Professional Documents

Culture Documents

Biomechanical Analysis of Electric Powered Wheelchair by Reverse Engineering Modelling Technology

Uploaded by

Dileep KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biomechanical Analysis of Electric Powered Wheelchair by Reverse Engineering Modelling Technology

Uploaded by

Dileep KumarCopyright:

Available Formats

Biomedical Research 2017; 28 (8): 3651-3659 ISSN 0970-938X

www.biomedres.info

Biomechanical analysis of electric powered wheelchair by reverse engineering

modelling technology.

Mai S. Mabrouk1*, Samir Y. Marzouk2, Heba M. Afify3

1Department of Biomedical Engineering, MUST University, Egypt

2Departement of Basic and Applied Science, Arab Academy of Science and Technology, Egypt

3Department of Bioelectronics Engineering, MTI University, Egypt

Abstract

Wheelchair technology is one of the most significant technologies in biomechanics sector. The demand of

Electric Powered Wheelchairs (EPWs) has been increasing due to improving the lifestyles of patients

suffering from one or more disabilities, including motor control problems, spinal injuries, arthritis,

balance disorders and amputation under the term of rehabilitation technologies. Hence, the healthcare

research has made several plans for improving control of EPW to provide well-being, and safety by

minimal cost. On the other hand, Reserve Engineering (RE) is a powerful technique for creating a new

model to uncover the features of commercial products and enhance them. As such, we applied RE to

develop a functional model through teardowns that designed by SolidWorks 3D Computer Aided Design

(CAD) software to provide the full specifications of EPW. Moreover, we implemented an Arduino

microcontroller to change the EPW directionality by using a joystick. This model evaluates the

flexibility and wireless control of EPW by adding further improvements such as an ultrasonic sensor

and Bluetooth connection. Ultrasonic sensor acts as an emergency stop switch to notify the patient when

roaming close to an obstacle as a safety precaution. Bluetooth connection device allows the patient to

remotely control the electric wheelchair if it was out of reach or there’s no one close to assist. The main

characteristic of our model is mobility performance without depending on others’ help that based on an

affordable cost.

Keywords: Electric powered wheelchairs, Rehabilitation, Reserve engineering, SolidWorks, Computer aided design.

Accepted on January 10, 2017

Introduction small joystick and translate that motion into power to the

wheels to move in the desired direction. The earliest research

Improved wheelchair mobility could be an important factor in by Beekman [3] explained that patients with paraplegia and

realizing increased independence for patients unable to walk. It tetraplegia have the ability of mobility readily by using

attempts to restore human abilities that have been reduced or lightweight wheelchairs instead of standard wheelchairs.

lost by disease, accident or aging [1]. Manual wheelchairs can Brown et al. [4] presented a model for PID controller

be operated by patients who have the use of their upper body or implemented on a microprocessor, which is used for joystick

someone available to assist [2]. EPWs have been developed to controllers of EPWs. This model lacks stability. Furthermore, it

be used when neither of these cases is available. However, is an inappropriate for wheelchair's motion changes.

there have been few advances made with EPW due to lack of a

high level of user control thus it can result in injury to the In recent decades, many biomechanical studies have discussed

patient during the EPW operating process. the possibilities of EPW to improve the stability and mobility

of handicapped patients who are too weak to propel themselves

The capability of patients to push their own wheelchair [5,6]. Rentschler et al. [7] discussed five types of EPW which

successfully is affected by three main factors: patient included three Rear Wheel Drive (RWD), one Mid-Wheel

characteristics (e.g. type and degree of disability, patient Drive (MWD) and one Front Wheel Drive (FWD). These were

dimensions, patient weight and patient age), wheelchair implemented on set of experiments which provided an

properties (e.g. size and weight of wheelchair, size and type of important influence on moving with stability and safety.

wheels and tires, axle position, backrest height and use of

armrests), and wheelchair/patient interface (e.g. patient adapt Wheelchairs that based on renewable energy systems (batteries

and adjust of the chair for patient). The most basic task of the and solar panels) have been studied in another research [8], in

chair is to take input from the patient, usually in the form of a which solar panels have been found to be employed as a good

Biomed Res- India 2017 Volume 28 Issue 8 3651

Mabrouk/Marzouk/Afify

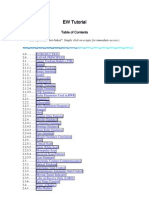

and cheap source of energy. However, the time taken to charge RE mechanical components. RE modelling and analysis, and

the chair was an obstacle. If chair charge need to be increased, redesign [17] as shown in Figure 2. The first phase is divided

many number of panels needed to be fitted resulted in in five steps; the first step includes investigation, prediction,

increasing the wheelchair weight. Humaira et al. [9] produced and hypothesis. The second step is concrete experience, the

a successful prototype of an Electric Wheelchair (EWC) of US third step is function, the forth step is engineering constraint

$ 400, while the minimum cost of EWC was around US$ 1100 and the fifth step is characterizations form. The main

in USA. In this prototype, a 40-pin PIC18F4520 objectives of the first phase are treating, experiencing the

microcontroller was used to secure EWCs movement in the operating factors, analysing the customer needs and deducing

required direction after received a signal from the joystick. product components. The second phase is based on two steps

Information gathered [10] was purposed to raise awareness of including, design models and design analysis that is used to

wheelchair technology and improve the performance of patient development, analysis, calibration, and experimentation of

who relied on EPW. Moreover, it enhanced many parameters model. The third phase is based on the product redesign from

such as velocity, traction, suspension, stability, and navigation. the results of the RE and modelling phases. Redesign phase

consists of a parametric redesign that is used for optimization

Due to advances of computerized technology, Ambient

analysis of the design models, an adaptive redesign that is used

Company has developed a device for intercepted electrical

product components and subassemblies and original redesign

signals sent by brain to larynx in an attempt to speak [11]. It

that is needed to fulfil the customer needs. Functional analysis

was used as a guide for wheelchair, and enables patients to

step from the RE phase is directed to the redesign phase.

cross without moving or speaking loudly. Ambient was used in

the Rehabilitation Institute of Chicago to support patients with

nervous system problems by computer and electronic devices

Experimental work

regardless of their inability of muscle control. Drive wheel motor torque: We assumed the model criteria as

Generally, RE technique [12] is used as a learning tool to shown in Table 1.

disassemble, examine and analyse the product or device for The RF is resistance factor that accounts frictional losses

reproducing with different mechanisms. In addition, it between bearings and axles. Standard values are between 1.1

discovers the concepts involved in manufacture in order to and 1.15. There are many factors that affected on calculation of

produce something similar. The process of RE is a three-phase maximum torque [18,19] such as the following.

process that includes scanning, point processing, and

application geometric development. CAD models generation 1) Rolling Resistance (RR): is based on vehicle weight and

within RE is required to produce the accurate representation by rolling resistance factor during motion of the vehicle as in

three-dimensional reconstruction. Additionally, its arrangement Equation 1.

is stable and has less error of data transfer formats [13]. Yu RR [lb]=GVW [lb] × Crr [-] → (1)

[14] focused on the engineering application of RE based on

measurement machine and CAD software. Recently, the where Crr=surface friction as shown in Table 2.

powerful RE technique is used for modelling the biostructures Grade resistance (GR): is based on gravitational force that

in the mechanical analysis. Thus, building comprehensive used to drag the vehicle back when it is scaling an oblique

developments for biomechanical analysis, particularly for surface as in Equation 2.

prostheses framework [15].

GR [lb]=GVW [lb] × sin (α) → (2)

The outstanding progresses in rehabilitation field have created

excitement about EPW manufacture now and for the future. 2) Acceleration force (FA): is based on needed force to stop

Therefore, this study used the 3D CAD which had been the maximum speed in the required time as in Equation 3.

constructed by means of RE technique to design new and FA [lb]=GVW [lb] × Vmax [ft/s]/(32.2 [ft/s2] × ta [s]) → (3)

compatible wheelchairs. The latest is cheaper than that

currently used. We developed an affordable device with 3) Total tractive effort (TTE): is based on three forces RR,

advanced features based on moving in different directions GR, and FA as in Equation 4.

easily. All connections between motors, microcontroller and TTE [lb]=RR [lb]+GR [lb]+FA [lb] → (4)

joystick were introduced.

4) Wheel motor torque (Tw): is based on the TTE as in

Equation 5.

Material and Methods

Tw [lb-in]=TTE [lb] × Rw [in] × RF [-] → (5)

The model of EPW was applied with RE by using CAD

program and mechanical systems. An example of CAD

Mechanical and electrical equipment

program is SolidWorks software [16], which provides detailed

drawings that are manually fed to the computer. According to a The EPW is moved via an electric DC motor and a

lightweight wheelchair structure, this model was designed to navigational control system which consists of a small joystick

carry a disabled person with maximum 100 Kilograms (Kg) mounted on the armrest, rather than manual one. It is designed

including equipment and body weight. Figure 1 explained the by two major components, the power base containing two DC

3652 Biomed Res- India 2017 Volume 28 Issue 8

Biomechanical analysis of electric powered wheelchair by reverse engineering modelling technology

motors, wheels, and a control module. For this work, some of configuration circuit for fan speed controller by temperature

the electrical and electronic components are briefly described and Arduino is described in [26].

as follows:

The block diagram of our model which is composed of all the

• Arduino mega 2560: it is a microcontroller board based on components listed earlier is given in Figure 5.

the ATmega1280. It has 54 input pins, 15 output by Pulse

Wave Modulation (PWM). It has 128 KB of flash memory, and Results

8 KB of static random access memory. All features of this

microcontroller board are explained in [20]. From the above calculation of mechanical parts by using

Equations 1-5, we found that TW equals 322 N. M and torque

• Analog joystick module (4 Directions): It is a physical of each wheel is 200 N. m approximately (2000 Kg/cm-1). We

device that used to control in movement. It needs to determine used the concept of RE technology and all vehicle design

the angle and direction on two axes: -X-axis and Y-axis. X-axis parameters for modelling the EPW. The design of our model is

refers to left and right directions but Y-axis refers to up and presented by 3D SolidWorks mechanical design automation

down directions. The Analog joystick consists of a momentary software which is used parametric characteristics for producing

push button and two potentiometers. Speed values of joystick synthesis model. Parameters indicated to the values for

are between 0 and 1023 and threshold values are between 462 definition the form of the model. Parameters divided into

and 562 as in Figure 3. Figure 4 explained the flow chart of numeric parameters (e.g. line length, circle diameter) and

motor control by using Joystick. geometric parameters (e.g. tangent, parallel, concentric,

• Motor driver BTS7960 43A: it has a voltage of 24 V and a horizontal, and vertical). Numeric parameters are linked to

current of 43 A. It requires a high amount of current which geometric parameters by different relations, which allowed

bridges for motor drive control, especially for controlling a them to complete the required design.

high power motor such as the MY1016Z2 DC motor that used In our work, we measured distance, angle, and size of between

to Maneuver the electric wheelchair. The main specifications lines, points and surfaces by calliper and meter. After taking

of the motor driver are illustrated in [21]. The motor driver is measurements of the chair, we have entered the measured data

used an H-Bridge [22] as the main concept of operation to in SolidWorks.

control the DC motors.

Here the most instructions in SolidWorks for design:

• DC motor: it is a device which converts electrical energy

into mechanical energy. DC motor used in this model is the 1) Sweep: create model shape by moving a 2D design profile

MY1016Z2-250W DC motor manufactured by Yeuqing along a 2D or 3D design path. There are different options of

Instruments. The specifications of the motor are given in [23]. this powerful feature.

This motor improved the efficiency, save power and its price is 2) Fillet: create rounded external or internal faces on the parts.

low.

3) Extrude cut: is another cool feature which helps to remove

• Ultrasonic range HC-SR04: it extends to range 2 cm-400 material from a 3D model.

cm and accuracy can reach to 3 mm. This device includes

ultrasonic transmitters, receiver, and control unit. Ultrasonic 4) The circular pattern: property manager appears when the

sensors evaluate the execution time between sending the signal user pattern one or more features around an axis.

and receiving the echo to calculate the distance to an object 5) Mirroring features: this ability is found at part level and

[24]. creates a copy of one or more features mirrored about a face or

• Bluetooth-HC05-module: it is a wireless device for a plane.

exchanging data over short distances from mobile devices, and 6) An assembly design: consists of some assembled

building Personal Area Networks (PANs). It provides range of components by using parametric relations. In SolidWorks,

10 meters. It is widely used for wireless network such as GPS these relations are known as mates that provided the dealing

device, and remote control. It consists of radio, memory chips, with components freely.

26 MHz crystal, and antenna as in [25].

We presented details of implementation stages by using

• Fan speed controlled by temperature and arduino: it is SolidWorks in Figures 6-20.

used for monitoring the DC fan speed depending on the

temperature reading by an LM35 sensor. The LM35 is Figure 21 showed the complete wheelchair assembly. All

precision integrated-circuit calibrated directly in degree wheelchair specifications are given in Table 3.

Celsius. Its linear scale factor+10 mV/°C. Its ensured accuracy The mechanical and electrical components that were used to

is 0.1 degree Celsius. This will make it as an advantage over build this model incurred a cost as in Table 4. It should be

linear temperature. It is rated from -50°C to +150°C. A Liquid noted that our model costs 5675 EGP (nearly US$ 600), which

Crystal Display (LCD) shield is used to show the temperature is less than commercially available price at US$ 1100. The

and speed of the fan. In this model, the BD139 transistor, and a comparison between the EPWs from different manufacturers

9 V battery are utilized. The LM35 temperature sensor and red that already used in Egypt market is given in Table 5.

led are provided with 5 V from the microcontroller board. A

Biomed Res- India 2017 Volume 28 Issue 8 3653

Mabrouk/Marzouk/Afify

Discussion certainly important to continue to implement appropriate

biomechanical advances of EPW in order to improve the health

Because of the market potential and rapid advances in and benefit of a patient with disabilities.

biomechanics, notable progress is being made in wheelchairs.

The EPW evaluation is based on the quality, safety, and cost-

Conclusion

effectiveness of wheelchairs. Efficient EPW model with a low

cost is presented. Our EPW model is distinguished from most Based on the principles of RE technology, we applied RE

other similar EPW in its attempts to use practical components technology in the design and manufacturing of EPW by using

for minimizing maintenance concerns through simplicity and SolidWorks 3D CAD. EPWs have improved the quality of life

durability. for many patients with physical disabilities through the

mobility they provide. The EPW acts as a good bio-test for

Overall, this model consists of software and hardware interface

mechanical and electrical integration packages due to the

parts. SolidWorks designing software was established to build

compact and multifaceted nature of the vehicle. The cost of

3D CAD model with full specifications of EPW by using RE

EPW manufacturing processes is increasing rapidly, for which

technology. The implementation of RE technology allowed

many patients might not be able to afford the rising costs. This

reusing past data for design composition model [27]. It

paper discussed how both electrical and mechanical

facilitates analysis of the model that based on historical

implementations have turned the wheelchair into a smart and

product data and produces practical developments during

adaptive vehicle with a low cost. It also examined the most

product assembly procedures. For example, General Motors

recent advances in EPW technology by using Bluetooth and

Company have vehicles assessment center that dissected and

ultrasonic sensor. Moreover, this model may be a guide for

analysed 40 of rivals’ vehicles every year by using a

future trends to enhance the rehabilitative and assistive needs

“teardown” process [28] to learn how much each component

of patients. It would be interesting to redevelop of EPWs

costs for producing, how to achieve lower costs, and how to

technology to give patients access to perform the daily tests

progress industrialization process. By using RE technology,

with themselves easily.

marketplace trends and competitiveness can be defined. This

technology extended to product teardowns of mechanical and

electronics as shown in our model.

For hardware parts, the core of this model is the Arduino Mega

2560 microcontroller which is also capable of functioning as a

micro web server and the interface for all the hardware parts

[29]. A microcontroller is controlled by DC motors for

transmission in all directions or to stop by using a joystick. All

communication and controls in this model passed through this

microcontroller effectively. A recent development controlled

EPW was implemented using the Bluetooth device and

ultrasonic sensor. Bluetooth device is used for wireless control

of the electric wheelchair and enables it to work as a

standalone device. We have used two ultrasonic sensors that

stable at a known distance. Speed of the object is estimated by

divided the distance between the two sensors by the time Figure 1. Mechanical components of reserve engineering.

difference of the object. The ultrasonic sensor is designed for

easy usage and much cheaper with outstanding performance,

especially in an automated device.

Another interesting feature is control of components

temperature. The temperature of electrical components is

affected by the ambient temperature of the environment, the

heat produced by the components, and the efficiency of heat

removal provided by the thermal system. Component

temperature can be decreased by improving any of these

factors. Based on fan Speed controlled by temperature, more

efficient component gives off less heat and the advanced

thermal system is capable of quickly removing heat.

Finally, disabled patients are challenged for operating the EPW

in different environments. Hence, the EPW designed in this

model is a successful electronic device that provided for

patients the ability to recover part of their mobility and ease the Figure 2. General composition of reverse engineering, modelling and

lives of patients suffering from one or more disabilities. It is analysis, and redesign technology.

3654 Biomed Res- India 2017 Volume 28 Issue 8

Biomechanical analysis of electric powered wheelchair by reverse engineering modelling technology

Grass (firm/soft) 0.55/0.075

Sand (firm/soft/dune) 0.060/0.150/0.300

Figure 3. Threshold values of joystick.

Figure 5. Block diagram of the electric wheelchair control.

Figure 4. Flowchart of motor control via joystick.

Figure 6. Lower chaises.

Table 1. Vehicle design criteria.

Parameters Value

Gross Vehicle Weight (GVW) 300 Kg

Weight on each drive wheel (WW) 4.5 Kg

Radius of wheel/tire (Rw) 0.1 m

Desired top speed (Vmax) 0.25 m/s

Desired acceleration time (ta) 1 sec

Maximum incline angle (a) 20 degree

Worst working surface Sand (good)

Resistance Factor (RF) 1.3

Figure 7. Middle chaises.

Table 2. Rolling resistance factors.

Table 3. Technical specifications of the model.

Contact surface Crr

Description Measurements

Concrete (good/fair/poor) 0.010/0.015/0.020

Seat width 47 cm

Asphalt (good/fair/poor) 0.012/0.017/0.022

Neat depth 46 cm

Wood (dry’ dusty wet) 0.01/0.005/0.001

Armrest height 25 cm

Snow (2 inch/4 inch) 0.025/0.037

Seat height 48 cm

Dirt (smooth/sandy) 0.025/0.037

Back height 46 cm

Mud (firm/medium/soft) 0.037/0.090/0.150

Overall open width 65 cm

Biomed Res- India 2017 Volume 28 Issue 8 3655

Mabrouk/Marzouk/Afify

Overall length 80 cm

Weight w/o 55 Kg

Weight capacity 140 kg

Rear wheel size 31 cm

Front wheel size 19 cm

Footrests height 10 cm

Figure 11. Chair back chaises.

Figure 8. Piston base.

Figure 12. Left and right arm.

Figure 9. Piston arm.

Figure 13. Arm rest.

Figure 14. Motor left and right.

Figure 10. Upper chaises.

3656 Biomed Res- India 2017 Volume 28 Issue 8

Biomechanical analysis of electric powered wheelchair by reverse engineering modelling technology

Figure 19. Bottom sponge.

Figure 15. Back wheels.

Figure 20. Back sponge.

Figure 16. Front wheels.

Figure 21. Complete wheelchair assembly.

Table 4. Parts list and cost of the model.

Description Category Quantity Price

Rear wheels Mechanical 2 1000

Front wheels Mechanical 2 200

DC motors 24 V Electronic 2 1500

Figure 17. Front wheel chaises.

Chair skeleton Electronic 1 300

Intelligent battery charger Electronic 1 200

Tablet Electronic 1 400

Wires+Cables Electronic - 50

Battery (12 V) Electronic 2 920

Digital ultrasonic module for Electronic 2 60

Arduino

DC motor driver Electronic 2 300

Arduino Mega 2560 Electronic 1 370

Figure 18. Bottom sponge.

Bluetooth HC-05 Electronic 1 75

Biomed Res- India 2017 Volume 28 Issue 8 3657

Mabrouk/Marzouk/Afify

10. Ding D, Cooper RA. Electric powered wheelchairs. IEEE

Model joystick 4 direction Electronic 1 50

Cont Sys Magaz 2005; 25: 22-34.

Board components Electronic 250 11. Ambient Corporations, New Human-Computer Interface

Total cost 5675 EGP 5675 EGP called Audeo Intercepts Words When Thought, 2007.

12. Thompson WB, Owens JC, de St HJ. Germain, featured-

Table 5. Comparison between the EPW Prices in Egypt. based reverse engineering of mechanical parts. IEEE Trans

Robot Autom 1999; 15: 57-66.

Type Spare parts Price (EGP) 13. Sun WBS, Nam J, Darling A. Bio-CAD modelling and its

Egypt Non 7,000

applications in computer aided tissue engineering,

computer-aided design. Elsevier 2005; 37: 970- 1114.

China Available 8,000 14. Zhang Y. Research into the engineering application of

Taiwan Non 9,000 reverse engineering technology. J Mater Proc Technol

Elsevier Sci 2003; 139: 472-475.

Korea Non P,000

15. Latif Aghili A, Goudarzi AM, Hojjati MH, Rabiee SM,

Germany Available 15,000 Misagh I, Ali P. Biomechanical investigation of human

femur by reverse engineering as a robust method and

References applied simplifications. W Appl Sci J 2013; 28: 2152-2157.

16. SolidWorks software: https://www.solidworks.com/sw/3d-

1. Rafidah R, Afiqah Y, Norashikin MT, Jamilah K. Design cad-design-software.htm

and development of electrical powered wheelchair model 17. Otto K, Wood K. A reverse engineering and redesign

for navigation control. IEEE Symp Industr Electr Appl methodology for product evolution. Proc ASME Design

2011; 675-680. Theory Methodol Conf 1996.

2. Boninger ML, Baldwin M, Cooper RA, Koontz A, Chan L. 18. Hibbeler RC. Engineering mechanics: statics and dynamics.

Manual wheelchair pushrim biomechanics and axle Pearson Prentice Hall (11th edn.) 2007; 441-442.

position. Arch Phys Med Rehabil 2000; 81: 608-613.

19. Rony A. The electric vehicle, technical report. Santa

3. Beekham CE, Miller-Porter L, Schoneberger M. Energy Barbara Coll Eng Univ Mar. 2010.

cost of propulsion in standard and lightweight wheelchairs

20. Arduino Mega 2560: https://www.arduino.cc/en/Main/

in people with spinal cord injuries. Phys Therap 1999; 79:

ArduinoBoardMega.

146-158.

21. Motor Driver BTS7960 43A: http://

4. Brown KE, Inigo RM, Johnson BW. Design,

www.instructables.com/id/Motor-Driver-BTS7960-43A/

implementation, and testing of an adaptable optimal

controller for an electric wheelchair. IEEE Trans Industr 22. Manjunath BR, Chakrasali RL. Speed-torque characteristic

Appl 1990; 26: 1144-1157. of dc motor fed by h-bridge converter. Int J Energ Power

2014; 3: 49-53.

5. Tan YK, Sasidhar S. Engineering better electric powered

wheelchairs to enhance rehabilitative and assistive needs of 23. Bature AA, Mustapha M, Auwalu MA. Parameter

disabled and aged populations, rehabilitation engineering. identification of a class of dc motor. Int J Res Eng Sci

Tan Yen Kheng INTECH Singap 2009; 79-108. 2013; 1: 69-72.

6. Cooper RA, Boninger ML, Spaeth DM, Ding D, Guo S, 24. Ultrasonic Range HC-SR04: http://

Koontz AM, Fitzgerald SG, Cooper R, Kelleher A, Collins randomnerdtutorials.com/complete-guide-for-ultrasonic-

DM. Engineering better wheelchairs to enhance community sensor-hc-sr04/

participation. IEEE Trans Neur Sys Rehab Eng 2006; 14: 25. Bluetooth-HC05-Module:https://arduino-

438-155. info.wikispaces.com/BlueTooth-HC05-HC06 Modules-

7. Rentschler AJ, Cooper RA, Fitzgerald SG, Boninger ML, How-To?

Guo S, Ammer WA, Vitek M, Algood D. Evaluation of responseToken=05c18a8b1549720cec433fac0c91e8bfc

selected electric-powered wheelchairs using the ANSI/ 26. Fan Speed Controlled by Temperature and Arduino: http://

RESNA standards. Arch Phys Med Rehab 2004; 85: www.electroschematics.com/9540/arduino-fan-speed-

611-619. controlled-temperature/

8. Arvind P, Snehal S, Priyanka R, Ashish S. Powered 27. Otto K, Wood K. Product design: techniques in reverse

wheelchairs. Int J Sci Technol Res 2013; 2. engineering and new product design. Prentice Hall 2001.

9. Humaira S, Hafiz R, Pratik KK, Fahmid JSBM, 28. Hoffman C. The teardown artists. Wired 2006; 136.

Nasiruzzaman KBM, Rahman MDM. Design and 29. Nathan D, Abafor C, Aronu U, Edoga O. Design of a home

implementation of an electric wheel-chair to economize it automation system using Arduino. Int J Sci Eng Res 2015;

with respect to Bangladesh. Int J Multidiscipl Sci Eng 6: 795-803.

2014; 5.

3658 Biomed Res- India 2017 Volume 28 Issue 8

Biomechanical analysis of electric powered wheelchair by reverse engineering modelling technology

*Correspondence to

Mai S. Mabrouk

Department of Biomedical Engineering

MUST University

Egypt

Biomed Res- India 2017 Volume 28 Issue 8 3659

You might also like

- RehabilitationDocument1 pageRehabilitationEbru SayılganNo ratings yet

- Design and Development of A Lightweight, High-Torque, and Cost-Effective Hip ExoskeletonDocument6 pagesDesign and Development of A Lightweight, High-Torque, and Cost-Effective Hip ExoskeletonSultan Mahi ZubairNo ratings yet

- Various Types of Wheel Chair ControlDocument6 pagesVarious Types of Wheel Chair ControlIAEME PublicationNo ratings yet

- Main Content PDFDocument27 pagesMain Content PDFYash BuddhadevNo ratings yet

- Litrature ReviewDocument3 pagesLitrature ReviewAbi DemNo ratings yet

- Design Process and Development of A Prototype Electric WheelchairDocument7 pagesDesign Process and Development of A Prototype Electric WheelchairKANAK SHARMANo ratings yet

- Analysis and Optimisation of All Terrain WheelchairDocument10 pagesAnalysis and Optimisation of All Terrain WheelchairAshish NandaNo ratings yet

- Mechatronics: Umut Mayetin, Serdar KucukDocument17 pagesMechatronics: Umut Mayetin, Serdar Kucukalamin khondakerNo ratings yet

- Research Paper On WheelchairDocument5 pagesResearch Paper On Wheelchairajqkrxplg100% (1)

- Ain Shams Engineering Journal - Chatterjee, Roy - 2021 - A Low-Cost Assistive Wheelchair For Handicapped & Elderly PeopleDocument7 pagesAin Shams Engineering Journal - Chatterjee, Roy - 2021 - A Low-Cost Assistive Wheelchair For Handicapped & Elderly PeopleErdem UZUNNo ratings yet

- Research Paper WheelchairDocument5 pagesResearch Paper Wheelchairgw0w9j6d100% (1)

- Choi 2019Document11 pagesChoi 2019onikabekunNo ratings yet

- Performance Assessment of A Pushrim-Activated Power-Assisted Wheelchair Control SystemDocument6 pagesPerformance Assessment of A Pushrim-Activated Power-Assisted Wheelchair Control SystemsdgNo ratings yet

- Robust Control of A Cable-Driven Soft Exoskeleton Joint For Intrinsic Human-Robot InteractionDocument11 pagesRobust Control of A Cable-Driven Soft Exoskeleton Joint For Intrinsic Human-Robot InteractionHassan abokouraNo ratings yet

- Electric Power Steering - An Overview of Dynamics Equation and How It - S Developed For Large VehicleDocument8 pagesElectric Power Steering - An Overview of Dynamics Equation and How It - S Developed For Large VehiclecieloNo ratings yet

- Design and Fabrication of A Voice Controlled Wheelchair For Physically Disabled PeopleDocument10 pagesDesign and Fabrication of A Voice Controlled Wheelchair For Physically Disabled PeopleLendry NormanNo ratings yet

- Electric Power Steering An Overview of DDocument8 pagesElectric Power Steering An Overview of DEkemini StephenNo ratings yet

- A Novel Elbow Pneumatic Muscle Actuator For Exoskeleton Arm in Post-Stroke RehabilitationDocument6 pagesA Novel Elbow Pneumatic Muscle Actuator For Exoskeleton Arm in Post-Stroke RehabilitationSathvik BhatNo ratings yet

- Design and Development of One Degree of Freedom Upper Limb ExoskeletonDocument6 pagesDesign and Development of One Degree of Freedom Upper Limb ExoskeletonWarnithaNo ratings yet

- Development of Solar Powered Electric Wheelchair For Physically Challenged PersonsDocument7 pagesDevelopment of Solar Powered Electric Wheelchair For Physically Challenged PersonsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Voice Controlled Wheel ChairDocument96 pagesVoice Controlled Wheel ChairbhavanaNo ratings yet

- Modeling and Manufacturing of Powered Vehicle For Physically Challenged PeopleDocument10 pagesModeling and Manufacturing of Powered Vehicle For Physically Challenged PeopleIJMERNo ratings yet

- 01 - 2020 - Usability Testing On DevelopedDocument10 pages01 - 2020 - Usability Testing On DevelopedFitri nuraini setiyowatiNo ratings yet

- A Review On Various Methods For Self Balancing PDFDocument6 pagesA Review On Various Methods For Self Balancing PDFiron manNo ratings yet

- Exoskeleton ProposalDocument8 pagesExoskeleton ProposalFALAK FATIMANo ratings yet

- Treadmill Power Generation Cycle Project ReportDocument21 pagesTreadmill Power Generation Cycle Project ReportPrashant Karande100% (1)

- Manual Wheelchair Propulsion UnitDocument14 pagesManual Wheelchair Propulsion Unitarondaniel ocampoNo ratings yet

- Wheelchair Literature ReviewDocument8 pagesWheelchair Literature Reviewaixgaoqif100% (1)

- ESDA2014-20364: Analysis of A New Measurement System of The Chain Strength For Electrically Assisted BicyclesDocument6 pagesESDA2014-20364: Analysis of A New Measurement System of The Chain Strength For Electrically Assisted BicyclesJuan David Garcia PereiraNo ratings yet

- Wheelchair Research PaperDocument7 pagesWheelchair Research Paperfvf4r6xq100% (1)

- Tricycle Side Wheel Energy Harvester: Research TitleDocument33 pagesTricycle Side Wheel Energy Harvester: Research TitleConan Grace AgasNo ratings yet

- Head Gestured Automated Wheelchair: Bachelor of Technology Department of MECHANICAL EngineeringDocument42 pagesHead Gestured Automated Wheelchair: Bachelor of Technology Department of MECHANICAL EngineeringNimitesh SinghNo ratings yet

- Carney (2021)Document12 pagesCarney (2021)Fernanda LealNo ratings yet

- 1 s2.0 S277315372200041X MainDocument3 pages1 s2.0 S277315372200041X MainWEIWEI YANGNo ratings yet

- Wheel ChairDocument16 pagesWheel ChairAadarsh tripathiNo ratings yet

- APJMR 2015-3-172 Bike Powered Electricity GeneratorDocument10 pagesAPJMR 2015-3-172 Bike Powered Electricity Generatorsuper meal coleenNo ratings yet

- Design and Development of Anti-Roll Back Mechanism: V. D. Kolate, R. R. Kurup, A. M. LatakeDocument4 pagesDesign and Development of Anti-Roll Back Mechanism: V. D. Kolate, R. R. Kurup, A. M. LatakePreeti BhamreNo ratings yet

- Control System With Head MovementsDocument6 pagesControl System With Head MovementsKelappan NairNo ratings yet

- Ifac Wheelchair FinalDocument6 pagesIfac Wheelchair FinalRafiqul IslamNo ratings yet

- ImechE Project Proposal-Robotic Prosthetic (FINALIZED)Document6 pagesImechE Project Proposal-Robotic Prosthetic (FINALIZED)Avk SanjeevanNo ratings yet

- Irjet V7i5640Document5 pagesIrjet V7i5640Bhuvana NNo ratings yet

- Design and Fabrication of Dynamic WheelchairDocument7 pagesDesign and Fabrication of Dynamic WheelchairIJRASETPublicationsNo ratings yet

- Electric Wheelchair Design and Its Impacts On Life Among The Disabled Individuals A ReviewDocument3 pagesElectric Wheelchair Design and Its Impacts On Life Among The Disabled Individuals A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sakthivel 2020Document7 pagesSakthivel 2020s2002hadiNo ratings yet

- ViewDocument2 pagesViewDian LiuNo ratings yet

- Powered Wheelchair Control: Human - Machine System ModellingDocument5 pagesPowered Wheelchair Control: Human - Machine System ModellingRafiqul IslamNo ratings yet

- Mangharam-Highlights 2014Document3 pagesMangharam-Highlights 2014Rizwan MukatiNo ratings yet

- Asi 04 00078 v2Document27 pagesAsi 04 00078 v2P TNo ratings yet

- Virtual Prototyping of An Electric Power Steering SimulatorDocument10 pagesVirtual Prototyping of An Electric Power Steering SimulatorBalajiNo ratings yet

- Mechanical Design of Piezoelectric Energy Harvesters: Generating Electricity from Human WalkingFrom EverandMechanical Design of Piezoelectric Energy Harvesters: Generating Electricity from Human WalkingNo ratings yet

- 运动捕捉和能量收集 下肢系统Document16 pages运动捕捉和能量收集 下肢系统123No ratings yet

- Smart Wheel Chair SynopsisDocument7 pagesSmart Wheel Chair SynopsisTanvi KhuranaNo ratings yet

- Islameka 2019 J. Phys. Conf. Ser. 1402 044054Document7 pagesIslameka 2019 J. Phys. Conf. Ser. 1402 044054BT20MEC120 Jyoti ThakurNo ratings yet

- Dynamic Simulation Platform Design For Cubesat With Reaction Wheel Control SystemDocument6 pagesDynamic Simulation Platform Design For Cubesat With Reaction Wheel Control SystemJosue Manuel Pareja ContrerasNo ratings yet

- Literature Review of Flywheel DesignDocument4 pagesLiterature Review of Flywheel DesignPotru vinodh KumarNo ratings yet

- GS 2015 P-2 IcpsdtDocument11 pagesGS 2015 P-2 IcpsdtRõČķ BőÝNo ratings yet

- Automatic Wheelchair 4473Document3 pagesAutomatic Wheelchair 4473Tina GuptaNo ratings yet

- A Batteryless Remote Control For Volvo, Results of A Feasibility StudyDocument9 pagesA Batteryless Remote Control For Volvo, Results of A Feasibility StudyShouvik DasNo ratings yet

- Modeling and High-Definition Control of A Smart Electroadhesive Actuator Toward Application in Rehabilitation1 PDFDocument11 pagesModeling and High-Definition Control of A Smart Electroadhesive Actuator Toward Application in Rehabilitation1 PDFAnjing ChengNo ratings yet

- Braking Distance ForwardDocument9 pagesBraking Distance ForwardAjay AgarwalNo ratings yet

- BTCDocument1 pageBTCDileep KumarNo ratings yet

- BITCOIN Pub KeyDocument2 pagesBITCOIN Pub KeyDileep Kumar100% (1)

- First Go To TOOLS - OptionsDocument3 pagesFirst Go To TOOLS - OptionsDileep KumarNo ratings yet

- RPGDocument502 pagesRPGDileep Kumar0% (1)

- DOP Guidelines AML KYC For MTSS and Forex13112018Document19 pagesDOP Guidelines AML KYC For MTSS and Forex13112018DEBADITYA CHAKRABORTYNo ratings yet

- How To Generate Bitcoin and Ethereum Addresses: Tuna Tore - Founder at Https://mycrypto - ToolsDocument29 pagesHow To Generate Bitcoin and Ethereum Addresses: Tuna Tore - Founder at Https://mycrypto - ToolsDileep KumarNo ratings yet

- Udemy Course - Tuna Tore Course: How To Create Bitcoin and Ethereum Crypto Addresses OfflineDocument6 pagesUdemy Course - Tuna Tore Course: How To Create Bitcoin and Ethereum Crypto Addresses OfflineDileep KumarNo ratings yet

- Indian Post Ofice RulesDocument146 pagesIndian Post Ofice RulesAkshay BhasinNo ratings yet

- The Government Savings Promotion Act, 1873: PreliminaryDocument10 pagesThe Government Savings Promotion Act, 1873: PreliminaryDileep KumarNo ratings yet

- Gs PR EnglishDocument24 pagesGs PR Englishkabani pushparajanNo ratings yet

- The Indian Post Office Act 1898Document31 pagesThe Indian Post Office Act 1898amol96No ratings yet

- 001 A Operators Manual 3100a HfovDocument97 pages001 A Operators Manual 3100a HfovEmanuel Naskosi Santiz AguilarNo ratings yet

- Spu 1253Document1 pageSpu 1253Josemir MarquesNo ratings yet

- Tosvert vfs9Document198 pagesTosvert vfs9Mariano Martinez LaraNo ratings yet

- RAN - Ericsson LTE Gold Standard E-UTRAN L14ADocument1,001 pagesRAN - Ericsson LTE Gold Standard E-UTRAN L14Aniyaz63% (16)

- Instrumentation 172Document172 pagesInstrumentation 172adarsh snija100% (1)

- AC Motor Single PhaseDocument14 pagesAC Motor Single PhaseMohamed HAMDYNo ratings yet

- Sciencedirect: Dragline Retrofit For Ac Motion PowerDocument4 pagesSciencedirect: Dragline Retrofit For Ac Motion PowerJavier Alejandro RodriguezNo ratings yet

- A 034791Document332 pagesA 034791g960405No ratings yet

- Py201 Assignment VDocument6 pagesPy201 Assignment VSiddharth RajamohananNo ratings yet

- Radar TutorialDocument15 pagesRadar TutorialrkbinddrdoNo ratings yet

- Emt 4103 Sensors and Transducers On 10th June Lesson 4Document31 pagesEmt 4103 Sensors and Transducers On 10th June Lesson 4SEAN WALLACENo ratings yet

- Battery Study - Executive SummaryDocument14 pagesBattery Study - Executive SummaryLelosPinelos123No ratings yet

- Neca200 10 PDocument30 pagesNeca200 10 Pcharlesc5746No ratings yet

- Electrical System Planning StudyDocument400 pagesElectrical System Planning Studymisbahahmed111No ratings yet

- NEC Ipaso FrequencyDocument31 pagesNEC Ipaso FrequencyEr Praveen ThakurNo ratings yet

- Shift Happens 6.0 Source SlidesDocument59 pagesShift Happens 6.0 Source SlideselawrNo ratings yet

- Tec-561 t4 Creativity ChartDocument5 pagesTec-561 t4 Creativity Chartapi-370625377No ratings yet

- SHPMDocument14 pagesSHPMvikasoza100% (1)

- Dual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch GebruikershandleidingDocument21 pagesDual Band DAB Pocket Radio: User Manual Manuel D'utilisation Manual Del Usuario Benutzerhandbuch Gebruikershandleidingminerva_manNo ratings yet

- Verilog A Language: Adapted From (The Designer'S Guide To VERILOG-AMS, Kenneth S. Kundert)Document14 pagesVerilog A Language: Adapted From (The Designer'S Guide To VERILOG-AMS, Kenneth S. Kundert)Ahmed EdrisNo ratings yet

- Irjash-Paper Ravindra ParabDocument9 pagesIrjash-Paper Ravindra ParabRavindra ParabNo ratings yet

- Lithium Ion Battery Identification ReferenceDocument5 pagesLithium Ion Battery Identification ReferenceUncle PaneNo ratings yet

- Relay 4-Bit Ripple Carry AdderDocument3 pagesRelay 4-Bit Ripple Carry AdderJon SchmidtNo ratings yet

- UTC 2SD1616/A NPN Epitaxial Silicon TransistorDocument4 pagesUTC 2SD1616/A NPN Epitaxial Silicon Transistornishatiwari82No ratings yet

- Waves WorksheetDocument1 pageWaves WorksheetEunice CorreaNo ratings yet

- ProfiBus PADocument44 pagesProfiBus PAVarun KumarNo ratings yet

- TimeProvider 5000 IEEE 1588 Grandmaster PDFDocument2 pagesTimeProvider 5000 IEEE 1588 Grandmaster PDFahmedmidanyNo ratings yet

- Wistron Bad40-Hr Bad50-Hr Revsd PDFDocument109 pagesWistron Bad40-Hr Bad50-Hr Revsd PDFJokoKiyerNo ratings yet

- Async NandDocument158 pagesAsync NandRavi Krishna MalkaNo ratings yet

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFDocument15 pagesRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngNo ratings yet