Professional Documents

Culture Documents

Potato Slicer 2

Uploaded by

contact ADLCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Potato Slicer 2

Uploaded by

contact ADLCopyright:

Available Formats

Jas Enterprises

An ISO 9001:2008 Certified Company

POTATO CHIPS MAKING MACHINE(SLICER)

Potato wafers and chips are one of the most celebrated in the ready to eat munchies market,

relished in almost all the parts of the world. They serve as an appetizer, side dish, or snack.

In India it is being produced not only on large scale by big firms, but also on cottage/home

scale in semi-urban and rural areas. Though there exists some international as well as

national brands but majority of the market base is under the control of local manufacturers.

With proper strategy and network, it is possible to penetrate the market. Owing to this,

there are a number of companies from both the organized as well as unorganized sector

who are already catering to the needs of tea stalls, restaurants, railway stations, tourist

places et cetera Still there is a huge demand to be met for these products in interior and

remote places in different parts of the country.

An exclusive machine for producing superior quality potato chips is providing by jas enterprises.

prissses.

es Comp

Complete

ple

let

ete system

for the production of potato chips of excellent quality and less fat pickup. These machines are based on technology

accepted world-wide; modifications are incorporated to meet local conditions. We provide complete technical

support, process know-how.

Flow diagram of commercial automatic potato chips, wafer, French fry making machine

The simplest chips of the kind that are just cooked and salted, but manufacturers can add a wide variety of seasonings

of herbs, spices, cheese or artificial additives. Potato wafers must be manufactured in a scientific manner and under

hygienic conditions. The production process mainly comprises of the following steps:-

De-stoning & Washing Peeling

↓

Slicing

↓

Slice Washing

↓

Blanching

↓

De-watering

↓

Frying

↓

Inspection

↓

Flavoring

↓

Cooling

↓

Packing

The manufacturing process of automatic potato chips, wafer, French fries making machine

The potatoes selected for wafers should be large oval shape free from disease & fully grown. Potatoes should have

the minimum numbers of eyes to cut down the losses by trimming. Potatoes are before peeling them with the help

of a peeler. Then these potatoes are put in brine water for 30-35 minutes to prevent browning.

The potatoes pass through a revolving impaler/presser that cuts them into paper-thin slices, Straight blades produce

regular chips while rippled blades produce ridged potato chips. Potatoes are sliced as per required thickness in a

slicing machine. The slices are again placed in cold water whenever there is considerable delay you can subsequent

operation of blanching. Then slice are kept in water containing 0.05% potassium metabolism (the chemical processes

that occur within a living organism to maintain life) to avid oxidation. The slice are blanched for 3 to 5 minutes in

boiling water and spread on trays at the rate of 4.88 kg to 7.30 kg per square meter tray surface, the blanched chips

are then subject to hydro extracting machine (centrifugal) to remove excess of water and fried in edible oil at 140-

240° c, for 3-4 minutes. The fried chips are then subject to hydro extracting machine (centrifugal) to remove excess of

oil. This wafer and other ingredients like salts; spicy mixture is sprayed as per required taste. Now this potato wafers

are then packed in the bags and sealed.

© 1990-2016 Jas Enterprises, All Rights Reserved. Page No. # 78

Jas Enterprises

An ISO 9001:2008 Certified Company

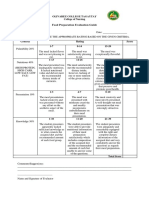

Model No Jas-PCM-105 Jas-PCM-111

Production Capacity 300 Kilograms / Hr. 500 Kilograms / Hr.

Electric motor 0.5 HP 1 HP

Slicing Blade Internal Diameter

Dimension 61 X 38 X 76 cm 64 X 46 X 107 cm

Net / Gross Weight (kilograms) {Shipping Volume 50 / 70 kilograms 0.31 m³ 60 / 85 Kilograms 0.51 0.31

(m³)} m³

Construction of automatic potato chips, wafer, French fries making machines

Jas enterprise is specializing in manufacturing and export of super grade potato chips making machines that are in

wide demand in the global marketplace. Commercial potato chips machine is made from heavy duty stainless steel

fabricated body. Adjustable stainless steel blades are fitted on aluminum casted rotor. Chips slicing die is rotated

by suitable electric motor. . Stainless steel easily detachable hopper is supplied with these potato chips making

machines.

Uses of Automatic potato chips, wafer, French fry making machine

The potato wafer machine is specially designed for production of Potato chips of different qualities - Plain , Ruffles,

Crinkle, Strip cut and ‘V’ cut Potato sticks.

Key Features of Automatic potato chips, wafer, French fry making machine

Automatic potato chips, wafer, French fry making machine provide uniformly Slices with excellent results. Easy

operating system and simplified design needed less maintenance and easy to cleaning. Change the different types

of cut very easily and fast.

Standard accessories of Automatic potato chips, wafer, French fry making machine

• Suitable totally enclosed fan cooled single or three phase Squirrel cage motor as per IS: 325 or 996 is supplied

with potato slicer {Electricity (Special power can be accommodated): 110/220/380/415 Volts, 50/60 Hz , 1/3

Phase }

• Two numbers of Blades ( one Number for Slicing, one number for French fry-3mm size wafer which are most of

all use for farali chevada)

Extra Accessories of Automatic potato chips, wafer, French fry making machine

• 1- raffle type chips, 2- French fry suitable for 6mm,8mm,10mm,12mm

• Suitable miniature circuit breaker for over load protraction of Single Phase Electric Motor or starters,.

• de watering / Water Extractor

• Coating Pan

© 1990-2016 Jas Enterprises, All Rights Reserved. Page No. # 79

You might also like

- Healing With Herbs and Spices Heal Your Body, Mind and Spirit PDFDocument29 pagesHealing With Herbs and Spices Heal Your Body, Mind and Spirit PDFGabriel Stoica100% (1)

- Omega Juicer and Beverage Equipment ManualDocument28 pagesOmega Juicer and Beverage Equipment ManualDennis MirandaNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CLE Materials PacketDocument694 pagesCLE Materials Packetcontact ADLNo ratings yet

- Mcdonald'S Corporation: 26 Crazy Mcdonald'S Items You Can'T Get in AmericaDocument9 pagesMcdonald'S Corporation: 26 Crazy Mcdonald'S Items You Can'T Get in Americaapi-505775092No ratings yet

- Effect of Heat Treatment On The Nutritional Quality of Milk ProteinsDocument4 pagesEffect of Heat Treatment On The Nutritional Quality of Milk ProteinsLộc Võ Tường100% (1)

- AMFE50 Plus Shapes Catalog - CompressedDocument25 pagesAMFE50 Plus Shapes Catalog - CompressedJoey DEDOMNo ratings yet

- Fruit Pulp Extraction Machine For Stone Fruits and BerriesDocument7 pagesFruit Pulp Extraction Machine For Stone Fruits and BerriesAmmad ImamNo ratings yet

- Monarch Water Product GuideDocument16 pagesMonarch Water Product Guidenermeen ahmedNo ratings yet

- @280 Pesos @400 Pesos @650 Pesos @375 Pesos @310 Pesos @450 Pesos @547 Pesos @340 Pesos @475 Pesos @530 PesosDocument1 page@280 Pesos @400 Pesos @650 Pesos @375 Pesos @310 Pesos @450 Pesos @547 Pesos @340 Pesos @475 Pesos @530 PesostonNo ratings yet

- KSB Etabloc Jelleggorbe 50hzDocument172 pagesKSB Etabloc Jelleggorbe 50hzUmar MajeedNo ratings yet

- Potato Chips Production TechnologyDocument28 pagesPotato Chips Production TechnologyJustė ŠiaudvytytėNo ratings yet

- August 2017Document44 pagesAugust 2017PROMonthlyNo ratings yet

- CDC-rupture Disk Product-Selection-Guide-1Document24 pagesCDC-rupture Disk Product-Selection-Guide-1Thefairman UnkownNo ratings yet

- JBPrince Catalog Summer2014Document40 pagesJBPrince Catalog Summer2014Rénier Jacques KotzéNo ratings yet

- Pasta Machines and EquipmentDocument6 pagesPasta Machines and EquipmentKOMATSU SHOVELNo ratings yet

- Frozen French Fries (1) - 0Document11 pagesFrozen French Fries (1) - 0Shikha DhakreNo ratings yet

- Potato and Banana Chips Making MachineDocument8 pagesPotato and Banana Chips Making MachineSantosh BasnetNo ratings yet

- Mansion Single Wide Up Grades 2Document1 pageMansion Single Wide Up Grades 2Victor RodriguezNo ratings yet

- Nov Lunch 9-12Document1 pageNov Lunch 9-12angie.marano08No ratings yet

- LiviaBrochure Manual1Document20 pagesLiviaBrochure Manual1Mini cooperNo ratings yet

- BROUCHER nEW-1Document4 pagesBROUCHER nEW-1SL CONSULTANCYNo ratings yet

- LAGOM Mini Quick GuideDocument16 pagesLAGOM Mini Quick Guidedaichi.takenakaNo ratings yet

- Ice Cream Machine - Kitchen Equipment - Singapore Sale Closing DownDocument1 pageIce Cream Machine - Kitchen Equipment - Singapore Sale Closing DownEva100% (1)

- Bali Beans Coffee & MachineDocument11 pagesBali Beans Coffee & MachinejojohNo ratings yet

- Process Chart For Detergent Cake & Utencle BarDocument2 pagesProcess Chart For Detergent Cake & Utencle BarDinesh Kumar MittalNo ratings yet

- GD511A 1PdfDocument32 pagesGD511A 1PdfDanar PrasastyoNo ratings yet

- Philippine Offshore Gaming Operators (Pogos) Business Process Outsourcing (Bpo)Document10 pagesPhilippine Offshore Gaming Operators (Pogos) Business Process Outsourcing (Bpo)chimigabu11No ratings yet

- 1909 Catalogo EN REL. 01 PubblicoDocument40 pages1909 Catalogo EN REL. 01 PubblicoRui MendesNo ratings yet

- Potato Chips ProcessingDocument29 pagesPotato Chips ProcessingLê Thắng100% (3)

- Silvercrest SBB850D1 - IAN 292013: Recipes: Page 19Document1 pageSilvercrest SBB850D1 - IAN 292013: Recipes: Page 19pavappleid23No ratings yet

- Manual PartesDocument164 pagesManual Partesoborda2769No ratings yet

- 06 Cleaning Supplies EbookDocument51 pages06 Cleaning Supplies EbookmayNo ratings yet

- FST459Document5 pagesFST459Afiqah OsmeraNo ratings yet

- A10 PDFDocument1 pageA10 PDFrcantuNo ratings yet

- Kobe Burger RossiniDocument2 pagesKobe Burger RossinifelixrajasNo ratings yet

- All Grain Brewing GuideDocument3 pagesAll Grain Brewing GuideEidetikosNo ratings yet

- Comparing Low RPM Juicers by John KohlerDocument12 pagesComparing Low RPM Juicers by John Kohlerandra_panaitNo ratings yet

- Portable Compressor ManufacturerDocument2 pagesPortable Compressor ManufacturerRotair spaNo ratings yet

- Process Flowchart of Jute SpinningDocument5 pagesProcess Flowchart of Jute SpinningEshwar Hariharan0% (1)

- Traffic Analysis Sheet - Tower1Document5 pagesTraffic Analysis Sheet - Tower1ril895072No ratings yet

- Sunny Fresh French Toast CargillDocument1 pageSunny Fresh French Toast CargillKim StClairNo ratings yet

- 2023 Detergent BrochureDocument13 pages2023 Detergent Brochurechris.tlholoNo ratings yet

- AA-RCC6S-dual: $2875/unit (220v50hz, 1ph) $3025/unit (110v50hz, 1ph)Document1 pageAA-RCC6S-dual: $2875/unit (220v50hz, 1ph) $3025/unit (110v50hz, 1ph)James BindNo ratings yet

- Textile Wet Processing UNIT - 1Document14 pagesTextile Wet Processing UNIT - 1Chaarvi SaranyaNo ratings yet

- Sunswell - 24000BPH 600ml Water Bottling Line Proposal - CombiDocument57 pagesSunswell - 24000BPH 600ml Water Bottling Line Proposal - Combinatty.sol2093No ratings yet

- InglésDocument11 pagesInglésDANIA URPI VEGA IZARRANo ratings yet

- Manual Brilladora Por Agua ZukaiDocument13 pagesManual Brilladora Por Agua ZukaiJulian RankinNo ratings yet

- Variable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ADocument72 pagesVariable Displacements Axial Piston Pumps: Edition: 06/06.2020 Replaces: MVP 05 T ARidha AbbassiNo ratings yet

- BV Catalog 2016-17Document28 pagesBV Catalog 2016-17Rigel Aguilar GonzalezNo ratings yet

- CertificadoDocument1 pageCertificadoCrafting in my ClosetNo ratings yet

- Server - Aternos - Free Minecraft ServerDocument1 pageServer - Aternos - Free Minecraft Servermangoprinter27No ratings yet

- Bertuzzi Machinery For PassionFruitDocument4 pagesBertuzzi Machinery For PassionFruitPastillas DesodorantesNo ratings yet

- Dal Mill MachineDocument7 pagesDal Mill MachineviewpawanNo ratings yet

- Coffeebar LayoutDocument1 pageCoffeebar LayoutJonas Celiz DatorNo ratings yet

- Delonghi 2008 Kitchen Price List 01-10-08Document10 pagesDelonghi 2008 Kitchen Price List 01-10-08anjaleelolNo ratings yet

- Max Bar Stool - Office ExpertsDocument1 pageMax Bar Stool - Office Expertssubhanabid381No ratings yet

- The Grandé Paradise E-BrochureDocument13 pagesThe Grandé Paradise E-Brochurezartash.ashrafNo ratings yet

- Blenders Mixers & CrushersDocument4 pagesBlenders Mixers & CrushersMeghana YedunuthalaNo ratings yet

- DINING COLLECTIONS - pdf-2020Document164 pagesDINING COLLECTIONS - pdf-2020Oana MoldovanNo ratings yet

- Food Preparation ProductsDocument4 pagesFood Preparation ProductsMeghana YedunuthalaNo ratings yet

- 1.M. CardioDocument21 pages1.M. CardioAna MîndrilăNo ratings yet

- The Perfect Blending CookbookFrom EverandThe Perfect Blending CookbookRating: 4.5 out of 5 stars4.5/5 (3)

- DAC Glossary PDFDocument65 pagesDAC Glossary PDFinayat1No ratings yet

- IPSINTELLIGENCE FaceRelaAnal enDocument2 pagesIPSINTELLIGENCE FaceRelaAnal encontact ADLNo ratings yet

- Potato Peeler Instruction Manual: Model DB-25HDDocument8 pagesPotato Peeler Instruction Manual: Model DB-25HDcontact ADLNo ratings yet

- Underground Activity Detection System: Tunnels DisclosureDocument4 pagesUnderground Activity Detection System: Tunnels Disclosurecontact ADLNo ratings yet

- Mechanization & Development of Potato Peeling Machine: A ReviewDocument4 pagesMechanization & Development of Potato Peeling Machine: A ReviewGilbertQuindozaBulyegewNo ratings yet

- Abandoned Baby: Bearish Dark Cloud Cover CandlestickDocument5 pagesAbandoned Baby: Bearish Dark Cloud Cover Candlesticksugeng widodoNo ratings yet

- The Search For The Holly' Grail: Brian Shannon @alphatrendsDocument37 pagesThe Search For The Holly' Grail: Brian Shannon @alphatrendscontact ADL0% (1)

- Ichha PradhanangaDocument120 pagesIchha PradhanangaMonika DhitalNo ratings yet

- Instrumen Saringan Membaca Tahun 3Document13 pagesInstrumen Saringan Membaca Tahun 3cikgudillaNo ratings yet

- HjjsjaDocument8 pagesHjjsjaRikaa MandasariNo ratings yet

- PASTICCERIA INTERNAZIONALE World Wide Edition 2014-24Document52 pagesPASTICCERIA INTERNAZIONALE World Wide Edition 2014-24Mat KumNo ratings yet

- WLBC Dec CalDocument1 pageWLBC Dec CalkristymadimikeNo ratings yet

- Perspectives in PharmacyDocument7 pagesPerspectives in Pharmacygizelle mae pasiolNo ratings yet

- Week 3 - Classificationand Uses of PlantsDocument141 pagesWeek 3 - Classificationand Uses of PlantsPrincess De LeonNo ratings yet

- Bread and Pastry Production Ncii Grade 11 Assessment Week1-2Document2 pagesBread and Pastry Production Ncii Grade 11 Assessment Week1-2Rio Krystal Reluya MolateNo ratings yet

- Crossword Cake Assem 1Document1 pageCrossword Cake Assem 1Pawan CoomarNo ratings yet

- ColivaDocument6 pagesColivaalinaluca30No ratings yet

- Lagundi (Vitex Negundo) Spray Dried Extract1Document6 pagesLagundi (Vitex Negundo) Spray Dried Extract1Charmaine GarcesNo ratings yet

- Alnat Revised 6-6-2023 Ks2 Set BDocument38 pagesAlnat Revised 6-6-2023 Ks2 Set BjervesNo ratings yet

- Food Preparation Evaluation Guide: Olivarez College Tagaytay College of NursingDocument2 pagesFood Preparation Evaluation Guide: Olivarez College Tagaytay College of NursingRaquel M. MendozaNo ratings yet

- Soal Semester Ganjil - Bahasa Inggris - Kelas Ix - KTSPDocument10 pagesSoal Semester Ganjil - Bahasa Inggris - Kelas Ix - KTSPHendra Sukma Ari PrayitnoNo ratings yet

- Pork TocinoDocument1 pagePork TocinoMaria Ivz ElborNo ratings yet

- Calculation of Seed Rate and Germination %Document4 pagesCalculation of Seed Rate and Germination %Gautam Kumar100% (1)

- ModifiersDocument6 pagesModifiersAndreia Mihaila100% (1)

- UNIT-3 Gueridon Service PDFDocument4 pagesUNIT-3 Gueridon Service PDFTejasNo ratings yet

- Verbal Analogy Exercise 1Document6 pagesVerbal Analogy Exercise 1DianaDomingoNo ratings yet

- Case Study (Contempo) PDFDocument13 pagesCase Study (Contempo) PDFKarl Andrei CarandangNo ratings yet

- 14 GrammarDocument89 pages14 GrammarLiu InnNo ratings yet

- Skills: 1 Sweet HistoryDocument2 pagesSkills: 1 Sweet HistoryEIREEN KRISTINE GOMEZ OTINIANONo ratings yet

- Reading The History of FantaDocument3 pagesReading The History of FantaSeza BayerNo ratings yet

- Clipping Words: Write Sentences Using The Clipped Words From The Following WordsDocument2 pagesClipping Words: Write Sentences Using The Clipped Words From The Following WordsBrito Raj100% (1)

- Adabi Assignment FormationDocument1 pageAdabi Assignment FormationArifFahmiNo ratings yet

- Fs Kitchen Safety With ServsafeDocument14 pagesFs Kitchen Safety With Servsafeapi-228479263No ratings yet

- The Best Buttercream RecipeDocument7 pagesThe Best Buttercream RecipepalkhinNo ratings yet