Professional Documents

Culture Documents

Short Term Gain For Long Term Pain

Uploaded by

Putro Asta NagaraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short Term Gain For Long Term Pain

Uploaded by

Putro Asta NagaraCopyright:

Available Formats

Hall, B E, 2006. Strategic versus Tactical Approaches in Mining, Perth.

“Short Term Gain for Long Term Pain”

How focussing on tactical issues can destroy long term value

By B E Hall 1

Introduction The examples are in the context of underground metalliferous

mines, though similar situations no doubt exist in other sectors

Operating policies at many mines ensure that shareholder value of the industry. The challenge for mine technical and

is not maximised. In a number of studies developing strategic managerial staff is to identify where these types of things are

mine plans, it has become evident that traditional methods and happening in their operations, and to address the culture and

conventional wisdom often do not achieve stated corporate attitudes that allow them to continue to occur.

goals. Changing the overall strategy can provide significant

value gains. Typically, the new optimal plan involves a Chasing every high-grade tonne

significant increase in the cutoff grade, at least in the earlier It is often said that “grade is king”, and correctly so. Yet on

years. An increase in the underground development rate or open many operations, small amounts of high-grade ore are targeted

cut stripping rate is often associated with this, at least in the without consideration being given to how this impacts on the

short term, to establish the new strategy. Cost minimisation is overall achievement of production and financial targets. In

found to be counter-productive. Counter-intuitive plans are some cases, there is no assessment of the desirability of getting

often found to be optimal. For example, optimal cutoffs for those tonnes at all: if it is above cutoff, it is to be mined, and

different parts of an underground mine may be significantly the higher the grade, the more desirable it is, regardless of the

different, even if mineralisation and cost structures are similar. cost. Additional development, often through poorer ground than

Optimal plans have been found in many cases to be relatively normal, with reduced advance rates and increased costs, may be

insensitive to changes in major value drivers, such as metal required. It may also be necessary to deliberately incur dilution

prices, while sub-optimal strategies are frequently found to to produce practical mining shapes to recover this material: the

have a significantly greater financial risk. Identifying and then high-grade material in-situ can easily become an average or

operating within the framework of an optimal strategic plan can low-grade ore source.

have substantial benefits over a plan being continually driven

by short-term tactical issues. Many operations at least do an analysis to identify whether such

material actually generates a positive cash flow, taking account

Expediency in Operational decision- of the costs directly incurred to produce it and the additional

making revenue received from it. To the extent that this analysis fully

accounts for dilution and increased costs due to slower advance

The main thrust of this paper deals with planning and conscious rates and increased ground support, this is good. However, it is

decisions about long-term operating policies. This section, rare to find an analysis which accounts for the “opportunity

however, highlights briefly the impact of expediency in cost” of applying mining resources to this material.

operational decision-making, and the impact that this may have

on the achievement of the overall corporate goals. A few All mines have limited resources, including such things as

examples are given. These are typical of many instances labour hours and machine hours per time period. One of the

observed over the years by the author and his colleagues, and goals of the planners and the operators must be to make best

have occurred at a number of operations. It is suggested that use of these resources. As well as identifying the simple

these types of decisions often arise because of the measures profitability or otherwise of a target block of ground, it may be

used to assess the performance of operating managers, which worthwhile identifying the effort involved, and generating

often place a high emphasis on regular achievement of measures other than metal grade per tonne by which potential

production targets. This is of course a good thing, but if it leads ore sources may be ranked. Measures such as “net revenue per

to decisions which generate “short term gain for long term mill hour” (especially useful if different rock and mineral types

pain”, then perhaps the focus of senior management, or the have different milling rates and metallurgical recoveries), and

understanding of the goals by the operating manager, needs to “net profit per man-shift” or “per jumbo-hour” may give a

change. None of this should be taken to imply that management totally different view of the value of a block of ground from

is not free to make such decisions if all factors, both short-term just grade alone. All other things being equal, the goal of the

and long-term, have been identified and weighed, and an operation should be to generate the most profit from the

informed decision made. Frequently, however, these decisions resources available, and grade alone will often not be the best

arise from a corporate, or even industry, culture that values only guide to what should and should not be mined.

short-term performance, and that either fails to identify long-

term effects, or deliberately ignores them, assuming that they In this and other contexts, there will be the associated issue of

will be fixable at a later date. “if we don’t mine it now, it will be sterilised forever”. This is

addressed later in this paper.

Avoiding production delays to install infrastructure

1. Principal Mining Consultant, AMC Consultants Pty Ltd,

12/179 North Quay, Brisbane QLD 4000 For a variety of reasons – some acceptable as a normal part of

E-mail: bhall@amcconsultants.com.au

the ongoing obtaining of knowledge in mines, others due to

Short Term Gain for Long Term Pain

poor planning or earlier operational decisions – it will For a full understanding of modern cutoff theory, it is important

sometimes be necessary to disrupt production activities in order to appreciate these differences. All operations will have

to install infrastructure for the future of the operation. Where capacity limitations for all three material types, and at least one

the decision involves for example access to future production of these will normally be constraining the operation. Often, and

areas, the short-term disruption will usually be seen as a particularly in mature operations, ongoing debottlenecking will

necessary evil, and the planned work will proceed. But if the result in a balance of both rock and ore capacities – in open

planned work is for services, such as ventilation and drainage, pits, both the mining fleet and the treatment plant will be

then depending on the culture of the company, the relative working at capacity, though the run-of-mine (ROM) cutoff may

power of operators and planners, and the time horizon of vary to maintain this situation. In underground operations,

management, it may be that the decision is to forego the waste access development and ore throughput will be at their

installation to avoid the short-term disruption. The long-term limits, though the ore limitation may be in either the mine or

effect of this may be that the operation can never deliver the the treatment plant. In underground operations that continue

planned production rate, as the facilities to support it have not below a previous open pit, it is not uncommon to find that the

been provided. access development rate is the overall limitation – even if

performing at its maximum capability, insufficient

As indicated above, if all of this has been evaluated, and the mineralisation with grades adequate to cover marginal costs of

relative costs and benefits of the alternative plans have been production and treatment is exposed to “fill the mill”. Product

assessed, then it is the prerogative of the management to make constraints are not a concern for most operations. Treatment

the decision as they see fit. Unfortunately, it is often the case plants are usually designed to handle maximum ore quantities

that the downsides of these options are not fully evaluated: at grades above the expected average, and downstream product-

planners may have significantly less power than operators who handling facilities are also designed to cope with these, perhaps

perceive that the temporary reduction in output will reflect with some short-term stockpiling of product, so normal grade

badly on them, and / or the shortage of technical staff currently fluctuations do not constrain the ore throughput. However,

experienced in the industry results in there being insufficient some operations have genuine constraints on the amount of

time to evaluate fully the relative effects of the two options. In product they can sell, and many operations experience periods

the absence of information about the downsides, an uninformed of extra-high grade production, when the amount of product

and ultimately costly decision is made. that can physically be generated or handled becomes the overall

production constraint. However, strategic options that involve

Cutoffs and Production Rates increasing the cutoff and therefore the head grade may result in

scenarios where the capacity of the product part of the mill

In many operations, the importance of cutoff for delivering circuit becomes the overall constraint.

long-term value from the operation is still not well understood.

The optimum cutoff will generally vary over time, and at any Underground Operations

point in time (Lane, 1988) depends on the prices for the Existing strategies have been found to be suboptimal in a

product(s), the cost structure of the operation, the tonnage / number of strategy optimisation studies conducted by the

grade relationships of the mineralisation accessible in the author and his colleagues in recent years. Figure 1 shows a

period being assessed, and the capacities of the operation to: typical “Hill of Value” (HoV) for an underground metalliferous

1. Mine “rock”, which is then available for classification mine. The vertical axis is Net Present Value (NPV), though

as “ore” or “waste”, HoVs can be generated for all parameters of interest to the

company (Hall, 2003, Hall and de Vries, 2003), to allow

2. Produce and treat “ore”, and selection of strategic policies that deliver close to the best for a

3. Produce, handle and sell “product” number of corporate goals, rather than the best for one goal

only.

The term “ore” in this context refers to mined material that is

sold or sent for processing to generate a saleable product. It is Operations are found to be frequently operating with both

not used in the strict sense of the definitions in the various cutoff and production rate lower than optimal, as shown in the

international codes for the public reporting of resources and figure. Some of the reasons for this are discussed below.

reserves.

Typical causes of sub-optimal strategies

In open pits, “mining” in the simplest cases is the removal of all The sub-optimal production rate is often found to result from

the “rock” from within the designed pit limits, and this does not failure to utilise the existing productive capacities, which in

notionally become “ore” or “waste” until trucks diverge on the turn is often due to cost savings that result in insufficient

haul routes to ore and waste dumps on surface. In more development of ore sources to ensure that planned production

complex cases, with different drilling patterns and / or loading can be maintained should something go wrong with one of

and trucking fleets for ore and waste, there is a more complex them. “Just In Time” development in underground mines

relationship between ore and waste handling capacities, and frequently turns out to be “Just Too Late”. Cost savings can

hence between rock and ore handling capacities, within the pit. severely reduce overall value.

In underground mines, “mining” in this context typically relates

to development of declines and strike access development in Cutoffs are frequently too low because they typically fail to

waste. These openings give access to mineralised material account for “sustaining” capital expenditure (the regular

which can then be classed as “ore” and stoped, or left in-situ as ongoing cost of maintaining the productive capacities of the

“waste”. In this three-fold classification of material as rock, ore, plant and equipment and mine accesses), and the time-value-of-

or product, most activities in open pit mines are typically money “opportunity” cost of deferring higher-grade sources in

dealing with rock, whereas most activities in underground order to produce from lower-grade sources. Sustaining capex is

mines are typically dealing with ore. simply another regular cash outgoing, the same as

administration overheads. Its separate treatment in the financial

AMC Reference Library – www.amcconsultants.com.au 2

Short Term Gain for Long Term Pain

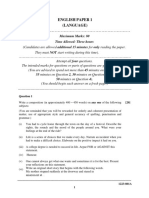

Figure 1 - Variation of NPV with cutoff and production target – underground

accounts should not cause it to be ignored in cutoff between development and production rates and developed ore

determinations. In fact it can be shown (though it is beyond the stocks has been re-established.

scope of this paper to do so) that the net cost of capital

expenditure is higher than that of an equivalent amount of This does not imply that cutoffs cannot be changed quickly.

operating expenditure, and it should therefore if anything bear a Rather it highlights that cutoff is an important strategic mine

surcharge rather than be ignored in “breakeven” calculations. design parameter, and changing from an existing strategy to a

(It should be noted that the terms “breakeven” and “cutoff” are new one is not a simple operational tactical issue, but one that

not synonymous, though breakeven calculations are frequently requires careful planning and scheduling of the transition to

used to determine the value used as the cutoff.) predict and avoid problems such as those described.

Moving to an optimal strategy Varying multiple strategic policy items over time

The “production rate” axis in Figure 1 is the ore production and It is assumed in Figure 1 that at each cutoff and production rate

treatment rate. Maximising value at the same cutoff will combination, the optimum mining schedule has been

typically involve an injection of working capital by way of a developed. There is no guarantee that a general development

temporary increase in the development rate. This will increase and stoping sequencing strategy that is optimal for one set of

the number of sources producing concurrently, in order to design parameters will be optimal for another. A full

guarantee delivery of the actual ore handling and treatment optimisation methodology must be able to account for this.

capacity already available. Increasing the cutoff at the same

production rate will require both a permanent increase in the Also, the three-dimensional nature of the chart allows plotting

development rate, since the ore tonnes per metre of of only two independent design variables and one dependent

development will typically reduce with increasing cutoff, and a variable. The cutoff specified on the cutoff axis is fixed for the

further temporary increase, to re-establish the working stocks of life of the mine, which is how many if not most mining

“developed ore”. The HoV shown also accounts for product operations are planned. Even with this limitation, increases in

constraints that may become active at high production rates and NPV of 10% to 50% have been observed in a number of

/ or cutoffs. studies, for cutoff increases ranging from 30% to 50% of the

value in use at the start of the study (Hall and Stewart, 2004).

Many operations that increase their cutoffs, particularly as a However, cutoff and the rock, ore, and product capacities can

rapid response to poor profitability and a perceived need to all vary, and it is well known that maximum value is obtained

increase head grade, do so almost instantaneously, with little or with a cutoff that can vary over time. The HoV shown could

no planning or immediate increase in development capacity. therefore be at least four-dimensional, with another independent

Developed ore stocks remaining at the higher cutoff are quickly variable axis for time, or perhaps six-dimensional, to allow for

consumed and within a few months, the mine has a production independent specification of alternative mine access

shortfall, as there are insufficient sources developed to sustain development and product handling capacity changes. By

the planned production rate at the new cutoff. If lower grade varying the cutoff over time, additional value is potentially

sources that had been developed at the previous lower cutoff obtainable by mining higher-grade material first, then lower-

are still accessible, these may have to be mined as marginal grade material at a later date, to the extent that it has not been

material, but often with increased costs for access rehabilitation sterilised by the earlier higher-cutoff mining. But even if all

and / or extra development, and with a significant reduction in lower grade material is sterilised at any cutoff, the HoV as

overall head grade. If these areas have been sterilised, there shown indicates what the best cutoff is.

may be no alternative but to suffer the loss until the balance

AMC Reference Library – www.amcconsultants.com.au 3

Short Term Gain for Long Term Pain

In caving mines, there may also be at least two different breakeven and cutoff, are mined. Different lives for the two

cutoffs, the one defining the “footprint” or in-situ volume of areas result in an unprofitable low production rate tail that will

ground planned to be developed as “ore”, the other being the be truncated by mine closure (if fixed costs cannot be

“shutoff” defining the lowest grade of broken rock to be sufficiently reduced to allow it to be mined profitably). During

extracted from drawpoints. the life of the mine, production from the longer-life area will

contain material that is above the common cutoff for both areas,

Varying strategic policy items by location but which is of lower grade than some of the material that

remains unmined when the mine closes. The second plot shows

Different cutoffs can also be applied to different areas within a how the cutoff in this area can be increased so that, at the time

mine to increase value (Hall and Stewart, 2004, Horsley, 2005). the mine does close, the best possible grades have been mined

Figure 2 shows schematically how this arises. In the first part of from both areas.

the figure, two areas with similar mineralisation, mining

methods, and costs structures, and therefore notionally the same

Figure 2 - Value-adding by different cutoffs in similar areas

In this simple example, the cutoff policies to maximise value Consider for example spare ore development capacity.

would be easily determined. In a real operation, dependencies Although the mill is being kept full at the optimum cutoff, there

between various mining areas and other scheduling and is always the temptation to mine lower-grade material, whose

sequencing constraints and options may make the selection of grade nevertheless is sufficient to pay for its own marginal

the optimal cutoff policy for all areas over time non-intuitive costs, because “if it’s not mined now, it will be sterilised

and non-trivial. Sophisticated optimisation techniques may be forever”. There is therefore the temptation to utilise the spare

required to select the best strategy. ore development capacity to extend ore development into

material slightly below the identified optimum cutoff, which

Dangers of sub-optimising for subsidiary parameters improves the utilisation statistics for the development

equipment. Although the mill is being filled with above-

Assume an underground operation that is both developing at the optimum-cutoff material, developing into lower-grade areas

maximum rate in waste access headings, and, at the identified will result in those areas also being produced, effectively

optimum cutoff, delivering the maximum quantity of ore that lowering the cutoff, and thereby moving to a lower-value area

the mill can treat. There are also a number of activities in the on the Hill of Value, by deferring production of the higher-

mine that could potentially constrain the amount of ore grade ore that should have been mined.

produced. These include the in-ore development rate, the

production drilling rate, the charging and blasting rate, the ore If the mill were not being filled with above-optimum-cutoff

mucking rate, and the ore trucking or shaft hoisting rate. Given material, this would be a good tactical plan in the short-term.

the variations in these over time, and the different sizes of However, it must cause the mine staff to question why this

incremental capacity steps in each, it is unlikely that all of these situation has arisen. If simply a result of “normal” variations in

will always be in balance. the mining cycle, short-term variations in effective cutoff are an

appropriate response. But if the shortage of above-optimum-

Short-term tactical key performance indicators (KPIs) for cutoff material is longer-term and resulting from a deviation

operating managers typically include such things as maximising from the strategic long-term plan, it will be necessary to not

equipment utilisation. While this is notionally good, a better only devise a short-term tactical plan to get back to the

KPI is optimising utilisation. The difference is subtle but optimum long-term plan, but also to identify what led to this

critical. Because of the imbalance in capacities of the various situation and take appropriate steps to prevent its reoccurrence

potential ore-constraining activities, the optimum mining in the future.

strategy will involve some activities, and therefore the

associated equipment, operating under capacity, rather than at The big danger, however, is for the short-term tactical response

maximum capacity. Attempting to operate all activities and to become the long-term strategy by default. It is easier to fill

equipment at maximum capacity will at best increase costs, and the mill with a lower cutoff (it takes some of the pressure off

at worst, result in a defacto lowering of the effective cutoff, the waste access development), the additional “ore” is

thereby reducing value. apparently “economic”, and the jumbo utilisation statistics

improve. The apparent tactical benefits will result in a move to

AMC Reference Library – www.amcconsultants.com.au 4

Short Term Gain for Long Term Pain

a sub-optimal strategic plan. If there were no other productive are the ROM cutoff (for ore sent directly to the mill) and the

work for them, it would actually be preferable to pay the overall “rock” (i.e. ore + waste) mining rate, expressed in this

development crews to do nothing, rather than to incur the case as a percentage of the base case rates in the pre-existing

additional variable costs of extra development that then causes plan, which may vary from period to period.

value-destroying material to be added to the ore stream.

The figure indicates that, as the mining rate increases from low

A similar situation often exists in sublevel caving operations, values, more material is available for treatment, and the cutoff

where the shutoff used is often a relatively low marginal can be increased to supply higher grades to the mill. Material

breakeven grade. Significant value can be destroyed by below the ROM cutoff is stockpiled for later treatment if

continuing to draw low-grade material when the next ring could profitable. Up to a point, the higher grade, and hence increased

have been blasted and higher-grade ore produced. revenue, more than pays for the increased mining costs, and

value increases. Eventually, the mining rate will increase to the

Open Pit Operations point where the tonnage / grade relationships of the deposit are

such that any revenue gains are exceeded by the extra mining

Suboptimal strategies have also been found in use in open pits. cost.

Figure 3 shows a typical “Hill of Value” for an open pit base

metal mine, plotted as contours of NPV. The independent axes

Figure 3 - Variation of NPV with cutoff and mining rate – open pit

Varying multiple strategic policy items over time Dangers of sub-optimising for subsidiary parameters

Figure 3 has been generated simply by accelerating or It was noted above that the simple picture presented by Figure 3

decelerating the existing planned mining sequence. There is no at higher mining rates might not be achievable, but a more

guarantee that this sequence is the best, or is even practical, at detailed analysis would account for any implicit

all mining rates evaluated in the initial calculation. As with the impracticalities. However, a reduced mining rate will always be

underground situation in Figure 1, the three-dimensional nature a practical alternative. It is not uncommon to encounter a desire

of the chart allows plotting of only two independent design to reduce the mining rate, in effect by deferring waste stripping,

variables and one dependent variable. The cutoff and mining which reduces the overall rock mining capacity earlier in the

rate factors in Figure 3 are fixed for the life of the mine, but mine’s life. (This may or might not be countered by an increase

cutoff and rock, ore, and product capacities can all vary, and it later.) The effect of a lower mining rate is to reduce the amount

is well known that maximum value is obtained with a cutoff of mineralised material available for classification as ore in the

that can vary over time. Other design parameters that can be time period in question. To maintain mill throughput, it is

varied include such things as the sinking rate of the pit (e.g. in necessary to reduce the ROM cutoff, moving to a new mining

terms of metres or benches per year) and the ultimate size of the position below and to the left of the current position on the plot.

pit (expressed perhaps as a volume, tonnage, or Whittle “Pit The value of the operation reduces, as the cost savings from

Shell Number”). The HoV shown could again be multi- reduced mining rates are more than offset by a drop in revenue

dimensional, to allow for independent specification of from lower ore grades.

alternative mining and treatment capacity and rate changes.

It can also be seen in Figure 3 that the value contours are

significantly closer to the left of and below the peak in the

figure than in the other areas of the chart. The overall

AMC Reference Library – www.amcconsultants.com.au 5

Short Term Gain for Long Term Pain

implication of this pattern is that it is more costly in the long exploration and / or more detailed studies. Subsequent studies

run to be mining too slowly than to be mining too fast by the often then result in the specification of mining fleets and

same proportion. facilities and treatment plants designed to handle waste and ore

quantities (and qualities) defined by the initial approximate

Issues Common to Open Pits and Underground cutoff, with no guarantee that the best combination of capacities

Operations and cutoffs has been selected. Tactical decisions (i.e. to save

time and costs) during the evaluation and feasibility study

The danger of evaluations at one cutoff or production process can result in the specification of a significantly

rate suboptimal strategy.

Many operations still use a simple break-even grade as the

cutoff. This takes account of prices and costs only, though the Figure 4 illustrates how this can happen. Using only a single

rock, ore and product production capacities provided will cutoff in the evaluation, “Strategy A” may appear significantly

influence the costs used in the calculation. It is also not better than “Strategy B”. An analysis at a range of cutoffs can

uncommon to find that these cutoffs are set early in the give a significantly different outcome. The same effect may be

exploration process, using high-level cost estimates, when the seen for other strategic decision parameters, such as rock

size and shape of the “orebody” is first becoming apparent. mining and ore production rates.

Scoping studies are conducted to obtain an initial estimate of

the value of the potential project and to justify further

Figure 4 - Potential losses from evaluations at one cutoff

Testing the impact of apparent limitations within acceptable ranges for the various parameters, there are

no problems. But if the peak of the HoV lies beyond one of

There will be practical upper limits on many physical capacity these limits, the difference between the peak value and the

parameters, such as the rock, ore, and product rates, which will value at the limit gives an indication of what could be spent to

make some parts of the HoV impractical. If the value of the remove the limitation, which in many cases will be more a

HoV surface is increasing at those limits, the “hill” effectively function of current practices than an absolute and unchangeable

ends at a “cliff”, and the indicated optimum strategy will be to constraint.

work with that particular limiting parameter at its limiting

value. In other cases, the value of the operation will be falling

when it reaches the cliff, and the optimum strategy will then

The effect of mining rate on optimum cutoff

occur at the peak of the HoV. It is not uncommon to find that an increase in mining rate is the

solution proposed to get a marginal mine out of trouble. The

As well as the more usual apparent constraints, such as limits assumption is that similar head grades, and hence cutoff grades,

on the various production rates, there may be practical upper can be maintained. If the transition to a higher rate is properly

limits on, for example, cutoff. The nature of the mineralisation planned and executed, with a corresponding increase in the

may be such that zones above a particular grade may not be waste development (underground) or waste stripping (open pit)

able to be delineated for selective mining in practice, even rate, this may be so, and value gains can be realised – e.g. by

though geologically they are known to exist. The cutoff cannot moving higher up the HoV in Figure 1 at the same cutoff, but

practically be specified above that grade. Similarly, the existing not going as far as the “Typical improvement proposal” shown

geological model may have been developed to identify material there. (If waste mining rates are not increased, similar

above a certain grade, and “orebodies” at cutoffs significantly production shortfalls such as those described above for

below that grade may be unreliable. However, it is often increasing the cutoff in an underground mine may occur.)

worthwhile continuing calculations and evaluations beyond

these apparent limits. If the peak of the HoV is found to lie

AMC Reference Library – www.amcconsultants.com.au 6

Short Term Gain for Long Term Pain

It is often then postulated that, if the production rate is The Timing of Infrastructure Capital

increased, the cutoff can be reduced to increase the reserve and

the return. It is reasonable to expect that increasing the Spending

production rate will reduce the breakeven cost per tonne of ore.

However, Figure 1 demonstrates clearly that reducing the Saving or deferring of costs is always an important and valid

cutoff, though it may increase the reserve, will reduce the NPV, way of improving the value of an operation. Frequently,

not increase it. The cutoff will however have to be reduced if however, the short-term tactical benefits cause long-term

the waste mining rate does not increase in line with the ore strategic problems. The issues often arise at the time of

production rate: this is the same situation as reducing the waste preparing the annual capital and operating cost budgets.

mining rate at the same ore treatment rate, as described for open Provisional budget items are often treated as “wish lists”, and

pits above. the question will often be to the effect of: “Do we have to do or

spend this now? Can it be deferred?” The answer is often “Yes,

The implication of this is that the optimum combination of but . . .” “Yes”, the item can be deferred, in the sense that the

waste mining and ore treatment rates and cutoff will vary mine is not going to come to a complete standstill overnight if it

depending on whether one of the constraints is to be artificially is not done. “But” the operation may be less efficient, and the

constrained or not, e.g. by deliberately reducing the waste cost, either extra direct costs of doing it later, or lost revenue

mining rate, or by deliberately or unconsciously not allowing it from lower production, may be significantly greater than the

to increase in line with a planned ore production rate increase. immediate savings apparently made.

The costs savings from imposing a limit may be more than

eroded by loss of revenue from lower head grades. As above, if all aspects of the alternatives have been evaluated,

and the relative costs and benefits of the alternative plans – to

The effect of metal prices and costs on optimum cutoff spend or not to spend – have been assessed, then it is the

prerogative of the management to make the decision as they see

Conventional wisdom suggests that if prices go up, cutoffs fit. But again, it is often the case that the effects are not fully

should go down in inverse proportion, and vice versa. And evaluated – the downside costs or loss of revenue may be

similarly, if costs reduce, cutoffs should go down in direct difficult to quantify, while the direct cost of the item in question

proportion, and vice versa. These are true of breakeven grades, is plain – and in the absence of information about the

and if the cutoff selected is a breakeven, then they will be true downsides, an uninformed decision to “save costs” is made.

of those cutoffs also. However, Hall (2003) and Hall and

deVries (2003) have demonstrated that this is not the case for Service Facilities

optimum cutoffs that maximise NPV.

If the planned work is for service facilities, foregoing the

For optimum cutoffs, a number of case studies have installation to save costs in the short-term may result in a

demonstrated that the changes in optimal cutoffs are failure to provide the services needed to support the planned

substantially less than suggested by the preceding hypotheses. production in the future. “Required Volume of Clean Air” is a

The methodology developed by Lane (1988) indicates resource that rarely appears in mine scheduling systems, but it

theoretically why this is so. If a “balancing cutoff” as defined may be crucial to enable various planned activities to proceed

by Lane is the current effective cutoff, it will be unaffected by in parallel. If it is not available, activities may have to proceed

price and cost variations, being solely the result of the physical sequentially, extending the overall duration of mining activities

plant capacities and the nature of the mineralisation. The associated with a given tonnage of ore, thereby reducing the

“opportunity cost” terms in two of Lane’s “limiting” cutoffs overall mining rate. Similarly, inadequate drainage can not only

even make it possible for these cutoffs to move in the opposite result in increased wear and tear on equipment, but can also

direction to that suggested by the conventional wisdom, and reduce the rate at which it can operate, restrict access to

this effect in the optimum cutoff has been seen by the author in working places, and / or require labour and equipment that

some studies. could otherwise be allocated to productive activities to be

allocated to drainage system maintenance and clean-up of mine

These effects make it impossible to predict the movement in openings.

optimum cutoffs for any specified price or cost changes without

performing a full analysis of the strategic plan. Mining Information and Production Infrastructure

Cost savings by deferring capital development underground or

Hall (2003) and Hall and deVries (2003) have also waste stripping in open pits, and expenditure on exploration or

demonstrated how working with a typical sub-optimal cutoff infrastructure such as a shaft, can also have a significant

will increase the volatility of returns as prices change, and can negative impact on overall profitability. Deferral of waste

significantly increase the risk of achieving low or negative stripping in open pits has been discussed above. Slowing

returns when prices fall. Operating with optimum cutoffs for decline advance rates in underground operations can have a

lower prices will frequently capture most of the upside from similar effect.

price rises, and can significantly reduce the downside risk of

price falls. The relatively small changes in optimum cutoffs While improving truck haulage efficiencies are continuing to

observed, coupled with the relative flatness of the peaks of the extend the economic depth of trucking – in many instances to

Hills of Value, often mean that optimum mining strategies are below 1000m below the tipping point – this does not

relatively insensitive to changes in economic conditions, necessarily imply that a shaft should not be sunk until that

whereas suboptimal strategies on the slopes of the HoVs may depth is reached. Deferring the sinking of a shaft can both

require significant changes, perhaps with little notice, when reduce the value of the operation and significantly shorten its

conditions change. life. However, the increasing economic depth of trucking

appears to provide some comfort to managers deciding to defer

shaft sinking capital expenditure. Also, many operations limit

in-mine exploration expenditure to merely continue to provide

perhaps two or three years’ worth of reserves. Together these

AMC Reference Library – www.amcconsultants.com.au 7

Short Term Gain for Long Term Pain

types of cost-saving policies can have a major negative impact Value lost by deferring spending on infrastructure

on value. The limited reserves may never be sufficient to justify

the capital outlays for more efficient infrastructure, by reducing Hall (2005) describes a hypothetical steeply-dipping orebody,

operating costs over a long enough period of time. If sufficient with a single production front moving vertically down through

mineralisation is eventually proven, it may be too late to have it. Production is by truck haulage, currently to surface, and a

an effect. shaft to 1000m depth has been proposed. In the scenario

presented, Proven and Probable Reserves currently extend to

The example below relates to trucking all ore to surface, versus 900m depth, and Inferred Resources extend some distance

installation of a shaft, with reduced trucking up to the bottom of beyond that. The deposit is still open at depth. The analysis has

the shaft. The rationale however applies to any situation where projected the known orebody characteristics to 2000m depth to

major capital expenditure to install efficient systems can assess what the company’s options might be. Figure 5 shows

significantly reduce future operating costs. the effect of deferring the shaft sinking decision.

Figure 5 - NPV with trucking only, and a shaft starting at different times

The “trucking only” curve shows a maximum value at a little about 1030m. The value of the shaft option falls below the

over 1000m depth, which is therefore the economic limit of maximum value with trucking only if the start of shaft hoisting

trucking. A dashed line at this value to greater depths indicates is deferred beyond when the production front is at about

the value that a shaft option must have to be better than 1140m. If the mineralisation is closed off at a shallower depth,

trucking only. A dotted and dashed line $5M dollars above this earlier shaft starting times are needed to make the shaft option

indicates the value that a shaft option must have to be that much viable.

better than trucking only – a “safety margin” to perhaps account

for some of the risk associated with the large up-front capital If analyses were done at one final depth of the mine only

cost of the shaft option. With a 1000m deep shaft, the economic (typically the known bottom of mineralisation at the time of the

depth of the mine – with trucks hauling up to a tipping point evaluation, and often with a downgrading factor applied to

above the skip loading station – is about 1550m - 1575m. Inferred Resources), a value destroying decision could be made.

This is similar to the situation in Figure 4, for analyses done at

The time of the start of shaft hoisting is expressed as the one cutoff. Although the value of the shaft option is greater

elevation of the production front, which in the scenario than the value of trucking only for most specified final depths

illustrated is moving down at 40 vertical metres per year (“vm / below the shaft starting depth, shaft hoisting is nevertheless not

yr”). The lines plotted for shaft hoisting starting at 100 vm always the best option. As is evident in Figure 5, the value of

intervals therefore represent deferral time increments of 2.5 the shaft option at a range of final depths of the mine can be

years. It can be clearly seen that deferring the shaft option (the significantly less than the value at the economic limit of

value of which includes the capital costs thereof) results in trucking only if the shaft is deferred too long.

decreasing value, as the later the start, the less ore is hoisted at

the lower shaft operating costs. It can also be seen that deferral of the shaft effectively results in

a range of uneconomic final depths of mining. For shaft

If the mineralisation extends to at least the economic depth of hoisting starting when the production front is at 1000m depth,

say 1550m, then the shaft option will no longer deliver the mineralisation extending below the economic limit of trucking

required $5M margin over trucking only if the start of shaft (at approximately 1030m depth) is uneconomic unless it

hoisting is deferred beyond when the production front is at extends below 1150m, at which point the shaft curve exceeds

AMC Reference Library – www.amcconsultants.com.au 8

Short Term Gain for Long Term Pain

the maximum trucking-only value. If the shaft is deferred to depth, the mineralisation must extend to 1030m for the shaft

start when the production front is at 1100m, the uneconomic option to break even with trucking only, and to 1130m to

final depth extends to approximately 1230m. If mineralisation generate an extra $5M, which are 130m and 230m respectively

extends only to these depths, its value will be lost if the shaft is below the hoisting starting point. However, if shaft hoisting

deferred too long – the mine should cease with trucking only at starts when production is at 1000m depth, the required

the economic limit of 1030m depth. But if the shaft is built minimum depths of mineralisation become 1150m and 1330m,

early enough, the mine will be economic for any depth of 150m and 330m respectively below the hoisting starting point.

mineralisation, down to the economic depth with shaft hoisting Working backwards from the starting point of shaft hoisting, to

of 1550m, and the value will be significantly greater than with allow for construction, preceded by analysis and decision-

trucking only. making, the time when the exploration data must be available

can be estimated. In the example used, this is a total of 2.5

Identifying the exploration target required to justify the years, or 100 vertical metres of production advance. Depending

infrastructure on the existing knowledge, the timing of the start of the

exploration programme and the overall depth that it has to

Hall (2005) also describes how hypothetical calculations for a cover can be determined. Applying this process to a range of

range of potential depths of mineralisation can identify the shaft starting depths, curves such as in Figure 6 can be derived.

reserves required to justify the proposed infrastructure. It can be

seen that, if shaft hoisting starts when production is at 900m

Figure 6 - Exploration requirements to justify infrastructure capital

The dotted lines show the minimum depth, in absolute terms, of 240m, with hoisting starting when production is at

mineralisation required, which is shown on the left-hand approximately 920m. This is equivalent to 6 years’ production

vertical axis. The solid lines show this as the extra depth or at 40 vm / yr.

exploration lead at the time of starting the analysis and

evaluation, after the exploration results are available, with If it is decided to limit exploration costs by maintaining say 2 or

values shown on the right-hand vertical axis. 3 years’ reserves only ahead of the production front, it is clear

that a shaft will never be justifiable, even though it may have

It can be seen, as is also evident in Figure 5, that as shaft been a better option. As well as limiting exploration

sinking is deferred, the required depth of mineralisation to expenditure, the mine can also now avoid the costs of an

justify it increases, and at an increasing rate. The required expensive study of shaft hoisting, since this will never generate

exploration lead, however, has a minimum at somewhat less a better scenario with the limited reserves data available. The

than the trucking-only economic limit. Although Figure 5 mine must close at the economic limit of trucking only,

indicates that, if it is justified, the earlier a shaft can be installed regardless of how much deeper the mineralisation may

the better, Figure 6 suggests that there may be practical ultimately be found to extend, and the fact that, with hindsight,

constraints on this. If for example drilling cannot be done to the shaft could have been installed with significant benefits.

depths beyond 300m, it will never be possible to prove a shaft

with a $5M margin over trucking only. If however it is only Conclusions

necessary for the shaft to break even with trucking only, this

will be feasible for shaft hoisting starting when the production Numerous strategic plan optimisation case studies are showing

front is anywhere between 700m and 1080m. The absolute that conventional wisdom is often far from wise. Typical

minimum exploration lead for breaking even is approximately industry practices for determining cutoffs result in mine plans

AMC Reference Library – www.amcconsultants.com.au 9

Short Term Gain for Long Term Pain

that are often far from optimal. Significant extra value can be Hall, B.E. and deVries, J.C. (2003) Quantifying the economic

obtained from many operations, often by increasing the cutoff risk of suboptimal mine plans and strategies. AusIMM

and thereby reducing the reserve and the mine life. These Managing Risk in Mining Projects Conference, Sydney,

strategies can also reduce the volatility of returns when prices Australia, September 2003.

change, and in particular can reduce the risk of negative returns

when prices fall. Hall, B.E. and Stewart, C.A. (2004) Optimising the strategic

mine plan – methodologies, findings, successes and failures.

The natural desire to reduce costs is often counter-productive. AusIMM Orebody Modelling and Strategic Mine Planning

Reducing the waste-stripping rate in open pits, and the rate of Conference, Perth, Australia, November 2004.

decline advance underground, reduces the amount of Lane, K.F. (1988) The economic definition of ore; cutoff grades

mineralised material available to work with, and will typically in theory and practice. Mining Journal Books, London.

result in reduced cutoffs to keep the mill full, and reduced

revenues that more than outweigh the mining costs saved. Horsley, T.P. (2005) Differential cut-off grades. 9th AusIMM

Delaying or failing to provide apparently expensive services Underground Operators' Conference, Perth, Australia, March

infrastructure can later result in the services being unable to 2005

support the planned production rates, with the loss of revenue

again outweighing the apparent saving.

Savings obtained by deferring exploration expenditure may

make it impossible to ever justify capital expenditure for

efficient and low operating cost production facilities, which

could have extended the economic depth of mining, the mine

life, and increased the overall value extracted from the deposit.

Even if the expenditure is justified, continual deferral of capital

expenditure can result in there ultimately being insufficient

resource left to pay for it, again resulting in a reduction in both

mine life and value obtained for the company’s owners.

Ideally, the short-term tactical mine plan and the mine

operations should be working within the framework of an

optimised long-term plan that best delivers the company’s

goals. Occasional deviations from the strategic plan are a reality

in mining, but the tactical plans should be seeking to return to

the optimum strategic plan, which may in some circumstances

have to change as a result of events in the operations. The

danger comes when the tactical deviations are allowed to

become the long-term strategy by default, without an

assessment of how this may drive the operations away from

achieving the corporate goals. Tactical expediency can very

easily become “short term gain for long term pain”. The

planning and analysis tools and processes are available to

deliver more and better information to decision makers than

they have had in the past. The industry must look beyond

unwise conventional wisdom, and the costs of generating

optimum strategies, to see the long-term benefits that are

available but unfortunately are often not realised in our

operations today.

Acknowledgements

The author wishes to thank the management of AMC

Consultants Pty Ltd for permission to prepare and present this

paper. Past and present members of the AMC strategy

optimisation team are thanked for their contributions to the

development of the methodologies and knowledge and the

conduct of case studies that support the findings presented in

this paper.

References

Hall, B.E. (2003) How mining companies improve share price

by destroying shareholder value. Paper 1194, CIM Mining

Conference, Montreal, Canada, May 2003.

Hall, B.E. (2005) A quantitative assessment of the factors

influencing the shaft vs trucks decision. AusIMM Hoist and

Haul 2005 Conference, Perth, Australia, September 2005.

AMC Reference Library – www.amcconsultants.com.au 10

You might also like

- Enterprise OptimisationDocument13 pagesEnterprise OptimisationMarcos BuenoNo ratings yet

- G. Whittle - Optimising Project Value and Robustness PDFDocument10 pagesG. Whittle - Optimising Project Value and Robustness PDFcristobal olaveNo ratings yet

- Alternative Process Flow For Underground Mining OpDocument14 pagesAlternative Process Flow For Underground Mining OpEduardo MenaNo ratings yet

- Chapter 2: Literature ReviewDocument14 pagesChapter 2: Literature ReviewShahadat HossainNo ratings yet

- Investigative Methods for Controlling Groundwater Flow to Underground Mine WorkingsDocument45 pagesInvestigative Methods for Controlling Groundwater Flow to Underground Mine WorkingsJamealNo ratings yet

- 1 Modifying Factors E TulcanazaDocument21 pages1 Modifying Factors E TulcanazaRafael MatosNo ratings yet

- BenchFill VillaescusaDocument10 pagesBenchFill VillaescusaFredd_AlvaroNo ratings yet

- Sublevel Caving (SME Mining Engineering Handbook) - RNADocument17 pagesSublevel Caving (SME Mining Engineering Handbook) - RNARisman N. AriestNo ratings yet

- Planning For Narrow Vein Mines: G GemellDocument4 pagesPlanning For Narrow Vein Mines: G GemellBendigo BanksNo ratings yet

- Establishing A Site Specific Mining Geotechnical Logging Atlas PDFDocument9 pagesEstablishing A Site Specific Mining Geotechnical Logging Atlas PDFJnthan Prado AlvarezNo ratings yet

- Issue110 Evolution MiningTrucksDocument4 pagesIssue110 Evolution MiningTrucksluisparedesNo ratings yet

- Long Hole ProceduresDocument16 pagesLong Hole ProceduresJimmy Junior Blas VenegasNo ratings yet

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pages10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulNo ratings yet

- UG Mine Design for Fishmeri Gold DepositDocument97 pagesUG Mine Design for Fishmeri Gold DepositLiNo ratings yet

- Review of Scheduling AlgorithmsDocument31 pagesReview of Scheduling AlgorithmsJose GonzalesNo ratings yet

- Surface Pit Design and Range DiagramsDocument11 pagesSurface Pit Design and Range DiagramsRizal FauziNo ratings yet

- A New Underground Auger Mining SystemDocument8 pagesA New Underground Auger Mining SystemmzulfikarmuslimNo ratings yet

- Mine PlanningDocument14 pagesMine PlanningFebri Ruswandi Anggara PutraNo ratings yet

- Application of Conveyors For UG HaulageDocument11 pagesApplication of Conveyors For UG Haulageminerito2211No ratings yet

- Optimum Ramp Design in Open Pit MinesDocument9 pagesOptimum Ramp Design in Open Pit MinesFrancys CcoriNo ratings yet

- A Low-Cost, Remotely Operated Mining MethodDocument10 pagesA Low-Cost, Remotely Operated Mining MethodRicardo Contreras BNo ratings yet

- Mine PlanningDocument10 pagesMine PlanningFebri Ruswandi Anggara PutraNo ratings yet

- Long Taylors Rule With ErrataDocument9 pagesLong Taylors Rule With ErratamarrtomNo ratings yet

- Shaft or DeclineDocument10 pagesShaft or DeclineElias ArayaNo ratings yet

- Open Pit Mining: Mine Planning & Design: Focus On Surface Mining Technology: Lecture 2Document34 pagesOpen Pit Mining: Mine Planning & Design: Focus On Surface Mining Technology: Lecture 2TinozivasheNo ratings yet

- Mine ManagementDocument7 pagesMine ManagementBranden OxfordNo ratings yet

- Incline Caving As A Massive Mining MethodDocument9 pagesIncline Caving As A Massive Mining MethodwalterloliNo ratings yet

- Mine Backfill - Optimisation OpportunityDocument2 pagesMine Backfill - Optimisation OpportunityCarlos A. Espinoza MNo ratings yet

- An Empirical Relation To Calculate The Proper Burden in Blast Design of Open Pit Mines Based On Modification of The Konya RelationDocument6 pagesAn Empirical Relation To Calculate The Proper Burden in Blast Design of Open Pit Mines Based On Modification of The Konya RelationhnavastNo ratings yet

- Appendix E13 - UG Mitchell PFS 31MAY2012 PDFDocument247 pagesAppendix E13 - UG Mitchell PFS 31MAY2012 PDFAlfaro RoblesNo ratings yet

- Topic5 MiningMethods PartI SurfaceminingDocument76 pagesTopic5 MiningMethods PartI SurfaceminingAditya kumar GuptaNo ratings yet

- Mining Methods-Part III Surface Mining-Placer Mining: February 2010Document11 pagesMining Methods-Part III Surface Mining-Placer Mining: February 2010Ferdinand SiahaanNo ratings yet

- Ccourse Notes June 2009Document400 pagesCcourse Notes June 2009N NNo ratings yet

- LKAB Tests 50m Sublevel Caving at Konsuln MineDocument13 pagesLKAB Tests 50m Sublevel Caving at Konsuln MinekinsaeyaNo ratings yet

- A Simple and Accurate Method For Ore Reserve Estimation in SLC MinesDocument15 pagesA Simple and Accurate Method For Ore Reserve Estimation in SLC MinesRalain NgatchaNo ratings yet

- Geomembrane and Pipe Design Issues in Deeper Heap Leach PadsDocument13 pagesGeomembrane and Pipe Design Issues in Deeper Heap Leach PadsdreamerangelNo ratings yet

- Aggregate Planning Strategies and TechniquesDocument29 pagesAggregate Planning Strategies and TechniqueskushalNo ratings yet

- Waste Dump Design 2016 06 19 06 23 16 UTCDocument24 pagesWaste Dump Design 2016 06 19 06 23 16 UTCmohanNo ratings yet

- Hardrock Presentation v1.3Document35 pagesHardrock Presentation v1.3Vian YoungNo ratings yet

- Pillar Design: DR - Ohn Thaik Department of Mining EngineeringDocument38 pagesPillar Design: DR - Ohn Thaik Department of Mining EngineeringohnthaikNo ratings yet

- Three Methods of Tailings Disposal Are:: OverburdenDocument4 pagesThree Methods of Tailings Disposal Are:: OverburdenNyasha JumahNo ratings yet

- Datamine PDFDocument2 pagesDatamine PDFLukiesse Ntima AlexandreNo ratings yet

- Three-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata Solution PDFDocument16 pagesThree-Dimensional Simulation of Cave Initiation, Propagation and Surface Subsidence Using A Coupled Finite Difference-Cellular Automata Solution PDFDiego Ignacio VelizNo ratings yet

- National Institute For Occupational Safety and HealthDocument5 pagesNational Institute For Occupational Safety and Healthleoalsants1984No ratings yet

- Orion South Diamond ProjectDocument404 pagesOrion South Diamond ProjectFYC1989100% (1)

- Transition From Open-Pit To Underground As A New Optimization Challenge in Mining EngineeringDocument10 pagesTransition From Open-Pit To Underground As A New Optimization Challenge in Mining EngineeringSasha ElenaNo ratings yet

- Longwall MethodsDocument36 pagesLongwall MethodsWindi HilmanNo ratings yet

- Geotek-Rock Engineering For UndergroundDocument48 pagesGeotek-Rock Engineering For UndergroundKiky Rizky IsalNo ratings yet

- Full Paper Freiberg Conference 2013Document8 pagesFull Paper Freiberg Conference 2013jlzmotricoNo ratings yet

- Excavator SelectionDocument10 pagesExcavator SelectionMario HezkeeaNo ratings yet

- Selecting Shaft or DeclineDocument8 pagesSelecting Shaft or DeclineluisparedesNo ratings yet

- Haulage Impact on Cut-Off Grade StrategyDocument8 pagesHaulage Impact on Cut-Off Grade StrategyJorgeNo ratings yet

- Full Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineDocument10 pagesFull Scale Near Field Flow Behaviour at The Ridgeway Deeps Block Cave MineandresmaureiravNo ratings yet

- And The Design of Shaft-Sinking Projects: Project ManagementDocument25 pagesAnd The Design of Shaft-Sinking Projects: Project ManagementIamEm B. MoNo ratings yet

- 2017 Geovia Whitepaper PseudoflowDocument9 pages2017 Geovia Whitepaper PseudoflowFarouk AzzouhriNo ratings yet

- Sub-Level Caving: Where Is It Headed?Document8 pagesSub-Level Caving: Where Is It Headed?anon_747293279No ratings yet

- Geology of Carbonate Reservoirs: The Identification, Description and Characterization of Hydrocarbon Reservoirs in Carbonate RocksFrom EverandGeology of Carbonate Reservoirs: The Identification, Description and Characterization of Hydrocarbon Reservoirs in Carbonate RocksNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Innovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentFrom EverandInnovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentA. K. MoitraNo ratings yet

- Effect of land use change on property valuesDocument3 pagesEffect of land use change on property valueseesuola akinyemiNo ratings yet

- Acros Organics Acta N°006Document20 pagesAcros Organics Acta N°006Atomer FormationNo ratings yet

- Sample Lesson Exemplars in Understanding Culture Society and Politics Using The IDEA Instructional ProcessDocument4 pagesSample Lesson Exemplars in Understanding Culture Society and Politics Using The IDEA Instructional ProcessJen Jeciel PenusNo ratings yet

- Easy Eight's Battleground World War II Normandy NightmareDocument97 pagesEasy Eight's Battleground World War II Normandy NightmareAdolfo JoseNo ratings yet

- VsamDocument24 pagesVsamRodrigoNo ratings yet

- Ginger by NcipmDocument53 pagesGinger by NcipmAbhishekNo ratings yet

- Paper 1R MSDocument25 pagesPaper 1R MSAkashNo ratings yet

- Centered Nursing Process Approach (9th Ed.) - St. Louis, MO: ElsevierDocument1 pageCentered Nursing Process Approach (9th Ed.) - St. Louis, MO: ElsevierfaizaNo ratings yet

- The Columbian Exchange ReadingDocument3 pagesThe Columbian Exchange Readingapi-286657372No ratings yet

- 2280-Product Manual - 14 - 07 - 2015 - PtarDocument83 pages2280-Product Manual - 14 - 07 - 2015 - PtarRay Ronald Quevedo VeintimillaNo ratings yet

- Sources of Subject of ArtDocument32 pagesSources of Subject of ArtAlaina De GuzmanNo ratings yet

- ISC 2023 English Language Question PaperDocument5 pagesISC 2023 English Language Question PaperMohit JoshiNo ratings yet

- Hdpe Guide PDFDocument81 pagesHdpe Guide PDFbalotNo ratings yet

- Tafila Technical University Course Syllabus for Manufacturing Processes (1) / Metal CuttingDocument4 pagesTafila Technical University Course Syllabus for Manufacturing Processes (1) / Metal CuttingG. Dancer GhNo ratings yet

- UntitledDocument39 pagesUntitledKaren CobachaNo ratings yet

- Weak Downlink Data for Multiple TRX Indices Over TimeDocument3,643 pagesWeak Downlink Data for Multiple TRX Indices Over TimeSK Basak BDNo ratings yet

- Questions Answers: Legarda vs. Saleeby: The Real Purpose of The Torrens System Is To Quiet Title To Land To Put A StopDocument19 pagesQuestions Answers: Legarda vs. Saleeby: The Real Purpose of The Torrens System Is To Quiet Title To Land To Put A StopNico RoaNo ratings yet

- Sakha DictionaryDocument14 pagesSakha DictionarySojeong MinNo ratings yet

- Mhdp-08-Rsdll Report Issue 6.0Document159 pagesMhdp-08-Rsdll Report Issue 6.0billNo ratings yet

- Soft Course Material Iran 2007 PDFDocument646 pagesSoft Course Material Iran 2007 PDFLa Picarona del Peru100% (1)

- TENSION PNEUMOTHORAX (Malav Shah)Document66 pagesTENSION PNEUMOTHORAX (Malav Shah)Sharath PsNo ratings yet

- Logix 5000 CIP Sync ConfigurationDocument180 pagesLogix 5000 CIP Sync Configurationاحتشام چوہدریNo ratings yet

- (Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Document3 pages(Giao An Nay Duoc Chia Moi Tiet 1 File. Cac Tiet Khac Ko Duoc Hien Len, Nhung Co Day Du Khi Down Ve Va Giai Nen) Lesson Plan 1Hoai Ngoc NguyenNo ratings yet

- Master Gardener Home Vegetable Guide: Chapter 1 - Gardening BasicsDocument30 pagesMaster Gardener Home Vegetable Guide: Chapter 1 - Gardening BasicsAmr M. SaidNo ratings yet

- THE END - MagDocument164 pagesTHE END - MagRozze AngelNo ratings yet

- Navier-Stokes Equations - Wikipedia, The Free EncyclopediaDocument13 pagesNavier-Stokes Equations - Wikipedia, The Free EncyclopediaAwadeshNo ratings yet

- Nouveau Document TexteDocument6 pagesNouveau Document Texteamal mallouliNo ratings yet

- CPO Science Foundations of Physics: Unit 7, Chapter 24Document47 pagesCPO Science Foundations of Physics: Unit 7, Chapter 24dheerajbhagwatNo ratings yet

- CH 2 Financial Analysis Technoques PresentationDocument44 pagesCH 2 Financial Analysis Technoques PresentationHamza AsifNo ratings yet

- E - Efma Rbi Insp Interval Assess Projector - PP SimtechDocument10 pagesE - Efma Rbi Insp Interval Assess Projector - PP SimtechAbhimanyu SharmaNo ratings yet