0% found this document useful (0 votes)

1K views2 pagesMerchandiser Job Description

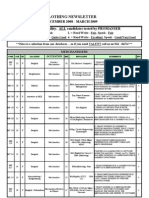

The document outlines the key responsibilities and processes involved in merchandising for the garments sector. It discusses that merchandisers are responsible for communicating with marketing and production, executing orders according to costing and pricing, and ensuring a smooth merchandising process. The main duties of a merchandiser include receiving and analyzing orders, developing samples, negotiating prices, booking fabrics and accessories, arranging pre-production meetings, overseeing production quality, and preparing documents for shipment. Merchandisers play a critical role in facilitating production and delivery according to a buyer's requirements.

Uploaded by

manav lekhwaniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as RTF, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views2 pagesMerchandiser Job Description

The document outlines the key responsibilities and processes involved in merchandising for the garments sector. It discusses that merchandisers are responsible for communicating with marketing and production, executing orders according to costing and pricing, and ensuring a smooth merchandising process. The main duties of a merchandiser include receiving and analyzing orders, developing samples, negotiating prices, booking fabrics and accessories, arranging pre-production meetings, overseeing production quality, and preparing documents for shipment. Merchandisers play a critical role in facilitating production and delivery according to a buyer's requirements.

Uploaded by

manav lekhwaniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as RTF, PDF, TXT or read online on Scribd