcedureDocument6 pagesDesign Guide For Slug Force Calculation ProcedurePratik PatreNo ratings yet

- Koboko Bpit-1Document1 pageKoboko Bpit-1Okello StevenNo ratings yet

- Man B&W S65ME-C8.6: Project GuideDocument496 pagesMan B&W S65ME-C8.6: Project GuideДмитроNo ratings yet

- AM PAPER CT 2Document2 pagesAM PAPER CT 2Saurabh KumarNo ratings yet

- Seminar FinalDocument23 pagesSeminar FinalJithin Jose0% (1)

- Portin 2010-Wartsila Dual Fuel (DF) Engines For Offshore Applications and Mechanical DriveDocument6 pagesPortin 2010-Wartsila Dual Fuel (DF) Engines For Offshore Applications and Mechanical DrivesestoubosNo ratings yet

- Driver Selection For Large Offshore Production Facilities: An Important Early Project DecisionDocument22 pagesDriver Selection For Large Offshore Production Facilities: An Important Early Project DecisionzsmithNo ratings yet

- RASEL 637,1 70lt 43kg 42barDocument8 pagesRASEL 637,1 70lt 43kg 42barmilanNo ratings yet

- Mumbai Trans Harbour Link Package 1 Sewri Interchange Pavement DesignDocument9 pagesMumbai Trans Harbour Link Package 1 Sewri Interchange Pavement Designasif_22ukNo ratings yet

- Specification For Sprinkler DesignDocument14 pagesSpecification For Sprinkler DesignFarhan AhmedNo ratings yet

- Detroitdiesel MHDD A2900174 7d7-5d1 0d20-0d01Document3 pagesDetroitdiesel MHDD A2900174 7d7-5d1 0d20-0d01Erick RodriguesNo ratings yet

- HC SCR - Yr2018Document10 pagesHC SCR - Yr2018Mr Mathavan SNo ratings yet

- Time Zones 1 & 2: Answer Each Section in Separate BookletsDocument12 pagesTime Zones 1 & 2: Answer Each Section in Separate BookletsIdlan IzharNo ratings yet

- Haultruckfuelconsumption PublishedDocument6 pagesHaultruckfuelconsumption PublishedVc CvNo ratings yet

- 5510 0172 00ppr - Using Methanol Fuel in The - Low PDFDocument16 pages5510 0172 00ppr - Using Methanol Fuel in The - Low PDFarunNo ratings yet

- (Compare Report) SAES-A-401Document42 pages(Compare Report) SAES-A-401kartik_harwani43870% (1)

- Ae/Aee RWS, Mandal: YedapallyDocument22 pagesAe/Aee RWS, Mandal: Yedapallydee balkondaNo ratings yet

- RASEL 632,1 70lt 43kg 42barDocument8 pagesRASEL 632,1 70lt 43kg 42barmilanNo ratings yet

- B116XW03 V0 AuoDocument31 pagesB116XW03 V0 AuoNerta NaturaNo ratings yet

- High Speed Railway Lines - enDocument53 pagesHigh Speed Railway Lines - enaleitaosilva100% (3)

- 028120-SPL-005 Pipeline Installation Rev. CDocument36 pages028120-SPL-005 Pipeline Installation Rev. CRokan Pipeline100% (6)

- RASEL 631,2 32lt 23kg 42barDocument8 pagesRASEL 631,2 32lt 23kg 42barmilanNo ratings yet

- PrismaticDocument15 pagesPrismatica.agila03No ratings yet

- TCM3.2L La 22PFL1234 D10 32PFL5604 78 32PFL5604 77 42PFL5604 77Document67 pagesTCM3.2L La 22PFL1234 D10 32PFL5604 78 32PFL5604 77 42PFL5604 77castronelsonNo ratings yet

- Chemistry Report DT 31.05.2022Document2 pagesChemistry Report DT 31.05.2022anil peralaNo ratings yet

- Spectrapak 315 - (PDF Document)Document1 pageSpectrapak 315 - (PDF Document)ginanjarNo ratings yet

- Preliminary Tech. Doc. OG120C TG 5Document17 pagesPreliminary Tech. Doc. OG120C TG 5Михаил Гуляев100% (1)

- SAE Viscosity PDFDocument5 pagesSAE Viscosity PDFMusaferNo ratings yet

- Damage To Engine Bearings - 861097Document72 pagesDamage To Engine Bearings - 861097Derrick AramNo ratings yet

- Guidelines On Operation On Distillate Fuels: Service Letter SL09-515/CXRDocument5 pagesGuidelines On Operation On Distillate Fuels: Service Letter SL09-515/CXRginanjarNo ratings yet

- SKF Hydraulic CouplingsDocument32 pagesSKF Hydraulic CouplingstanasaNo ratings yet

- Overflow TankDocument3 pagesOverflow TankginanjarNo ratings yet

- 2007 Kamewa CPP System PDFDocument4 pages2007 Kamewa CPP System PDFsameh farghaly100% (2)

- Hydraulic Bow and Stern ThrustersDocument2 pagesHydraulic Bow and Stern ThrustersginanjarNo ratings yet

- BookDocument28 pagesBookFebrian Wardoyo100% (1)

- ABB Turbocharging VTC PDFDocument8 pagesABB Turbocharging VTC PDFhanifNo ratings yet

- Density Lab: Objective: To Discover The Identity of Each Cube Based On Its Density. Pre-LabDocument3 pagesDensity Lab: Objective: To Discover The Identity of Each Cube Based On Its Density. Pre-LabJacob FernandesNo ratings yet

- Homeworks 1-10 PDFDocument95 pagesHomeworks 1-10 PDFWendy LinNo ratings yet

- LNG Tank RolloverDocument7 pagesLNG Tank RolloverrendraprasetiyoNo ratings yet

- BLACK HOLES Final DraftDocument2 pagesBLACK HOLES Final DrafttejareddyNo ratings yet

- Kelompok 2Document22 pagesKelompok 2Akantha CasiaNo ratings yet

- Brrisl 47 65Document5 pagesBrrisl 47 65asrihamidNo ratings yet

- Variacion de Temperatura en El Enfriamiento de Un MetalDocument84 pagesVariacion de Temperatura en El Enfriamiento de Un MetalAndrés CaicedoNo ratings yet

- Soran University Faculty of Engineering Department of Petroleum EngineeringDocument7 pagesSoran University Faculty of Engineering Department of Petroleum EngineeringMuhamad S BraimNo ratings yet

- Standard Subgrade and Base Construction 200Document77 pagesStandard Subgrade and Base Construction 200Kamagara Roland AndrewNo ratings yet

- Calibration of Weighing MachinesDocument17 pagesCalibration of Weighing MachinesSaraswanto100% (12)

- ChemDocument2 pagesChemBaliuag Guia100% (4)

- Lab Tests in ConstructionDocument17 pagesLab Tests in Constructionsridhar k.l50% (4)

- Building Materials Unit 3Document123 pagesBuilding Materials Unit 3Suhail RazaNo ratings yet

- 02513Document10 pages02513Jeffrey Carlo Viduya AgliamNo ratings yet

- Caleffi: Valvole Di BilanciamentoDocument16 pagesCaleffi: Valvole Di BilanciamentoThomas GregantiNo ratings yet

- Colombian Olympiad PhysicsDocument120 pagesColombian Olympiad Physicssanits591100% (8)

- Astm D883Document16 pagesAstm D883Anonymous nxfFHG32k100% (6)

- Die Rendon CK 1998Document5 pagesDie Rendon CK 1998UlricNo ratings yet

- Final Project Report - Group 7Document26 pagesFinal Project Report - Group 7Nhut NguyenNo ratings yet

- Liquid Cargo HandlingDocument77 pagesLiquid Cargo HandlingFerit Aslanyürek100% (1)

- Masonry Retaining Wall DesignDocument8 pagesMasonry Retaining Wall Designusmanaltaf1100% (1)

- Chemistry Quiz For Grade 11Document3 pagesChemistry Quiz For Grade 11lij yoNo ratings yet

- EXPANDIT 10 Mortar Comparison TestDocument1 pageEXPANDIT 10 Mortar Comparison TestLaura GarcíaNo ratings yet

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNo ratings yet

- Seminar R PTDocument25 pagesSeminar R PTNEENU MARY JAMESNo ratings yet

- KE-42 3000 5. Cooling TowerDocument23 pagesKE-42 3000 5. Cooling Towersimodo1No ratings yet

- Physics Practical QuestionBank Final 2020-21Document13 pagesPhysics Practical QuestionBank Final 2020-21Mary ThummaNo ratings yet

- ASTM C 567 Método Normalizado de Ensayo para La Determinación de La Densidad de Concreto Estructural LivianoDocument3 pagesASTM C 567 Método Normalizado de Ensayo para La Determinación de La Densidad de Concreto Estructural LivianoPaola VargasNo ratings yet

- Lecture 2-3 - Introduction To Aerodynamics & FundamentalsDocument15 pagesLecture 2-3 - Introduction To Aerodynamics & FundamentalsAli RazaNo ratings yet

- Tutorial-7 SolDocument3 pagesTutorial-7 SolAvengerNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Petroleum Production Engineering, A Computer-Assisted ApproachFrom EverandPetroleum Production Engineering, A Computer-Assisted ApproachRating: 4.5 out of 5 stars4.5/5 (11)