Professional Documents

Culture Documents

Vyttila Substation Guide

Uploaded by

Suja PulparambathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vyttila Substation Guide

Uploaded by

Suja PulparambathCopyright:

Available Formats

Operating Instructions

CONTENTS

110KV SUBSTATION VYTTILA

SF6 CIRCUIT BREAKER

ON LOAD TAPCHANGER (OLTC)

BATTERY

RELAY FAMILY

TYPES OF RELAY

110KV Substation, Vyttila Page 1

Operating Instructions

1.110 kV SUBSTATION VYTTILA

The 110kV Vyttila substation is one of the oldest substations. This substation

is feeding major part of Kochi and three auxiliary substation viz. 66 kV substation

Perumanoor, Panampilly Nagar and Puthencruz and EHT consumers; M/S HOC & M/S

PCBL. The 110kV supply feeding to the substation is from 220kV substation

Kalamassery, through the 110 kV Vyttila single circuit feeder and from 110kV substation,

Newvyttila through 110 kV UG CABLE feeder. Inaddition to this 110 kV feeders there are

two 66 kV incoming feeders from 220 kV substation,Kalamassery.

The 110kV substation New Vyttila is fed from 220KV substation Brahmapuram

through feeders BR- NV ( Brahmapuram – New Vyttila) and BR-KD( Brahmapuram-

Kadavanthra) feeder. BR-NV conductor is HTLS ( High Temperature Low Sag).There are

six 66 kV feeders; Puthencruz I &II and Perumanoor I&II which are outgoing feeders and

Vyttila I&II are the standby feeders from 220kV substation Kalamassery.

The station capacity is 128 MVA, (Including 40 MVA and 63 MVA 110/66

kV transformers and two 12.5 MVA 110/11 kV transformers). The 11 kV distributions is

from the Crompton Greaves make 11 kV VCB panel. There are nine 11 kV outlets other

than auxiliary.

M/S PCBL (Philips Carbon Black Limited) has captive generation of 10 MW

capacity and they export their generation to the grid through 66 KV Vyttila- Puthencruz

No.II feeder and is named as 66 KV Vyttila-PCBL feeder. Their average exports to grid

are about 4.5MW to 5.5MW.

110KV Substation, Vyttila Page 2

Operating Instructions

2.FEEDER DETAILS

o/c

Name of feeder Code CT Conductor Relay Permissible

ratio setting load

110kV Kalamassery-

Vyttila 1KLVT 600/1 WOLF 0.75 343A

110kV New Vyttila-

Vyttila 1NVVT 600/1 WOLF 1 600 A

66 kV Vyttila-

Perumanoor I 6VTPN 400/1 DOG 0.75 250A

66 kV Vyttila- 6VTPR 300/1 DOG 1.5*0.5 225A

Perumanoor II

66 kV Vyttila- 6VTPT 1 300/1 DOG 0.8 240A

Puthencruz

66 kV Vyttila- PCBL 6VTPT II 300/1 DOG 1.5*0.5 225A

66 kV Kalamassery - 6KLNP 200/1 DOG 2.5*0.5 250A

Vyttila I

66 kV Kalamassery- 6KLVT 400/1 DOG 1.5*0.5 300A

Vyttila II

110KV Substation, Vyttila Page 3

Operating Instructions

CABLE CAPACITY

Name of feeder Capacity

110kV Kalamassery-Vyttila 330A

110kV New Vyttila-Vyttila 600A

66 kV Vyttila- Perumanoor I 254A

66 kV Vyttila-Perumanoor II 254A

66 kV Vyttila- Puthencruz 254A

66 kV Vyttila- PCBL 254A

66 kV Kalamassery -Vyttila I 254A

66 kV Kalamassery- Vyttila II 254A

110KV Substation, Vyttila Page 4

Operating Instructions

2.1. 11 kV FEEDERS

Incomer I & II 600A 600/5 1*500 mm2 XLPE

Vadakkekotta 200A 200/5 3*300 mm2 XLPE

Nettoor 200A 200/5 3*300 mm2 XLPE

Kadavanthra 200A 200/5 3*300 mm2 XLPE

Palarivattom 200A 200/5 3*300 mm2 XLPE

Eroor 200A 200/5 3*300 mm2 XLPE

Ambalamugal 200A 200/5 3*300 mm2 XLPE

Udayamperoor 200A 200/5 3*300 mm2 XLPE

Ernakulum 200A 200/5 3*300 mm2 XLPE

Chakkaraparambu 200A 200/5 3*300 mm2 XLPE

Load break switches are installed for 11kV Nettoor and Ernakulam feeders. 11 kV

Kadavantra feeder is inter linked with 11 kV Gandhi square feeder from New Vyttila

Substation by installing one CCC RMU (CG LUCY Make) at yard. It has two incoming

supply [one is from Vyttila Substation (Kadavantra feeder) and other from New Vyttila

Substation (Gandhi square feeder). The RMU and load break switches are operated

110KV Substation, Vyttila Page 5

Operating Instructions

manually.11 kV vadakkekkotta,Palarivattom.Eroor,Udayampoeroor and Ambalamugal

feeders are provided with CC RMU s(Siemens make).

New 11kV XLPE cables are laid through the new trench for 11 kV Nettoor, 11 kV

Ernakulam and 11 kV Kadavantra feeders. Remaining power cables are laid through the

old cable trench.

Name of 11 KV feeders and connected substations to which the 11 KV feeders of

Vyttila to be back fed during shut downs and emergencies

NAME OF THE NAME OF THE FEEDER TO BE

NAME OF SUBSTATION

FEEDER AT VYTTILA BACKFED

Vadakkekotta Tripunithura New Vyttila

Muthedam,Panangadu Panangadu,Kadavanthra,

Nettoor

Kundannoor,Maradu, New Vyttila

Palarivattom Chalikkavattom New Vyttila

Kadavantra Gandhi square New Vyttila

Eroor Thuthiyoor Kakkanadu

Ambalamugal Irumbanam,Chithrapuzha Kakkanadu,Brahmapuram

Udayamperoor Puthiyakavu Kandanadu

Ernakulam S A Road Kadavantra

Chakkaraparambu Vennala Kakkanadu

110KV Substation, Vyttila Page 6

Operating Instructions

2.2 11 kV FEEDERS AND THEIR CONTROLLING SECTIONS

,

Feeder Controlling Electrical Section

Vadakkekotta Eroor,Tripunithura

Nettoor Maradu, Panangadu,Vyttila

Kadavantra (CITY) Maradu,Vyttila

Palarivattom(CITY) Vennala,Vyttila

Eroor Eroor,Tripunithura

Ambalamugal Trippunuthura,Eroor,Chottanikkara

Udayamperoor Eroor,Tripunithura

Ernakulam(CITY) Vyttila

Chakkarapparambu(CITY) Vennala

All city feeders are under the control of Distribution control room ,Ernakulum. Any

operations /interruptions to city feeders should be intimated to control room.

3.POWER TRANSFORMER

The transformer is the most important equipment in the substation; every

effort shall be taken to see that it is in the proper working condition as stipulated. The

periodic check as per the maintenance schedule shall be conducted and corrective action

taken without delay.

TYPES OF TRANSFORMERS

1. Step Up Transformer & Step Down Transformer - Generally used for stepping up

and down the level of power in transmission and distribution power network.

110KV Substation, Vyttila Page 7

Operating Instructions

2. Three Phase Transformer & Single Phase Transformer - Former is generally used in

three phase power system as it is cost effective than later but when size matters, it is

preferable to use bank of three single phase transformer as it is easier to transport three

single phase unit separately than one single three phase unit.

3. Electrical Power Transformer, Distribution Transformer & Instrument Transformer -

Transformer is generally used in transmission network which is normally known as ,

distribution transformer is used in distribution network and this is lower rating transformer

and & , we use for relay and protection purpose in system and in different instruments in

industries are called instrument transformer.

4. Two Winding Transformer & - Former is generally used where ratio between high and

low is greater than 2. It is cost effective to use later where the ratio between high and low

is less than 2.

5. Outdoor Transformer & Indoor Transformer - Transformers that are designed for

installing at outdoor are outdoor transformers and transformers designed for installing at

indoor are indoor transformers.

3.1 TEMPERATURE SETTING OF POWER TRANSFORMER

Trip

Wdg.

Transformer Make Fan On Oil Wdg

Temp.Alarm

Temp Temp

12.5 MVA No. I(110/11

TELK 55oc 75-80 75 85

kV)

12.5 MVA No.II

Indotek 55oc 75-80 75 85

(110/11 kV)

63 MVA (110/66 kV) TELK Manual 70-80 75 85

40 MVA (110/66 kV) TELK Manual 75-80 75 85

110KV Substation, Vyttila Page 8

Operating Instructions

3.2LOADING CAPACITY OF POWER TRANSFORMERS

Rating with Max Loading Capacity

Transformer

out fan

12.5 MVA No. I(110/11

10MVA 600 A(Incomer CT is 600A)

kV)

12.5 MVA No.II(110/11

10MVA 600 A(Incomer I CT is 600A)

kV)

63 MVA (110/66 kV) 42MVA 530 A with all fans on

330-340A(with all fan switch on is

40 MVA (110/66 kV) 30MVA

350A)

3.3 ON LOAD TAP CHANGING IN POWER TRANSFORMERS

Ensure 11kV voltage at all time except during tap restriction.

The driving mechanism is provided with a front door, which can be

opened for handle operations and control, switch operations. Fuses, power supply

ON/OFF switch, remote/local control selector‟s switches and raise/lower push button

switches are mounted on two control boards. To prevent electrical operation during

manual cranking, the hand operation interlock switches, which are mounted on the back of

the switchboard, will open, when the motor handle change over lever is turned to „Handle‟

position for inserting the hand crank in to the shaft. The mechanical stroke counter for

registering the total number of tap changing operations carried out and the heater switch

are mounted on the fuse board. Tap position of the transformer indicated in two ways, i.e.

by a mechanical position indicator, which can be seen through the window on fuse board,

in the driving mechanism and by a tap switch which conveys signals to tap position

indicator on the remote control panel.

110KV Substation, Vyttila Page 9

Operating Instructions

An indication wheel with a green zone is provided on the mechanical tap

position indicator to indicate the point of completion of tap changing operations during

manual cranking. Green zone on the indicator marks the rest position of the tap changer.

Under normal condition 12.5 MVA (110/11kV) transformers No. I

and No.II are not coupled. It will be coupled only when load in one transformer becomes

more than 600A.

Transformer taps are to be changed up and down to maintain 11 kV

voltage at distribution level. Possible tap position in which 12.5 MVA (110/11kV)

transformers can be coupled is 1-1, 2-2, 3-3, 4-4, 5-5, 6-6, 7-7, 8-8, 9-9, and 10-10.

40 MVA (110/66kV) and 63 MVA (110/66kV) transformers are kept in

coupled condition normally (bus coupler isolator I4 under closed condition). Possible tap

position in which they can be coupled is 1-1, 3-2 and 9-5.Considering the tap settings of

63 MVA and 40MVA transformers, the percentage of high voltage and tap position

indicates in name plate details is that the percentage of high voltage is same for 1-3, 1-1,

3-2, 5-3, 7-4, 9-5 taps of 63 MVA and 40 MVA respectively.

But in 63 MVA transformer diverter switch of tap changer at 5 and 7 tap

positions is cracked and it is sealed and sticked using araldite resin so only 3 taps are

applicable during coupled condition. But normally we did not change the tap and kept tap

position in one for both.

110KV Substation, Vyttila Page 10

Operating Instructions

4.STATION BATTERY

Exide make plante type Lead acid battery with 55 No‟s of cell for 110V DC supply is in

service float voltage is 123.75. Each battery will have output voltage of 2.0V-2.2V at float

mode Another operating mode available in the charger is boot mode. Battery will be

changed to this mode if it is off for some time.

PRECAUTIONS

Battery room should be well ventilated and room temperature should be

<35ºc.Specific gravity of the Lead acid cell is 1.21.

Never allow a flame, light a cigarette or store inflammable material near battery.

Do not wear rings, bracelets or any other metallic object while working on the

battery.

Normal float voltage is 2.25volts/cell.

Specific gravity of cell should be taken in every month.

Specific gravity exceeds the limit add battery water to top up.

If specific gravity is below the limit add acid to top up.

5.ELECTRICAL CIRCUIT BREAKER

Electrical Circuit Breaker is a switching device which can be operated manually as well as

automatically for controlling and protection of respectively. According to their arc

quenching medium the circuit breaker can be divided as ,SF6,VCB,MOCB etc , .

Different types of CB available in this substation are VCB(11kV) and SF6

CB(66&110kV)

110KV Substation, Vyttila Page 11

Operating Instructions

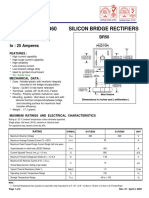

5.1 SF6 GAS PRESSURE IN DIFFERENT CIRCUIT BREAKERS

Name of Feeder

Maximum

or Transformer Make Normal Alarm Lockout

filling

Bay

110kV Line (1 0.51

Areva .64Mpa 0.54 Mpa 0.9 Mpa

KLVT) Mpa

110KV NV-VT CGL

63 MVA 0.51

Areva .64 Mpa 0.54 Mpa 0.9 Mpa

trf(110kV side) Mpa

40 MVA 0.60

ABB 0.7Mpa 0.62 Mpa 0.9 Mpa

trf(110kV side) Mpa

12.5MVA trf No. 0.60

ABB 0.7Mpa 0.62 Mpa 0.9 Mpa

1 (110kV side) Mpa

12.5MVA trf No.

BHEL 6.5 bar 5.7 bar 0.9 Mpa

11 (110kV side)

63 MVA

Siemens 6.0 bar 5.2 bar 5.0 bar 0.8 Mpa

trf(66kV side)

40 MVA 0.60

ABB 0.7Mpa 0.62 Mpa 0.8 Mpa

trf(66kV side) Mpa

66kVKLMSY- 0.60

ABB 0.7Mpa 0.62 Mpa 0.8 Mpa

VTLA No I Mpa

66kVKLMSY-

ABB 6kg/cm2 5.5kg/cm2 5kg/cm2 7.2kg/cm2

VTLA No II

66 kV VTLA-

CG 6kg/cm2 5.5kg/cm2 5kg/cm2 7.2kg/cm2

PMNR No I

66 kV VTLA-

CG 6kg/cm2 5.5kg/cm2 5kg/cm2 7.2kg/cm2

PMNR No II

66 kV VTLA-

CG 6kg/cm2 5.5kg/cm2 5kg/cm2 7.2kg/cm2

PCBL

66 kV VTLA-

CG 6kg/cm2 5.5kg/cm2 5kg/cm2 7.2kg/cm2

PTZ

110KV Substation, Vyttila Page 12

Operating Instructions

5.2NORMAL OPERATIONAL STATUS OF SUBSTATION

Incoming supply is availed through 110 kV

Kalamassery –Vyttila feeder.

110 KV New Vyttila – Vyttila feeder under switch off condition

At normal condition both 12.5MVA No: 1 & 2, 110/11 kV transformer is

condition.uncoupled condition. 11kV bus coupler under switch off and

racked out

63 MVA and 40MVA 110/66 kV transformers are coupled condition.

(66 kV bus coupler isolator I4 is closed)

66kV bus No: 1 & 2 are coupled condition.

Only half part of Perumanoor substation load (i.e. 2 transformer load

66/11kV) is feeding from this substation through Vyttila-Perumanoor

No: 1 feeder.

Vyttila-Perumanoor No: 1 & 2 feeders are coupled at 66kV substation

Perumanoor.

66kV Kalamassery- Vyttila No: 1 & 2 feeders are isolated but CB is on

condition for energizing CT

Both 66 kV Bus 1 and Bus 2 PT s are in energized condition.

66kV VTLA-PCBL and 66kV VTLA-PTZ feeders are tied at 66kV

substation Puthencruz.

Incoming supply is availed through 110 kV New Vyttila- Vyttila feeder feeder.

110 KV Kalamassery – Vyttila feeder under switch off condition

At normal condition both 12.5MVA No: 1 & 2, 110/11 kV transformer is

110KV Substation, Vyttila Page 13

Operating Instructions

condition.uncoupled condition. 11kV bus coupler under switch off and

racked out

63 MVA and 40MVA 110/66 kV transformers are coupled condition.

(66 kV bus coupler isolator I4 is closed)

66kV bus No: 1 & 2 are coupled condition.

Full load of Perumanoor substation is feeding from this substation

through Vyttila-Perumanoor No: 1feeder

Vyttila-Perumanoor No: 1 & 2 feeders are coupled at 66kV substation

Perumanoor.

66kV Kalamassery- Vyttila No: 1 & 2 feeders are isolated but CB is on

condition for energizing CT

Both 66 kV Bus 1 and Bus 2 PT s are in energized condition.

66kV VTLA-PCBL and 66kV VTLA-PTZ feeders are tied at 66kV

substation Puthencruz.

BUS SECTIONAL BREAKER

After commissioning bus sectional breaker supply condition will

be as follows

Both 110/11 kV transformers will be fed from 110 kV New

Vyttila-Vyttila feeder.

Bus sectional breaker under switched off condition.

Both 110/66 kV transformers will be fed from 110 kV KLVT

feeder.

110KV Substation, Vyttila Page 14

Operating Instructions

6.GENERAL INSTRUCTIONS TO OPERATORS

The person posted to the substation as operators should be conversant with all

operational activities of the substation during the parallel shift posting.

Carefully study the layout/single line diagram etc of the station; physically

ascertain the location of various equipment incoming and outgoing feeders etc.

Carefully study the operation/instructions manuals of transformers circuit

breakers, isolators, control panels, station battery, battery charger, L.T panels,

fire fighting equipments etc.

Gain thorough knowledge of 11kV feeders provided from the substation, the

areas to which supply is extended, details of section concerned.

Study the operational problems, if any, peculiarities of functioning of any

peculiar equipment of the station etc. in detail and make personal notes.

Get a precise idea of the wiring details of alarm annunciations related inferences

etc. of the station and control equipments and on various switches and fuses

controlling each circuit/ function.

Properly understand the mode of giving permit to work on feeder, transformers

and other equipments.

Study the safety aspect of the station, operation of fire fighting equipments etc in

detail.

Be conversant with the mode of reporting incidents of various operations to the

higher officers in time and in appropriate manner.

110KV Substation, Vyttila Page 15

Operating Instructions

7. DUTIES AND FUNCTIONS OF SHIFT OPERATORS

1. Be in complete charge of the station during shift duty.

2. Carry out the operations of the substation as per standing instructions.

3. Ensure the correctness of operations carried out by the subordinates.

4. Issue and cancel permit to work on conductors connected to the substation

equipments.

5. Maintain the operators dairy while on shifts.

6. Mention the details of operations in remark column of operator dairy.

7. Reason for the change in load should be mentioned in the remark column of log

sheet.

8. Maintain SOS while on shift including interruptions details.

9. Keep strict watch of the performance of plants and equipments in the station;

rectify abnormalities, which could be attended to immediately report to the

Assistant Executive Engineer and the Assistant Engineer in charge of

maintenance.

10.Assist the superior and the Assistant Engineer in charge of maintenance works

while on shifts.

11.Carry out any other work that may be specifically assigned to him.

110KV Substation, Vyttila Page 16

Operating Instructions

8.OPERATING INSTRUCTIONS

8.1 GENERAL

1. Whenever the HV supply (110 kV) failure occurs, the entire load on LV side may be

switched off except that of auxiliary transformer.

2. Then contact the feeding station immediately and act as per their Instruction.

3. If 11kV feeder trips on heavy fault and it again trip similarly on test charge, further test

charges may be done after contacting the concerned distribution officers.

4. Whenever any alarm is received on any feeder/ equipment or any trouble is noticed switch

off that particular equipment and investigates and report.

5. Healthy trip indication of all feeders and equipment may be tested at the beginning of each

shift

6. Maintain the voltage level, increase or decrease the taps as and when required to maintain

this.

7. When alarm on over current or winding temperature is received due to overload on the

power transformer, reduce the load and wait for resetting the alarm.

8. If winding temperature alarm is received on other than overload condition the transformer

should not be test charged. The fact may be reported to the Station Engineer.

9. If a transformer trips on overload, reduce the load and then test charge.

10.If the transformer trips on buchholz, differential protection, low oil level, control D.C.

failure etc. it should not be test charge and the Station Engineer may be intimated

immediately

110KV Substation, Vyttila Page 17

Operating Instructions

11.Transformer should be test charged under no load. Always test charge primary side breaker

first.

8.2 KEEPING RECORDS

1. Each and every operation should be recorded in detail in the operator's diary

2. At 00 hours all meter readings must be recorded in full digits.

3. Write names of shift staff legibly and clearly when taking over charge. The name of

security guard on shift also must be written.

4. Write the actual time of handing over and taking over.

5. Write the date on each top.

6. The station statistics should be recorded in the logbook by each operator during his/her

shift itself, other data's should be filled by the operator on night shift duty.

7. Reason for additional load other than normal should be mentioned in remark column of

logbook.

8. Tripping should always be noted in red ink

9. Switch off should be written in green ink.

10.The permit to work, isolation certificate and switch off should be given only after

confirming the identity of the person if request is over phone.

11.Outages of all EHT feeders should be reported during morning and evening shift before

6.30 am and 6.30 pm to the O/D, 220kV substation, Ambalamugal daily.

12.Enter station statistics on pse.kseb.in without fail.

8.3 ISSUING PERMIT TO WORK

1. No person shall be permitted to work on any equipment installed in the substation

premises or line supplied from the substation without issuing a permit to work.

2. Before issuing permit to work, the equipment/line shall be isolated from all sources of

110KV Substation, Vyttila Page 18

Operating Instructions

supply and earthed as required.

3. Non-back feeding certificates shall be obtained where ever supply from other sources is

possible.

4. Permit to work shall not be issued to an employee below the rank of a sub engineer in any

case.

5. For taking permit to work (PW) on 110 kV and 66 kV feeders and yard equipments, prior

sanction from Executive Engineer shall be obtained. In the case of lines and equipment of

66 kV and above, PW shall be issued to the concerned AE/AEE only, except during

unavoidable circumstances. During an emergency break down, in the absence of Station

Engineer, PW on yard equipment shall be taken by the operator (AE) or shall be issued to

the Sub Engineer, maintenance.

8.4 PERMIT TO WORK ON 11 kV FEEDERS

1. Switch off the VCB by tripping electrically/mechanically.

2. Ensure CB is open.

3. Rack out the VCB.

4. The control circuit plug of the CB shall remain in the control circuit jacket of the cubicle, if

the truck is not required to be moved away from the cubicle for maintenance work.

5. Open the AB switch of the concerned feeder and lock, if necessary.

6. Exhibit `Men at work'/`Permit to work' caution boards in the cubicle as well as in the feeder

structure.

7. Normally the 11 kV feeders are not earthed by the substation personnel at the time of

issuing permit and an Isolation Certificate (IC) is issued instead of PW.

8. `Permit to work'/`Isolation Certificate' card shall be prepared and the original issued to the

authorized person. If PW is issued over phone the operator should ensure the authenticity of

110KV Substation, Vyttila Page 19

Operating Instructions

the requesting person.

9. If PW is over phone a "CODE" shall invariably be assigned for the permit.

10.In case a second PW on the same feeder is to be issued, a second PW card shall be prepared

and noted in the operators' diary. Cross-reference shall be recorded in both the permit book

copies and a second `men at work' board should be exhibited on the panel. This is to avoid

charging the line when one permit to work is returned.

11.Pad locks are provided for all 11kV feeders with separate key displaying name of feeders.

Ensure that front doors of all VCB‟s are in locked condition and kept in safe custody while

issuing permits.

9. ROCEDURE FOR CHARGING THE 11kV FEEDER AFTER

THE WORK

1. When the permit to work is returned by the concerned person ensure that the Certificate

declaring that all men, materials and earthing are cleared from the line is signed by the

person to whom permit to work is issued.

2. The operator on return of PW check for any other PW issued on the line / associated cable /

AB switch.

3. If everything is clear cancel the PW and proceed to charge the line. Remove the caution

boards. Close the AB switch if it is opened, rack in the VCB. Charge the spring electrically

or manually using spring charging handle till the spring is fully charged. Ensure that the

control circuit plug is in the jacket of the cubicle.

4. The circuit breaker shall be electrically closed and check for the current in each phases by

turning the ammeter selector switch.

110KV Substation, Vyttila Page 20

Operating Instructions

5. Note down all the details in the operators diary.

10. ACTIONS TO BE TAKEN ON THE OCCURRENCE OF THE

FOLLOWING EVENTS

10.1 WHEN AN 11KV FEEDER TRIPS.

a. When an 11kV feeder trips, there will be an audible alarm in the 11kV panel.

b. Immediately accept the alarm by pressing the `Alarm Accept' push button switch in

the panel.

c. Check for `Breaker off' indication in any panel. The feeder supplied from that

panel stands now tripped. Note down the relay indication.

d. Reset the relay.

e. Charge the spring and close the breaker electrically after three minutes. (Manual

closing may be resorted to only when there is a snag in the closing system.)

f. If the fault in the feeder was momentary the line will stand charged. Otherwise the

feeder will trip again.

g. If the feeder trips again accept the alarm note down the relay indications and reset

the relay.

h. If the fault is suspected to be heavy, declare the feeder as faulty and exhibit a

feeder `Faulty' board on the VCB panel.

i. Note down all the operations with time in the operators diary.

j. Report the matter to the concerned Electrical section over phone.

k. When the maintenance personnel (Sub Engineer, AE) of the Electrical section

request for a further test charging, ascertain whether

1)the fault has been located and cleared

110KV Substation, Vyttila Page 21

Operating Instructions

2)If so, location and nature of fault

3) If not any link/ AB switch is opened, its location and other details.

l. Note down the details in the operators diary and test charge the feeder.

m. If there is any long delay in attending the fault by the electrical section open the

11kV AB switch of the concerned feeder in the substation yard and keep the feeder

up to the structure charged.

n. If the fault is due to any cable failure / LA failure inside the substation premises,

the feeder will again trip and in such case report the matter to the Station

Engineer/Maintenance sub engineer and take action for speedy rectification.

10.2 WHEN A 66KV FEEDER TRIPS.

1. When an EHT feeder trips accept the alarm and note down the relay indications.

2. Reset the relays.

3. Inspect yard equipment for abnormalities.

4. Enquire to all concerned substations and EHT consumers for any visible fault in the line at

their premises.

5. If any fault is reported at the consumer‟s premises or on the line, declare the feeder as

faulty and inform the same to the transmission line maintenance section.

6. If everything is normal, test charge the feeder.

7. If the feeder again trips, note down the relay indications and declare the feeder as faulty.

8. Inform the matter to transmission line maintenance section.

10.3 WHEN 110KV FEEDER TRIPS

1. Switch off all outgoing 11kV feeders except auxiliary feeder and contact 220kV

substation Kalamassery. If supply failed from Kalamassery end due to a grid failure, wait

till the supply is resumed and take the auxiliary supply from 110 kV Substation, New

110KV Substation, Vyttila Page 22

Operating Instructions

Vyttila through Gandhi square Feeder. When the supply gets restored, contact Kalamassery

Substation and normalize the main supply and auxiliary supply. Also inform 66 kV

substations Perumanoor, Panampilly Nagar and Puthencruz to normalize the supply.

2. If it takes considerable time for resuming the 110kV supply from KLSY, arrange to avail

supply from 110 KV NV-VT after contacting 110kv New vyttila substation(vise-versa)

3. If it takes considerable time for resuming both 110kV supply, arrange to avail supply from

standby 66kV feeders. The 66kV supply can be availed from the standby 66kV

Kalamassery- Vyttila No. I and II feeders as per the instruction from 220kV substation,

Kalamassery. The feeders are to be coupled at this end.

Before charging 66 kV Kalamassery –Vyttila 1 and 2 feeders, it must be ensure that the

110 kV Kalamassery –Vyttila feeder is under switched off condition.

4. Close 66kv line isolators of 66kV KL-VT No. I and II feeders and charge the feeders.

5. In order to reduce load, change over 66kV Perumanoor substation and Panampilly Nagar

substation to 110 kV Substation, Kaloor via 66kV Kaloor -Marine drive GIS UG cable

feeder.

6. Arrange maximum possible back feeding if required.

11. SPECIFIC INSTRUCTIONS

11.1 FOR ISSUING NBC (No back feeding Certificate) on 110kVKalamassery-Vyttila

Feeder

1. Switched on 110 kV NVVT feeder and simultaneously switched off 110kV KL-VT

110KV Substation, Vyttila Page 23

Operating Instructions

feeder Switch on as per the instruction of Operator,220kV Substation, Kalamassery and

Brahmapuram

2. Open line isolator IL1 and issue NBC.

3. Earth should be provided only if specifically instructed and see that the same is removed

before the line is charged.

11.2 ON RETURN OF NBC on 110kV Kalamassery-Vyttila line after giving earthing

removal confirmation

1. Close the line isolator IL1 and charge 110kV KL-VY feeder.

11.3 66KV KALAMASSERY-VYTTILA 1&2 STANDBY FEEDER

As on 16.07.2015, LILO arrangement at 66KV s/s Kakkanadu is changed to tap to 66KV-

KL-VT No.1&2 feeders.

KLVT No.1 is named as KLNP up to 66 kV substation,Thrikkakkara and from

thrikkakkara to vyttilait is NPVT.

CARE SHOULD BE TAKEN

I. Permit work on 66 KV KL-VT No:2 feeder should be given after ensuring NBC from

Vyttila, Kakkanadu (tap 2) and HMT,NBC at Kalamassery after switch off, isolate and

earthing confirmation from Kakkanadu, Vyttila and Kalamassery.

II. Permit work on 66 KV KL-VT No.1 feeder – A portion with Kakkanadu- Vyttila does not

exist because in No.1 feeder permit can be availed only in Thrikkakara-Vyttila portion.

110KV Substation, Vyttila Page 24

Operating Instructions

11.4 FOR AVAILING SUPPLY FROM STAND BY 66kV VYTTILA FEEDER 1&2

If 110kV KL-VY feeder trips having any Permit to Work, then avail standby 66kV KL-

VT No.II feeder

1. Ensure 110Kv KL-VT feeder is switched off AND line isolator is opened.

2. Charge SF6 CB of 66kV KL-VTNo:II feeder as per the instruction of Operator, 220kV

substation, Kalamassery

3. Before normalizing the feeding, switch off the standby 66KV KL-VT .

4. No.1&2 feeder and open 66KV line isolator I23

Normally 66KV KL-VT-1 is feeding to Thrikakkara. The standby supply can be availed

from 66KV KL-VT-1&2 feeders simultaneously limiting the overloading of 1&2 feeder.

Both feeders can be availed at one bus by doing Bus splitting arrangement

11.7 FOR ISOLATING 66kV BUS

1. 66kV Bus 1

Open isolators I 5(bus 1 isolator of 40 MVA, I 7(bus 1 isolator of KL-VT No.1,I 9(bus 1

isolator of KL-VTNo. 2,I 15(bus 1 isolator of PCBL) , I 17(cross bus 1 isolator of PTZ and

PMNR1 and I25(bus 1 isolator of PMNR2).

2. 66kV Bus 2

Open isolators I 6(bus 2 isolator of 63MVA),I 8(bus 2 isolator of KL-VT No.1 ),I 10(bus 2

isolator of KL-VT No.2),I 16(bus 2 isolator 0f PCBL) , I 18 (cross bus 2 isolator of PTZ and

PMNR1)and I26(bus 1 isolator of PMNR2.

11.8 For AVAILING BOTH 110KV SUPPLY

1. 11kv feeders are feed from 110kv NV-VY feeder , remaining station load from 110kv KL-

110KV Substation, Vyttila Page 25

Operating Instructions

VT feeder

1.1 Switch off all 11kv feeder except AUXILIARY .

1.2 Switch off primary side CB of both 12.5 ,MVA transformer .

1.3 Open the Cross sectional isolator IN 5( CB is not installed ).

1.4 Close line Isolator of 110kv NV-VT feeder.

1.5 Charge 110kv NV-VT Feeder

1.6 Charge both primary side CB of 12.5 MVA Transformer

1.7 Charge all 11kv feeder

110KV Substation, Vyttila Page 26

Operating Instructions

11.9 SHUT DOWN OF TRANSFORMERS FOR MAINTENANCE/ INSPECTION

WORKS

1. 40MVA Transformer

a. S/off 110kV side and 66kV side SF6 CB of 40 MVA Transformer

b. Open 66 kV Bus isolator I5 and bus coupler isolator I4

c. Open 110 kV transformer isolator I1.

2. 63MVA Transformer

a. S/off 110kV and 66kV side SF6 CB of 63MVA Transformer

b. Open 66kV side Bus isolator I6 and bus coupler isolator I4

c. Open 110kV isolator, I2.

3. 12.5MVA Transformer

a. S/off and rack out the VCB of respective incomer.

b. S/off 110kV SF6 CB of transformer.

c. Open the respective IN1/IN2.

d. Reached out incomer PT.

4. Auxiliary Transformer

a. Change over station auxiliary to the LT supply from 110kV New Vyttila Substation.

This auxiliary stand by supply from Gandhi square feeder (LT supply from OEN

transformer).

b. S/off and rack out the VCB of 11kV auxiliary feeder.

Remove the LT fuse of auxiliary transformer.

110KV Substation, Vyttila Page 27

Operating Instructions

OTHERS

1. The control panels, meters, telephones, switch boxes, relays ,battery etc should be

cleaned daily during the 1st shift by the shift staff including overseer and operator.

2. Operators are to inspect the yard equipments periodically during shift duty around the

yard as often as possible especially during peak hours and listen for any change in usual

sound, see for loose connections, verify oil level etc. and report to the station engineer if

there is any abnormality.

3. Operators are to report all messages to the Station Engineer and get his initials in the

message book as soon as the messages are received.

12. 66kV BUS PT

66kV panels are having distance relays. It will be working only if current from CT and

corresponding voltage from PT is given to it. 66kV Bus No.1 and Bus No.2 is having separate

PTs. If the two 66kV buses are in coupled condition then doesn‟t matter which PT connection is

given to each feeder. But if the 66kV Bus No.1 and Bus No.2 are not in coupled condition then

care should be given to select the actual PT of the feeder.PT selection switches are provided at

the backside of feeder panels. The feeders which are fed from bus 1 should be put in bus 1 PT

itself.

110KV Substation, Vyttila Page 28

Operating Instructions

11.5 PERMIT TO WORK ON 66kV FEEDERS.

1. Permit to work should be given to authorized persons on emergencies and on prior

sanction from competent authorities.

2. The affected substations, EHT consumers and the press should be informed in

advance.

3. Obtain NBC on respective feeders.

Care should be taken while giving permit work to 66kV VTLA-PTZ No1 and

66kV VTLA-PMNR No.1 feeder since cross bus exists between both.

a. For 66kV Vyttila- Puthencruz feeder

Obtain NBC from 66kV substation Puthencruz and the EHT consumer, M/S

HOC, VTLA-Puthencruz No.1.

Earthing confirmation from Puthencruz after switch off isolate and earthing at

Vyttila.

b. For 66kV Vyttila- PCBL feeder

Obtain NBC from 66kV substation and the EHT consumer viz, M/S HOC and

PCBL.

Earthing confirmation from PCBL after switch off isolate and earthing at

PCBL.

c. For VTLA-PTZ No.2 feeders PCBL-PTZ portion

Obtain NBC from PCBL and PTZ s/s

Earthing to be provided at PCBL and PTZ s/s

d. For 66kV Perumanoor No:I feeder

110KV Substation, Vyttila Page 29

Operating Instructions

Obtain NBC from 66kV Perumanoor substation, earthing to be provided after

switch off isolate and earthing at our end.

e. For 66kV Perumanoor No:II feeder

Obtain NBC from 66kV Substation Perumanoor and Panampilly Nagar

substations according to the portion of work.

For Vyttila- Panampilly Nagar portion obtain NBC from 66kV Substation Panampilly

Nagar and for Panampilly Nagar – Perumanoor portion obtain NBC from 66kV Substation

Panampilly Nagar and Perumanoor.

Since 66kV Substation Panampilly Nagar is not having line circuit breaker, s/off the feeder

at Vyttila end before opening the line isolator at Panampilly Nagar Substation.

1. Switch off and isolate the respective feeder.

2. Provide earth on both sides of feeder. Note that earthing should be given first at feeding

end.

3. Issue permit to work.

11.6 ON RETURN OF PERMIT WORK

1. Remove all the earthing provided on the feeder and confirm.

2. Close the isolators and charge the circuit breaker of the respective feeder.

3. Return the NBC.

12.1 PROCEDURE FOR SELECTING 66kV BUS PT

The relay of PT which is live will be in flagged condition. In order to change the Bus PT

selection

1. The switch below the un flagged relay should be put to the reverse position first.

2. Immediately after that put the other switch to reverse position.

3. Now both relays will be in flagged condition. Reset both the relays. The Relay

corresponding to the PT which is not live will get reset.

110KV Substation, Vyttila Page 30

Operating Instructions

ALARM:-

When a fault occurs, Fault Annunciator draws the attention of the

supervisor with an indication flag and audible alarm. The audible alarm can be stopped, by

pressing the alarm cancel push button. However, the red painted flag remains to show the

continuation of the fault. It is possible to reset the flag by means of lever on the indicator.

But if the fault persists the flag cannot be reset.

PROTECTION RELAYS PRESENT AT FEEDER CONTROL AND RELAY PANEL

AND TRANSFORMER CONTROL AND RELAY PANEL

NAME OF FEEDER/TRANSFORMER PANEL MAIN PROTECTION RELAYS

MAKE/TYPE

Distance relay

TOSHIBA-GRZ100

Operation:To reset the relay

press”RESET” key more than three

110KV KLMSY-VTLA times on the “latest fault” screen

,then trip LED continues to lit.

Backup relay

AREVA-CDD

Cable Differential relay

110KV NV-VT

110KV Substation, Vyttila Page 31

Operating Instructions

Distance relay

SIFANG-CSC162

66KV KLMSY-VTLA NO:1

Backup relay

EASUN REYROLLE-2TJM12

Distance relay

SIFANG-CSC162

66KV KLMSY-VTLA NO:2 Backup relay

EASUN REYROLLE-2TJM12

Distance relay

SIFANG-CSC162

66KV VTLA-PMNR NO:1 Backup relay

EASUN REYROLLE-2TJM12

Distance relay

SIFANG-CSC162

66KV VTLA-PMNR NO:2 Backup relay

EASUN REYROLLE-2TJM12

Distance relay

SIFANG-CSC162

66KV VTLA-PCBL

Backup relay

EASUN REYROLLE-2TJM12

Distance relay

ALSTOM-P40

66KV VTLA-PTZ

Backup relay

ALSTOM-P14DB11A2C0500A

110KV Substation, Vyttila Page 32

Operating Instructions

Auxiliary relay

ALIND

REF relay

ALIND-TDZA10

12.5MVA 110/11KV TRANSFORMER NO.1

Backup relay

ALIND-TSRA111

Differential relay

SEL SEL-787

Auxiliary relay

ALIND

REF relay

ALIND-TDZA10

12.5MVA 110/11KV TRANSFORMER NO.2

Backup relay

ALIND-TSRA111

Differential relay

Genisis MIB202

40MVA 110/66KV TRANSFORMER NO:1 Backup relay

Auxiliary relay

ALIND

63MVA 110/66KV TRANSFORMER NO:2

Backup relay

ALIND-TSRA111

Backup relay

40MVA 110/66KV TRANSFORMER (66KV side)

SEL-SEL-315

Backup relay

63MVA 110/66KV TRANSFORMER (66KV side)

ALIND-TSRA111

110KV Substation, Vyttila Page 33

Operating Instructions

13 INTRODUCTION TO RELAYS AND POWER

EQUIPMENTS IN CONTROL ROOM AND YARD

13.1 POWER TRANSFORMER

Power transformers are classified

Base on Application

Generator Transformers.

11/110KV, 11/220KV

Transformers used in Major Substations

(Auto Transformers 400/ 220 KV, 220/110KV, 110/66 KV)

Transformers used for Sub Transmission

110/11 KV, 66/11KV.

Distribution Transformers 11/433V

13.2. PROTECTION OF POWER TRANSFORMER

13.2.1 BUCHHOLZ PROTECTION

In oil immersed transformers, limited arcing under oil originates from poor electrical

connections of conductors and core faults. This might not bedetectable by differential or

ref relay. Buchholz protection gives alarm and tripping during heavy faults due to P/F and

E/F.

The gas actuated Buchholz Relay is a protective device designed to give

indication of faults occurring in oil filled conservator type transformer, on load tap

changers, capacitors etc.

110KV Substation, Vyttila Page 34

Operating Instructions

All types of faults occurring within oil filled transformer are accompanied

by gas generation. This phenomenon has been effectively utilized by Buchholz Relays to

provide the best-known protection arrangement for transformers.

The high sensitivity and capability of the relay has been successfully

proved to detect faults stated below:-

o Defective core laminations.

o Break down of core insulations.

o Local overheating of windings.

o Phase to phase, phase to earth or internal short circuits.

o Insulation breakdown of major nature.

The gas collected in the relay can, from its colour, odour and

compositions, indicate the nature and location of faults up to a greater extent.

FAULT INFERENCE

By studying the nature of gas collected, fault inference can be made as

explained below:

Sl.No. Name of gas Probable fault

1 Colourless and Odourless. Air trapped in oil or insulations.

2 Grayish white with pungent Overheating of insulations, Press

Smell, non-inflammable board etc.

3 Yellowish inflammable Decomposing of wood insulations

4 Dark grey inflammable. Flash over in oil. Excessive over

110KV Substation, Vyttila Page 35

Operating Instructions

13.2.2 EARTH FAULT PROTECTION

REF protection is a unit protection scheme for one winding of the transformer. It is

generally of the high impedance type. The residual current of three line current

transformers is balanced against the output of the neutral conductor.

It is an instantaneous relay with low settings. The whole fault current is measured. Even if

the prospective current level decreases as fault positions progress nearer the neutral end of

the winding, with a low effective setting a large percentage of the winding can be covered.

The main windings and the core and other accessories are mostly oil immersed.

Therefore this equipment develops fault rarely than over head

Lines, but if a fault occur in a transformer. It costs much more time and money than that

required to rectify a fault on the line. The fault on a transformer should there be cleared

fast to protect the equipment or minimize the damage.

TYPES OF FAULT

Through faults

Internal faults

THROUGH FAULTS

o Over current protection: it covers transformer, station, bus bar, and a protection.

o Overload protection : detected through thermal overload protection

o Oil temperature protection

o Winding temperature protection

110KV Substation, Vyttila Page 36

Operating Instructions

Oil temp indicator alarm tripping (75-85)

(85-95)

Winding temperature alarm tripping (80-90)

indicator (90-100)

Cooling fans starting stopping (55-60)

(60-65)

13.2.3 DIFFERENTIAL PROTECTION

A differential relay responds to a vector difference between two or more similar electrical

quantities. Differential protection is a unit protection .The protected zone is determined by

location of CTs. The vector difference is achieved by suitable connection of current

transformer or voltage transformer.

APPLICATION

Protection of generator, protection of generator transformer unit

Protection of transformer

Protection of transmission line by pilot wire protection

Protection of transmission line by phase comparison

Protection of large motors

Bus zone protection

13.2.4 BACK UP O/C AND E/F PROTECTION

This acts as backup relay for downstream side feeder uncleared faults and also acts as

backup relays of transformer relays.

13.2.5 OIL HEATING PROTECTION

Oil thermometer gives alarm and trip for persisting and high oil temperatures.

110KV Substation, Vyttila Page 37

Operating Instructions

Long time constant delays oil for getting true winding temperature and hence incorrect

replica used also to start cooler fans.

13.2.6 WINDING TEMPERATURE PROTECTION

Sensing through bulb and heating through resistor connected from CT sec. gives hot spot

temperature. Usually shows higher reading during short time heavy overload than long

time higher overload.

BREATHER

OPERATION:-

Whenever the temperature of the transformer oil varies either due to

variations in transformer loading or due to variation in temperature of surrounding air,

there will be corresponding change in level of oil in conservator. This change of level of

oil causes the transformer to perform breathing action. To remove moisture and dust from

the air breathed thus, silica gel and dust filler are provided in the breathing path.

Air while passing through oil pot, dust will be filtered and while passing

through silica gel, moisture also will be removed to allow only dry air to go into the

transformer. The oil pot also performs another important function, which prevents the

atmospheric air to come into contact with silica gel when the transformer is not performing

breathing action.

The container is filled with a mixture of white and blue gels in the ratio

3:1. As the blue gel absorbs moisture its colour changes to whitish pink.

110KV Substation, Vyttila Page 38

Operating Instructions

14. INSTRUMENT TRANSFORMER

14.1 CURRENT TRANSFORMER

CT is a current measuring device. Primary winding is connected in series with the

load. The ammeter, watt meter, energy meter, relays etc. are connected across secondary.

When the Load current is passed through primary winding a flux is produced in the

core (The mmf is proportional to Primary current and number of turns).The secondary

winding is wound on the core and an emf is induced in it.

Since the secondary is shorted through the low impedance (Ammeter) , a current is

circulated in the circuit. The Secondary Ampere turn is called the counter ampere turn. If

the secondary is opened when primary current is flowing there will not be any counter

ampere turns. The primary mmf will set up an abnormally high flux in the core which will

produce high voltage across the secondary terminals.Therefore no fuses shall be provided

at the secondary of a CT. The secondary should be short circuited while removing the

meters.

14.2 POTENTIAL TRANSFORMER

PT is a voltage measuring device. Potential transformers (PT) (also called voltage

transformers (VT)) are a parallel connected type of instrument transformer. They are

designed to present negligible load to the supply being measured and have an

accurate voltage ratio and phase relationship to enable accurate secondary connected

metering.

Capacitor Voltage Transformer

CVT s are single phase units ,connected in HV net works between Line and Ground .

It is used for HV Metering ,Protection, and as a Coupling Element for Carrier

Communication System. It Consists of Capacitor Voltage Dividers and a Transformer

110KV Substation, Vyttila Page 39

Operating Instructions

15. SF6 CIRCUIT BREAKER

15.1 MAIN PARTS

1) Interrupter

Fixed contact,

Moving Contact,

Puffer cylinder,

Current carrying conductors,

Teflon nozzle

and SF6 Gas etc housed in the Interrupter porcelain

2) Support porcelain

Hollow porcelain to provide insulation for the interrupter and surround the

operating rod.

3) Insulation Operating rod

It is used to move the moving contact.

It should have good mechanical strength and dielectric strength.

4) Operating Mechanism

Trip coil

Closing coil

operating cylinder

operating piston,

control valves,

Pilot valves, auxiliary switches etc.

Terminal Blocks

Gas Density Detector, Space Heater etc

110KV Substation, Vyttila Page 40

Operating Instructions

15.2 WORKING PRINIPLE

When a circuit is interrupted an arc is formed In between the fixed and

moving contacts of the circuit breaker. In Circuit breakers, the electric arc is a self-

sustained discharge of Electricity between the two contacts in a dielectric medium .When

contacts are separated the dielectric medium gets ionized mainly due to the intense heat

produced during separation and dielectric medium thus changes into a plasma state. The

dielectric medium which formerly a nonconductor becomes a good conductor .The arc

discharge is thus conduction of Electricity through this ionized dielectric medium.

The unique feature of VCBs is that no arc extinguishing medium employed in it to

quench the arc. Vacuum circuit breakers are self-arc extinguishing type. Arc cannot persist

in an ideal vacuum. When the current carrying contacts are separated, ionized metal vapors

are released from the contacts tips giving rise to plasma, thus supporting arc. During the

decreasing mode of the current wave, the rate of release of vapour decreases. At the

current zero collapse of ionization and vapour condensation is very fast regaining

dielectric strength of the arc gap and the arc is self-extinguished.

The interrupting process is characterized by an arc which appears for a limited

period of time between the main contacts. Interruption of the circuit occurs after current

zero, the fixed contact and moving contact being pulled apart by the operating mechanism.

By this movement, the quenching medium inside the cylinder is forced to flow through the

contact system, and it rapidly removes the energy converted within the arc plasma and

changes the path between the open contacts into an insulating gap.

110KV Substation, Vyttila Page 41

Operating Instructions

16.ON LOAD TAPCHANGER (OLTC)

OLTC facilitates changing of Tap connections without interruption of Supply.

Taps are provided at the neutral end of the three phase Star connected HV windings. For

Three phase Delta connected HV windings taps are provided at the line ends. Taps are

connected at the line end of the single phase auto Transformer banks.

OLTC CONSISTS OF

1) Diverter switch.

2) Tap Selector.

3) Driving Mechanism.

4) Remote Tap Changer Control Panel.

Diverter Switch – Separate Oil compartment. On load circuit breaking taking

place with in 150 milli second.

Consists of

1) Two concentric Insulation Cylinders,

2) Contact Compartment (Fixed and moving contacts (Copper tungsten)

named as ODD and EVEN).Movement of contact from ODD to EVEN AND

EVEN to ODD.

3) Transition Resistors (Nichrome).

Operating Time - 150 milli Seconds.

Operating Force - Charged Spring

Tap Selector–Immersed in Transformer tank. Off load tap changing

operation taking place.

The tap lead wires from the tap winding of the Transformer are brought and

terminated at the fixed contacts of the tap selector.

There are two Set of Rotary Switches for Tap Selector.

110KV Substation, Vyttila Page 42

Operating Instructions

The ODD numbered tappings are connected to one Switch.

The EVEN Numbered tapings are connected to another Switch

The two Switches are operated according to the operation of diverter switch.

The tap selector operates under No Load Condition

17.BATTERY

Battery is the heart of power station. It provides the ultimate and final DC back- up

for operating emergency equipments which power the turbo generators. DC power is

required for operation of all switchgears, protection relays, indicating lamps and

annunciators.Switchgear and relays will not operate causing extensive damage to

transformers and power lines.

18. RELAY FAMILY

1. Based on actuating parameter

o Current relays

o Voltage relays

o Frequency relays

o Power relays

2. Electromagnetic Based on characteristic

o Definite time relays

o Inverse time relays with define minimum time(IDMT)

o Instantaneous relays

o IDMT with inst.

o Stepped characteristic

o Programme switches

o Voltage restraint over current relay

110KV Substation, Vyttila Page 43

Operating Instructions

3. Static Based on logic

o Differential

o Unbalance

o Neutral displacement

o Directional

o Restricted earth fault

o Over fluxing

o Distance schemes

o Bus bar protection

o Reverse power relays

o Loss of excitation

o Negative phase sequence relays

4. Mechanical

o Thermal

OT Trip

WT Trip

Bearing temperature trip

o Float type

Buchholz

OSR

PRV

Water level control

o Pressure switches

o Mechanical inter locks

o Pole discrepancy relay

110KV Substation, Vyttila Page 44

Operating Instructions

19.TYPES OF RELAY

19.1 DIRECTIONAL PHASE FAULT OVERCURRENT RELAY

When fault currents can flow in both directions through relay location, it may be necessary

to make the response of the relay directional by the introduction of a directional control

facility. The facility is provided by use additional voltage inputs to the relay.

19.2 DISTANCE RELAY

Distance relay is relaying device which measures impedance or reactance of the line which

are proportional to distance. Distance relay suitable for long EHV lines and is not normally

applied for lines less than 5 miles.

ADVANTAGES

Fast fault clearance

Fault coverage independent of source impedance variation

Provides primary and backup in single unit

Can be adapted to work like unit protection with signaling channel

PRINCIPLE

A distance relay compares the currents and voltages at the relaying point with current

providing the operating torque and the voltage provides the restraining torque. In other

words an impedance relay is a voltage restrained over current relay.

19.2.1TYPES OF DISTANCE RELAYS

a. Impedance relay

b. Reactance relay

c. Mho relay

d. Modified impedance relay

110KV Substation, Vyttila Page 45

Operating Instructions

ADDITIONAL FEATURES IN DISTANCE SCHEME

1) Power swing blocking relay

2) VT fuse failure relay

3) Switch onto fault relay

4) Fault locator

5) Auto-reclosing scheme

6) Carrier communication scheme

110KV Substation, Vyttila Page 46

Operating Instructions

CHAKKARAPARAMBU RELAY SETING

`CGI 14C

Current relay

CGI 14C Fault No=01 Fault No. & fault trip counter

Fault records Tcntr=-16 indication

Fault type indication

I>:IL1 “I >” for IDMT fault &

I>>:

“I >>” for high set fault

Date and time indication on

Flt;26/2/10

18;45;04;285

which fault occurred

Secondary phase fault current

IL1(sec):000.08 “IL1(R phase)” & “IL2 (Y

IL2(sec):000.06 phase)” indication

Secondary phase fault current

IL3(sec):000.08 “IL3(B phase)” & Earth fault

IL0(sec):000.06 current “Io” indication

Primary phase fault current

IL1(pri):00000 “IL1(R phase)” & “IL2 (Y

IL2(pri):00000 phase)” indication

Primary phase fault current

IL3(pri):00000 “IL3(B phase)” & Earth fault

I0(pri) :00006 current “Io” indication

Fault duration

Fault duration indication

000.000sec

110KV Substation, Vyttila Page 47

Operating Instructions

20. ISOLATOR

Circuit Breaker always trip the circuit but open contacts of breaker cannot be visible

physically from outside of the breaker and that is why it is recommended not to touch any

electrical circuit just by switching off the . So for better safety there must be some

arrangement so that one can see open condition of the section of the circuit before

touching it. Isolator is a mechanical switch which isolates a part of circuit from system as

when required. Electrical isolators separate a part of the system from rest for safe

maintenance.

Isolator is a mechanical switching device capable of opening and closing a circuit

when a negligible current is broken or made or when no significant voltage across the

terminals of each pole exists. Isolators shall be capable of carrying current under normal

conditions and for a specified time short circuit currents. In open position, the isolating

shall provide an isolating distance between the terminals.

20.1 EARTHING SWITCH

It is a mechanical switching device for earthing a part of the circuit and capable of

withstanding short circuit current for a specified time

20.2 INTERLOCKING DEVICE.

It is a device which makes the operation of an isolator or earthing switch depending

upon the position or operation of a circuit breaker or an isolator

20.3 AUXILIARY CONTACT

A contact in the auxiliary circuit which is mechanically operated by the isolator or

earthing switch, while closing and opening.

20.4 RATED VOLTAGE

The rated voltage of an isolator or earthing switch indicates the upper limit of the

highest voltage of the system for which it is designed. Normal standard values are 3.6kv,

12kv, 36kv, 72.5kv, 123kv, 145kv, 245kv and 420kv.

110KV Substation, Vyttila Page 48

Operating Instructions

20.5 RATED NORMAL CURRENT

The standard values of rated normal current are 200 A,400 A,630 A,800 A,1250

A,1600 A,2000 A,2500 A,3150 A,4000 A,5000 A,6300 A.

20.6 RATED SHORT TIME WITHSTAND CURRENT

The standard values are 8 KA,10 KA,12.5 KA,16 KA,20 KA,25KA,31.5 KA,40

KA,50 KA,63 KA,80 KA,100 KA.

When an earthing switch is combined with an isolator as a single unit, both shall

have the same rated short time withstand current unless otherwise specified.

20.7 DURATION OF SHORT CIRCUIT CURRENT

The standard value of rated duration of short time withstands current for isolator and

earthing switch is normally 1sec. A value of 3 sec is also sometimes specified.

21 .LOAD – BREAK SWITCHES

These are load interrupters combined with isolating switches, enabling the desired

breaking of load currents without circuit breakers. Generally these devices are auxiliary in

nature. The load interruption is achieved by one of the following

(i) Insertion of a resistor in the circuit following opening of the main switch contact

and interruption of the current drawn between the arcing contacts in the air.

(ii) Use of air blasting and other gases to effectively lengthen the arc resulting in the

main contacts.

(iii) Use of an interrupter parallel to the main contacts just prior to the opening, and

interrupting in this auxiliary chamber after the main contacts are open.

110KV Substation, Vyttila Page 49

Operating Instructions

22 EARTHING

Earthing is to provide a Zero potential surface in and around and under the area where

the electrical equipment is installed or erected. The non-current carrying parts of the

electrical equipment is connected to the general mass of the earth which prevents the

appearance of dangerous voltage on the enclosures and helps to provide safety to working

staff and public.

22.1 EARTH GRID

A system of the grounding electrodes which consists of inter-connected conductors

buried in the earth to provide a common ground for electrical devices and metallic

structures

22.2 EARTH MAT

A grounding system formed by a grid of horizontally buried conductors and which

serves to dissipate the earth fault current to earth and as an equipotential bonding

conductor system.

22.3 SUBSTATION EARTHING

Power system earthing has several important purposes. In the case of an ungrounded

system, it will be inherently coupled capacitively to the earth through the system

capacitance. During a ground fault the charging current will rise to three times the zero

sequence current, developing a very high value of over voltage. So the main intention of

earthing is to limit this transient over voltage caused by restricting ground faults, to the

level that the equipment is designed to withstand, which will be normally about 250% of

the rated voltage.

Proper system earthing will give a high degree of protection against steep wave

front surges entering the station and passing to earth through its grounding system. Under

fault conditions, the flow of current to earth will result in gradients within and around the

110KV Substation, Vyttila Page 50

Operating Instructions

station. Unless earthing system are designed carefully, the maximum gradient along the

surface may be great enough to endanger a man walking in the vicinity.

22.4 IMPORTANCE OF EARTHING

The earthing is provided for

Safety of Personnel

Prevent or at least minimize damage to equipment as a result of flow of heavy fault

currents.

Improve reliability of Power supply

To keep the earth resistance as low as possible in order to achieve safe step and

touch voltages, an earth mat shall be buried at the specified depths below ground

and the mat shall be provided with grounding rods at suitable points. All non-current

carrying parts at the Substation shall be connected to this grid so as to ensure that

under fault conditions, none of these parts are at a higher potential than the

grounding grid.

The earth resistance shall be as low as possible and shall not exceed the following limits:

Power Stations - 0.5 Ohms

EHT Substations - 1.0 Ohms

33KV Stations - 2.0 Ohms

D/t Structures - 5.0 Ohms

Domestic installations - 10.0 Ohms

Tower foot resistance - 10.0 Ohms

22.5 SPECIFICATION FOR EARTHING SYSTEM EHT SUBSTATION

The supporting structures, C.T. chambers, P.T. tanks, Cable glands etc., are to be

connected to earth.

110KV Substation, Vyttila Page 51

Operating Instructions

1. POWER TRANSFORMERS:

A) The transformer body or tank is directly connected to earth grid. In addition,

there should be direct connection from the tank to the earth side of the lightning

arresters.

B) The transformer track rail should be earthed separately.

C) The neutral bushing is earthed by a separate connection to the earth grid.

2. POTENTIAL AND CURRENT TRANSFORMERS:

The bases of the CTs and PTs. are to be earthed. All bolted cover plates of the

bushing are also to be connected the earth grid.

3. LIGHTNING ARRESTERS:

The bases of the L.As are to be earthed with conductors as short and straight as

Possible (for reducing impedance). Each L.A. should have individual earth rods,

which are in turn connected to earth grid.

4. CIRCUIT BREAKERS:

The supporting structures, C.T. chambers, P.T. tanks, Cable glands etc., are to be

connected to earth.

5. OTHER EQUIPMENT‟S:

All equipment‟s, structures, and metallic frames of switches and isolators are to be

earthed separately.

6. FENCING:

Providing separate earth or connecting to the station earth depends upon the distance

of the fence the station earth. If the distance is within feet, an inter-connection made

to the station earth. If not, the metallic fences are earthed by means of earth rods

spaced at not more than 200 feet.

7. GROUND WIRES:

The ground wires over the station are connected to the station earth. In order that the

station earth potentials during fault conditions are not applied to transmission line

110KV Substation, Vyttila Page 52

Operating Instructions

ground wires and towers, all ground wires coming to the stations shall be broken on

the first tower external to station by means of strain disc insulators.

23. SAFETY

7 steps of safety

1. Permission

2. Isolation

3. Notice

4. Lock

5. Inspection

6. Testing

7. Earthing

23.1 SAFE WORK PRACTICES

BEFORE STARTING WORK…

De-energize, Lock, Tag and Test all circuits of 50 volts or more

De-energize all Power Sources

Disconnect from all electric energy sources Control circuit devices such as

push buttons

selector switches

interlocks

May not be used as the sole means for de-energizing circuits or equipment.

Lock & Tag all Sources

Place Lock & Tag on each disconnecting means used to de-energize circuits

Attach Lock so as to prevent operating the disconnecting means

Place Tag with each Lock

If a Lock cannot be applied

110KV Substation, Vyttila Page 53

Operating Instructions

A tag used without a lock must be supplemented by at least one additional safety

measure that provides a level of safety equal to that of a lock.

Removal of an isolating circuit element such as a fuse

Blocking of a controlling switch

Opening of an extra disconnecting device

Release Stored energy before starting work

Discharge all Capacitors &

Short-Circuit & Ground all high capacitance elements

Verify the system is De-energized

Operate the equipment controls to check that equipment cannot be restarted

Use test equipment to the test circuits & electrical parts for voltage and

current.

110KV Substation, Vyttila Page 54

You might also like

- J3520.03 Ltac Panel R3 - Ab 06.03.20Document83 pagesJ3520.03 Ltac Panel R3 - Ab 06.03.20dhinakaranNo ratings yet

- 12kV VCB-ABB India PVT LTDDocument18 pages12kV VCB-ABB India PVT LTDSuMit MisHraNo ratings yet

- Crest SLDDocument1 pageCrest SLDSECI 2020No ratings yet

- 20150402522.electrical SLD-Model PDFDocument1 page20150402522.electrical SLD-Model PDFjaianit89No ratings yet

- Ltbe1 With Blk222Document12 pagesLtbe1 With Blk222rpshvjuNo ratings yet

- 29.voltage Flicker Compensation Using STATCOMDocument6 pages29.voltage Flicker Compensation Using STATCOMdeepu227No ratings yet

- Cable Diff. 11,22KV Specification 4-4-2006Document3 pagesCable Diff. 11,22KV Specification 4-4-2006Mouhemed MouhaNo ratings yet

- L&T MN RelaysDocument6 pagesL&T MN RelaysYogeshJaiswalNo ratings yet

- 765kV Greater Noida-Mainpuri Line - Rev 0Document24 pages765kV Greater Noida-Mainpuri Line - Rev 0Abhisek SurNo ratings yet

- Traction - PKPattanaik-2019Document7 pagesTraction - PKPattanaik-2019Guru MishraNo ratings yet

- 12493-500kva CRT With Oltc-R2Document8 pages12493-500kva CRT With Oltc-R2Hari HaranNo ratings yet

- Approved - 216 KV LA - GTP & DrgsDocument22 pagesApproved - 216 KV LA - GTP & DrgsGuru MishraNo ratings yet

- Solar RadiationDocument30 pagesSolar RadiationHiren Kumar0% (1)

- 4.multi Panel CRPDocument59 pages4.multi Panel CRPraj_stuff006No ratings yet

- Downloaded File 30Document21 pagesDownloaded File 30EBENo ratings yet

- ElectricalDocument14 pagesElectricalbharat_ravulapalliNo ratings yet

- Railway CT Specification for AC Traction SubstationsDocument29 pagesRailway CT Specification for AC Traction SubstationsGurmeet SinghNo ratings yet

- 110kV CRP Trafo SchemeDocument31 pages110kV CRP Trafo SchememaheshNo ratings yet

- Schematic Diagram: Davr Type Vxd22D M/S Isgec Heavy Engineering Ltd. 1 50 MW, 11 KV STGDocument37 pagesSchematic Diagram: Davr Type Vxd22D M/S Isgec Heavy Engineering Ltd. 1 50 MW, 11 KV STGravish kumarNo ratings yet

- National and Regional Power PlanningDocument43 pagesNational and Regional Power PlanningrahulNo ratings yet

- ( (Premier Batch: Problem Solving DQG ( (HuflvhsheetDocument31 pages( (Premier Batch: Problem Solving DQG ( (HuflvhsheetAYUSH GUPTANo ratings yet

- 33KV Switchboard Panel DetailsDocument3 pages33KV Switchboard Panel DetailsArunava Basak100% (1)

- Turbine MaintainanceDocument9 pagesTurbine Maintainanceer_sanjaypatel100% (2)

- 01 - Power System Protection-Basics and Breakers v2 (Revised) PDFDocument55 pages01 - Power System Protection-Basics and Breakers v2 (Revised) PDFJawwad Sadiq Ayon100% (1)

- Hico SF Gas Circuit Breaker: Power Systems PUDocument6 pagesHico SF Gas Circuit Breaker: Power Systems PUSubir ChattopadhyayNo ratings yet

- Why Horizontal NH3 ConverterDocument21 pagesWhy Horizontal NH3 ConverterHoàng Hải Linh100% (1)

- ALSTOM Relay CatalogueDocument112 pagesALSTOM Relay CatalogueVivek Vous AimeNo ratings yet

- SF6-GAS CIRCUIT BREAKERS FOR OUT-DOOR USE UPTO 36kVDocument4 pagesSF6-GAS CIRCUIT BREAKERS FOR OUT-DOOR USE UPTO 36kVLinh VănNo ratings yet

- XR351Document4 pagesXR351ecplpraveen100% (1)

- Alan Electronics' Story of Quality, Consistency and ReliabilityDocument6 pagesAlan Electronics' Story of Quality, Consistency and Reliabilitysathishsutharsan87No ratings yet

- Kx6k Sc06 6611kv Transformer-2 Protection Rev Za 15.03.2018Document82 pagesKx6k Sc06 6611kv Transformer-2 Protection Rev Za 15.03.2018Ravi Shankar V100% (1)

- PDF Created With Pdffactory Pro Trial VersionDocument7 pagesPDF Created With Pdffactory Pro Trial Versionwaveengg.coNo ratings yet

- Selectivity Catalog Domestic 291015Document12 pagesSelectivity Catalog Domestic 291015Samarendu BaulNo ratings yet

- Three Phase HTCT Multi Port Meter Er300pDocument3 pagesThree Phase HTCT Multi Port Meter Er300pD RAJANNo ratings yet

- Kx6k Sc02 6611kv Transformer-1 Protection Rev Za 15.03.2018Document82 pagesKx6k Sc02 6611kv Transformer-1 Protection Rev Za 15.03.2018Ravi Shankar VNo ratings yet

- 33 KV Outdoor VCB Pv1750bDocument4 pages33 KV Outdoor VCB Pv1750bAnoop Kumar PandayNo ratings yet

- Crompton GreavesDocument26 pagesCrompton GreavesAnonymous DJybroNXNo ratings yet

- TNEB 110KV Incomer-I TNEB 110KV Incomer-IIDocument14 pagesTNEB 110KV Incomer-I TNEB 110KV Incomer-IINKNo ratings yet

- D"KZ.K Lalfkkiu Funs'Kky : Traction Installation DirectorateDocument52 pagesD"KZ.K Lalfkkiu Funs'Kky : Traction Installation DirectorateUgur AydinNo ratings yet

- Megawin Switchgear: Numerical Over Current ProtectionDocument4 pagesMegawin Switchgear: Numerical Over Current ProtectionRock hackNo ratings yet

- Functional Features of Static Energy Meters PDFDocument78 pagesFunctional Features of Static Energy Meters PDFJ HARSHA YADAVNo ratings yet

- Essential assignment questions on entrepreneurship and managementDocument43 pagesEssential assignment questions on entrepreneurship and managementHauzaan KalimatullahNo ratings yet

- Vacuum Circuit Breakers: For Out-Door Use Upto 36KvDocument4 pagesVacuum Circuit Breakers: For Out-Door Use Upto 36KvtoogooodNo ratings yet

- 145 KV ABB Make BreakerDocument1 page145 KV ABB Make BreakerStephen BridgesNo ratings yet

- Minilec CatalougeDocument64 pagesMinilec CatalougePrajin KundoorNo ratings yet

- Power Tech India: D-6 Kavi Nagar Industrial Area Ghaziabad, MDocument13 pagesPower Tech India: D-6 Kavi Nagar Industrial Area Ghaziabad, MHari HaranNo ratings yet

- Type P8n, PQ8n, PN8n: Auxiliary RelayDocument7 pagesType P8n, PQ8n, PN8n: Auxiliary RelayDinesh ThevanNo ratings yet

- Schematic CRP Line Bay Silae 02 PDP PLN SiemensDocument61 pagesSchematic CRP Line Bay Silae 02 PDP PLN SiemensmamassanjayaNo ratings yet

- Diagrams Attach 4Document6 pagesDiagrams Attach 4tej0707840% (1)

- As BuiltDocument139 pagesAs Builtwalter100% (1)

- FATEHGARH-II 765-400-220KV SLD REv 01-ModelDocument1 pageFATEHGARH-II 765-400-220KV SLD REv 01-ModelANUP KAMBOJNo ratings yet

- Tender - 47 - Metering Cubicles (Final) PDFDocument46 pagesTender - 47 - Metering Cubicles (Final) PDFNitesh GawlliNo ratings yet

- Catalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01Document4 pagesCatalogue-CGV-24C-UV-OV Relay-CAT-CGV24C-01waveengg.coNo ratings yet

- Troubles Occuring in Air Compressors and RemediesDocument13 pagesTroubles Occuring in Air Compressors and Remediesvenkat19832003No ratings yet

- KVAh Metering BasicsDocument34 pagesKVAh Metering Basicsvenkin845074100% (1)

- Multi-function protection relays SCADA systemDocument4 pagesMulti-function protection relays SCADA systemqaisar_shafi100% (1)

- Odisha Power Transmission Approves 420kV Disconnector DrawingsDocument31 pagesOdisha Power Transmission Approves 420kV Disconnector DrawingsGuru MishraNo ratings yet

- 11kv 200a Ab Switch PDFDocument2 pages11kv 200a Ab Switch PDFhimanshuNo ratings yet

- Supply Specification for 11 KV Indoor VCB PanelsDocument80 pagesSupply Specification for 11 KV Indoor VCB PanelsVishnu Singhal100% (1)

- 33 11 SubstationDocument21 pages33 11 SubstationRamdevNo ratings yet

- Reyrolle 5 Catalog Edition 3.0Document66 pagesReyrolle 5 Catalog Edition 3.0maxvanmaxNo ratings yet

- Indent No. Annexure - 1 Technical Specification of Alstom / Areva/ Make Protection Relay With Case. 1. CDG31 As Below Specs 4 NosDocument7 pagesIndent No. Annexure - 1 Technical Specification of Alstom / Areva/ Make Protection Relay With Case. 1. CDG31 As Below Specs 4 NosYaseen SagarNo ratings yet

- DP STRUCTURE BY KSEBDocument8 pagesDP STRUCTURE BY KSEBHafiz RahimNo ratings yet

- 110kV Substation ManualDocument45 pages110kV Substation ManualFaiz MangalasseryNo ratings yet

- Angelica Honorica Grade 11 BPP 1 AlmedaDocument5 pagesAngelica Honorica Grade 11 BPP 1 AlmedaAnonymous kbGkF15AzrNo ratings yet

- BSC Physics Iind SemDocument4 pagesBSC Physics Iind SemDavid JonesNo ratings yet

- In A Quality Control TestDocument5 pagesIn A Quality Control TestHarry Frianota IDNo ratings yet

- Engineering Mechanics MCQDocument6 pagesEngineering Mechanics MCQeafz111No ratings yet

- MAR3040 05-Blade Element TheoryDocument16 pagesMAR3040 05-Blade Element TheoryMursh AlmuqimiNo ratings yet

- DC Circuit TheoryDocument41 pagesDC Circuit TheoryNicole Angela Gila RamonidaNo ratings yet

- DIWALI ASSIGNMENT GYROSCOPEDocument5 pagesDIWALI ASSIGNMENT GYROSCOPEDhruvesh AsnaniNo ratings yet

- EINA No11p34-36 PDFDocument3 pagesEINA No11p34-36 PDFSnehaSinghNo ratings yet

- Ac PDFDocument159 pagesAc PDFArunNo ratings yet

- Fuji Electric RSA30LCC + ROR30LCTservice ManualDocument27 pagesFuji Electric RSA30LCC + ROR30LCTservice ManualMaurizio DumitracheNo ratings yet

- AP Physics Work Energy Power PDFDocument17 pagesAP Physics Work Energy Power PDFAli khan7No ratings yet

- TD1501Document18 pagesTD1501Hernando GamaNo ratings yet

- Implementation of A Microcontroller Based 5 KVA Automatic Voltage StabilizerDocument9 pagesImplementation of A Microcontroller Based 5 KVA Automatic Voltage StabilizerUMA AKANDU UCHENo ratings yet

- SB2500 SB3000 14 BE2906 Inverter DatasheetDocument2 pagesSB2500 SB3000 14 BE2906 Inverter DatasheetAdrian OprisanNo ratings yet

- Online Final Exam: Mass BalanceDocument11 pagesOnline Final Exam: Mass BalanceJan Olaf Müller JohanssenNo ratings yet

- Lesson1 Intro To DampingDocument6 pagesLesson1 Intro To DampinglucaNo ratings yet

- GIC Bourdon SensingDocument2 pagesGIC Bourdon SensingNCNo ratings yet

- 4th Practice Test PeriodicDocument3 pages4th Practice Test PeriodicRachel Angelette ChanNo ratings yet

- Gandhi Seminar21Document25 pagesGandhi Seminar21Bhukya GandhiNo ratings yet

- Villanueva, Brian Harvey A. BE-4/2015108217 CHE143-1/E01Document4 pagesVillanueva, Brian Harvey A. BE-4/2015108217 CHE143-1/E01Renren PNo ratings yet