Professional Documents

Culture Documents

Fill The Pipe With Enough Sand To Cover Two To Three Inches Above The Planned Bend

Uploaded by

Lester ConztantineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fill The Pipe With Enough Sand To Cover Two To Three Inches Above The Planned Bend

Uploaded by

Lester ConztantineCopyright:

Available Formats

1.

Fill the pipe with enough sand to cover two to three inches above the planned

bend. Make a mark where the center of the bend needs to be, then mark an extra six to

eight inches on either side of this center mark. This will be your "heat zone," where you

need to direct the heat.

Keep any planned bends at least three to five inches away from any joints.

You may need to block the end of the pipe with tape to prevent the sand from falling out.

2. Apply the heat evenly around your planned bend. The sand inside will make this take

longer, but it also ensures that the pipe holds its form and doesn't cave or warp. Turn the

pipe regularly, applying heat to the inner and outer bend throughout your entire marked

heat zone.

Keep the heat source at least two to three inches away from the pipe to prevent burning the

PVC.

3. Slowly bend the pipe, applying more heat as necessary. Keep applying heat and bending until

you get your desired shape. If you want a perfect bend, use a metal can or object to provide a

"mold" for you bend

4. Remove the sand and let the pipe cool. Do not try and keep bending the pipe after the sand is

removed. This can cause cracks and warping. You can save the sand to use again

https://www.bing.com/videos/search?q=pvc+pipe+offset+vend&ru=%2fsearch%3fq%3dpvc

%2bpipe%2boffset%2bvend%26FORM

%3dHDRSC1&view=detail&mmscn=vwrc&mid=73B5703D58F06ACD050273B5703D58F06ACD

0502&FORM=WRVORC

You might also like

- Build Your Own Wind GeneratorDocument14 pagesBuild Your Own Wind GeneratorClaude-Michel Prevost100% (1)

- Build A Simple Solar Water HeaterDocument36 pagesBuild A Simple Solar Water HeaterAdithya Adiga100% (1)

- How To Make Paintball Gun and Other Homemade Tips (Ebook, 12 Pages)Document12 pagesHow To Make Paintball Gun and Other Homemade Tips (Ebook, 12 Pages)Ainis ŠtelemėkasNo ratings yet

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- Making A BurnerDocument13 pagesMaking A BurnerangelNo ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Foundry Practice - A Treatise On Moulding And Casting In Their Various DetailsFrom EverandFoundry Practice - A Treatise On Moulding And Casting In Their Various DetailsNo ratings yet

- Brewery Construction GuideDocument23 pagesBrewery Construction GuideCesar Diaz100% (6)

- Water Motor: Figure 105 Is A Perspective View of ADocument4 pagesWater Motor: Figure 105 Is A Perspective View of AHenry Pannell100% (1)

- The Boy Mechanic: 700 Things for Boys to Do 1From EverandThe Boy Mechanic: 700 Things for Boys to Do 1Rating: 5 out of 5 stars5/5 (1)

- GL Venturi DesignDocument6 pagesGL Venturi DesignRoland GarciaNo ratings yet

- Hot AirEngine PDFDocument9 pagesHot AirEngine PDFHenry PannellNo ratings yet

- Science: Hoop House Construction For New MexicoDocument10 pagesScience: Hoop House Construction For New MexicoWen RollandNo ratings yet

- Solar Air HeaterDocument8 pagesSolar Air Heaterkorisnik123No ratings yet

- Rocket Motor Construction TutorialDocument19 pagesRocket Motor Construction TutorialAzher Uddin100% (1)

- The Quickest and Easiest Steps To Set-Up The Simple Water Fuel-How It WorksDocument11 pagesThe Quickest and Easiest Steps To Set-Up The Simple Water Fuel-How It WorksdavomusikNo ratings yet

- Saw Dust Burning Space Heater StoveDocument10 pagesSaw Dust Burning Space Heater StovepitufitoNo ratings yet

- Making CruciblesDocument3 pagesMaking Cruciblesborakas2011No ratings yet

- SFAStirling Engine TemplatesDocument4 pagesSFAStirling Engine TemplatesEl GroneNo ratings yet

- 22LR HomeMade SilencerDocument7 pages22LR HomeMade SilencerOtis196475% (4)

- Cot 2 Lesson Plan Eim 12Document7 pagesCot 2 Lesson Plan Eim 12Lester ConztantineNo ratings yet

- 55 Watt Gas CO2 Laser TubeDocument66 pages55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Rubber Lining ApplicationDocument9 pagesRubber Lining ApplicationeyslNo ratings yet

- Detailed Lesson Plan in EIM 2023Document6 pagesDetailed Lesson Plan in EIM 2023Lester Conztantine100% (2)

- Pipe ForgeDocument6 pagesPipe ForgePierre799esNo ratings yet

- Can Steam EngineDocument6 pagesCan Steam EngineKyle RagasNo ratings yet

- Chemistry Full ProjectDocument6 pagesChemistry Full ProjectArkaprabha SahaNo ratings yet

- Add A RadiatorDocument6 pagesAdd A RadiatormickyalemuNo ratings yet

- Transfer Mold Design TipsDocument13 pagesTransfer Mold Design TipsRANJEET CHAUHANNo ratings yet

- KNO3 / Sorbitol J-425 Segmented 3-Grain Motor Construction TutorialDocument19 pagesKNO3 / Sorbitol J-425 Segmented 3-Grain Motor Construction TutorialMark D VillanuevaNo ratings yet

- Sheet Metal RoofingDocument5 pagesSheet Metal Roofingjack.simpson.changNo ratings yet

- Generator Bushing DesignsDocument10 pagesGenerator Bushing DesignsPradeep_VashistNo ratings yet

- Proceso de Soldadura PVC George FisherDocument10 pagesProceso de Soldadura PVC George FisherMarco Antonio Hernandez MotaNo ratings yet

- Food - Bucket StoveDocument3 pagesFood - Bucket StoveMoreMoseySpeedNo ratings yet

- In The: CavityDocument9 pagesIn The: Cavitybrowar444No ratings yet

- Bien Phap Thi CongDocument27 pagesBien Phap Thi Congminh ThaoNo ratings yet

- Blue Points: 1 " Well Point Installation InstructionsDocument8 pagesBlue Points: 1 " Well Point Installation InstructionsRobert McAlisterNo ratings yet

- Sect 6 Injection Mold Design TipsDocument17 pagesSect 6 Injection Mold Design TipsRanataNo ratings yet

- HRST Boiler Biz Newsletter - Winter 07Document6 pagesHRST Boiler Biz Newsletter - Winter 07SeindahNyaNo ratings yet

- Cable Repair Procedure (OVER 1.75)Document7 pagesCable Repair Procedure (OVER 1.75)Mahmoud Tobala100% (1)

- MOS For Water Supply Pipe Installation Inside ToiletDocument3 pagesMOS For Water Supply Pipe Installation Inside ToiletSherif M. ElgebalyNo ratings yet

- Spiral Wound Pipe InstallationDocument4 pagesSpiral Wound Pipe InstallationFNo ratings yet

- Guidelines For Durable DrivewaysDocument6 pagesGuidelines For Durable DrivewaysAmine HakimiNo ratings yet

- 04 - Roofing Work (C-PAC Monier)Document29 pages04 - Roofing Work (C-PAC Monier)PHOUNG sokearaNo ratings yet

- Spruing and Investing HandoutDocument23 pagesSpruing and Investing HandoutMariam SherifNo ratings yet

- Brewery Construction GuideDocument23 pagesBrewery Construction GuideodairnettoNo ratings yet

- Zmaj Od GrijanjaDocument4 pagesZmaj Od GrijanjaTihomir KosticNo ratings yet

- Thermoforming TroubleshootingDocument10 pagesThermoforming TroubleshootingdynafloNo ratings yet

- Procedures For Brazing Pipe and TubingDocument10 pagesProcedures For Brazing Pipe and TubingWilson AgustinNo ratings yet

- Part 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary NotesDocument9 pagesPart 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary Notesmohannad eliassNo ratings yet

- Refrigeration PipelinesDocument2 pagesRefrigeration PipelinesDavidB1206No ratings yet

- Brazing Fittings InsDocument4 pagesBrazing Fittings InsRichard PaulsonNo ratings yet

- 3 Liter Pop Bottle MiniDocument11 pages3 Liter Pop Bottle MiniTo NYoNo ratings yet

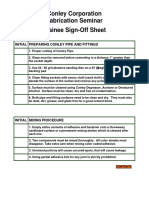

- Conley Corporation Fabrication Seminar Trainee Sign-Off SheetDocument3 pagesConley Corporation Fabrication Seminar Trainee Sign-Off SheetDieguitoOmarMoralesNo ratings yet

- Brazing and Soldering - Learn Refrigeration PDFDocument2 pagesBrazing and Soldering - Learn Refrigeration PDFAblePraxisNo ratings yet

- Hints on cheese-making, for the dairyman, the factoryman, and the manufacturerFrom EverandHints on cheese-making, for the dairyman, the factoryman, and the manufacturerNo ratings yet

- Intent LetterDocument1 pageIntent LetterLester ConztantineNo ratings yet

- PHILO-QUIZ CrosswordsDocument1 pagePHILO-QUIZ CrosswordsLester ConztantineNo ratings yet

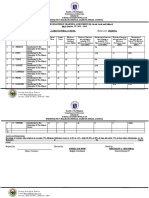

- PHILO - Report On Quarterly Learning AssessmentDocument2 pagesPHILO - Report On Quarterly Learning AssessmentLester ConztantineNo ratings yet

- Department of Education: Individual Workweek PlanDocument2 pagesDepartment of Education: Individual Workweek PlanLester ConztantineNo ratings yet

- Las-In Eim 11 Week 1Document3 pagesLas-In Eim 11 Week 1Lester ConztantineNo ratings yet

- Work Immersion AnimationDocument21 pagesWork Immersion AnimationLester ConztantineNo ratings yet

- Week 1 2 Whlpcontemporary Arts 12Document2 pagesWeek 1 2 Whlpcontemporary Arts 12Lester ConztantineNo ratings yet