Professional Documents

Culture Documents

Item Units Data by Buyer Data by Vendor Notes: Continous Information Required From Bidder

Uploaded by

yoel cueva arquinigo0 ratings0% found this document useful (0 votes)

14 views3 pagesThe document requests continuous information from bidders regarding pump specifications including dimensions, materials, seals, bearings, weights, motor data, and electrical requirements. Specifically it outlines 202 items across four sections (A-D) pertaining to the center pump, shaft, seals, bearings, as well as the electrical motor's general requirements, efficiency, cooling, bearings, and terminals. Bidders are asked to provide data for each item, with notes indicating compliance with standards like NEMA for some fields.

Original Description:

Original Title

BOMBA HD2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document requests continuous information from bidders regarding pump specifications including dimensions, materials, seals, bearings, weights, motor data, and electrical requirements. Specifically it outlines 202 items across four sections (A-D) pertaining to the center pump, shaft, seals, bearings, as well as the electrical motor's general requirements, efficiency, cooling, bearings, and terminals. Bidders are asked to provide data for each item, with notes indicating compliance with standards like NEMA for some fields.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views3 pagesItem Units Data by Buyer Data by Vendor Notes: Continous Information Required From Bidder

Uploaded by

yoel cueva arquinigoThe document requests continuous information from bidders regarding pump specifications including dimensions, materials, seals, bearings, weights, motor data, and electrical requirements. Specifically it outlines 202 items across four sections (A-D) pertaining to the center pump, shaft, seals, bearings, as well as the electrical motor's general requirements, efficiency, cooling, bearings, and terminals. Bidders are asked to provide data for each item, with notes indicating compliance with standards like NEMA for some fields.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

CONTINOUS INFORMATION REQUIRED FROM BIDDER

104 ITEM UNITS DATA BY BUYER DATA BY VENDOR NOTES

105 Center to center distance (*)

106 Number of belts / size (*)

107 Service factor 1.15

108 SHAFT

109 Diameter at bearing mm (*)

110 Diameter mm (*)

111 Shaft material (*)

112 Sleeve material (*)

113 Sleeve thickness mm (*)

114 Linning hardness (*)

115 Method of impeller attachment (*)

116 SEALS (*)

117 Type

118 Packing material (*)

119 Mech. Seal mfr. (*)

120 Type Mechanical

121 Model No. (*)

122 Seal water flow (*)

123 Pressure (*)

124 BEARINGS (*)

125 Type / Size (near pump) (*)

126 Type / Size (near motor) (*)

127 Manufacturer (*)

128 Lubrication (*)

129 Seal type (*)

130 Life (I-10 rating) hr 60000

131 WEIGHTS AND SIZES

132 Total shipping weight kg (*)

133 Heaviest piece for installation kg (*)

134 Heaviest piece for maintenance kg (*)

Documento elaborado por BISA AGUA FRESCA

Larrabure y Unanue 146, Lima 1 – Perú T.(511)6266200 F.(511)4332842 Página 3 de 5

C.- ELECTRICAL MOTOR DATA SHEETS

135 ITEM UNITS DATA BY VENDOR NOTES

136 GENERAL REQUIREMENTS

137 Manufacturer (*)

138 Model Type (*)

139 Rated output power sea level HP 3.0

140 Voltage V 460.0

141 Phases / Frecuency 3 / 60 Hz

142 Primary Standard NEMA MG-1

143 Design fault level (*)

144 Operating duty (*)

145 Mounting type:

146 Horizontal or Vertical Horizontal

147 Foot or Flange (*)

148 Starting method (*)

149 Starting performance (general) (*)

150 Starting performance (conveyors) (*)

151 Speed operation (fixed/variable) (*)

152 Speed (without VFD) (*)

153 Speed range (with VFD) (*)

154 Frame size (*)

155 Degree of protection:

156 Motor / Junction box TEFC / NEMA 4

157 Fan (if required) (*)

158 Stator winding (Delta/ Star) (*)

159 Number of poles (*)

160 Current at:

161 Full load A (*)

162 Locked rotor A (*)

163 No load A (*)

164 Standard Motor designs NEMA B

165 Efficiency at:

166 100% load % NEMA PREMIUM

167 75% load % NEMA PREMIUM

168 50% load % NEMA PREMIUM

169 25% load % NEMA PREMIUM

170 Power factor at:

171 100% load NEMA PREMIUM

172 75% load NEMA PREMIUM

173 50% load NEMA PREMIUM

174 Cooling Motor Requirements:

175 Cooling method (*)

176 Water flowrate (*)

177 Inlet water temperature (*)

178 Outlet water temperature (*)

179 Cooling tube material (*)

180 Slip at full load % (*)

181 Torque:

182 100% /75% /50% load kN-m (*)

183 Starting kN-m (*)

184 Pullup kN-m (*)

185 Breakdown kN-m (*)

186 Load torque curve (*) f

187 Torque & current speed curves (*) f

188 Load inertia kg-m² (*)

189 Rotor inertia kg-m² (*)

190 Insulation class F

191 Temperature rise (*)

192 Thermal rating (NEMA MG 1) Class B

193 Number of starts since cold / hot in one hour (*)

194 Stall time (max time with 6 x IFL ) s (*)

195 Bearing (*)

196 Bearing type (model Nº/ manuf.):

197 Drive end (*)

198 Non-drive end (*)

199 Bearing seal arrangement (*)

200 Bearing L10 life h (*)

201 Lubrication system (*)

Documento elaborado por BISA AGUA FRESCA

Larrabure y Unanue 146, Lima 1 – Perú T.(511)6266200 F.(511)4332842 Página 4 de 5

CONTINOUS ELECTRICAL MOTOR DATA SHEETS

202 ITEM UNITS DATA BY BUYER DATA BY VENDOR NOTES

203 Non drive end insulated bearings (Yes/No) (*)

204 Noise level (dBA at 1m) dB MG-1 e

205 Derating factors VFD operation % (*)

206 Maximum 3 phase cable size allowed (Cu) mm² (*)

207 Terminal box (standard/oversize) Oversize

208 Terminal box location Side

209 Terminal box cable entry opening Bottom

210 Stress allowance in terminal box (*)

211 Anti condensation heaters: (*)

212 Required Yes

213 Voltage V 220

214 Rated kW (*)

215 Temperature detection: (*)

216 RTD quantity (Ver nota 2) (*)

217 RTD type (*)

218 Ground terminal (*)

219 CTs required in motor junction box (*)

220 CT ratio and details (*)

221 Surge arrestors required in motor junction box (*)

222 Full performance test for first motor in group Yes

223 Routine testing for remainder of motors in group (*)

224 Enclousure TEFC

225 DIMENSION (*)

226 Motor weight kg (*)

227 Shipping weight kg (*)

228 Shipping dimensions (l x w x h) mm (*)

229 Outline drawing Nº (*)

NOTES (ELECTRIC MOTOR)

230 a.- RTD's qty. = 2 by each phase winding + 1 by each bearing + 1 by ambient temperature

231 b.- Abbreviations used : VTS = Vendor to specify

232 TBB = to be advised by BISA

233 N/A = not applicable

234 RHS = right hand side

235 VFD= variable frequency drive

236 CT = current transform

237 IFL= current full load

238 VTC = vendor to confirm

239 c.- Non-Drive end Right Side (main box and auxiliary box)

240 d.- Attack cupper, cupper alloy, aluminum and bronze.

241 e.-According to NEMA MG-1, Table 9.1

242 f.- Attach curves.

Documento elaborado por BISA AGUA FRESCA

Larrabure y Unanue 146, Lima 1 – Perú T.(511)6266200 F.(511)4332842 Página 5 de 5

You might also like

- Service Manual: FastracDocument1,027 pagesService Manual: Fastracred100% (7)

- Winch, Manrider (FA150KGi) Product InstructionsDocument16 pagesWinch, Manrider (FA150KGi) Product InstructionsTonyNo ratings yet

- Brosur Yuema Helical Gear TRDocument200 pagesBrosur Yuema Helical Gear TRzend1999No ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Lesson IV & V Electrical Tools & EquipmentDocument60 pagesLesson IV & V Electrical Tools & EquipmentRoss Armyr GeliNo ratings yet

- Daf Ix Achea BlockdiagramDocument46 pagesDaf Ix Achea BlockdiagramMircea GilcaNo ratings yet

- Vehicle Maintenance Schedule DynaDocument3 pagesVehicle Maintenance Schedule Dynaisland14No ratings yet

- JCB 3185ABS FASTRAC Service Repair Manual SN 00642001-00643010 PDFDocument77 pagesJCB 3185ABS FASTRAC Service Repair Manual SN 00642001-00643010 PDFfjksemfmmdNo ratings yet

- TransformerDocument204 pagesTransformerdevcharu75% (4)

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- Specifications: Cat C7.1 ACERT™ Industrial Power Unit IndustrialDocument14 pagesSpecifications: Cat C7.1 ACERT™ Industrial Power Unit IndustrialAbo Achraf LaalawiNo ratings yet

- Ingersoll-Rand SD45D Spec TechDocument2 pagesIngersoll-Rand SD45D Spec TechJoséManuelSalamancaOlisNo ratings yet

- S50MC-C8 - 2 Man B&WDocument381 pagesS50MC-C8 - 2 Man B&WhaizriNo ratings yet

- Brosur Transmax Helical Gear TRDocument200 pagesBrosur Transmax Helical Gear TRbangpaiNo ratings yet

- 185 CFM - To - 250 CFM QXD - ENDocument2 pages185 CFM - To - 250 CFM QXD - ENJamal HabbasNo ratings yet

- 12M PDFDocument8 pages12M PDFallan lariosaNo ratings yet

- Ingersollrand P260WIRDocument2 pagesIngersollrand P260WIROjik OnlineNo ratings yet

- 2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Document4 pages2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Mohamed HamedNo ratings yet

- STC 4 Blades Twin OtterDocument1 pageSTC 4 Blades Twin OtterCelin Concha Araneda100% (1)

- Air Powered Man Rider Winch LS2-150RLP Series ModelsDocument12 pagesAir Powered Man Rider Winch LS2-150RLP Series ModelsHesam Ghaffari100% (1)

- Toaz - Info o Amp M Manual PRDocument205 pagesToaz - Info o Amp M Manual PRRony DensitelNo ratings yet

- Motor HidráulicoDocument48 pagesMotor HidráulicoDante De Alcantara PintoNo ratings yet

- TCDS PW150 Series Issue 01 - 20141119 - 1.0Document7 pagesTCDS PW150 Series Issue 01 - 20141119 - 1.0Manabendra M DeNo ratings yet

- 16iz ENG Full LetterDocument228 pages16iz ENG Full LetterJunior BatistaNo ratings yet

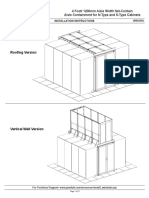

- VRF Trane Tr200 Tr2 Bas-svx19a-EnDocument171 pagesVRF Trane Tr200 Tr2 Bas-svx19a-Enignacio montesNo ratings yet

- 1890 No Till Air Drill 3 Section IntroductionDocument4 pages1890 No Till Air Drill 3 Section IntroductionOleksandr YermolenkoNo ratings yet

- 544J Loader S N 611799 IntroductionDocument4 pages544J Loader S N 611799 IntroductionBryant Legarda GarcésNo ratings yet

- InfomaciónDocument4 pagesInfomaciónEdy Waldemar CardozoNo ratings yet

- HYDRO A320 - Equipment CatalogueDocument166 pagesHYDRO A320 - Equipment CatalogueKrishna bogiNo ratings yet

- INGERSOLLRAND 7.120. SpecificationDocument2 pagesINGERSOLLRAND 7.120. Specificationghafour saidNo ratings yet

- Legal StatementDocument202 pagesLegal StatementDiego Gonzalez BuendiaNo ratings yet

- Thchnical Manual: Hyper Inverter Packaged Air-ConditionersDocument210 pagesThchnical Manual: Hyper Inverter Packaged Air-ConditionersJOHON SANCHEZNo ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- Generator - Technical Evaluation - 250kva - AMI - R1Document1 pageGenerator - Technical Evaluation - 250kva - AMI - R1sarahalawa222No ratings yet

- Doosan Platinum p185 t4Document4 pagesDoosan Platinum p185 t4dany riversNo ratings yet

- Report AHU - Air BalanceDocument8 pagesReport AHU - Air BalanceAhmed MahmoudNo ratings yet

- Futaba 16iz (En)Document228 pagesFutaba 16iz (En)Marly Salas GonzalezNo ratings yet

- N RKV00029KL Rev00 EngDocument71 pagesN RKV00029KL Rev00 EngSandra Paola Pulido PeñuelaNo ratings yet

- Operating Instructions: Variotrane Tr1 Series 2800Document145 pagesOperating Instructions: Variotrane Tr1 Series 2800Carrera TeoNo ratings yet

- 45VPFTDocument4 pages45VPFTLeo LeiNo ratings yet

- Cybenetics Evaluation Report Corsair HX1000Document9 pagesCybenetics Evaluation Report Corsair HX1000MartinNo ratings yet

- Brochure - Next Generation Rotary Screw Compressors RS-Series 11-22 KW (I & N) PDFDocument2 pagesBrochure - Next Generation Rotary Screw Compressors RS-Series 11-22 KW (I & N) PDFdononoNo ratings yet

- KP D100PDocument5 pagesKP D100PDerek ChenNo ratings yet

- Farm Duty Motors: TEFC (IP55) Single Phase: DescriptionDocument2 pagesFarm Duty Motors: TEFC (IP55) Single Phase: DescriptionBhushan KalgaonkarNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalJazmín Del ValleNo ratings yet

- 35VPFTDocument4 pages35VPFTLeo LeiNo ratings yet

- SD-77DX & SD-77F: TF Series Soil CompactorsDocument2 pagesSD-77DX & SD-77F: TF Series Soil CompactorsCarlos Ediver Arias Restrepo50% (2)

- A31CE Rev 11Document4 pagesA31CE Rev 11Wenderson Soares PiresNo ratings yet

- Cessna 525 LimitationsDocument16 pagesCessna 525 LimitationsCesar BanchoffNo ratings yet

- Erv - Veb1000ath - Specsheet - 2022Document1 pageErv - Veb1000ath - Specsheet - 2022TMVR's TVNo ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- TASK 71-00-00-811-821-A Low EPR - TGT Limited - TGT Goes To Maximum Limit Before Set EPR PDFDocument2 pagesTASK 71-00-00-811-821-A Low EPR - TGT Limited - TGT Goes To Maximum Limit Before Set EPR PDFWidya DamayantiNo ratings yet

- 110 CFM To 260 CFM QXD - ENDocument2 pages110 CFM To 260 CFM QXD - ENJamal HabbasNo ratings yet

- DHC 6 - Faa TCDS A9eaDocument16 pagesDHC 6 - Faa TCDS A9eaRichard MayNo ratings yet

- AEQ FuzesDocument7 pagesAEQ FuzesClaudio Souza OliveiraNo ratings yet

- Component Detail Driver PDFDocument2 pagesComponent Detail Driver PDFMortada AlsonniNo ratings yet

- 05 - Fuel SystemDocument119 pages05 - Fuel SystemWimpie KeyterNo ratings yet

- 1LE7501-1BB23-5AA4 Datasheet enDocument1 page1LE7501-1BB23-5AA4 Datasheet enVinit ShrivastavaNo ratings yet

- Wanner Control Freak ManualDocument28 pagesWanner Control Freak ManualT. LimNo ratings yet

- FILE 20220214 005220 02242021 GM200 Installation and Configuration Guide v3.0Document126 pagesFILE 20220214 005220 02242021 GM200 Installation and Configuration Guide v3.0Khánh Phạm QuốcNo ratings yet

- DA3107 - 0.4kV DGDocument2 pagesDA3107 - 0.4kV DGCassy AbulenciaNo ratings yet

- Type Certificate Data Sheet No. Ia196 Rev 3 (30.10.2017)Document36 pagesType Certificate Data Sheet No. Ia196 Rev 3 (30.10.2017)Juan Manuel Roldán Carretero100% (1)

- CDW3 User manual-ENDocument56 pagesCDW3 User manual-ENJason SonidoNo ratings yet

- Environmental Issues in Peru: Oil & GasDocument2 pagesEnvironmental Issues in Peru: Oil & Gasyoel cueva arquinigoNo ratings yet

- Estudio de Factibilidad de Los Depósitos de Residuos - Proyecto Planta de Cobre de Río SecoDocument1 pageEstudio de Factibilidad de Los Depósitos de Residuos - Proyecto Planta de Cobre de Río Secoyoel cueva arquinigoNo ratings yet

- Warman Slurry Correction Factors HR and ER Pump Power: MPC H S S L Q PDocument2 pagesWarman Slurry Correction Factors HR and ER Pump Power: MPC H S S L Q Pyoel cueva arquinigoNo ratings yet

- Standard Upvc Pipe Sizes: From Iplex 4.5 6 9 12 15 Nominal Size (DN) Outside Diam. Wall Thickness (MM)Document3 pagesStandard Upvc Pipe Sizes: From Iplex 4.5 6 9 12 15 Nominal Size (DN) Outside Diam. Wall Thickness (MM)yoel cueva arquinigoNo ratings yet

- Pump Selection According "Warman Slurry Pumping Handbook"Document12 pagesPump Selection According "Warman Slurry Pumping Handbook"yoel cueva arquinigoNo ratings yet

- Pump Calculation According "Warman Slurry Pumping Handbook": W S W PDocument12 pagesPump Calculation According "Warman Slurry Pumping Handbook": W S W Pyoel cueva arquinigoNo ratings yet

- Entregables Mecánico Piping.1Document1 pageEntregables Mecánico Piping.1yoel cueva arquinigoNo ratings yet

- Richest Athletes: ForbesDocument3 pagesRichest Athletes: Forbesyoel cueva arquinigoNo ratings yet

- R059-01 1x BOM Ts PDFDocument1 pageR059-01 1x BOM Ts PDFCarlos Cesar De SouzaNo ratings yet

- PTOLDAVR10202008Document14 pagesPTOLDAVR10202008tigerpower50% (2)

- Training Report - Ramjas RajpurohitDocument63 pagesTraining Report - Ramjas RajpurohitRAMJAS RAJPUROHITNo ratings yet

- Presentation On Design of Transmission System For A GokartDocument21 pagesPresentation On Design of Transmission System For A GokartNikhil WarungaseNo ratings yet

- Specifications: 2015 G 1.2 MPI KAPPA Automatic Transaxle System SpecificationsDocument49 pagesSpecifications: 2015 G 1.2 MPI KAPPA Automatic Transaxle System SpecificationsHikmah Jevie YusriNo ratings yet

- Avk Centric U-Section Butterfly Valve, PN 10 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric U-Section Butterfly Valve, PN 10 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDavidRNunesNo ratings yet

- Design and Analysis of A Cooling Control System of A Diesel Engine, To Reduce Emissions and Fuel ConsumptionDocument10 pagesDesign and Analysis of A Cooling Control System of A Diesel Engine, To Reduce Emissions and Fuel Consumptionnck_kvNo ratings yet

- Ahmad Shahril Ashraf MohamedDocument24 pagesAhmad Shahril Ashraf MohamedManoj BallaNo ratings yet

- 2V3B-4.1 O2 Spares1217Document1 page2V3B-4.1 O2 Spares1217بشير المتوكلNo ratings yet

- RC2 Series Screw Compressor Maintenance Manual PDFDocument162 pagesRC2 Series Screw Compressor Maintenance Manual PDFthenshanNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- RAC (7th&8th) May2016 PDFDocument2 pagesRAC (7th&8th) May2016 PDFSachin MohalNo ratings yet

- Clutch Type GDocument11 pagesClutch Type GarfanilyasNo ratings yet

- T78u PDFDocument1 pageT78u PDFRenny DevassyNo ratings yet

- Mesys ManualDocument285 pagesMesys Manual王念社No ratings yet

- Dryer Electrolux EDV5051 - EDV6051 PDFDocument12 pagesDryer Electrolux EDV5051 - EDV6051 PDFAdrian GillilandNo ratings yet

- Technical Specification: ConfigurationDocument5 pagesTechnical Specification: ConfigurationKarl ToddNo ratings yet

- Check and AdjustmentDocument4 pagesCheck and Adjustmentjohansen05No ratings yet

- 1kz Te Banda de MotorDocument5 pages1kz Te Banda de MotorTaller Energy EnergyNo ratings yet

- Linked PDFDocument192 pagesLinked PDFroparts cluj0% (1)

- Filter AllDocument3 pagesFilter Alllilik100% (1)

- FS-1128MFP: Parts ListDocument45 pagesFS-1128MFP: Parts ListMikhail100% (1)

- Bajai Qute SpacifiDocument79 pagesBajai Qute Spacifimekonenabdisa3No ratings yet

- Electric Bypass Valve Counteracting Turbo Lag With New Technology 51631Document2 pagesElectric Bypass Valve Counteracting Turbo Lag With New Technology 51631supljinaNo ratings yet