Professional Documents

Culture Documents

Static Structural Analysis of Gear Tooth: Abstract

Static Structural Analysis of Gear Tooth: Abstract

Uploaded by

Ans BarrungOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Static Structural Analysis of Gear Tooth: Abstract

Static Structural Analysis of Gear Tooth: Abstract

Uploaded by

Ans BarrungCopyright:

Available Formats

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

Static Structural analysis of gear tooth

RESEARCH ARTICLE OPEN ACCESS

Pravin B. Sonawane1, P.G.Damle2

1

B.E. Mechanical, SSBT’s COE Bambhori, Jalgaon

2(Associate Prof.) Department. of Mechanical Engineering ,COE , Bambhori, Jalgaon.

Abstract:

This study investigate the characteristics of a gear system including contact stresses, bending

stresses, and the transmission errors of gears in mesh. Gearing is one of most critical component in

mechanical power transmission systems. The bending stresses in the tooth root were examined using 3D

model.

Current methods of calculating gear contact stresses use Hertz’s equations and Lewis Equation

which were originally derived for contact between two cylinders. To enable the investigation of contact

problems with FEM, the stiffness relationship between the two contact areas is usually established

through a spring placed between the two contacting areas. This can be achieve by inserting a contact

element in between the two areas where contact occurs. The results of the three dimensional FEM analysis

from ANSYS are presented. These stresses were compared with theoretical values. Both results agree very

well. This indicates that the FEM model is accurate.

This report also considers the variations of the whole body stiffness arising from gear body

rotation due to bending deflection, shearing displacement and contact deformation. Many different

positions within the meshing cycle were investigated. Investigation of contact and bending stress

characteristics of spur gears continues to be immense attention to both engineers and researchers in spite

of many studies in the past.

This is because of the advances in the engineering technology that demands for gears with ever

increasing load capacities and speeds with high reliability, the designers need to be able to accurately

predict the stresses experienced the stresses by the loaded gears.

Keywords — Spur Gear Tooth, Ansys 14.5 Workbench and classic, Lewis Equation.

INTRODUCTION: breakage is clearly the worst case of damage, since

Spur gears are the most common means the gear could have seriously hampered operating

of transmitting power in the modern mechanical condition. Because of this, the stress in the tooth

world. They vary from tiny size used in the watches should always be carefully studied in all practical

to the large gears used in marine speed reducers; gear application. The fatigue process leading to

bridge lifting mechanism and railroad turn table tooth breakage is divided into crack initiation and

drivers. They for vital elements of main and crack propagation period. However, the crack

ancillary mechanism in many machine tools, initiation period generally account for the most of

rolling mills, hoisting and transmitting machinery service life, especially in high cycle fatigue.

and marine engines etc. Spur gears are very useful in numerous

The four major failure modes in gear applications. Not only can they transfer velocity

systems are tooth bending fatigue, contact fatigue, and torque one shaft to other shaft, but, by using

surface wear and scoring. Two kinds of teeth different size gears, they can alter the ratio between

damage can occur on gears under repeated loading velocity and torque as they transfer them; a gear

due to fatigue; namely the pitting of gear teeth with many teeth driving a gear with fewer teeth will

flanks and tooth breakage in the tooth root. Tooth

ISSN: 2395-1303 http://www.ijetjournal.org Page 39

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

have less torque, but greater velocity and vice

versa. Unfortunately, spur gears require a very

specific shape for their teeth to work smoothly.

Even a simple mockup gear would require a

complex surface in order to function properly.

Without the calculations required to create these

surfaces, two gears would not mesh together

smoothly, making it difficult to test the gears. But

mockup does not need to work for a long period of

time; it can be made of lighter, easily cut materials.

These lighter materials could be handle by a laser

cutter if suitable instructions were developed so

that the proper shape of teeth could be computed.

The tooth of spur gear is based on a

mathematical shape as an involute. Since each

tooth can be described by a series of mathematical

equations, it is possible to define a gear in terms of Figure 1 Gear teeth meshing.[1]

a few key parameters, such as the number of teeth SPUR GEAR TERMINOLOGY:

and diameteral pitch. These parameters make it

easy to tell if two gears can mesh together.

Similarly by specifying the parameters first, it

would be simple to design a gear for any given

applications from scratch.

Because spur gear is essentially two

dimensional shapes they could be cut out quickly

using a laser cutter. Laser cutters use a laser beam

to slice two dimensional shapes out of flat material,

so the silhouette of a spur gear would be easy to

make using a laser cutter. Unfortunately, most laser

cutter do not have built in software’s to cut gears;

They are driven by a series of simple move-to and

draw-to commands, tracing out straight lines or

elliptical arcs across the material. Therefore, an

involute must first be converted into

approximations using these simple commands in

order for the cutter to understand it. If a laser cutter Figure 3.1 Gear terminology [1]

is to be useful in creating mockups, it must be able DEFINITIONS:-

to cut these gear designs quickly and easily.

1) Module: - It is defined as the ratio of diameter to

the number of teeth.

2) Face width (b):- It is the width along the contact

surface between the gears.

3) Addendum: - The radial distance between the pitch

circle and the top land of the gear is called the

addendum.

4) Dedendum: - The radial distance between the pitch

circle and the bottom land of the gear is called

dedendum.

ISSN: 2395-1303 http://www.ijetjournal.org Page 40

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

5) Pitch circle: - It is an imaginary circle which by The theoretical design calculations are performed

pure rolling action would give the same motion as using the input parameters given below

the actual gear. No. of Teeth in the Pinion = 20

6) Root circle: - It is the circle drawn through the No. of Teeth in the Gear = 80

bottom of the tooth. Module m = 4 mm

7) Pressure angle: - It is the angle between the Width of Teeth = 60 mm

common normal to two gear teeth at the point of Speed of Pinion N = 400 rpm

contact and the common tangent at the pitch point. Tooth profile = 20 degree involute

The standard pressure angles are 14.5 and 20. Service factor = Cs = 0.8

8) Diametral pitch: - it is the ratio of number of teeth Velocity factor = Kv = 3

to the pitch circle diameter. Allowable bending strength of material

= 200 Mpa, for pinion

DESIGN PARAMETERS: = 160 Mpa, for Gear

= Velocity factor SOLUTION:-

= Structural stiffness Lewis form factor = 0

Velocity factor

U = Displacement vector Dp = m * Tp = 4 * 20 = 80 mm

Dg = m * Tg = 4 * 80 = 320 mm

F =Applied load vector Addendum = m = 4 mm

Dedendum = 1.25 * m = 1.25* 4 = 5 mm

Pmax = Maximum contact stress Minimum clearance = 0.25 * m = 0.25 * 4 = 1 mm

Tip circle dia. Of pinion = Dp + (2*m) = 88 mm

Dp = Pinion pitch diameter Root circle dia. Of Pinion = Dp –(2 * m) = 72 mm

Tip circle dia. Of Gear = Dg +(2 * m) = 328 mm

Dg = Gear pitch diameter Root circle dia. Of Gear = Dg – ( 2*m) = 312 mm

V = 3.14* Dp*Np/ (60*1000)

Fi =Load per unit width = 3.14*80*400/(60*1000)

= 1.67 m/s

Φ =Pressure angle Velocity factor Cv = 3 / (3+ 1.67)

= 0.642

E = Young‘s modulus Lewis form factor for pinion =

Yp = 0.154 – (0.912/20)

b = face width = 0.1084

Lewis form factor for Gear =

pd = Diametric pitch Yg = 0.154 – (0.912/80)

= 0.1426

Y = Lewis form factor Therefore tangential force transmitted is given by

Ft =

Ks = Size factor = 200*0.642*3.14*60*4*0.1426

= 8382.40 N

Ft = Normal tangential load Now power transmitted for the given force is

P = Ft *1.67 = 13998.60

MATHEMATICAL CALCULATIONS: =13.99 kw

PROBLEM:- For calculating bending stress for gear, the Lewis

Calculate the power that can be transmitted safely equation is

by a pair of spur gears with the data given below. σ t = Ft/(Kv*m*b*Yp)

Calculate the power and the bending stress induced σ t = 8382.40/(3*4*60*0.1084)

in the two wheels when the pair transmits that σ t = 107.40 Mpa

power. [1] And bending stress for pinion is calculated using

ISSN: 2395-1303 http://www.ijetjournal.org Page 41

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

σ t = Ft/(Kv*m*b*Yg) manufacturers have to reply on this technique to

= 8382.4/(3*4*60*0.1420) stay competitive.

= 81.98 Mpa FEA has been used routinely in high volume

MATERIAL PROPERTIES:- production and manufacturing industries for many

years, as to get a product design wrong would be

Properties Gear

detrimental. For example, if a large manufacturer

Material Name Structural Steel had to recall one model alone due to a hand brake

design fault, they would end up having to replace

Youngs Modulus 2E5 Mpa up to few millions of hand brakes. This will cause a

Yield strength 250 Mpa heavier loss to the company.

STATIC ANALYSIS:-

Poissons Ratio 0.3 There are two types of static analysis

1) Linear static analysis:

Density 7850 kg/m3

Linear means straight line. In this analysis

the ratio stress to strain is linear or straight line. But

in real life after crossing yield point material

FINITE ELEMENT ANALYSIS: follows nonlinear curve but software follows same

straight line. Component brake into two separate

The basic concept in FEA is that the

pieces after crossing ultimate stress but software

body or structure may be divided into smaller

based analysis never shows failure in this fashion.

elements of finite dimensions called “Finite

It shows single unbroken part with red colour zone

elements”. The original body or the structure is

at the location of failure. Analyst has to conclude

then considered as an assemblage of these elements

whether the component is safe or failed by

connected at a finite number of joints called

comparing the maximum stress value with yield or

“Nodes” or “Nodal Points”. Simple functions are

ultimate stress.

chosen to approximate the displacement over each

finite element. Such assumed functions are called

“shape functions”. This will represent the

displacement within the element in terms of the

displacement at the nodes of the element.

The FEM is a mathematical tool for

solving ordinary and partial differential equations.

Because it is a numerical tool, it has the ability to

solve the complex problem that can be represented

in differential equations form. The applications of

FEM are listless as regards the solution of practical

design problems. Due to high cost of computing

power of years gone by, FEA has a history of being

used to solve complex and cost critical problems.

Classical methods alone usually cannot provide

adequate information to determine the safe Fig. 5.1 Stress and Strain curve

working limits of a major civil engineering There are two conditions for static analysis

construction or an automobile or aircraft. Force is static. i.e. no variation with respect to

In the recent years, FEA has been time(dead weight).

universally used to solve structural engineering Equilibrium condition: - summation of forces and

problems. The departments, which are heavily moments in x,y and z direction is zero. FE model

relied on this technology, are the automotive and fulfils this condition at each and every nodes.

aerospace industry. Due to the need to meet the

extreme demands for faster, stronger, efficient and

lightweight automobiles and aircraft,

ISSN: 2395-1303 http://www.ijetjournal.org Page 42

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

From the physics of the problem we

have to apply the field conditions i. e. loads and

constraints, which will help us in solving for the

unknowns.

Assembling the system equations:-

This involves the formulations of

respective characteristics (stiffness in case of

structural) equation of matrices and assembly.

Solution for system equation:-

Fig. 5.2 static force Solving for the equations to know the

2) Non-linear static analysis: unknowns. This is basically the system of matrices

which are nothing but a set of simultaneous

In nonlinear analysis stress Vs strain curve equations are solved.

Viewing the results:-

is nonlinear.

After the completion of the solution we have to

review the required results. The first two steps of

the above said process is known as pre-processing

stage, third and fourth is the processing stage and

final stage is known as post-processing stage.

What is an element?

Element is an entity, into which a system

under study can be divided into. An element

definition can be specified by nodes. The shape

(area, length, and volume) of the element depends

upon the nodes with which it is made up of.

What are Nodes?

Fig.5.3 stress and strain curve of metals and nonmetals Nodes are the corner points of the

element. Nodes are independent entities in the

WHY FEA?

space. These are similar to points in geometry. By

FEA used in problems moving a node in space an element shape can be

where analytical solutions are not easily obtained. changed.

Mathematical expressions required for solutions TYPES OF FINITE ELEMENTS:

not simple because of complex geometry, loading 1-D Element: -( Line Elements: )

and material properties. 2-D Element:-

Analytical methods involve solving for 3-D Element: -

entire system in one operation. FEA involving CREATING A SOLID MODEL:

defining equations for each element and combining Modeling provides the design engineer

to obtain system solution. comfortable modeling techniques such as

BASIC STEPS INVOLVED IN FEA: sketching, feature based modeling, and dimension

Basic steps: - driven editing. An excellent way to begin a design

Discretization of domain:- concept is with a sketch. When you use a sketch, a

All real life objects are continuous. rough idea of the part becomes represented and

Means there is no physical gap between any two constrained, based on the fit and function

consecutive particles. As per material science any requirements of your design. In this way, your

object is made of small particles, particles of design intent is captured. This ensures that when

molecules, molecules of atom and so on. Hence the the design is passed down to the next level of

task is to divide the continuous object into number engineering, the basic requirements are not lost

of subdivisions called Element. Based on when the design is edited.

continuum it can be divided into line or area or

volume elements.

Application of Boundary conditions:-

ISSN: 2395-1303 http://www.ijetjournal.org Page 43

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

Modeling CATIA and ending with a finished model. First, you can

create a sketch "outline" of curves.

Then you can sweep or rotate these curves to create

a complex portion of your design.

Start

SPUR GEAR ANALYSIS:

Get the input data Now, the 3D which was created in

required CATIA is imported in ANSYS workbench 12 for

stress analysis. It is done by saving drawing in STP

or IGS file format in CATIA. After the model is

imported in ANSYS workbench 12, as the both

Draw the parts as per

teeth are already in contact, our main purpose is to

given

find the root bending stress. This is done by using

following steps in ANSYS workbench 12.

The objective of the analysis is to perform

Assemble all the structural static analysis on the gear by applying

individual parts tangential load and examine the deflections and

stresses.

The 3-D model of the spur gear in CATIA

Save the files in iges converted it into “iges” and “step” file. And then

/step format iges file is then imported into ansys workbench.

3-DIMENSIONAL ANALYSIS OF SPUR GEAR: - For

imported 3-dimensional geometry, firstly we select

Stop 3-D and static structural analysis from menu and

connecting the geometry to the analysis tab. Then

PARAMETRIC MODELING OF GEAR USING CATIA next we enter Young’s modulus and Poisson’s ratio

V5 of the material.

MESH GENERATION AND BOUNDARY

CONDITION:- (supports and load):- A tetrahedron

solid elements is used in mesh generations.

Boundary condition refers to the external load on

the border of the structure. We assumed gear is

with fixed support and pinion is subjected to a

moment or torque along its axis with frictionless

support.

MESHING OF GEAR:-

Figure 7.1 3D model of gear

The strategy you use to create and edit

your model to form the desired object depends on

the form and complexity of the object. You will

likely use several different methods during a work

session. The next several figures illustrate one

example the design process, starting with a sketch

ISSN: 2395-1303 http://www.ijetjournal.org Page 44

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

BOUNDARY CONDITION OF GEAR:- Figure 8.1 Boundary Conditions

RESULT:

MAXIMUM VONMISSES STRESS:-

ISSN: 2395-1303 http://www.ijetjournal.org Page 45

International Journal of Engineering and Techniques - Volume 2 Issue 3, May – June 2016

Theoretically result obtained by Lewis formula are

comparable with Finite Element Analysis of spur

gear.

Maximum von mises stress observed in structural

steel gear is 105 Mpa on Ansys and 107 Mpa by

theoretically.

Maximum deflection of 0.035mm observed in the

gear along x-direction.

ACKNOWLEDGEMENT:

It gives me a great pleasure in expressing

my thanks and profound gratitude to Dr. D. S.

Deshmukh HOD, Mechanical Engineering

Department, COE, Bambhori,Jalgaon for their

DEFLECTION :-

valuable guidance and encouragement throughout.

I am heartily thankful to him for his continuous

suggestions and clarifying the concepts of the topic

that helped me a lot during this study.

REFERENCE:

1) R.S.Khurmi “ Machine Design”.

2) Nitin S. Gokhale “Practical

Finite Element Analysis”.

3) Sushilkumar Tiwari and

Upendra kumar Joshi “Stress

Analysis Of Mating Involute Spur

Gear”IJERT 2012.

4) Ansys 14.5

5) Catia v5 R20

I Am Pravin B. Sonawane , B.E. Mechanical from

MSS’s CET,Nagewadi,Jalna,2010.

Now Pursuing M.E. Mechanical (Machine Design)

from SSBT’s COE Bambhori, Jalgaon.

Guide- P.G.Damle, (Associate Prof.) Department.

CONCLUSION: of Mechanical Engineering ,COE , Bambhori,

Jalgaon.

The above study shows that the Finite Element

Method can be used for bending stress analysis in a

pair of gear. Bending Stress calculation is play

more significant role in the design of gear. This

study is shows that Lewis formula is use for

calculating bending stress in a pair of gear.

ISSN: 2395-1303 http://www.ijetjournal.org Page 46

You might also like

- A Guide To Your Dampers Chapter From FSAE Book by Jim Kasprzak UpdatedDocument26 pagesA Guide To Your Dampers Chapter From FSAE Book by Jim Kasprzak UpdatedPRAVEEN KUMARNo ratings yet

- Project Report Manufacturing Process and Design of Machine Elements Gear BoxDocument23 pagesProject Report Manufacturing Process and Design of Machine Elements Gear BoxNisarg PatelNo ratings yet

- Design of Spur GearDocument67 pagesDesign of Spur GearShubham DhurjadNo ratings yet

- Structural Analysis 7 Edition in SI Units: Approximate Analysis of Statically Indeterminate StructuresDocument43 pagesStructural Analysis 7 Edition in SI Units: Approximate Analysis of Statically Indeterminate StructuresAre FiqNo ratings yet

- Chapter-3 Load and Stress AnalysisDocument96 pagesChapter-3 Load and Stress AnalysisDhinesh3693100% (1)

- A New Approach For The Calculation Of: Worm Shaft DeflectionDocument10 pagesA New Approach For The Calculation Of: Worm Shaft DeflectionrozenilNo ratings yet

- Gearbox NOisesDocument5 pagesGearbox NOisesvijay anandhNo ratings yet

- Optimization of Gear Reduction Unit Through Ray DiagramDocument7 pagesOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- Design and Structural Analysis of Spur Gear Using Various MaterialsDocument15 pagesDesign and Structural Analysis of Spur Gear Using Various MaterialsprajeeshNo ratings yet

- GearDocument57 pagesGeargautham_93100% (1)

- Pressure Vessel Design12Document85 pagesPressure Vessel Design12Victor Rizal Filosofi100% (9)

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of GearboxChandrakiran AlapatiNo ratings yet

- 9 Markscheme HL Paper1Document40 pages9 Markscheme HL Paper1lmao heyNo ratings yet

- Machine Design & Drawing - II - GEARSDocument12 pagesMachine Design & Drawing - II - GEARSSenthil KumarNo ratings yet

- Face Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannDocument8 pagesFace Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannosaniamecNo ratings yet

- Finite Element Method: Project ReportDocument15 pagesFinite Element Method: Project ReportAtikant BaliNo ratings yet

- Spur Gears Are The Most Common Type of GearsDocument9 pagesSpur Gears Are The Most Common Type of GearsEngineering ProjectNo ratings yet

- Ingranaggi Esempoi Agma Inglese 33360-32959-4-PB PDFDocument7 pagesIngranaggi Esempoi Agma Inglese 33360-32959-4-PB PDFmgualdiNo ratings yet

- Design Process of Energy Effective Shredding Machines For Biomass TreatmentDocument5 pagesDesign Process of Energy Effective Shredding Machines For Biomass TreatmentAhmed ShawkiNo ratings yet

- Contact Stress and Fatigue Analysis of Spur GearDocument6 pagesContact Stress and Fatigue Analysis of Spur GearSharath P CNo ratings yet

- Design and Analysis of Lead Screw For FixtureDocument7 pagesDesign and Analysis of Lead Screw For FixtureA PPNo ratings yet

- Gear ShavingDocument6 pagesGear ShavingRuchira Chanda InduNo ratings yet

- Finite Element Analysis of Spur Gear UseDocument7 pagesFinite Element Analysis of Spur Gear UseDevendranath MagantiNo ratings yet

- Design of Spur Gear - Fundamentals - 1Document19 pagesDesign of Spur Gear - Fundamentals - 1Dhyan PatelNo ratings yet

- Gear Mechanism 409Document15 pagesGear Mechanism 409raveshrathod061No ratings yet

- Irjet V5i5220Document4 pagesIrjet V5i5220afaq AhmadNo ratings yet

- Comparative Study of Stress Analysis ofDocument6 pagesComparative Study of Stress Analysis ofMrigyank MishraNo ratings yet

- Faculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, PuneDocument57 pagesFaculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, Puneraghav maskeNo ratings yet

- Transient Stress Analysis On Spur GearDocument8 pagesTransient Stress Analysis On Spur GearPrithviraj DagaNo ratings yet

- 6-Screw and Gear MeasurementDocument50 pages6-Screw and Gear MeasurementRohit BhangaleNo ratings yet

- Design and Fabrication of Metal Spinning ComponentsDocument6 pagesDesign and Fabrication of Metal Spinning ComponentsAnonymous VRspXsmNo ratings yet

- Gear Box Machine DesignDocument28 pagesGear Box Machine DesignPankaj DoshiNo ratings yet

- Elements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasDocument13 pagesElements of Metric Gear Technology: Table 1-5 (Cont.) Spur Gear Design FormulasRakeshvb10No ratings yet

- 2 Gear BasicsDocument6 pages2 Gear BasicsMohamed Adel RizkNo ratings yet

- No Work FilesDocument8 pagesNo Work FileslitonNo ratings yet

- Experimental Set Up On Metal Spinning PDFDocument7 pagesExperimental Set Up On Metal Spinning PDFAnonymous VRspXsmNo ratings yet

- C504051018 PDFDocument9 pagesC504051018 PDFlitonNo ratings yet

- Spur Gear Design Some New Perspectives DDocument12 pagesSpur Gear Design Some New Perspectives DUsama GulzarNo ratings yet

- Thread Root RadiusDocument6 pagesThread Root RadiusVasile CojocaruNo ratings yet

- Design Analysis of Spur Gear With The Usage of The Advanced ComputerDocument6 pagesDesign Analysis of Spur Gear With The Usage of The Advanced ComputerMohammed JimmyNo ratings yet

- A New Dynamic Model For Drilling and Reaming Processes Yang2002Document13 pagesA New Dynamic Model For Drilling and Reaming Processes Yang2002RihabChommakhNo ratings yet

- penerbit,+RPMME+Vol 2+no 1+ (213-222)Document10 pagespenerbit,+RPMME+Vol 2+no 1+ (213-222)phongkhungphuhoi1986No ratings yet

- DJJ 10033-Chapter 5Document45 pagesDJJ 10033-Chapter 5Abbas SeuNo ratings yet

- General Aspects of Speed Increaser GearboxesDocument10 pagesGeneral Aspects of Speed Increaser GearboxesRahul AgnihotriNo ratings yet

- Finite Element Analysis of Ultrasonic Stepped HornDocument6 pagesFinite Element Analysis of Ultrasonic Stepped HornDr. Ziad Shakeeb Al SarrafNo ratings yet

- GRDJEV01I110053Document4 pagesGRDJEV01I110053ajiejohn56No ratings yet

- A Study On Optimized Design of A Spur Gear Reduction UnitDocument7 pagesA Study On Optimized Design of A Spur Gear Reduction UnitSolomon Muhabaw MulatNo ratings yet

- Engineering MetrologyDocument16 pagesEngineering Metrologyvedantbakal043No ratings yet

- Design of Involute Spur Gears With Asymmetric Teeth & Direct Gear DesignDocument4 pagesDesign of Involute Spur Gears With Asymmetric Teeth & Direct Gear DesignPushparaj VigneshNo ratings yet

- Notes Machine DesignDocument13 pagesNotes Machine DesignVishak ReguNo ratings yet

- Design and Fabricaion of Metal Spinning With Lathe CarriageDocument6 pagesDesign and Fabricaion of Metal Spinning With Lathe CarriageInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Research Paper 165577Document13 pagesResearch Paper 165577alberto garciaNo ratings yet

- Synthesis and Analysis of Plastic Curved Facewidth Spur GearsDocument9 pagesSynthesis and Analysis of Plastic Curved Facewidth Spur GearsMarilena MereutaNo ratings yet

- Paper Rajshahi 1Document6 pagesPaper Rajshahi 1Shantonu Mitra ShantoNo ratings yet

- GEARSDocument35 pagesGEARS1237Nasmal NNo ratings yet

- Ilovepdf MergedDocument10 pagesIlovepdf Mergedhigabac297No ratings yet

- Iba2019 Article VisualizationOfPhaseDifferenceDocument7 pagesIba2019 Article VisualizationOfPhaseDifferenceranim najibNo ratings yet

- Design of GearsDocument62 pagesDesign of Gearsصبا رياض فتاح الرفاعيNo ratings yet

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of Gearboxijaert100% (1)

- Analysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisDocument7 pagesAnalysis of Stress and Deflection of Spur Gear by Using New Analytical Method Based On Taguchi Method and Finite Element AnalysisEditor IJTSRDNo ratings yet

- Design and Finite Element Analysis of Broaching Tools: A.V. Pradeep, K. Ram Prasad, T. Victor BabuDocument8 pagesDesign and Finite Element Analysis of Broaching Tools: A.V. Pradeep, K. Ram Prasad, T. Victor BabuSanchit SinglaNo ratings yet

- Bending Stress Analysis of Spur Gear by Using Modified Lewis FormulaDocument7 pagesBending Stress Analysis of Spur Gear by Using Modified Lewis FormulalitonNo ratings yet

- Performance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisFrom EverandPerformance-Based Gear Metrology: Kinematic - Transmission - Error Computation and DiagnosisNo ratings yet

- VK DK ?KKS"K.KK I : GLRK (KJ Izek - KHDJ.K VF/KDKJH DK Uke E In, Oa LhyDocument1 pageVK DK ?KKS"K.KK I : GLRK (KJ Izek - KHDJ.K VF/KDKJH DK Uke E In, Oa LhyPRAVEEN KUMARNo ratings yet

- Presentation 1Document7 pagesPresentation 1PRAVEEN KUMARNo ratings yet

- SAE India - Member PanelDocument1 pageSAE India - Member PanelPRAVEEN KUMARNo ratings yet

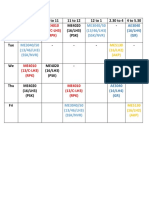

- Time TableDocument1 pageTime TablePRAVEEN KUMARNo ratings yet

- Topic 7 FF in Res 1Document18 pagesTopic 7 FF in Res 1Aneesch PreethaNo ratings yet

- Dynamic Meteorology 9Document16 pagesDynamic Meteorology 9Harish ChoudharyNo ratings yet

- Me-302 Id (Ao819) PDFDocument2 pagesMe-302 Id (Ao819) PDFVikasNo ratings yet

- Lesson Plan: Institute of Space TechnologyDocument4 pagesLesson Plan: Institute of Space TechnologyShahZaib AnwarNo ratings yet

- Analiza Arbore Cotit La VibratiiDocument3 pagesAnaliza Arbore Cotit La VibratiiLuca VictorNo ratings yet

- Assignment 3 DmeDocument3 pagesAssignment 3 DmeSubash DgłNo ratings yet

- 201110041553114e8b2be737b6cDocument17 pages201110041553114e8b2be737b6cAngel LaraNo ratings yet

- 075 DPDocument9 pages075 DPsharvan10No ratings yet

- 07a4ec10-Em Waves and Transmission LinesDocument5 pages07a4ec10-Em Waves and Transmission LinesSRINIVASA RAO GANTANo ratings yet

- Proceedings of Spie: Photoelastic Determination of Fatigue Crack Stress Intensity FactorsDocument9 pagesProceedings of Spie: Photoelastic Determination of Fatigue Crack Stress Intensity FactorsUdhamNo ratings yet

- Study Guide For Module No. 2Document6 pagesStudy Guide For Module No. 2khyle alaganoNo ratings yet

- Unit-1 Questions-Applied PhysicsDocument2 pagesUnit-1 Questions-Applied Physicsrajesh.v.v.kNo ratings yet

- Energy of Electron in Bohr'S Orbit Iit Jee - NeetDocument19 pagesEnergy of Electron in Bohr'S Orbit Iit Jee - NeetjosephNo ratings yet

- Akcc - 1Document2 pagesAkcc - 1intel pcNo ratings yet

- 12 Physics Lyp 2017 Out Delhi Set2Document6 pages12 Physics Lyp 2017 Out Delhi Set2Gurpreet SinghNo ratings yet

- Boyles Law 2Document1 pageBoyles Law 2malaomarNo ratings yet

- Ring Laser GyroDocument6 pagesRing Laser GyrovishwaaskNo ratings yet

- EMECH 2 MarksDocument18 pagesEMECH 2 MarkspavanraneNo ratings yet

- 8.012 Physics I: Classical Mechanics: Mit OpencoursewareDocument8 pages8.012 Physics I: Classical Mechanics: Mit OpencoursewareAlexandru CiobanuNo ratings yet

- 3 Moment of A Force1Document5 pages3 Moment of A Force1Philip MooreNo ratings yet

- Atom Stations 19-20 Answer SheetDocument6 pagesAtom Stations 19-20 Answer SheetАбдурахман ПсиксNo ratings yet

- Penthouse Fall 1999Document2 pagesPenthouse Fall 1999John M. CavoteNo ratings yet

- All India Shri Shivaji Memorial Society's Polytechnic, Pune-01Document17 pagesAll India Shri Shivaji Memorial Society's Polytechnic, Pune-012031 Ayush KshirsagarNo ratings yet

- Sample Seismic Analysis ReportDocument14 pagesSample Seismic Analysis ReportricardobonillaNo ratings yet

- ACI Spring 2016 - Thixotropy - Kawashima - FinalDocument20 pagesACI Spring 2016 - Thixotropy - Kawashima - FinalerosNo ratings yet

- Learning HubDocument6 pagesLearning HubSai Santhosh ManepallyNo ratings yet