Professional Documents

Culture Documents

Custom Tanks Design Guide

Custom Tanks Design Guide

Uploaded by

Naveen HlCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Custom Tanks Design Guide

Custom Tanks Design Guide

Uploaded by

Naveen HlCopyright:

Available Formats

CUSTOM WATER, WASTE AND DIESEL CUSTOM WATER, WASTE AND DIESEL CUSTOM WATER, WASTE AND DIESEL

FUEL TANK DESIGN GUIDE FUEL TANK DESIGN GUIDE FUEL TANK DESIGN GUIDE

DIESEL TANKS

This guide has been designed to help you decide which type of fittings and Large fixed elbow shown is used

accessories you require on your custom built tank. There are five points you for 32, 38 and 50mm hosetails.

All straight hosetail fittings are screwed into a female BSP boss, which is All other sizes use a smaller body

need to address: permanently welded to the tank. All female bosses will stand 10mm off the tank standing 45mm high.

face when the fitting is removed. Female bosses are available in the following It is important that the direction of

- HOSE AND PIPE FITTING CONNECTIONS thread sizes: ½” BSP, ¾” BSP, 1” BSP, 1¼ ” BSP, 1 ½” BSP. Smaller sizes are

- AVOIDING INTERNAL BAFFLES the elbow is checked thoroughly.

available and are achieved by using a reducing bush screwed into the ½” BSP If the direction is not correct, the

- INSPECTION HATCHES boss, i.e. a ¼ ” BSP is attained using a ½”-¼ ” BSP reducing bush.

- LEVEL INDICATORS tank will have to be returned to us

- THE TANK DRAWING for repositioning.

Straight hosetails are required when connecting to a flexible hose. Size of tail Please refer to the Tek-Tanks

should be the same as the bore of the hose you are using. These are normally Fittings Guide for the full list of

Check off each heading as you cover them. You may decide that sender is not the inlet/filler hose and vent hose. Feeds and returns can be also flexible.

necessary as you will be able to see the contents through a tank wall, so just sizes available.

All straight hosetail fittings are supplied with a bonded seal also known as

ignore that section. a Dowty washer. These seals comprise of a zinc plated steel ring with a stiff ELBOW TYPE FITTINGS FOR FUEL

rubber seal bonded to the inside of the ring. The rubber seal is slightly thicker FEEDS AND RETURNS

than the steel ring so when the hosetail fitting is tightened up, the rubber

compresses and seals the underside of the hose tail flange and the face of the Elbow fittings are generally specified

HOSE AND PIPE FITTING CONNECTIONS female boss. for fuel feed and return because of their

The bonded seal does a similar job to a fibre washer, but is far more effective low profile.

First decide where the fittings need to go. Once you have established the as they are normally found in high pressure applications. Hosetail fittings for fuel A male - female elbow is screwed into

position, the size has to be decided. Once the size has been decided, please tanks are supplied in a marine grade brass. Please refer to the Tek-Tanks a reducing bush with either a hosetail

refer to the Tek-Tank Fittings Guide for the overall height and length of the Fittings Guide for the full list of available sizes. adaptor for flexible hose or a

fitting. This height or length can then be checked against the tank design, compression fitting for copper pipe.

to see if there any problems with clearance. For example, you may have Tek-Tanks will position the elbow in the

a clearance above you tank design of 75mm and want to fit an 1 ½” direction shown on the drawing using

elbow inlet. This would not be possible as an 1 ½” elbow actually stands up a thread sealant / adhesive

108 mm and would foul whatever is above the tank. The tank height would Flexible Hose (Permabond A 131). Should the elbow

then have to be reduced by 25mm to allow for the fitting. need to be repositioned then the seal

Jubilee Clips can be easily broken. Repositioning will

require a fresh application of either

WATER, GREY WATER AND WASTE HOLDING TANKS Permabond or a similar sealant /

adhesive of which there are many

All fittings on water, grey water and waste holding tanks, whether straight or types available.

elbows are screwed onto a BSP threaded male adaptor, which is permanently

welded to the tank. All adaptors will stand 24mm off the tank face when the Brass Hosetail Feeds should be placed on the top of

fitting is removed as shown on the drawing below. the tank as with all the other fuel tank

Dowty Seal fittings if possible. Gravity feed is now

really a thing of the past as most

24 Tank Surface modern engines have very good lift

pumps. If the tank is a replacement for

a gravity fed engine then we will put the

feed at the bottom of the tank, but it is

not advisable from a “leak potential”

Each fitting needs to be checked against the tank design and the boat structure point of view. A gravity feed could

Cross section of S38B

to avoid any problems later when the tank is fitted . Time spent now checking brass hosetail assembly

Example of fitted hose tail. possibly develop a drip after many

the size and position of each fitting will pay off, as it is not normally possible to Double clipped opposite years of vibration from the engine

showing Dowty washer

sides is best practice.

modify the tank. and threaded boss. whereas a top feed would just show

All elbows are multidirectional, hence the direction they need to point does not signs of seeping and would probably

need to be shown. Once the tank is installed they can be swivelled in the right be easier to see. A total failure of a

direction and then the locknut can be tightened. Elbow hosetails are also used for connecting flexible hose to the tank. These gravity feed (i.e. a split or worn flexible

Hosetail fittings for water, grey water and waste tanks are supplied in plastic. come off a face of the tank and turn through 90°. Tek-Tanks fuel tank elbows are hose), would almost certainly fill the

Please refer to the TekTanks Fittings Guide for the full list of available sizes. of a fixed type and cannot be rotated once attached to the tank. bilges with diesel.

TEK TANKS TEK TANKS TEK TANKS TEK TANKS

The Old Stables,West End Farm, Upper Froyle, Alton, Hampshire GU34 4JR. England The Old Stables,West EndThe Old

Farm, Stables,West

Upper End Farm,

Froyle, Alton, Upper GU34

Hampshire Froyle,4JR.

Alton, Hampshire GU34 4JR. England

England The Old Stables,West End Farm, Upper Froyle, Alton, Hampshire GU34 4JR. England

Tel: +44 (0)1420 525478 fax: +44 (0)1420 520840 email: sales@tek-tanks.com Tel: +44 (0)1420 525478 Tel:fax:

+44 (0)1420

+44 525478

(0)1420 520840 fax:email:

+44 (0)1420 520840 email: sales@tek-tanks.com

sales@tek-tanks.com Tel: +44 (0)1420 525478 fax: +44 (0)1420 520840 email: sales@tek-tanks.com

www.tek-tanks.com www.tek-tanks.com

www.tek-tanks.com www.tek-tanks.com

Reg. Office: Cowdown Business Park, Micheldever,Winchester, Hampshire, SO21 3DN. England. a member of the Reg. Office: Cowdown Business Park, Micheldever,Winchester, Hampshire, SO21 3DN. England. a member of the Reg. Office: Cowdown Business Park, Micheldever,Winchester, Hampshire, SO21 3DN. England. a member of the

Registered in England No. 3857992 VAT Registration No: 744 9594 83 Registered in England No. 3857992 VAT Registration No: 744 9594 83 Registered in England No. 3857992 VAT Registration No: 744 9594 83

CUSTOM WATER, WASTE AND DIESEL CUSTOM WATER, WASTE AND DIESEL CUSTOM WATER, WASTE AND DIESEL

FUEL TANK DESIGN GUIDE FUEL TANK DESIGN GUIDE FUEL TANK DESIGN GUIDE

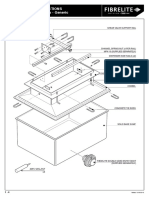

Dip pipes are manufactured from 10mm OD straight copper pipe. The copper LEVEL INDICATORS The following drawing is how we would ideally like the information presented but

pipe is soldered into a brass reducing bush, the banjo fitting is then screwed into we do realise that not everyone is a draughtsman and has access to drawing

the reducing bush and is sealed with a copper or nitrile washer. At Tek-Tanks we use a wide range of level indicators and gauges for remote programs. A hand drawn sketch is fine as long as all the information is there.

The whole assembly is then screwed into a ½” BSP boss welded to the tank top sensing on tanks.

or inspection hatch and sealed with a ½” BSP Dowty washer.

TANK DESIGN USING COMPUTER

Dip pipes are normally left slightly short of the bottom of the tank so as not to

pick up any water that may have condensated out or picked up with “bad” fuel.

Some engine manufacturers will specify dip pipes on the fuel returns as the

more powerful modern engines actually return the fuel back to the tank at quite 35 25 35

rate.This high return rate can cause foaming if there is no dip pipe. Return dip 8

pipes are quite rare and can normally be ignored.

AVOIDING BAFFLES

When designing your tank, it is important that the fittings avoid any baffles that

we put in. A custom tank can have fittings in almost any position, the only

restriction being the baffles. Nearly all custom built tanks will have baffles unless

the tank is very small, then it will have none.

The baffle spacing is based upon the length of the tank. All Tek-Tanks custom

built tanks have equal baffle spacing where possible. The spacing is normally Various senders showing

between 250 and 350mm depending on how the length divides up. For example height protrusion above

a tank 1200mm long will have 3 baffles with four compartments 300mm wide. tanks upper surface

A tank 675mm long will have 1 baffle with two compartments 337.5mm wide. If

in doubt about the number of baffles a tank will need, then please phone for Dimensions in mm

advice. HAND DRAWN TANK DESIGN

For more details on these units, please visit our webiste or call us.

TANK DRAWING

It is important to provide us with as much information as possible when

designing your tank. We will need the overall dimensions and a clear indication

of where the fittings are going to go. If the position of the fittings is critical then

they will have to be dimensioned from the edges of the tank. If they are not

critical then we will put them as near as possible to the position indicated.

When positioning the hatch or hatches, just remember to bear in mind where

the baffles will be, again give us a call if you are uncertain.

On a very complicated tank with many angles, please indicate any square

corners if any. This will help us greatly when we come to draw up the tank on

our computer aided design system.

Another method of supplying us with the information we need, is to supply us

INSPECTION HATCHES with a template or mockup in either plywood or cardboard. By doing this you can

satisfy yourself that the tank can be easily installed and that you can actually get

An inspection hatch cannot straddle two compartments. It has to be in one or the it in or out of the boat or vehicle. The template can then be marked up with all

other. the relevant fittings and hatches and either sent to us flat packed or you can

bring it along to the factory to discuss in detail.

For the comprehensive list of hatches, please refer to the Tek-Tanks Fittings

Guide or phone for advice. For quotation purposes a drawing will suffice.

TEK TANKS TEK TANKS TEK TANKS

The Old Stables,West End Farm, Upper Froyle, Alton, Hampshire GU34 4JR. England The Old Stables,West End Farm, Upper Froyle, Alton, Hampshire GU34 4JR. England The Old Stables,West End Farm, Upper Froyle, Alton, Hampshire GU34 4JR. England

Tel: +44 (0)1420 525478 fax: +44 (0)1420 520840 email: sales@tek-tanks.com Tel: +44 (0)1420 525478 fax: +44 (0)1420 520840 email: sales@tek-tanks.com Tel: +44 (0)1420 525478 fax: +44 (0)1420 520840 email: sales@tek-tanks.com

www.tek-tanks.com www.tek-tanks.com www.tek-tanks.com

Reg. Office: Cowdown Business Park, Micheldever,Winchester, Hampshire, SO21 3DN. England. a member of the Reg. Office: Cowdown Business Park, Micheldever,Winchester, Hampshire, SO21 3DN. England. a member of the Reg. Office: Cowdown Business Park, Micheldever,Winchester, Hampshire, SO21 3DN. England. a member of the

Registered in England No. 3857992 VAT Registration No: 744 9594 83 Registered in England No. 3857992 VAT Registration No: 744 9594 83 Registered in England No. 3857992 VAT Registration No: 744 9594 83

You might also like

- Dir Stake HoldersDocument19 pagesDir Stake HoldersChandilyan SNo ratings yet

- AirlinerMagazine 1960-09Document12 pagesAirlinerMagazine 1960-09Alejandro Vigar100% (1)

- VIGAS HENDRICKSON 45745-147d PDFDocument12 pagesVIGAS HENDRICKSON 45745-147d PDFCARLOS SALGADONo ratings yet

- Power HackSawDocument6 pagesPower HackSawMike Nichlos100% (2)

- Mineral Processing in Developing Countries - A Discussion of Economic, Technical and Structural Factors (1984, Springer Netherlands) PDFDocument62 pagesMineral Processing in Developing Countries - A Discussion of Economic, Technical and Structural Factors (1984, Springer Netherlands) PDFBrian VasquezNo ratings yet

- Keys and Keyways DesignDocument5 pagesKeys and Keyways Designalexandre_motta_3No ratings yet

- Geometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsFrom EverandGeometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsRating: 5 out of 5 stars5/5 (2)

- Airline EfficiencyDocument388 pagesAirline Efficiencya_sharafieh100% (1)

- Business Analysts and Agile Development - Practical GuideDocument24 pagesBusiness Analysts and Agile Development - Practical GuideAndrew QuanNo ratings yet

- Trico J P PDFDocument207 pagesTrico J P PDFsoomro99100% (2)

- Jetgala Magazine Issue 09/2011Document148 pagesJetgala Magazine Issue 09/2011Simon LászlóNo ratings yet

- Exhibitor List 2005Document5 pagesExhibitor List 2005Sadik ShaikhNo ratings yet

- PicnicTable PDFDocument2 pagesPicnicTable PDFAvi KarmonNo ratings yet

- Green BIM How Building Information Modeling Is Contributing... (2013)Document56 pagesGreen BIM How Building Information Modeling Is Contributing... (2013)Tiago de VasconcelosNo ratings yet

- NSK Tools CatalogDocument20 pagesNSK Tools CatalogRobert OrtegaNo ratings yet

- 5.plumbing - FixturesDocument33 pages5.plumbing - FixturesMenshafiNo ratings yet

- Pumps For Power Generation: Sintech Precision Products LimitedDocument16 pagesPumps For Power Generation: Sintech Precision Products LimitedSumit PrasadNo ratings yet

- 6 Merged Assembly Instruction Eaton Aeroquip Hose Fittings Adap - Final PDFDocument19 pages6 Merged Assembly Instruction Eaton Aeroquip Hose Fittings Adap - Final PDFDani Quirante Flaaut EtcNo ratings yet

- Spears Butterfly Valve InstallationDocument1 pageSpears Butterfly Valve Installationimmanuel izaniNo ratings yet

- Foot Valve: Technical Specifications Frequently Asked QuestionsDocument2 pagesFoot Valve: Technical Specifications Frequently Asked QuestionsmarvinNo ratings yet

- Fire Saftey of Ball ValveDocument1 pageFire Saftey of Ball ValvekapsarcNo ratings yet

- kx80 Página 172Document1 pagekx80 Página 172PabloNo ratings yet

- Goulds Vertical ReaderDocument20 pagesGoulds Vertical ReaderSonthi MooljindaNo ratings yet

- Hose Reel Cobra & Gleason ReelDocument28 pagesHose Reel Cobra & Gleason ReeljsgkhairulNo ratings yet

- Manual Series 3700Document8 pagesManual Series 3700edwinmena100% (1)

- EGD PAT - ResearchDocument10 pagesEGD PAT - ResearchayandaNo ratings yet

- A Simple Propeller Balancing StandDocument1 pageA Simple Propeller Balancing StandWafi AwfNo ratings yet

- The Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Document6 pagesThe Unique Surf Ace-Deep Well Pump C Ombination:: Ensive Deep Well Pumping Solutions Easy T o Install and Mainta in !!Kasim ButkovicNo ratings yet

- DP 3127.180 Impcod471 - BrochureDocument10 pagesDP 3127.180 Impcod471 - BrochurehectorNo ratings yet

- Medium Foam Pod Nozzle - NPB Series Fountain NozzleDocument2 pagesMedium Foam Pod Nozzle - NPB Series Fountain NozzleFachrul Rozi SuriyanaNo ratings yet

- Spiral Jet Technical DocumentDocument3 pagesSpiral Jet Technical DocumentykozeNo ratings yet

- Snap LoccatwebDocument16 pagesSnap Loccatwebnick martinNo ratings yet

- Staubli AdapetrsDocument36 pagesStaubli AdapetrsAbhishek Das100% (1)

- 370D4 2F 6RStandardsDocument1 page370D4 2F 6RStandardsAlejandro ParradoNo ratings yet

- WJ Hollow Med STDDocument7 pagesWJ Hollow Med STDAli MezaNo ratings yet

- LVTSL001 ELS Threaded VT Flyer - 2014Document2 pagesLVTSL001 ELS Threaded VT Flyer - 2014Ghassan ABO ALINo ratings yet

- 2 Inch Threaded Deep Well Owners Manual Rev A2Document23 pages2 Inch Threaded Deep Well Owners Manual Rev A2dkmgapkgNo ratings yet

- Installation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Document4 pagesInstallation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Camilo CorreaNo ratings yet

- Fork Rebuilding PDFDocument2 pagesFork Rebuilding PDFmxckcxzlm.c,No ratings yet

- Spraytech Ed - 2 Full ConeDocument20 pagesSpraytech Ed - 2 Full ConeRAMESH SHETTYNo ratings yet

- 300 Series Color BrochureDocument8 pages300 Series Color Brochurejohan diazNo ratings yet

- Dump Bailer PDFDocument1 pageDump Bailer PDFDaniex VillalobosNo ratings yet

- Paintearth Energy Tubing RotatorsDocument29 pagesPaintearth Energy Tubing RotatorsFabiancho PintoNo ratings yet

- Chemical Pump Co., Inc.: General BulletinDocument12 pagesChemical Pump Co., Inc.: General Bulletinnurfara39No ratings yet

- Cge578 CH4 Mac 2020Document82 pagesCge578 CH4 Mac 2020Nurfatini CheNo ratings yet

- Watts Radiant Radiant Heating ManifoldsDocument28 pagesWatts Radiant Radiant Heating Manifoldse-ComfortUSANo ratings yet

- Texsteam-Ñ Bomba QuímicaDocument8 pagesTexsteam-Ñ Bomba QuímicarivomarNo ratings yet

- En Bondioli变量闭式泵p2Document16 pagesEn Bondioli变量闭式泵p2cunvip163.comNo ratings yet

- Fasani Through Conduit Slab Type Bolted Bonnet ValvesDocument10 pagesFasani Through Conduit Slab Type Bolted Bonnet ValvesFrancis AlmiaNo ratings yet

- Data Sheets Welbond Model 5600 High Pressure Globe Valve Yarway en en 9878790Document12 pagesData Sheets Welbond Model 5600 High Pressure Globe Valve Yarway en en 9878790Miyka'el PaunNo ratings yet

- cat75HYD Us E4Document1 pagecat75HYD Us E4rudo25No ratings yet

- Nozzle M - Spray SystemDocument4 pagesNozzle M - Spray SystemAry SetiawanNo ratings yet

- Don't Weld To The Shell!Document1 pageDon't Weld To The Shell!ccpjeffNo ratings yet

- Grundfos Data Sheet: STN & SSN Brass Universal Head Shower Booster Pump RangeDocument2 pagesGrundfos Data Sheet: STN & SSN Brass Universal Head Shower Booster Pump RangeVIOSKOSNo ratings yet

- BH 29Document16 pagesBH 29Faiyaz Bin Mazid AhmedNo ratings yet

- Re Engineered Pumps Rev2010-2Document4 pagesRe Engineered Pumps Rev2010-2Chuong DongNo ratings yet

- Small Workshop CompressorDocument2 pagesSmall Workshop Compressorw4rh4ck3r-scribdNo ratings yet

- General High Banker Instructions: AssemblyDocument9 pagesGeneral High Banker Instructions: AssemblyJesús DíazNo ratings yet

- Cat75b HydDocument3 pagesCat75b HydrichardNo ratings yet

- Installation: Pinch Valve Technical InformationDocument1 pageInstallation: Pinch Valve Technical Informationenrique20No ratings yet

- LVTSL004 Grundfos - Peerless VT Pump BrochureDocument5 pagesLVTSL004 Grundfos - Peerless VT Pump BrochuredanilobossuNo ratings yet

- Foam Proportioning Equipment: DescriptionDocument32 pagesFoam Proportioning Equipment: Descriptionkiara nasutionNo ratings yet

- Nutech ControlsDocument5 pagesNutech ControlsmuralisunNo ratings yet

- 71-73 Dynabolts PDFDocument3 pages71-73 Dynabolts PDFErik HaryantoNo ratings yet

- NPL SprocketInfoSheetLowResDocument2 pagesNPL SprocketInfoSheetLowResnbennettengNo ratings yet

- Assignment 4Document3 pagesAssignment 4Abhishek VishwakarmaNo ratings yet

- Alkesh Pandya: Supply Chain Manager / Logistics / WarehousingDocument5 pagesAlkesh Pandya: Supply Chain Manager / Logistics / WarehousingChandanGuptaNo ratings yet

- Daftar Pustaka: Prarancangan Pabrik Methylamine Dari Methanol Dan Ammonia Kapasitas 25.000 Ton/tahun Daftar PustakaDocument2 pagesDaftar Pustaka: Prarancangan Pabrik Methylamine Dari Methanol Dan Ammonia Kapasitas 25.000 Ton/tahun Daftar Pustakatri meliasariNo ratings yet

- Engr. Prof. Peter OnwualuDocument35 pagesEngr. Prof. Peter OnwualuOladimeji TaiwoNo ratings yet

- Jakarta Struts: Manually Validating InputDocument30 pagesJakarta Struts: Manually Validating Inputluislaar33No ratings yet

- What Norways Experience Reveals About The Ev Charging MarketDocument6 pagesWhat Norways Experience Reveals About The Ev Charging MarketAnanchai UkaewNo ratings yet

- Wedge Socket For Wire Rope BS-7166 PDFDocument12 pagesWedge Socket For Wire Rope BS-7166 PDFMaazARazaNo ratings yet

- Material Management For Construction Site With Using ERPDocument2 pagesMaterial Management For Construction Site With Using ERPInternational Journal of Innovative Science and Research Technology100% (1)

- Optimization of Gas-Injected Oil WellsDocument11 pagesOptimization of Gas-Injected Oil Wellsgandalf the grayNo ratings yet

- Meeting Planner in Milwaukee Chicago Resume Nikki Dennard PayneDocument2 pagesMeeting Planner in Milwaukee Chicago Resume Nikki Dennard PayneNikkiDennardPayneNo ratings yet

- Sap MML Outline AgreementDocument8 pagesSap MML Outline AgreementKARAN JAWNo ratings yet

- CV PCBA Manufacturing EngineerDocument2 pagesCV PCBA Manufacturing EngineerFernando RodriguezNo ratings yet

- Maritime English Learning Tool IDocument28 pagesMaritime English Learning Tool IJTKirk61No ratings yet

- Checklist For C-172 Before Starting Engine Instrument Cockpit CheckDocument2 pagesChecklist For C-172 Before Starting Engine Instrument Cockpit CheckKonstantinos AirmanNo ratings yet

- No. of EmployeesDocument3 pagesNo. of EmployeesSuraj RawatNo ratings yet

- SR en 442 RadiatoareDocument3 pagesSR en 442 RadiatoareprodanNo ratings yet

- Introduction To Telecom IndustryDocument8 pagesIntroduction To Telecom Industryshabad_sharma564No ratings yet

- 2009 DDP FinalDocument178 pages2009 DDP FinalMaribel_Sapita_2313No ratings yet

- E 383 PDFDocument3 pagesE 383 PDFAditi SharmaNo ratings yet

- 600P Tubing & FittingDocument36 pages600P Tubing & FittingAnabel Hernández DíazNo ratings yet

- TamCem 6R V1ID 13Document2 pagesTamCem 6R V1ID 13Arfan Rahim100% (1)

- Fact Finding TechniquesDocument28 pagesFact Finding TechniquesCathy Love MoneroNo ratings yet