Professional Documents

Culture Documents

Hot Kiln Alignment

Uploaded by

Vicky KatariaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Kiln Alignment

Uploaded by

Vicky KatariaCopyright:

Available Formats

KILN ALIGNMENT & INSPECTION • TIRE & ROLLER RESURFACING

#/.3425#4)/. FULL-SERVICE KILN REPAIR

Hot Kiln Alignment Technology

All rotary kilns require yearly kiln alignment and quarterly support roller adjustments. This

work is done most accurately and cost effectively by NAK construction professionals using

the most advanced procedures.

NAK construction uses state-of-the-art, laser-based equipment to measure the hot tire diam-

eters and locate the tire centers. We then measure and record the shell flexing (shell ovality)

at each pier and adjust the support rollers to minimize shell distortion that occurs during kiln

rotation.

Shell flexing or distortion on a straight kiln is measurably higher near the burning zone than

at the cold end. Refractory life can be maximized by lowering the shell shear load

at piers with high shell ovality and increasing it at the other piers, assuring uniform and

minimum shell flexing over the length of the kiln. A properly aligned kiln will have

elevation misalignment consistent with uniform ovalities.

NAK construction uses laser theodolites to locate tire centers. All alignment calculations are computer

generated. We utilize hydraulic wrenches for fast and accurate bearing adjustments.

With NAK performing all support roller bearing adjustments, the plant is spared this labor-intensive

activity as well as the risks associated with large bearing adjustments.

NAK Hot Kiln Alignment procedures provide the most

comprehensive and accurate kiln alignment in the industry.

Measure Shell Ovalities Measure Tire Clearances

Adjust Roller Thrust Loads Check Tire Pads and Retainers

Correct Kiln Axis Alignment Inspect Drive Alignment

Measure Shell Runout Thorough Visual Inspection

Measure Roller Shaft Deflection All Bearing Adjustments Included

The NAK Alignment Procedure

The alignment procedure used by NAK Construction consists of six steps:

1) With the kiln in normal operation, the tire centers are located and placed in a straight line

using the most technologically advanced electronic equipment.

2) Ovality is then measured at each pier under normal operating conditions. Roller adjust-

ments are made until the ovality is uniform and minimum over the length of the kiln.

3) Roller bearings are adjusted for minimal thrust load. This assures very low thrust roller

loads and low bearing temperatures.

4) Shell runout measurements are taken as necessary to determine if “dogleg” conditions

threaten kiln mechanical stability.

5) A kiln alignment is not complete without considering the effect of roller slopes on kiln

operation. Roller slope changes are necessary to assure minimum tire pad wear and stop

block pressure.

6) A thorough visual inspection of all kiln components is conducted.

All of these procedures are performed with the kiln in operation and no kiln shutdowns are

necessary. This is absolutely essential because a cold kiln that is straight has a measurable

misalignment at operating temperatures.

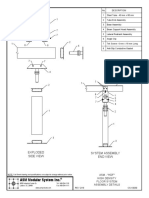

Theodolite

position 1

LINE 4

LI

NE 3

N

1

LI

E

LINE

TIRE THREE

5

TIRE FOUR

TIRE TWO

TIRE ONE

LINE 8 LINE 7

Theodolite LINE 6

position 2

NAK CONSTRUCTION

P.O. Box 1329 • Buford, Georgia 30515

phone (770) 831-8229 • (800) 331-KILN • fax (770) 831-3357

www.NAK-KILN.com

You might also like

- TEF 2650/2655 COMMANDER Searchlight Halogen & Hri User ManualDocument34 pagesTEF 2650/2655 COMMANDER Searchlight Halogen & Hri User ManualAbhishek KumarNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- TEF 2650/2655 User ManualDocument36 pagesTEF 2650/2655 User ManualevbulgakovNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Schlndler: 1 Replacement and Adjustment of Brake Contacts KB and KDocument8 pagesSchlndler: 1 Replacement and Adjustment of Brake Contacts KB and KallbsforakNo ratings yet

- Ex2/Ex1 Series: Automotive RelaysDocument8 pagesEx2/Ex1 Series: Automotive Relaysigomez8105No ratings yet

- Ex2/Ex1 Series: Automotive RelaysDocument8 pagesEx2/Ex1 Series: Automotive RelaysGianmarco CastilloNo ratings yet

- LG-6001 Lead Gage: Operation ManualDocument24 pagesLG-6001 Lead Gage: Operation ManualSukumarNo ratings yet

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- 20 NT I PDFDocument2 pages20 NT I PDFsidneyg12No ratings yet

- Parts Manual: CascadeDocument10 pagesParts Manual: CascadeLuca FroliNo ratings yet

- Aero2 ActuatorDocument15 pagesAero2 ActuatorAnh VoNo ratings yet

- Liquefied Gas SolutionDocument12 pagesLiquefied Gas SolutioncerberusdodoNo ratings yet

- Service BulletinDocument8 pagesService Bulletinsuperkid667100% (1)

- Tum 4560Document32 pagesTum 4560Alvaro Lopez PantojaNo ratings yet

- Carburetor Instruction Sheet MODELS 4165 & 4175: Read This FirstDocument6 pagesCarburetor Instruction Sheet MODELS 4165 & 4175: Read This FirstAlfonso JaureguiNo ratings yet

- Medidor de Paso de Cuerdas Api PDFDocument24 pagesMedidor de Paso de Cuerdas Api PDFLuisGarcia2608No ratings yet

- Adjustment of Extensions HIABDocument4 pagesAdjustment of Extensions HIABEDUARDO VEGANo ratings yet

- Series YD - YS Instruction ManualDocument16 pagesSeries YD - YS Instruction ManualEnerprec SASNo ratings yet

- Cable MotorDocument2 pagesCable MotorAlf NeroNo ratings yet

- 8L90 Valvule BodyDocument10 pages8L90 Valvule BodyJose Andres HuertaNo ratings yet

- MERLADocument11 pagesMERLAmoulounguianouckNo ratings yet

- C Type Precision High Speed Press Machine C 45Document39 pagesC Type Precision High Speed Press Machine C 45aravindNo ratings yet

- Sistema de Llenado Rápido CombustibleDocument22 pagesSistema de Llenado Rápido CombustibleHugo VillcaNo ratings yet

- Research&Development of America, Inc.: Suzuki 2005 GSX-R1000Document6 pagesResearch&Development of America, Inc.: Suzuki 2005 GSX-R1000Daniel MartínNo ratings yet

- Silo - Tips - Eaton Eb Er Brochure PDFDocument18 pagesSilo - Tips - Eaton Eb Er Brochure PDFValdo De BaráNo ratings yet

- BRAKE SYSTEM HyundaiDocument6 pagesBRAKE SYSTEM HyundaiAfshin GhafooriNo ratings yet

- Vista Mast RepairDocument28 pagesVista Mast RepairTan JaiNo ratings yet

- Larry Jeffus-Welding - Principles and Applications-Cengage Learning (2012) - 32Document20 pagesLarry Jeffus-Welding - Principles and Applications-Cengage Learning (2012) - 32Madani MecheriNo ratings yet

- Golden Sun CNC-201R Rotary TableDocument10 pagesGolden Sun CNC-201R Rotary TableGerald100% (2)

- EasySlider MaintenanceInstructionsDocument3 pagesEasySlider MaintenanceInstructionsbalaji baluNo ratings yet

- ZF8 Zip inDocument10 pagesZF8 Zip inEdgar BolañosNo ratings yet

- TSB201801001Document2 pagesTSB201801001Víctor FaríasNo ratings yet

- Desplazador Cascade 65F-SSS-B026R1.Document6 pagesDesplazador Cascade 65F-SSS-B026R1.victor laraNo ratings yet

- XT Mobile Shear: Reference GuideDocument12 pagesXT Mobile Shear: Reference GuidePrudzNo ratings yet

- Tighting Torque MethodDocument6 pagesTighting Torque Methodibrahim hegazyNo ratings yet

- CS-10030 - HDFS Assembly DetailsDocument1 pageCS-10030 - HDFS Assembly DetailsRoberto DiazNo ratings yet

- Desplazador Doble Tipo 55D Serie 55D-SW-054Document5 pagesDesplazador Doble Tipo 55D Serie 55D-SW-054SARAMQRNo ratings yet

- BPI Zap TLok Headed Bar InstructionsDocument3 pagesBPI Zap TLok Headed Bar InstructionshectoriturbeNo ratings yet

- Assembly Instructions: 5/S Wave Commercial Ground Plane With RadialsDocument6 pagesAssembly Instructions: 5/S Wave Commercial Ground Plane With Radialsbellscb100% (2)

- 6-Inch-CI-50-Hz Lubi PumpDocument76 pages6-Inch-CI-50-Hz Lubi PumpAhmed AbarchidNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Manual Book Service Yamaha Fino PreviewDocument10 pagesManual Book Service Yamaha Fino Previewdimaz_kecebur100% (1)

- LTM1080 PT1Document14 pagesLTM1080 PT1William VillanuevaNo ratings yet

- Yamaha Vino 125 Service ManualDocument294 pagesYamaha Vino 125 Service Manualezzeldin_2000No ratings yet

- Kumait@steelplantech - Co.jp Kikkawat@steelplantech - Co.jpDocument10 pagesKumait@steelplantech - Co.jp Kikkawat@steelplantech - Co.jpSANTOSH TIWARINo ratings yet

- Yamaha Vino Service Manual 2006 2009Document297 pagesYamaha Vino Service Manual 2006 2009Deák GáborNo ratings yet

- Form Report Overhaul TM 274 RevDocument14 pagesForm Report Overhaul TM 274 Revsersan darmin100% (1)

- 9300 SERIES: Parts ManualDocument28 pages9300 SERIES: Parts ManualRazvan MitruNo ratings yet

- Installation Manual T4900CRDocument36 pagesInstallation Manual T4900CRmayNo ratings yet

- 0.25L L (C/C) 0.25L: TP REGD - No.1173Document1 page0.25L L (C/C) 0.25L: TP REGD - No.1173Er Navneet JassiNo ratings yet

- Quick Couplers Mechanical Hydraulic 068700 PDFDocument26 pagesQuick Couplers Mechanical Hydraulic 068700 PDFSTEVHEN MARTHINNo ratings yet

- 4HF1 4HG1Document5 pages4HF1 4HG1Arifin Arif100% (2)

- Parts Manual: CascadeDocument18 pagesParts Manual: Cascadema100% (1)

- Tyrone Gear Pump DiagnosisDocument20 pagesTyrone Gear Pump DiagnosisMohamad SaremyNo ratings yet

- Parts List: Ultraa-K Utknt 40KDocument8 pagesParts List: Ultraa-K Utknt 40KKenny CreechNo ratings yet

- Gate Valve Installation InstructionsDocument20 pagesGate Valve Installation InstructionsRomi Kristanto100% (1)

- Servicekits R974Document3 pagesServicekits R974Andrés Esmoriz DíazNo ratings yet

- 2015-2017 Service Manual Yzf-R1Document704 pages2015-2017 Service Manual Yzf-R1FabianEbeling71% (7)

- 49366mss39118 3 PDFDocument6 pages49366mss39118 3 PDFManas Kumar SahooNo ratings yet

- MODULE in Stat Week 6Document10 pagesMODULE in Stat Week 6Joshua GonzalesNo ratings yet

- Livro - Egg Parasitoids in Agroecosystems With Emphasis On TrichogrammaDocument481 pagesLivro - Egg Parasitoids in Agroecosystems With Emphasis On TrichogrammaRuan Carlos Mesquita0% (2)

- Starlight 4 POSTERSDocument12 pagesStarlight 4 POSTERSTatianaGraur100% (1)

- Effective Home Remedy For AlmoranasDocument3 pagesEffective Home Remedy For AlmoranasMyk Twentytwenty NBeyondNo ratings yet

- Draft Policy On Referral SystemDocument19 pagesDraft Policy On Referral Systemcode4sale100% (3)

- Managing A Family BudgetDocument5 pagesManaging A Family BudgetGaurav Umbarkar100% (1)

- Audio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsDocument168 pagesAudio/video, Information and Communication Technology Equipment Part 1: Safety RequirementsneodvxNo ratings yet

- Hearnshaw TSBE Conference Paper 2012Document8 pagesHearnshaw TSBE Conference Paper 2012FUCKUNo ratings yet

- Pengaruh Penerapan Strategi Pelaksanaan Keluarga Terhadap Kemampuan Keluarga Merawat Pasien Halusinasi Di Kota Jambi Tahun 2017Document8 pagesPengaruh Penerapan Strategi Pelaksanaan Keluarga Terhadap Kemampuan Keluarga Merawat Pasien Halusinasi Di Kota Jambi Tahun 2017novanNo ratings yet

- Parle GDocument20 pagesParle GChetan Jain100% (2)

- Dr. Ahmed Shafai P6Document13 pagesDr. Ahmed Shafai P6Haya ZayedNo ratings yet

- Wage BoardDocument10 pagesWage BoardDaniel PeterNo ratings yet

- Chlamydia InfectionsDocument4 pagesChlamydia InfectionsPearl CalisNo ratings yet

- IntroductionDocument4 pagesIntroductionMarianna GurgutsovaNo ratings yet

- Balochistan Province Civil Servants Leave Rules 1981 PDFDocument10 pagesBalochistan Province Civil Servants Leave Rules 1981 PDFAhsan 130% (1)

- Polycythemi A: Presented By: Palaran, Nina Mae CDocument16 pagesPolycythemi A: Presented By: Palaran, Nina Mae CJichutreasureNo ratings yet

- Nchem2 PosttestDocument4 pagesNchem2 PosttestJessa GuerraNo ratings yet

- LGDocument9 pagesLGSandeep SinglaNo ratings yet

- Problem Identification - Illuminate EducationDocument6 pagesProblem Identification - Illuminate Educationhailemecaile kfileNo ratings yet

- Sars-Cov-2 (Covid 19) Detection (Qualitative) by Real Time RT PCRDocument3 pagesSars-Cov-2 (Covid 19) Detection (Qualitative) by Real Time RT PCRNM KPTNo ratings yet

- Home Page Principles Practitioners Help Yourself Contact: Main NavigationDocument2 pagesHome Page Principles Practitioners Help Yourself Contact: Main NavigationAbdurrahmanUsmanNo ratings yet

- Class 9 Science Annual Paper 2 Prince Public SchoolDocument3 pagesClass 9 Science Annual Paper 2 Prince Public SchoolSHAURYA VARDHANNo ratings yet

- Inverter TrainerDocument2 pagesInverter TrainerBudhi PrasetiyoNo ratings yet

- Yellow Book (Analysis of Rate)Document161 pagesYellow Book (Analysis of Rate)antt phweNo ratings yet

- BikesDocument109 pagesBikesKanika GuptaNo ratings yet

- 2011UCMC Trauma Care Q&ADocument2 pages2011UCMC Trauma Care Q&ASam CholkeNo ratings yet

- Nouvelle France Industrielle EnglishDocument76 pagesNouvelle France Industrielle EnglishasdasdNo ratings yet

- Stress Diary - Identifying Causes of Short-Term Stress PDFDocument6 pagesStress Diary - Identifying Causes of Short-Term Stress PDFgggNo ratings yet

- Cambridge IGCSE: Co-Ordinated Sciences 0654/22Document16 pagesCambridge IGCSE: Co-Ordinated Sciences 0654/22Gina ChenNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Deepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeFrom EverandDeepwater Deception: The Truth about the Tragic Blowout & Perversion of American JusticeNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Reservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesFrom EverandReservoir Engineering: The Fundamentals, Simulation, and Management of Conventional and Unconventional RecoveriesRating: 5 out of 5 stars5/5 (7)

- Offshore Projects and Engineering ManagementFrom EverandOffshore Projects and Engineering ManagementRating: 5 out of 5 stars5/5 (2)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Ship and Mobile Offshore Unit Automation: A Practical GuideFrom EverandShip and Mobile Offshore Unit Automation: A Practical GuideNo ratings yet

- The Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoFrom EverandThe Offshore Pipeline Construction Industry: Activity Modeling and Cost Estimation in the U.S Gulf of MexicoNo ratings yet

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonFrom Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNo ratings yet

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsFrom EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo ratings yet

- Practical Engineering Management of Offshore Oil and Gas PlatformsFrom EverandPractical Engineering Management of Offshore Oil and Gas PlatformsRating: 4 out of 5 stars4/5 (7)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)