Professional Documents

Culture Documents

SPI POY PETP 2x10 Back-To-back

Uploaded by

anil kapadiaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPI POY PETP 2x10 Back-To-back

Uploaded by

anil kapadiaCopyright:

Available Formats

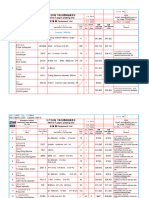

POLYESTER POY 2 X 10 ENDS BACK-TO-BACK

Titer final Process

50 - 300 den

Single filament titer

0,5 - 5,0dpf

Filament count

24 - 216

Ends per position

2 x 10

Mechanical speed

2500 - 4000 m/min

Chuck length

2 x 1500 mm

Bobbin weights

> 15 kg

individual yarn path for every winder (back-to-

back), thus a yarn break on one winder does not Extruder or direct spinning

have any impact on the other yarn path;

small yarn deflection, due to back-to-back spin- Spinning beam series

ning system; SPL6x (back-to-back)

machine is designed for lowest conversion costs;

small space requirement compared to regular Winder type series

spinning systems; 2 x ACW®

choice between an up to 40% lower residence

time, or an up to 40% larger machine;

machine combines high number of ends and

high throughtput; Technical data is dependent on individual opera-

no limits in spinpack size; tion conditions.

best CV values, better than GB standard; Not all values can be combined.

highest take off speeds for DTY and other down-

stream applications;

AA grade is our standard;

fulfills the energy saving requirements for

e-save with Barmag extruder series E8, E10 and

E11, as well as SPL6x.

The e-save label is given to systems and components

that have energy consumptions significantly lower

than standard equivalent systems and components

Example:

spinpack RD77, spinpack spacing 97 mm

=> position spacing 1440 mm instead of >

2000 mm

Barmag

Zweigniederlassung der Saurer GmbH & Co. KG

PZF09-0806

Leverkuser Strasse 65 42987 Remscheid

P.O. Box 11 02 40 42862 Remscheid Germany

Phone: +49 21 91 67-0 Fax: +49 21 91 67-12 04

www.barmag.de info@barmag.de

涤纶POY 2X10头丝背靠背

最终纤度 工艺

50 - 300 den

单丝纤度

0,5 - 5,0dpf

丝数

24 - 216

每位丝头数

2 x 10

机械速度

2500 - 4000 m/min

卡盘长度

2 x 1500 mm

丝饼重量

> 15 kg

每个卷绕头单独的丝路(背靠背),这样,一个卷

绕头发生断丝也不会对另外运行的丝道造成任 切片纺丝或直接纺丝

何影响。

由于采用背靠背的纺丝系统,丝的偏转很小, 纺丝箱体系列

设备为最低成本而设计, SPL6x(背靠背)

比较常规纺丝系统,需要空间很小,

停留时间低至40%,品种可扩大40%, 卷绕头系列

高丝头数和高产量相结合, 2 x ACW®

最好的CV值,高于GB标准,

为DTY和后续工艺需要的最高卷取速度,

AA级是我们的标准,

E8, E10, E11 系列挤压机和SPL6x纺丝箱体达到 技术数据取决于特定的操作状态。

节省能源要求的e-save标志。 不是所有数据都能结合。

e-save标志表示系统和元件的能源消耗显著低于市

场上同类系统和元件的标准能源消耗。

例如:

纺丝组件直径77mm,组件中心距97mm

=>以位距1440mm取代了原有的 > 2000mm

巴马格上海办事处

上海市娄山关路83号

新虹桥中心大厦1308室

电话 +86 21 6236 8005 转真 +86 21 6236 8021

www.barmag.com bso@china.saurer.com

You might also like

- Netsure 531 CaaDocument8 pagesNetsure 531 CaaJinjin GuoNo ratings yet

- Catalog 3c25+3c8 20210315 PUR 44.0Document3 pagesCatalog 3c25+3c8 20210315 PUR 44.0Hùng Lê VănNo ratings yet

- R880剑杆织机Document8 pagesR880剑杆织机du dellNo ratings yet

- Cutmaster 12-40mm手持等离子切割系统Document5 pagesCutmaster 12-40mm手持等离子切割系统carlosNo ratings yet

- BreezeAIR - AXE - 2023 June FINAL - En.zh TWDocument1 pageBreezeAIR - AXE - 2023 June FINAL - En.zh TWPengRyanNo ratings yet

- BX10 综合业务平台 用户手册 V2.4 (有标)Document64 pagesBX10 综合业务平台 用户手册 V2.4 (有标)SALVADORNo ratings yet

- 84334Document2 pages84334Ehsan KhayalNo ratings yet

- 越南西贡PF EA分切机报价10 23Document13 pages越南西贡PF EA分切机报价10 23Phu, Le HuuNo ratings yet

- Advanced Knitting TechnologyDocument2 pagesAdvanced Knitting TechnologycobaNo ratings yet

- RFSZ 柔性罗氏线圈.compressedDocument1 pageRFSZ 柔性罗氏线圈.compressedBaglaNo ratings yet

- C42 MiniDocument3 pagesC42 Minigaminglucky888No ratings yet

- EN1891對於靜力繩 (Static ropes) 的規範與測試Document2 pagesEN1891對於靜力繩 (Static ropes) 的規範與測試Tamara TrejosNo ratings yet

- Clip Die BondDocument8 pagesClip Die BondYeong-Tsuen PanNo ratings yet

- 奥蒂尔梳毛机Autefa Solutions OCTIR ChDocument12 pages奥蒂尔梳毛机Autefa Solutions OCTIR ChliuNo ratings yet

- Catalogue p27 RK Rnedafestoon 2PNCT 1Document5 pagesCatalogue p27 RK Rnedafestoon 2PNCT 1achmad maulanaNo ratings yet

- 28 DS 468 TM1 CAN SAE J1939 24V Screw Flange - ZHDocument9 pages28 DS 468 TM1 CAN SAE J1939 24V Screw Flange - ZHF. Z.No ratings yet

- 305Vac/275Vac) : Metallized Polypropylene Film Interference Suppression Capacitor (Class X2, 305Vac/275Vac)Document4 pages305Vac/275Vac) : Metallized Polypropylene Film Interference Suppression Capacitor (Class X2, 305Vac/275Vac)Faifai ChulanitaNo ratings yet

- 2、磊展设备清单 - D碎配连续碎解Document9 pages2、磊展设备清单 - D碎配连续碎解Aamir ShahzadNo ratings yet

- Sla 05VDC SL CDocument2 pagesSla 05VDC SL CEveraldo JúniorNo ratings yet

- 深圳朗光30W 793 105 0.22 R01 规格书Document2 pages深圳朗光30W 793 105 0.22 R01 规格书月难圆烟花易冷No ratings yet

- 28 DS 464 TM1 CAN SAE J1939 24V Plug-In Flange - ZHDocument9 pages28 DS 464 TM1 CAN SAE J1939 24V Plug-In Flange - ZHF. Z.No ratings yet

- 28 DS 473 TM1 CAN SAE J1939 12 24V Screw Flange - ZHDocument9 pages28 DS 473 TM1 CAN SAE J1939 12 24V Screw Flange - ZHF. Z.No ratings yet

- 28 DS 472 TM1 CANopen 12 24V Screw Flange - ZHDocument9 pages28 DS 472 TM1 CANopen 12 24V Screw Flange - ZHF. Z.No ratings yet

- 粗波分复用器Document3 pages粗波分复用器吴喜平No ratings yet

- 28 DS 471 TM1 CAN SAE J1939 12 24V Plug-In Flange - ZHDocument9 pages28 DS 471 TM1 CAN SAE J1939 12 24V Plug-In Flange - ZHF. Z.No ratings yet

- 2.5 25m/min 2x4kW 16t 2 20m/min 4/0.67m/min - P43 165kN 73kN 22.42kW A5 4x 315 - 12.5/2.1kW 2x0.96kW 10m WHT KAT87Document1 page2.5 25m/min 2x4kW 16t 2 20m/min 4/0.67m/min - P43 165kN 73kN 22.42kW A5 4x 315 - 12.5/2.1kW 2x0.96kW 10m WHT KAT87mijael104No ratings yet

- 2400-2420 CNDocument3 pages2400-2420 CNHui ChenNo ratings yet

- Moxa Nport 6400 6600 Series Datasheet v1.2 CHTDocument13 pagesMoxa Nport 6400 6600 Series Datasheet v1.2 CHTedipskglNo ratings yet

- 儀器工程規範3Document98 pages儀器工程規範3Yang WuNo ratings yet

- 28 DS 463 TM1 CANopen 24V Plug-In Flange - ZHDocument9 pages28 DS 463 TM1 CANopen 24V Plug-In Flange - ZHF. Z.No ratings yet

- SIRIUS Sample CN PDFDocument90 pagesSIRIUS Sample CN PDFHazzim Abu HanipahNo ratings yet

- 多通道層間短路測試系統Document1 page多通道層間短路測試系統Yu FelixNo ratings yet

- KOYO TRDDocument31 pagesKOYO TRDcq_No ratings yet

- Unitech RFID Tags 2023Document3 pagesUnitech RFID Tags 2023mamapam897No ratings yet

- 电线电缆设计、研发、分析改善计算公式大全Document128 pages电线电缆设计、研发、分析改善计算公式大全Tien Dung PhanNo ratings yet

- J K说明书Document30 pagesJ K说明书Эрхэс ЭрхэсNo ratings yet

- 丹弗斯MBC5100Document8 pages丹弗斯MBC5100JUN ZHOUNo ratings yet

- 上海沪析HL 16KS高速微量离心机Document3 pages上海沪析HL 16KS高速微量离心机huripNo ratings yet

- 28 DS 470 TM1 CANopen 12 24V Plug-In Flange - ZHDocument9 pages28 DS 470 TM1 CANopen 12 24V Plug-In Flange - ZHF. Z.No ratings yet

- 打開「ANC40 - - Ver.7 - - ( - ) - 201111」Document29 pages打開「ANC40 - - Ver.7 - - ( - ) - 201111」Oliver HungNo ratings yet

- MA5800-X17&X15&X7&X2 Datasheet 07Document11 pagesMA5800-X17&X15&X7&X2 Datasheet 07Gan LiNo ratings yet

- CN 3189Document2 pagesCN 3189Nata CocoNo ratings yet

- XKXG 高速数控纸吸管机 PDFDocument4 pagesXKXG 高速数控纸吸管机 PDFCiwi KNo ratings yet

- HSD型活塞式电动笛说明书Document13 pagesHSD型活塞式电动笛说明书Sam ZhangNo ratings yet

- CC6407 Sensor de Corriente PDFDocument10 pagesCC6407 Sensor de Corriente PDFsamuel celinNo ratings yet

- 28 DS 244 TM1 Current 24V Screw Flange - ZHDocument9 pages28 DS 244 TM1 Current 24V Screw Flange - ZHF. Z.No ratings yet

- Turner 660 800Document1 pageTurner 660 800Alex LopezNo ratings yet

- 越南西贡Facial tissue报价10-23Document11 pages越南西贡Facial tissue报价10-23Phu, Le HuuNo ratings yet

- FSD883T Data SheetDocument2 pagesFSD883T Data SheetDale XiaoNo ratings yet

- Integrated Coupling Manual: More Than Years of Technical Accumulation Focus On Precision MechatronicsDocument64 pagesIntegrated Coupling Manual: More Than Years of Technical Accumulation Focus On Precision MechatronicsMuhammad SyafiqNo ratings yet

- 28 DS 542 TM1 Voltage 12 24V Plug-In Flange - ZHDocument10 pages28 DS 542 TM1 Voltage 12 24V Plug-In Flange - ZHF. Z.No ratings yet

- FSD450NT Data Sheet - TMM4AD450LDocument2 pagesFSD450NT Data Sheet - TMM4AD450LDale XiaoNo ratings yet

- BOSCH PRO - ID IdDocument110 pagesBOSCH PRO - ID IdRully TeguhNo ratings yet

- 杰普特60W ..M7Document24 pages杰普特60W ..M7Info PLSNo ratings yet

- 翁先生Sansen's 10ft 无卡机和双卡机报价Document4 pages翁先生Sansen's 10ft 无卡机和双卡机报价Eric ChowNo ratings yet

- Technical Data Sheet. 2024.2.28Document4 pagesTechnical Data Sheet. 2024.2.28k.bifuNo ratings yet

- 屋內微簇型光纜Document20 pages屋內微簇型光纜AQUANo ratings yet

- WS976240135-M Datasheeet Rev A3Document2 pagesWS976240135-M Datasheeet Rev A3Reza AmaniNo ratings yet

- Atlas Copco APE - 空压机大机-中高风压Document4 pagesAtlas Copco APE - 空压机大机-中高风压NunoNo ratings yet

- XDXLXG系列PLC系统更新操作说明2023 3 9Document15 pagesXDXLXG系列PLC系统更新操作说明2023 3 9quân nguyễnNo ratings yet

- NC Editor ManualDocument346 pagesNC Editor ManualThecch MG RamziNo ratings yet

- ASTM D882-18 Standard Test Method For Tensile Properties of Thin Plastic Sheetin.Document12 pagesASTM D882-18 Standard Test Method For Tensile Properties of Thin Plastic Sheetin.resty manuelNo ratings yet

- What's New in Dental System 2019 - ChineseDocument29 pagesWhat's New in Dental System 2019 - ChineseDoctor JackNo ratings yet

- Foxit PhantomPDF - Quick GuideDocument35 pagesFoxit PhantomPDF - Quick GuidexNo ratings yet

- 《现代C 白皮书》电子版Document207 pages《现代C 白皮书》电子版fjz13No ratings yet