Professional Documents

Culture Documents

Wilo Fire Fighting Brochure

Wilo Fire Fighting Brochure

Uploaded by

Theofilus PratiknoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wilo Fire Fighting Brochure

Wilo Fire Fighting Brochure

Uploaded by

Theofilus PratiknoCopyright:

Available Formats

Pioneering for You

Product Catalogue

Wilo - Fire Fighting Pumps

Fire pump set complete with accessories

2

Wilo - Fire Fighting Pumps

NFPA 20 Standards Compliant,

UL Listed, FM Approved

Fire Pressure Boosting Systems

Today, fire safety has become an accepted and overemphasized issue

throughout the world. Fire extinguishing systems are one of the top

priorities in commercial, industrial building and infrastructure facility

project such as schools, hospitals, malls, airports, factories, warehouses,

dams, treatment facilities, etc.

Wilo Brochure – Fire Fighting Pump

3

Wilo - Fire Fighting Pumps

UL Listed/FM Approved (NFPA20 compliant)

Wilo Brochure – Fire Fighting Pump

4

UL LISTED CERTIFICATE

Wilo Brochure – Fire Fighting Pump

5

FM APPROVED CERTIFICATE

FM Approved Certificate from India

FM Approved Certificate from Italy

Wilo Brochure – Fire Fighting Pump

6

WILO FireSet UL/FM

Product Features

1 Design 4 Power supply

Compact design that Main pump with power

integrates pump and reserve based on 150 %

switchgear with UL/FM of the rated volume flow,

approved components available with electric

motor or diesel engine

2 Installation 5 Versatility

Robust axially split case Product configurations

pumps to cover the main available on request,

needs of commercial or depending on installation

industrial buildings conditions

3 Equipment 6 Maintenance

Elastic coupling with Safe and easy installation

misalignment compensator and maintenance

for electric pump and

universal coupling complies

with UL requirements and is

accepted by FM for diesel

pump

Scope of Supply

Diesel System Electric System Jockey System

→ Pumpset with diesel → Pumpset with electric → Pumpset with mounted

engine driver motor driver electric motor driver

→ Control Panel (GPD) → Control Panel (GPY) → Control Panel (JFA)

→ Pressure gauges → Pressure gauges

→ Air relief valves → Air relief valves

→ Circulation relief valves

→ Batteries

→ Fuel tank

Wilo Brochure – Fire Fighting Pump

7

UL/FM APPROVED PUMP DESIGN

Type Key

SCPFF 80-300 DV

SCPFF Pump series

80 Nominal outlet diameter (mm)

300 Nominal impeller diameter (mm)

DV Hydraulic Variant

•DV: Double Volute

•HA: Hydraulic type “A”

•HB: Hydraulic type “B”

6-8 CME MKII

6 Nominal outlet diameter (inch)

8 Nominal inlet diameter (inch)

CME MKII Pump Series

Pump Material Specification Pump Specification

Casing Cast Steel (A 216 Gr) Max Operating Pressure 16-25 bar

Impeller Bronze Casting (G-CuSn10) Operating Temperature 10-105 ˚C

Shaft Stainless Steel (SS410) Pump Type Axially split case

Shaft Sleeve Stainless Steel (SS304) Lubrication Grease

Wearing Ring Bronze Casting (G-CuSn10) Direction of Rotation Clockwise

Sealing Gland Packing (Optionally counter-

clockwise)

Pump Rated Rated Net Rated Net

Approx Speed

Pump Model Connection Capacity Pressure Pressure

(RPM)

(inch) (USGPM) Range (psi) Range (m)

SCPFF 80 - 300 DV 3x4 500 85 - 176 60 – 120 2980

SCPFF 125 - 360 DV 5x6 750 176 – 280 122 – 190 2980

6 - 8 CME MKII 6x8 750 69 – 102 49 – 72 1480

SCPFF 125 - 300 HA 5x6 750 123 – 199 86 – 140 2980

6 - 8 CME MKII 6x8 1000 65 – 100 46 – 70 1480

SCPFF 125 - 360 DV 5x6 1000 162 - 268 112 – 185 2980

SCPFF 150 - 300 HA 6x8 1000 134 - 173 94 – 122 2980

6 - 8 CME MKII 6x8 1250 60 - 98 42 – 68 1480

SCPFF 150 - 300 HA 6x8 1250 130 - 171 91 – 120 2980

6 - 8 CME MKII 6x8 1500 93 65 1480

SCPFF 150 - 300 HA 6x8 1500 122 - 163 86 – 115 2980

SCPFF 200 - 560 HB 8 x 10 2000 100 - 153 70 – 108 1480

SCPFF 200 - 560 HB 8 x 10 2500 99 - 149 69 - 105 1480

Wilo Brochure – Fire Fighting Pump

8

UL/FM APPROVED PUMP WITH ELECTRIC MOTOR

2 5

Key

Coupling Electric Motor

1 → KTR elastic coupling, accepted by FM 4 → UL-compliant motor, accepted by FM

→ Maximum operational reliability (breakage test) → Power corrected with safety factor and high reliability of

→ Prevention of shaft stress through compensation components

systems

Fire pump Switchgear

2 → UL & FM compliance with NFPA 20 as standard 5 → Switchgear components are UL/FM with CE marking as

→ Static and dynamic characteristics tested directly in standard.

production by Wilo → Designed in full accordance with NFPA 70 (NEC)

→ Designed to ensure high efficiency, and easy installation electrical standards

and maintenance operations → Logic of the control microprocessor based on recording

of the sequence of events following pressure changes

as standard.

→ Protection class IP54

→ Star-delta starting

FM Approval FM Approval

3 → The FM logo ensures that the pump is assembled with 6 → Easytransport thanks to the side eyebolts

FM- approved components in a factory authorised by → Standard base plate consisting of a sturdy steel frame to

FM facilitate on-site operations

→ Paintwork with RAL 3000 colour

Wilo Brochure – Fire Fighting Pump

9

UL/FM APPROVED PUMP WITH DIESEL ENGINE

3

6

2

5

7

Key

Coupling Baseplate

1 → Universal coupling compliant with UL requirements and 5 → Standard base plate consisting of a sturdy steel frame to

accepted by FM facilitate on-site operations

→ Maintenance-free with maximum operational reliability → Paintwork with RAL 3000 colour

→ Shaft may be moved in axial, radial and angular → Easy transport thanks to the side eyebolts

directions

Fire pump Combustible Tank

2 → UL & FM compliance with NFPA 20 as standard 6 → Designed and dimensioned in accordance with NFPA 20

→ Static and dynamic characteristics tested directly in standard

production by Wilo → Single-wall tank as standard

→ Designed to ensure high efficiency, and easy installation

and maintenance operations

Diesel Engine Battery Pack

3 → UL/FM-compliant diesel engine with silencer for 7 → Easy transport thanks to the side eyebolts

industrial installation and flexible drainage → Two lead batteries (12 V or 24 V) provide improved

→ Power revised with safety factor in accordance with reliability

NFPA 20 → Dimensioned in accordance with NFPA 20 standard

→ Engine cooling is ensured through a dedicated heat

exchanger

Switchgear FM Approval

4 → Switchgear components are UL/FM with CE marking as 8 → The FM logo ensures that the pump is assembled with

standard FM- approved components in a factory authorised by

→ Protection class IP54 FM

→ Simplified installation and maintenance procedures

Wilo Brochure – Fire Fighting Pump

10

Open Lineshaft Vertical Turbine

Fire Pumps

MOTOR

→ Optional right angle gear drives

→ Vertical hollowshaft of solid shaft

→ Can be supplied with a non-reverse ratchet

→ Top adjusting nut allows user to adjust lateral setting

→ Bearing designed to carry thrust loads and is oil

lubricated

→ Available in WP-I, WP-II, TEFC & Explosion-Proof

enclosures

STUFFING BOX

→ Packed with lantern ring standard

DISCHARGE HEAD → High-pressure stuffing boxes and shaft

→ Stainless steel top shaft sleeves are optional

→ Optional fabricated steel heads available → Grease port for throat bushing

→ Headshaft coupling connects top shaft lubrication

to headshaft

→ High profile head allows for ease in

servicing packing

→ Integral drip basin collects leakage from COLUMN ASSEMBLY

stuffing box → Larger diameter, steel shaft material

→ Spacer couplings are available for use → Heat straightened shafting standard

with VSS motors → Heavy wall carbon steel construction

→ Heavy duty ASTM A48 class 30 cast iron → Product lubricated lineshaft bearings

construction standard → Overall length is engineered to

customer specifications

→ Cast 304 stainless steel bearing

DISCHARGE CASE retainer with cutlass rubber insert

→ Two discharge bearings for additional → Threaded column is standard through

support 12” and flanged for larger sizes

→ Heavy duty ductile iron construction

standard

→ Additional vanes for minimizing

turbulence, thus improving efficiency BOWL ASSEMBLY

→ Bronze bowl bearings standard

→ 416 stainless steel bowlshaft is

standard

STRAINER → Impellers are expertly machined to

customer specifications

→ Basket or cone strainers are available

→ Heavy duty ASTM A48 class 30 cast

upon request

iron construction standard

→ Stainless steel materials are available

→ Heavy duty grease-packed suction

→ Vortex suppressors can be supplied to

case bearing with sand collar

minimize inlet stress

→ Diffuser bowls through 16” have

standard vitreous enamel lining

→ Heavy wall ASTM A48 class 30 cast

iron construction with 304 stainless

steel impellers

→ Tapered impeller collets are used on

bowls through 16” with keyed

impellers used on larger sizes

Wilo Brochure – Fire Fighting Pump

11

Open Lineshaft Vertical Turbine

Fire Pumps

Performance Specifications

SIZE: 10” to 19” (350-483 mm)

FLOWS: Up to 5,000 gpm (1,817 m3/hr)

HEADS: Up to 800 feet (244 meters)

PRESSURE: Up to 370 psi

● UL Listed Certified &Approved Pumps

● Compliance to NFPA 20 DesignRegulations

● Matches FM Approval requirements

● Multiple Range of Flow and Pressures

Wilo Brochure – Fire Fighting Pump

12

Range of Pumps

Rated Net

Rated Rated Net

Pressure Range Approx Speed

Pump Model Stage(s) Capacity Pressure Range

(psi) (RPM)

(USGPM) (m)

49-238 30-160 1450

500

12MC 3-10 69-349 49-240

1760

750 63-334 43-230

82-174 56-120 1450

14HCR 3-5 750

125-266 86-180 1760

79-226 54-150 1450

14MCR 3-6 750

119-343 82-240 1760

77-166 53-110 1450

14HCR 3-5 1000

114-258 78-180 1760

72-209 50-150 1450

14MCR 3-6 1000

112-323 80-220 1760

73-165 50-110 1450

14HCR 3-5 1250

108-148 75-100 1760

192 130 1450

14MCR 6 1250

298 200 1760

71-165 50-110 1450

14HCR 3-5 1500

103-249 70-170 1760

2 51-63 35-40

3 77-95 53-65

1450

4 102-112 70-77

5 128-140 90-100

16LC 1500

2 79-95 54-65

3 118-143 80-100

1760

4 158-191 110-130

5 197-213 130-145

14HCR 5 234 160 1760

2 47-58 30-40

3 70-88 50-60

1450

4 94-103 65-70

5 2000 117-129 80-90

16LC

2 75-90 52-62

3 112-135 80-93

1760

4 150-180 103-124

5 187-202 130-140

1 43-49 30-34

1450

2 86-92 60-64

19MC 2000

1 67-74 50-51

1760

2 133-141 92-98

2 70-84 48-58

3 106-126 73-87

16LC 2500 1760

4 141-168 97-120

5 176-190 120-130

1 41-48 28-33

1450

2 81-89 56-60

19MC 2500

1 62-72 43-50

1760

2 125-134 86-92

2 69-77 48-53 1450

19HC 1 3000 53-62 36-43

1760

2 107-115 74-79

2 84 58 1450

19MC 1 3000 59-70 40-48

1760

2 119-129 82-89

2 72 49 1450

19HC 1 3500 51-61 35-42

1760

2 101-112 70-77

19MC 2 3500 123 85 1760

68 47 1450

19HC 2 4000

106 73 1760

19MC 2 4000 116 80 1760

19HC 2 4500 101 70 1760 Wilo Brochure – Fire Fighting Pump

13

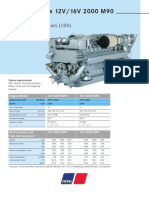

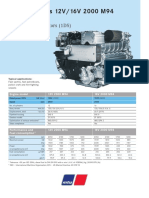

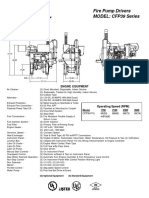

PUMP DRIVER

Diesel Engine Electric Motor

→ Listed engine driver

→ Listed motor driver

→ Heat exchanger and radiator engine cooling system

→ Low speed and high speed rotation (1500-2900 rpm)

→ Build in cooling loop on heat exchanger cooling system

→ Very wide range of power (depend on rotational speed)

→ Low speed and high speed rotation → IP55

→ Build in DC panel

→ Build in silencer with industrial clamped

→ Exhaust guarding, jacket water heater, and stub shaft

asoptional accessories (standard accessories on several types)

Built Up Controllers

UL Listed & FM Approved

Product Model Details Installation Comply to Standard

Diesel Fire Pump UL Listed &

GPD 12 or 24 VDC Wall Mounting

Controller FM approve

Electric Fire Pump GPA Across the line starter

Controller GPY Wye-Delta open starter UL Listed &

Rigid base and

GPR Autotransformer starter FM approve

Wall Mounting

GPS Electronic soft starter

GPW Wye-Delta closed starter

Jockey Pump

JFA Across the line starter Wall Mounting UL Listed

Controller

Wilo Brochure – Fire Fighting Pump

14

Wilo - Fire Fighting Pumps

Non-Listed (NFPA20 compliant)

Wilo Brochure – Fire Fighting Pump

15

WILO FireSet NFPA 20 Std.

Electric Fire Pump (EFP)

→ Pumpset with electric motor driver

→ Local Controller refer to NFPA20 Std.

Diesel Fire Pump (DFP)

→ Pumpset with diesel engine driver

→ Local Controller refer to NFPA Std.

→ Batteries

→ Fuel tank

Jockey Fire Pump (JFP)

→ Pumpset with mounted electric motor driver

→ Local Controller refer to NFPA20 Std.

Wilo Brochure – Fire Fighting Pump

16

NFPA20Pump

NFPA20 PumpDesign

Design

End Suction Pump Multistage Pump Horizontal Split Case Pump

Wilo – MISO/PISO (ISO 2858) Wilo - RN, HS PLURO, IPB Wilo - ASP

Q max. : 3300 USGPM Q max. : 6600 USGPM Q max. : 4000 USGPM

H max. : 170 m H max. : 900m H max. : 260m

Speed : 2950rpm Speed : 1450 - 2950rpm Speed : 2950rpm

Casing : Cast iron, Ni-CI, cast steel Casing : Cast iron, Ni-CI, cast steel Casing : Cast iron

stainless steel, duplex stainless steel, duplex Impeller : Bronze

stainless steel stainless steel Shaft : Stainless steel (SS410)

Impeller : Cast iron, bronze, stainless Impeller : Castiron, bronze, stainless

steel, duplex stainless steel steel, duplex stainless

Shaft : Stainless steel, steel

Shaft : Stainless steel,

duplex stainless steel

duplex stainless steel

→ Reduced life-cycle costs through → High pressure pump design → Robust design

optimised effisiency levels → Modular design ensures pump version → Customized solutions to meet exact

→ Bidirectional, force - flushed in a variety of materials and versions requirement

mechanical seal which can be adapted to meet → Shaft sleeve to ensure longer shaft

→ Low NPSH values, best cavitation customer demand sprecisely life

properties → Hydraulic pressure compensation → Optimum NPSHr

→ Shaft coupling with or without relieves load on bearings and ensures

→ Low noise and vibration

spacer coupling a longer service life

→ Reduced energy consumption

→ Multiple optional pressure connections

→ Less environmental impact

allow different pressures to be

supplied from a single pump

→ Can be applied as Jockey pump

Wilo Brochure – Fire Fighting Pump

17

NFPA20 Pump Design

Vertical Turbine Pump Split Case Pump Jockey Pump - Multistage Pump

Wilo - VMF, CNE, VAF Wilo - SCP, HSC, GME Wilo - Helix First V / EVO

Q max. : 176.000 USGPM Q max. : 149.000 USGPM Q max. : 350 USGPM

H max. : 450 m H max. : 245 m H max. : 280m

Speed : 980-2950 rpm Speed : 980-2950 rpm Speed : 2950 rpm

Casing : Cast iron, stainless steel, Casing : Cast Iron Ni-CI, stainless Casing : Cast iron, Stainless steel

cast steel, dupplex stainless steel Impeller : Stainless steel

steel Impeller : Castiron, bronze, stainless Shaft : Stainless steel

Impeller : Castiron, bronze, stainless steel, Ni-CI, duplex stainless

steel, Ni-CI, cast steel, steel

Shaft : Stainless steel, duplex Shaft : Stainless steel, duplex

Stainless steel stainless steel

→ Minimum surface area needed → Robust design → Efficiency- optimised, laser welded

→ High hydraulic efficiency → Customized solution to meet exact optimised 2D/3Dhydraulics

→ Submerged pump hydraulic requirement → Corrosion-resistant impellers, guide

→ Shaft sleeve to ensure longer shaft vanes and stage housing

→ Design to order as per customer

specification life → Flow and degassing-optimised

→ Trust bearing lubrication: Grease, → Low NPSHr hydraulics parts

oil Line shaft bearing lubrication: → Low noise and vibration → Reinforced pump housing, flow and

Self, forced (external) NPSH optimised

→ Reduced energy consumption

→ Bowl Assembly: Pull out or non- → Space-saving and esay maintenance

pull out → Less environmental impact

thanks to compact design

(almost 100% recyclable)

→ Space-saving and esay maintenance

→ Comply to RoHS directive for

thanks to compact design

European countries

→ Particularly sturdy coupling guard

Wilo Brochure – Fire Fighting Pump

18

Built Up Controllers

Product Model Details Installation Comply to Standard

Diesel Fire Pump GFD 12 or 24 VDC Wall Mounting NFPA20

Controller GPD 12 or 24 VDC UL Listed

GFA Across the line starter

GFY Wye-Delta open starter

Electric Fire Pump GFR Autotransformer starter Wall Mounting NFPA20

Controller GFS Electronic soft starter

GFW Wye-Delta closed starter

GPY Wye-Delta open starter UL listed

JP3 Across the line starter

Jockey Pump Controller Wall Mounting UL Listed

JPY Wye-Delta open starter

Local Controllers

Local(Refer to NFPA20

Controllers (ReferStd.)

to NFPA20 Std.)

→ Refer to NFPA20 standrad of fire

pump control panel

→ Manufactured locally in Indonesia

→ Many types of starter for electric

motor control

→ Wide standard range for electric

motor control panel

→ Diesel engine control panel for 12

and 24VDC

→ Across the line and Y-Delta starter

for jockey pump control panel

→ Wide standard range for jockey

pump control panel

EFP Controller DFP Controller JP Controller

Wilo Brochure – Fire Fighting Pump

19

PUMP DRIVER

Diesel Engine ElectricMotor

Electric Motor

→ Non-Listed engine driver → Non-Listed motor driver

→ Heat exchanger and radiator engine cooling system → Low speed and high speed rotation (1500-2900 rpm)

→ Build in cooling loop on heat exchanger cooling system → Very wide range of power (depend on rotational speed)

→ Low speed and high speed rotation → IP55

→ Build in DC panel

→ Build in silencer

Horizontal Split Case Pump c/w Diesel Engine Horizontal Split Case Pump c/w Electric Motor

End Suction Pump c/w Diesel Engine End Suction Pump c/w Electric Motor

Wilo Brochure – Fire Fighting Pump

PT Wilo Pumps Indonesia

Altira Business Park Blok A01-A02

Jl. Yos Sudarso Kav.85

Sunter Jaya, Tanjung Priok

Jakarta Utara Jakarta, 14350

T+6221 21882328

www.wilo.com/id/en

Warehouse & After Sales Service

Jl. Agung Timur 9 Blok N3 No. 5

Sunter Jaya, Tanjung Priok

Jakarta Utara Jakarta, 14350

T+6221 6509036

Pioneering for You www.wilo.com/id/en

You might also like

- SM3184-3184XT, SM3884-3884XT, SM4688-4688XTDocument6 pagesSM3184-3184XT, SM3884-3884XT, SM4688-4688XTJOHN0% (1)

- Circuit Diagram - Metso Lokotrack lt106Document18 pagesCircuit Diagram - Metso Lokotrack lt106LUIS HERNANDO100% (9)

- YALE (D801) OS030EF LIFT TRUCK Service Repair Manual PDFDocument25 pagesYALE (D801) OS030EF LIFT TRUCK Service Repair Manual PDFfjskekdmmem0% (1)

- Ford Pin DVDocument17 pagesFord Pin DVjtfjtf100% (1)

- No Start No CrankDocument11 pagesNo Start No CrankRH100% (1)

- Catalog AMK FastenerDocument196 pagesCatalog AMK FastenerBillNo ratings yet

- Naffco Vertical Turbine Fire PumpsDocument10 pagesNaffco Vertical Turbine Fire Pumpsmohammed husseinNo ratings yet

- 4227Document104 pages4227Markus JärveNo ratings yet

- Wilo Fire Fighting 2020Document16 pagesWilo Fire Fighting 2020Petualangan SejatiNo ratings yet

- Wilo Fire Fighting - 2021Document16 pagesWilo Fire Fighting - 2021Meiz AllfarizyNo ratings yet

- Wilo Fire Fighting - R13 - EdDocument28 pagesWilo Fire Fighting - R13 - EdriyoprilianNo ratings yet

- Flow-Moto 250GPM@8Bar End-Suction UL&FM DJDocument73 pagesFlow-Moto 250GPM@8Bar End-Suction UL&FM DJKarim NasserNo ratings yet

- Mtu 12v&16v2000m90Document2 pagesMtu 12v&16v2000m90Bruna RahdNo ratings yet

- Nas 6124 en PDFDocument5 pagesNas 6124 en PDFFrankDeviePaculguenQueridoNo ratings yet

- Diesel Engines 12V 4000 M93/M93L: For Fast Vessels With Low Load Factors (1DS)Document2 pagesDiesel Engines 12V 4000 M93/M93L: For Fast Vessels With Low Load Factors (1DS)cesarNo ratings yet

- VRLA Tech ManualDocument24 pagesVRLA Tech Manualrodolfoordiguez_70No ratings yet

- QSZ13-G5: EU Stage IIDocument3 pagesQSZ13-G5: EU Stage IIluis blancoNo ratings yet

- MTU 16V4000 DS2250: Diesel Generator SetDocument4 pagesMTU 16V4000 DS2250: Diesel Generator Settayden1970No ratings yet

- Diesel Engines 12V/16V 2000 M72: For Vessels With High Load Factors (1B)Document2 pagesDiesel Engines 12V/16V 2000 M72: For Vessels With High Load Factors (1B)Alberto100% (1)

- Double Suction Split Case Fire Pump: Series 4800Document8 pagesDouble Suction Split Case Fire Pump: Series 4800Carlos EafNo ratings yet

- Diesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)Document2 pagesDiesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)zaki100% (1)

- Inpro Fuel Handling Equipments For Diesel GeneratorsDocument40 pagesInpro Fuel Handling Equipments For Diesel GeneratorsRizwan ShaikhNo ratings yet

- Mtu 12v&16v2000m93Document2 pagesMtu 12v&16v2000m93vaibhavdabhade5No ratings yet

- Rock Valve: Stationary Concrete PumpsDocument8 pagesRock Valve: Stationary Concrete PumpsRafael R ANo ratings yet

- MTU 12 16V4000M71 SpecsificationDocument2 pagesMTU 12 16V4000M71 Specsificationzaki100% (1)

- Ficha Técnica Daily 55S17H - W WB 3.400 MMDocument14 pagesFicha Técnica Daily 55S17H - W WB 3.400 MMRodrigo San MartinNo ratings yet

- Generador Cat 3512bDocument4 pagesGenerador Cat 3512bcarlucido247970No ratings yet

- Mtu 12v4000 m53&m63Document2 pagesMtu 12v4000 m53&m63AlbertoNo ratings yet

- C250D6Document4 pagesC250D6Jose Javier Orellana ArmacanquiNo ratings yet

- Marine Spec 12V4000M73-L 1BDocument3 pagesMarine Spec 12V4000M73-L 1BYaseen MohammedNo ratings yet

- Grupo Mitsubishi Apd-Ulm800Document4 pagesGrupo Mitsubishi Apd-Ulm800Héctor Vila100% (1)

- Kta 38 G7Document3 pagesKta 38 G7ophar100% (1)

- Vantage 500: Setting A New Standard!Document8 pagesVantage 500: Setting A New Standard!Jorge Daniel Encinas GaldNo ratings yet

- Appendix 6.2-G - Fire Pump Engine SpecsDocument9 pagesAppendix 6.2-G - Fire Pump Engine Specs050678No ratings yet

- Data Sheet KPX C680PDocument5 pagesData Sheet KPX C680PJonathan RiveraNo ratings yet

- 55S17H W New Daily Euro Vi (F1C 3.0L) : Engineering Profile 1 31 Mar 2015Document14 pages55S17H W New Daily Euro Vi (F1C 3.0L) : Engineering Profile 1 31 Mar 2015emiliqn velikovNo ratings yet

- Diesel Engines 12V/16V 4000 M90: For Vessels With Low Load Factors (1DS)Document2 pagesDiesel Engines 12V/16V 4000 M90: For Vessels With Low Load Factors (1DS)Alberto100% (1)

- 1400 KvaDocument4 pages1400 KvaIhsan AhmedNo ratings yet

- Model:: Powered by DCECDocument4 pagesModel:: Powered by DCECPNGNo ratings yet

- SANY SF558/808/818 Multi-Purpose Electro-Hydraulic Track Pile Driving RigDocument10 pagesSANY SF558/808/818 Multi-Purpose Electro-Hydraulic Track Pile Driving RigRakhmat RamdhaniNo ratings yet

- Mtu 12v&16v2000m94Document2 pagesMtu 12v&16v2000m94ozakyus50% (2)

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocument4 pagesNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJohn YangNo ratings yet

- C1000D6RGDocument4 pagesC1000D6RGDavid GomezNo ratings yet

- KTA38-G9: Fuel OptimizedDocument3 pagesKTA38-G9: Fuel OptimizeddennysNo ratings yet

- Mtu 16v4000 m53&m63 PDFDocument2 pagesMtu 16v4000 m53&m63 PDFJoan Manuel Rivas Santandreu100% (1)

- Output Ratings Ratings and Performance DataDocument4 pagesOutput Ratings Ratings and Performance Datajaime leonNo ratings yet

- 6CTAA8.3-G7: Fuel OptimizedDocument3 pages6CTAA8.3-G7: Fuel OptimizedMohamed ElsagerNo ratings yet

- Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18405888-017 PDFDocument3 pagesPage: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-18405888-017 PDFAli YarahmadiNo ratings yet

- CBMDocument9 pagesCBMMuhidin KozicaNo ratings yet

- VTA28-G5: Fuel OptimizedDocument3 pagesVTA28-G5: Fuel OptimizedIslam HemdanNo ratings yet

- QSZ13G6Document3 pagesQSZ13G6Jonny Ubaldo Zambrano MeraNo ratings yet

- Fire Sprinkler SystemDocument14 pagesFire Sprinkler SystemrspawaiyaNo ratings yet

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Document3 pagesQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- Diesel Engines 16V 4000 M61R/M61: For Vessels With Unrestricted Continuous Operation (1A)Document2 pagesDiesel Engines 16V 4000 M61R/M61: For Vessels With Unrestricted Continuous Operation (1A)avinash_1229100% (1)

- Horizontal Split Case - 2900 RPMDocument7 pagesHorizontal Split Case - 2900 RPMmazzam75No ratings yet

- Proposal - GeneratePDF - MODELO JW6HDocument8 pagesProposal - GeneratePDF - MODELO JW6HMaurilio Batista de LimaNo ratings yet

- Diesel Pump Data SheetDocument24 pagesDiesel Pump Data SheetMurugaraj SelvarajNo ratings yet

- USA Purchased - Installed Outside The USA Fm-Ul-Cul Approved Ratings BHP/KWDocument2 pagesUSA Purchased - Installed Outside The USA Fm-Ul-Cul Approved Ratings BHP/KWRoronoa ZorroNo ratings yet

- BCV BAV FCV Utility Sets Catalog 600Document38 pagesBCV BAV FCV Utility Sets Catalog 600Martín OrtegaNo ratings yet

- 1013Document4 pages1013Ph03n1x-No ratings yet

- Gps Mtu 20v4000 2500kw Diesel Genset Sku 6530Document5 pagesGps Mtu 20v4000 2500kw Diesel Genset Sku 6530Mohammad TolounezhadNo ratings yet

- NTA855G4Document3 pagesNTA855G4Shahid Shaikh100% (1)

- Generator FinalDocument40 pagesGenerator FinalDoe QoinNo ratings yet

- Spec Sheet CFP39Document2 pagesSpec Sheet CFP39Noel RodríguezNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- TCL - Roku TV: User GuideDocument95 pagesTCL - Roku TV: User GuideFerjani MohamedNo ratings yet

- Massey FergusonDocument697 pagesMassey FergusonMarian TarasNo ratings yet

- Catalogo Polipastos A Cable Hyundai IngevalDocument40 pagesCatalogo Polipastos A Cable Hyundai IngevalOscar ValderramaNo ratings yet

- Blade Building Made Easy: Don FoggDocument162 pagesBlade Building Made Easy: Don FoggFerreirarocha Ferreira Rocha100% (4)

- Installation Instructions: 18SP548-Install Exhaust Back Pressure Sensor Kit On Series 50 or Series 60 Diesel Coach EngineDocument10 pagesInstallation Instructions: 18SP548-Install Exhaust Back Pressure Sensor Kit On Series 50 or Series 60 Diesel Coach EngineHamilton MirandaNo ratings yet

- Aerius - VB 5.5-7.5 - Parts ManualDocument11 pagesAerius - VB 5.5-7.5 - Parts ManualLuis SilvaNo ratings yet

- Cathode Ray Oscilloscope - CroDocument2 pagesCathode Ray Oscilloscope - Cromeenakshi sharmaNo ratings yet

- Bosch Go 3601JH21E0Document171 pagesBosch Go 3601JH21E0william uribeNo ratings yet

- B1900 NOTES Page 21-40Document20 pagesB1900 NOTES Page 21-40Hayden CourtneyNo ratings yet

- BS en 1759-4 - 2003Document20 pagesBS en 1759-4 - 2003Tausif LodhiNo ratings yet

- TiraktechDocument6 pagesTiraktechRadakovicZoranNo ratings yet

- Trailer Brake & Suspension Products Manual PDFDocument220 pagesTrailer Brake & Suspension Products Manual PDFVincent Price100% (1)

- TE 2019 MechDocument97 pagesTE 2019 Mechjoshikaustubhp070No ratings yet

- U Channel 2019Document18 pagesU Channel 2019aNo ratings yet

- Ps21867 P OriginalDocument6 pagesPs21867 P OriginalOmar LeonNo ratings yet

- Heavy Duty Air Conditioning Accessories CatalogDocument97 pagesHeavy Duty Air Conditioning Accessories CatalogAndrei Stefan DimaNo ratings yet

- GeneralIinstallation Guidelines and Procedures For A SpiraliftDocument5 pagesGeneralIinstallation Guidelines and Procedures For A SpiraliftSudha BattiniNo ratings yet

- PINBALL Gottlieb Pinball System 80 Repair TOCDocument2 pagesPINBALL Gottlieb Pinball System 80 Repair TOCBrianNo ratings yet

- 9815 EF Breathing Air Blower Systems PDFDocument2 pages9815 EF Breathing Air Blower Systems PDFMilton Toledo PerezNo ratings yet

- Serial Port Communication LabviewDocument5 pagesSerial Port Communication Labviewpj_bank100% (2)

- b&c18pzb46 8Document1 pageb&c18pzb46 8Jesus Ruy SanchezNo ratings yet

- Relay AP Suat Saginomiya SnsDocument2 pagesRelay AP Suat Saginomiya SnsNguyen Phuoc HoNo ratings yet

- Proposal Digital Clamp MeterDocument5 pagesProposal Digital Clamp MeterZeremia SamosirNo ratings yet