Professional Documents

Culture Documents

Manual Chain Hoists

Manual Chain Hoists

Uploaded by

Tintus PriambodhoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Chain Hoists

Manual Chain Hoists

Uploaded by

Tintus PriambodhoCopyright:

Available Formats

Instructions for the safe use of:

Hand Chain Blocks

The information in this leaflet should be passed to the user of the equipment

This document is issued in accordance with the requirements of Never galvanise or subject the chain, or other load bearing

Section 6 of the Health and Safety at Work etc Act 1974, parts, to any other plating process without the express approval of

amended March 1988. It outlines the care and safe use of the supplier.

HAND CHAIN BLOCKS and is based on Section 2 of the LEEA Installing and Commissioning

Code of Practice for the Safe Use of Lifting Equipment. It

should be read in conjunction with the requirements for lifting Follow any specific installation instructions issued by the

appliances for general purposes, given overleaf, which form an supplier and the general requirements given overleaf. Try the

integral part of these instructions. block to ensure that it operates correctly and that the brake is

effective. Ensure the chain is not twisted; it must move freely.

This information is of a general nature only covering the main The bottom hook must reach the lowest position required

points for the safe use of hand chain blocks. It may be without the chain running fully out.

necessary to supplement this information for specific

applications. Using Hand Chain Blocks Safely

Do not attempt lifting operations unless you understand the use of

the equipment and the slinging procedures.

ALWAYS:

Do not use defective blocks, slings or accessories and never

• Store and handle chain blocks correctly. use the block chain as a sling.

• Inspect chain blocks and accessories before use and before Check the slinging arrangement, that the block is safely rigged

placing into storage. and that chains are not twisted, particularly in the case of multi-fall

• For top hook suspension, use hooks that are fitted with safety blocks.

catches, or mouse the hook, ensuring the support fits freely Check the load is free to move before commencing and that the

into the seat of the hook. landing area has been prepared.

• For trolley suspension ensure the trolley is correctly set for Raise the load just clear, then halt the lift to check the integrity of

the beam width. the block, slinging method etc.

• Check that the bottom hook will reach its lowest point without Check the travel path is clear and that you have a clear view so as

running the chain fully out. to avoid accidental hook engagement or collision. Follow any

• Adopt safe slinging practices and follow the instructions for particular site safety rules applicable to the movement of

the safe use of the equipment used. suspended loads.

Keep fingers, toes etc clear when lowering loads.

NEVER:

• Expose chain blocks to chemicals, particularly acids, without In-service Inspection and Maintenance

consulting the supplier.

Follow any specific maintenance instructions issued by the

• Replace the load chain with a longer one without consulting supplier but in particular keep load chains lubricated and check

the supplier. the operation of the brake. Brakes must be kept free of oil,

grease etc. Never replace the load chain with a longer one

without consulting the supplier.

• Use undue effort to force the block to operate.

Regularly inspect the block and, in the event of the following

• Throw, drop or drag a chain block. defects, refer the block to a Competent Person for thorough

examination: wear; damage to trolley, hooks and fittings;

• Allow oil or grease to come into contact with the brake. damaged or distorted slack end anchor; chains worn, bent,

notched, stretched, corroded, do not hang freely, twisted or

• Expose a chain block directly to the elements, water spray, jump; load slips or will not lift; damaged block casing; illegible

steam etc without consulting the supplier. markings.

© Lifting Equipment Engineers Association 2011 SI No. 11.4

Selecting the Correct Block

Hand chain blocks are available in a range of capacities and Further information is given in:

with various types of suspension. Select the block to be used The Code of Practice for the Safe Use of Lifting Equipment.

and plan the lift taking the following into account: published by:

Type of suspension - hook, trolley etc.

Capacity, class of use and range of lift. LIFTING EQUIPMENT ENGINEERS ASSOCIATION

Most chain blocks are designed for vertical lifting only. Use of these 3 Osprey Court, Kingfisher Way,

at an angle requires additional risk assessment and precautions. Hinchingbrooke Business Park, Huntingdon

Some chain block designs permit use at an angle. Cambridgeshire. PE29 6FN. United Kingdom

Consult the supplier if the block is to be used in areas of high Tel: + 44 (0) 1480 432801

risk, exposed to the elements, water, steam etc, with hazardous Fax: + 44 (0) 1480 436314

substances, e.g. acids or chemicals, or subjected to extremes of E-mail: mail@leea.co.uk

temperature. Website: www.leeaint.com

Storing and Handling Hand Chain Blocks

Never return damaged blocks to storage. They should be dry,

clean and protected from corrosion.

Store blocks by their top suspension with chains clear of the

ground, the chains may be wrapped together to facilitate this.

Non-portable blocks stored outdoors should be covered and

protected from corrosion.

Blocks should not be dropped, thrown or dragged across the

floor.

GENERAL PURPOSE LIFTING APPLIANCES With power operated blocks the supply should be connected by

a suitably Qualified Person taking account of any statutory or

(MANUAL AND POWER OPERATED BLOCKS) technical requirements (eg Electricity at Work Regulations,

Pressure Systems and Transportable Gas Containers

The following information is based on Section 1 - Appendix 1.6 Regulations).

of the Code of Practice for the Safe Use of Lifting Equipment

and should be read in conjunction with the instructions for safe Test run to ensure the free and correct movement of the

use, given overleaf, of which it forms an integral part and with chain/rope. Check the operation of the brake. Check direction of

any specific instructions issued by the supplier. control command, position and operation of travel limits and

safety devices.

This information is of a general nature only covering the main

points for the safe use of manual and power operated blocks. Safe Use of Blocks

The basic objectives of any lifting operation are to move the

ALWAYS: load to the desired location and land it safely, efficiently and

without damage to the load, the equipment used or the

• Ensure suspension points and anchorages are adequate for surrounding buildings, plant etc. In addition to any specific

the full imposed load. instructions relating to the block the following general points

• Check the load chain/wire rope is hanging freely and is not must be observed:

twisted or knotted. o Never attempt lifting operations unless you have been trained

• Position the hook over the centre of gravity of the load. in the use of the equipment and slinging procedures.

• Check the operation of the brake before making the lift. o Position the hook directly over the centre of gravity so that the

line of pull is vertical.

• Ensure the slings are secure and load is free to be lifted.

o Do not use the chain/wire rope to sling the load, ie do not

• Check the travel path is clear. wrap it round the load, back hook or choke hitch.

• Ensure the landing area is properly prepared. o Do not lift on the point of the hook or overcrowd the hook with

NEVER: fittings.

o Never lift/lower more than the marked SWL. In the case of

• Exceed the marked SWL.

manual equipment if abnormally high effort is required, and

• Use the load chain/wire rope as a sling. with power operated appliances they fail to lift the load, or if

• Shock load the block or other equipment. the load slips this is an indication of too high a load or a fault -

check the load and the appliance.

• Lift on the point of the hook.

o Avoid unnecessary inching of power operated appliances and

• Overcrowd the hook with fittings. do not impose sudden or shock loads.

• Permit the load to swing out of control. o Push rather than pull loads suspended from appliances with

• Leave suspended loads unattended. push/pull trolleys and if un-laden pull on the bottom hook.

Never pull an appliance by the pendant control, supply cable

or hose.

Types of blocks o Avoid sudden movement of travel motion or undue effort in

A wide range of manual and power operated blocks is available. pushing the load which can cause the load to swing.

This section of the leaflet is concerned with matters which are o Avoid excessive or intentional use of motion limits unless they

common to the safe use of the following listed equipment when are additional limits intended for that purpose. Avoid running

used to lift in a vertical plane only. appliances against end stops.

Pulley blocks for fibre or wire rope used with winches, hand o Do not allow anyone to pass under or ride upon the load.

chain blocks, chain lever hoists, power operated wire rope Never leave suspended loads unattended unless in an

blocks and power operated chain blocks. The use of trolleys is emergency then ensure the area is cordoned off and kept

often associated with blocks and these may be built in with the clear.

trolley as an integral part of the appliance, or independent with

the block hung on. o Do not remove guards, protective covers, weather proof

covers, heat shields etc without the authority of a Competent

Operative Training Person

Lifting appliances should only be used by trained operatives In-Service Inspection and Maintenance

who understand their use and that of the associated equipment

used in the lift. The Provision and Use of Work Equipment Regulations 1998

and the Lifting Operations and Lifting Equipment Regulations

Installation and Commissioning 1998 both require that lifting equipment properly maintained.

This is an ongoing duty that falls on the user and a planned

The erection procedure will vary with the equipment and should routine maintenance programme will be necessary.

be carried out in accordance with the suppliers instructions

paying attention to the following matters: In addition to the statutory thorough examinations by a

Competent Person, regular in-service inspections should be

Prior to installation inspect the equipment to ensure no damage made to find any faults and damage that might arise. If any are

has occurred in store or transit. found they should be referred to the Competent Person.

Ensure the support structure is adequate for the full loads that The maintenance programme must meet the requirements of

will imposed, is tested and marked with the SWL. the manufacturers instructions and any special requirements

When erecting trolleys ensure they are correctly set for the due to the conditions of service. This may be combined with

beam width and that the track is fitted with end stops which maintenance of other equipment used in association with the

engage with the trolley frame or wheel tread. The track should appliance, eg power feed system. Check the block and its

remain level at all loads up to the maximum. associated equipment daily for obvious faults and signs of

When suspending appliances by a top hook ensure the support damage.

fits freely into the seat of the hook. Further information is given in:

After erection ensure that the chain/wire rope hangs freely and LEEA Code of Practice for the Safe Use of Lifting Equipment

is not twisted or knotted.

SI MPB 1.2 (2011)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- J.6.ANSI Z535!3!2011 - Criteria For Safety SymbolDocument57 pagesJ.6.ANSI Z535!3!2011 - Criteria For Safety SymbolAnonymous ggRTHDKe650% (2)

- J.5 ANSI Z535!2!2011 - Environtmental & Facility Safety SignsDocument52 pagesJ.5 ANSI Z535!2!2011 - Environtmental & Facility Safety SignsAnonymous ggRTHDKe6100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Design of Padma Multipurpose Bridge - Challenges and Solutions.Document10 pagesThe Design of Padma Multipurpose Bridge - Challenges and Solutions.Jahidul IslamNo ratings yet

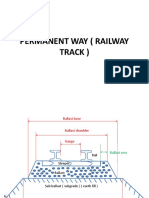

- Permanent Way in RailwayDocument19 pagesPermanent Way in RailwayPangerwati Ozukum100% (1)

- MSDS R134aDocument9 pagesMSDS R134aAnonymous ggRTHDKe6No ratings yet

- Natural Gas Installation Standards: 2018 HandbookDocument57 pagesNatural Gas Installation Standards: 2018 HandbookAnonymous ggRTHDKe6100% (1)

- Project On RailwayDocument15 pagesProject On RailwayGaurav AgarwalNo ratings yet

- Handbook On Maintenance of Air Brake System in LHB Coaches (FTIL Type) PDFDocument120 pagesHandbook On Maintenance of Air Brake System in LHB Coaches (FTIL Type) PDFIonut Valentin VladNo ratings yet

- NEOM-NPR-SOP-26 FRM001 Scaffolding Inspection ChecklistDocument3 pagesNEOM-NPR-SOP-26 FRM001 Scaffolding Inspection Checklistmohamed.elsawaf100% (1)

- Marine CateringDocument2 pagesMarine CateringKunwar Apoorv Singh Parihar100% (1)

- Project Charter - HKIADocument14 pagesProject Charter - HKIADhivya Prabhakar100% (2)

- EUA Cellex Rapid HCPDocument3 pagesEUA Cellex Rapid HCPAnonymous ggRTHDKe6No ratings yet

- Automotive Brochure EngDocument22 pagesAutomotive Brochure EngAnonymous ggRTHDKe6No ratings yet

- 1 773 Lifeline-Manual R03 2020-1Document30 pages1 773 Lifeline-Manual R03 2020-1Anonymous ggRTHDKe6No ratings yet

- Idemitsu SN/CF 10W-40 Semi-Synthetic: Lubricant Product InformationDocument2 pagesIdemitsu SN/CF 10W-40 Semi-Synthetic: Lubricant Product InformationAnonymous ggRTHDKe6No ratings yet

- Katalog Dan Daftar Harga Kacamata Safety Worksafe (Worksafe Safety Eyewear)Document5 pagesKatalog Dan Daftar Harga Kacamata Safety Worksafe (Worksafe Safety Eyewear)Anonymous ggRTHDKe6No ratings yet

- Im10294 PDFDocument60 pagesIm10294 PDFAnonymous ggRTHDKe6No ratings yet

- Tiga Arti Dalam TPM: TotalDocument6 pagesTiga Arti Dalam TPM: TotalAnonymous ggRTHDKe6No ratings yet

- R350 G65353Document3 pagesR350 G65353Anonymous ggRTHDKe6No ratings yet

- Family Nursing & Home Care Fire Safety ProcedureDocument4 pagesFamily Nursing & Home Care Fire Safety ProcedureAnonymous ggRTHDKe6No ratings yet

- Guide Completing Pallet Rack Inspection Checklist PDF en PDFDocument1 pageGuide Completing Pallet Rack Inspection Checklist PDF en PDFDavid Eugen100% (1)

- Ppe Product: CollectionDocument7 pagesPpe Product: CollectionAnonymous ggRTHDKe6No ratings yet

- Virtual Reality in Fall Protection: Kelvin Tan Senior Marketing Manager - AsiaDocument7 pagesVirtual Reality in Fall Protection: Kelvin Tan Senior Marketing Manager - AsiaAnonymous ggRTHDKe6No ratings yet

- Welding and CuttingDocument13 pagesWelding and CuttingAnonymous ggRTHDKe6No ratings yet

- Schneider Electric Introduces First ePAC, Combines PAC With Ethernet BackboneDocument19 pagesSchneider Electric Introduces First ePAC, Combines PAC With Ethernet BackboneAnonymous ggRTHDKe6No ratings yet

- Checkliste Druck en FD A9Document1 pageCheckliste Druck en FD A9Anonymous ggRTHDKe6No ratings yet

- 2010 Fatigue ExtendedWorkHours SafetyWorkplace ERG01Document10 pages2010 Fatigue ExtendedWorkHours SafetyWorkplace ERG01Anonymous ggRTHDKe6No ratings yet

- Printticket PDFDocument2 pagesPrintticket PDFDivya RanjanNo ratings yet

- Technical Comparison of Commercially Available TramsDocument16 pagesTechnical Comparison of Commercially Available TramsmilandivacNo ratings yet

- UC Berkeley: IURD Monograph SeriesDocument48 pagesUC Berkeley: IURD Monograph Serieskarinduarte30No ratings yet

- D Watch Rule 34Document2 pagesD Watch Rule 34Ron FlorenceNo ratings yet

- Train Times: Stanhope - Frosterley - Wolsingham - Bishop AucklandDocument1 pageTrain Times: Stanhope - Frosterley - Wolsingham - Bishop Aucklandapi-67805145No ratings yet

- 10.4 Modes of TransportDocument12 pages10.4 Modes of TransportAya Magdy AhmedNo ratings yet

- Works of Short and Long Duration, Protection Arrangements EtcDocument82 pagesWorks of Short and Long Duration, Protection Arrangements EtcThiyagarajan kNo ratings yet

- Chap 24 TransportDocument5 pagesChap 24 TransportAdnan QureshiNo ratings yet

- Ghid de Buzunar - CracoviaDocument148 pagesGhid de Buzunar - CracoviatziculNo ratings yet

- BY Wankar Sir: Indian Railways Group A ServiceDocument14 pagesBY Wankar Sir: Indian Railways Group A Servicekshitij vaidyaNo ratings yet

- Valleylab Force FX C Schematics SupplementDocument24 pagesValleylab Force FX C Schematics SupplementAsad AhmedNo ratings yet

- Past Simple, Past ContiniousDocument2 pagesPast Simple, Past ContiniousNadezhdaNo ratings yet

- G20 Security Zone GuideDocument1 pageG20 Security Zone GuideToronto StarNo ratings yet

- PTR 16-18Document22 pagesPTR 16-18wahaj shahNo ratings yet

- MP Misc 432 71 (Load Factor)Document17 pagesMP Misc 432 71 (Load Factor)Hanuma ReddyNo ratings yet

- TPC 3 Chapter 1 3Document35 pagesTPC 3 Chapter 1 3Arjay SolisNo ratings yet

- New Standard of Lashing SystemDocument12 pagesNew Standard of Lashing SystemAekJayNo ratings yet

- VDOT Volume V Part 2 Design AidsDocument1,188 pagesVDOT Volume V Part 2 Design AidsMJCHAMBERLANDNo ratings yet

- 1924 Traffic Street PlanDocument41 pages1924 Traffic Street PlanJason BentleyNo ratings yet

- On The Road 2Document2 pagesOn The Road 2Trina Nileena BanerjeeNo ratings yet

- 21 ConclusionDocument11 pages21 ConclusionrajibchattarajNo ratings yet

- Notes For Driving G2Document4 pagesNotes For Driving G2t2cssnqjhrNo ratings yet

- IrctcDocument3 pagesIrctcSrini VaSNo ratings yet