Professional Documents

Culture Documents

CV PCBA Manufacturing Engineer

Uploaded by

Fernando RodriguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CV PCBA Manufacturing Engineer

Uploaded by

Fernando RodriguezCopyright:

Available Formats

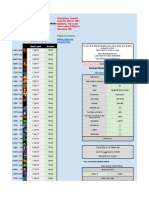

Felipe Rene Angeles

Apodaca, NL ▪ Cell: +52.81.86774743▪ Email: rene.angeles.torres@gmail.com

NPI, Design & Manufacturing

Dynamic engineering and new products launch with over 20 years experience in manufacturing of

electronics for automotive, safety, medical and lighting devices.

SIGNATURE STRENGTHS

NPI and project management.

Ability to lead cross functional teams

Manufacturing process expert.

Strong knowledge on manufacturing standards.

Familiarity on Ecad (PADs), proficient on Mcad (Solid Works).

Knowledge on quality tools.

CAREER SUCCESS

UTEC SANTA CATARINA SITE

Advanced Manufacturing Engineer Aug/2018 - Present

o Drive across functional teams for solving complex manufacturing/design issues.

o Participate in validation of new processes and products being transferred.

o Lead improvement projects for low yield / rate products.

o Implementation of production and process for new machines and products.

o Lead and support Failure mode and effect analysis

o Perform DFMA for incoming products.

OSRAM / SYLVANIA APODACA SITE

Sr. Mechanical Design Engineer. Oct/2012 - Aug/2018

o Lead projects trought different gates until it is released to mas production.

o Identify risks, issues and manage the associated action plans.

o First contact for manufacturing problems related to design issues.

o Provide technical support on product Design per manufacturing capabilities.

o DFMA for new products and provide feedback at early stages of the design (PCB gerber

and 3D Assemblies level).

o Design Mechanical parts (enclosures), define PCB out lines, create PCB panel array.

o Review of vendors design feedback coupled with analysis of vendor capability.

o Review/approve first article inspection reports for new components & assemblies.

o Serve as a technical resource to other engineering groups and project leaders

OSRAM / SYLVANIA APODACA SITE

Sr Project Leader (NPI) Feb/2010- Oct/2012

Lead the project to its closeout, including financial reconciliation, verification of job site equipment

arrival, installation, start-up, and training support.

o Coordinate the activities related to new products introduction.

o Lead functionally a project core team of cross functional disciplines.

o Define schedule, and equipment needed for new products introduction.

o Key player on equipment validation and analysis for process capabilities.

o Make NPI build plans and full fill check list.

o Analysis and purchase of equipment needed.

o Work with support team to define set up for new products introduction.

o Coordinate and follow capex involved.

MOTOROLA REYNOSA SITE

PCB NPI/ Sr Process Engineer June/2008– Jan/2010

o Set and monitor material usage and scrap levels.

o Development and analysis of new tools and or fixtures for improvements...

o Monitor yield and quality improvements plans.

o Transfer machines, products and technologies from other sites.

o Design of fixtures and tooling for electronic manufacturing process.

o Maintain a close working relationship with product development groups.

o Lead cost reduction & Quality improvements projects.

CELESTICA APODACA SITE

Operations Engineering Specialist Oct/2004 – Dec/2006

o Answer corrective actions to costumers.

o Responsible for creation of manufacturing documents and visual aids.

o Lead free pilot runs for RoHS compliance products (wave solder process).

o Responsible of PFMEA creation.

o Transfer machines & products from other sites.

o Process and machine support in other sites (USA and Canada).

o Member of the Celestica Global Team Engineering for the Wave Solder process.

CELESTICA APODACA SITE Aug/1999 – Mar/2004

Operations Engineering Support

o Development of plan for equipment preventive maintenance.

o Work along with machines suppliers for machine training and or troubleshooting.

o Performance corrective maintenance.

o Supervise personal (16 tech).

o Define Max and Min for Spare parts.

o Teaching activities to new employees.

o Provide information related to process to customer.

o Lines support.

o Work with Celestica support team to efficient the equipment & process.

EDUCATION & TRAINING

Mechanical Engineer

TECNOLOGICO DE CD VICTORIA, TAM

Mechanical Electrical Technician

C.B.T.i.s No 15

o English advanced. o Software

o Green Belt. o Solid Works

o Lean Manufacturing. o PADs

o Design Thinking. o MiniTab

o Motorola’s Approach to Quality. o ViewMate.

o Desarrollo de Habilidades Gerenciales. o SAP

o Bullet Proof Manager. o Windchill

o Essentials of Leadership.

You might also like

- KM-2023 Engineering Manager Update 1686573682728 KeshavaMurthyDocument5 pagesKM-2023 Engineering Manager Update 1686573682728 KeshavaMurthyvikranthjNo ratings yet

- Technical Support Engineer or Field Application Engineer or ProcDocument3 pagesTechnical Support Engineer or Field Application Engineer or Procapi-121427935No ratings yet

- Imelda Sager Resume 2023Document2 pagesImelda Sager Resume 2023Imelda SagerNo ratings yet

- Accomplished Engineering Pro Executive with 30+ Years ExperienceDocument5 pagesAccomplished Engineering Pro Executive with 30+ Years ExperienceGermma GunmanNo ratings yet

- Resume-Chetan-Dhuri-Mechanical Design FEADocument4 pagesResume-Chetan-Dhuri-Mechanical Design FEAChetan DhuriNo ratings yet

- Gabriel Enrique Lira SáenzDocument6 pagesGabriel Enrique Lira SáenzGabrielLiraNo ratings yet

- Resume-Indrajeet AtherDocument5 pagesResume-Indrajeet Atherhr.runrmobilityNo ratings yet

- Paultitchener Resume 071319Document1 pagePaultitchener Resume 071319api-244906204No ratings yet

- Career PlanningDocument9 pagesCareer PlanningRohan RautNo ratings yet

- MD Shahnewaz: Manufacturing EngineerDocument4 pagesMD Shahnewaz: Manufacturing Engineerkiran2710No ratings yet

- Ricardo Mendoza Rodríguez Mechanical Engineer: ObjetiveDocument2 pagesRicardo Mendoza Rodríguez Mechanical Engineer: ObjetiveRicardo MdzaNo ratings yet

- Arshad Resume - Dot PDFDocument6 pagesArshad Resume - Dot PDFArshad AnsariNo ratings yet

- Resume-Rahul Sah2Document5 pagesResume-Rahul Sah2Rahul SahNo ratings yet

- Vigneshwaran.S: Areas of ExposureDocument2 pagesVigneshwaran.S: Areas of Exposuremamillapalli sri harshaNo ratings yet

- Experienced Production Engineer Seeking New OpportunitiesDocument2 pagesExperienced Production Engineer Seeking New Opportunitiesw john franklinNo ratings yet

- Sample ResumesDocument3 pagesSample ResumesinboxsweetsNo ratings yet

- Monster CV Template Graduate - Mechanical - EngineeringDocument2 pagesMonster CV Template Graduate - Mechanical - Engineeringvinh nguyenNo ratings yet

- Shine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerDocument2 pagesShine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerPooja PoojaNo ratings yet

- Shine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerDocument2 pagesShine Daya Shankar 4yrs 1m Delhi 4.05 LPA New Product Development Senior EngineerPooja PoojaNo ratings yet

- Juan Fadrique Molina Naranjo RESUME Rev9Document6 pagesJuan Fadrique Molina Naranjo RESUME Rev9juan molinaNo ratings yet

- STAMOD Engineering ServicesDocument40 pagesSTAMOD Engineering ServicesvikasgodageNo ratings yet

- Resume - Shubhanjali Srivastava - Component Dev. - UpdateDocument3 pagesResume - Shubhanjali Srivastava - Component Dev. - Updatesurjitrajput8No ratings yet

- Hardware Program Project Manager in San Francisco Bay CA Resume Evan ChangDocument2 pagesHardware Program Project Manager in San Francisco Bay CA Resume Evan ChangEvanChangNo ratings yet

- Thesis ScaniaDocument7 pagesThesis Scanialisamoorewashington100% (1)

- Thesis Production EngineeringDocument6 pagesThesis Production Engineeringafktgvllsgajfw100% (2)

- Ammar Saeed: SummaryDocument4 pagesAmmar Saeed: SummaryMostafa GaberNo ratings yet

- Gelacio Guevara Quintero: Mexican / 23 Years OldDocument1 pageGelacio Guevara Quintero: Mexican / 23 Years OldMiguel GuevaraNo ratings yet

- Suggested KeywordsDocument6 pagesSuggested KeywordsHomer Texido FrangioniNo ratings yet

- Eng CV Diego Monreal MaiaDocument3 pagesEng CV Diego Monreal MaiaDiego MaiaNo ratings yet

- Victor Manuel Sanchez Rubio: ArcosaDocument2 pagesVictor Manuel Sanchez Rubio: ArcosaArmenta EdwinNo ratings yet

- Diego Monreal Maia - Cost EngineerDocument2 pagesDiego Monreal Maia - Cost EngineerDiego MaiaNo ratings yet

- CV WritingDocument3 pagesCV WritingSarabjeet KaurNo ratings yet

- Boeing JDDocument5 pagesBoeing JDJeromeNo ratings yet

- Praveena CVDocument7 pagesPraveena CVPraveenaNo ratings yet

- Engineer with Passion for Production ImprovementDocument3 pagesEngineer with Passion for Production ImprovementAleceandraNo ratings yet

- Snehith Vadlakonda - SAP ABAPDocument12 pagesSnehith Vadlakonda - SAP ABAPSamir SahooNo ratings yet

- Arvind Pati TripathiDocument4 pagesArvind Pati TripathiAnish SinghNo ratings yet

- Saulo Trejo.: Mechanical EngineerDocument1 pageSaulo Trejo.: Mechanical EngineerSaulo TrejoNo ratings yet

- MD Shahnewaz Sabit Faisal: Phone: Home: EmailDocument4 pagesMD Shahnewaz Sabit Faisal: Phone: Home: Emailkiran2710No ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Resume Faizal 1 Debug TechDocument3 pagesResume Faizal 1 Debug TechZafarin Salleh0% (1)

- Syed Aquib: Mechanicalengineer Career ObjectiveDocument3 pagesSyed Aquib: Mechanicalengineer Career ObjectiveSyed AquibNo ratings yet

- CV - Sr. Mechanical Design Engineer - Khanh Nguyen - ENDocument2 pagesCV - Sr. Mechanical Design Engineer - Khanh Nguyen - ENNguyễn Tiến DũngNo ratings yet

- Jeon A Lyn Jasmin 2019 OmDocument4 pagesJeon A Lyn Jasmin 2019 OmTobey Marcus PradoNo ratings yet

- Anna Waldvogel 2008.04.01.chron - ShortDocument3 pagesAnna Waldvogel 2008.04.01.chron - Shortapi-752076No ratings yet

- Senior Project Program Manager in Raleigh Durham NC Resume Gary FitzgeraldDocument2 pagesSenior Project Program Manager in Raleigh Durham NC Resume Gary FitzgeraldGary FitzgeraldNo ratings yet

- Design Engineer: Job DescriptionDocument2 pagesDesign Engineer: Job DescriptionAspire SuccessNo ratings yet

- CV Yogesh Pagare-1Document6 pagesCV Yogesh Pagare-1sachin0307No ratings yet

- Midas NFX BrochureDocument36 pagesMidas NFX BrochureApoorv SharmaNo ratings yet

- Diego Monreal Maia - Product EngineerDocument2 pagesDiego Monreal Maia - Product EngineerDiego MaiaNo ratings yet

- VP Operations Semiconductor Engineering in Silicon Valley CA Resume Jay KumarDocument3 pagesVP Operations Semiconductor Engineering in Silicon Valley CA Resume Jay KumarJayKumar1No ratings yet

- CV Design Engineer seeking opportunitiesDocument5 pagesCV Design Engineer seeking opportunitiesaditya_pandey_77No ratings yet

- Technology Executive with 12+ Years Leading Embedded Software TeamsDocument14 pagesTechnology Executive with 12+ Years Leading Embedded Software Teamsswapnil tiwariNo ratings yet

- Jitesh T. Adiani: Mobile Phone: +91-9757140909 E-MailDocument4 pagesJitesh T. Adiani: Mobile Phone: +91-9757140909 E-MailRajnikant SanganiNo ratings yet

- Rizky Lanbar Tanjung: Experienced System Development LeaderDocument3 pagesRizky Lanbar Tanjung: Experienced System Development LeaderSolusi KomputerNo ratings yet

- Profile ShinoyDocument3 pagesProfile ShinoyAmit KumarNo ratings yet

- Optimizing Aluminum Casting ProcessesDocument4 pagesOptimizing Aluminum Casting ProcessesRui TaiyouNo ratings yet

- Product Design Engineer - MechanicalDocument434 pagesProduct Design Engineer - MechanicalAkshita Muskan100% (1)

- TSN Murthy - Sap PPDocument7 pagesTSN Murthy - Sap PPvaddyseshuNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Determining PTH SizeDocument4 pagesDetermining PTH SizeFernando RodriguezNo ratings yet

- Determining PTH SizeDocument4 pagesDetermining PTH SizeFernando RodriguezNo ratings yet

- Hentec RPS Selective Presentation 2021 TBDocument36 pagesHentec RPS Selective Presentation 2021 TBFernando RodriguezNo ratings yet

- Failure Analysis of Capacitors and Inductors With ASM Cover CopyrightDocument17 pagesFailure Analysis of Capacitors and Inductors With ASM Cover CopyrightFernando RodriguezNo ratings yet

- Effect of Silver in Common Leadfree Alloyspapereng042309Document14 pagesEffect of Silver in Common Leadfree Alloyspapereng042309Fernando RodriguezNo ratings yet

- SMTA India Chapter SMTA DFM and DFA 2013 NovemberDocument51 pagesSMTA India Chapter SMTA DFM and DFA 2013 NovemberFernando RodriguezNo ratings yet

- Via-In-Pad Design Considerations For Bottom Terminated Components On PCB Assemblies - Printed Circuit Boards (PCB)Document31 pagesVia-In-Pad Design Considerations For Bottom Terminated Components On PCB Assemblies - Printed Circuit Boards (PCB)Fernando RodriguezNo ratings yet

- Improve SMT Assembly Yields Root Cause Analysis IpcDocument17 pagesImprove SMT Assembly Yields Root Cause Analysis IpcFernando RodriguezNo ratings yet

- Partial Discharge - Open ElectricalDocument2 pagesPartial Discharge - Open ElectricalBHALAJI BIRLANo ratings yet

- Brief History About Volley BallDocument1 pageBrief History About Volley BallAmbrad, Merlyn H.No ratings yet

- Pneumatic Pruning Equipment American Arborist Supplies, Tree Care, Climbing EquipmentDocument1 pagePneumatic Pruning Equipment American Arborist Supplies, Tree Care, Climbing EquipmentSalman JoNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Design Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment ICDocument3 pagesDesign Calculations of Thrust Blocks at Lower Indira: L&T Construction Water & Effluent Treatment IClagnajit dasNo ratings yet

- The Nature of Substance - Rudolf Hauschka PDFDocument250 pagesThe Nature of Substance - Rudolf Hauschka PDFBruno Morin100% (5)

- 3.1 Artifact OptimiserDocument120 pages3.1 Artifact Optimiseralex joNo ratings yet

- Bio Sem2 EssayDocument2 pagesBio Sem2 EssayEileen WongNo ratings yet

- Creme Brulee - Printer Friendly PDFDocument1 pageCreme Brulee - Printer Friendly PDFmtlpcguysNo ratings yet

- B Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Document3 pagesB Ed 3 Sem Physics Teaching Group C Science 1 Paper 1 Summer 2018Rrr KkkNo ratings yet

- Physics Formulas and Symbols: Physics I Symbol FormulaDocument5 pagesPhysics Formulas and Symbols: Physics I Symbol Formulakaparthy100% (9)

- HEAT EFFECTS (Cha 4) : Outline of Chapter OneDocument65 pagesHEAT EFFECTS (Cha 4) : Outline of Chapter OneAdam MekonnenNo ratings yet

- Load-Out and Sea-Fastening ProcedureDocument17 pagesLoad-Out and Sea-Fastening ProcedureAdaghara100% (2)

- Textile Internship Report AlokDocument39 pagesTextile Internship Report AlokRahul TelangNo ratings yet

- Kapla ResumeDocument35 pagesKapla ResumeAbinashNo ratings yet

- Textiles and Clothing SustaninabilityDocument134 pagesTextiles and Clothing Sustaninabilitydike100% (1)

- 1992SGSDesignersGuidetoPowerProductsApplicationManual2Ed 1182713547Document1,298 pages1992SGSDesignersGuidetoPowerProductsApplicationManual2Ed 1182713547analog changeNo ratings yet

- New Patient Needing Continuous Renal Replacement Therapy (CRRT)Document9 pagesNew Patient Needing Continuous Renal Replacement Therapy (CRRT)sergey_1972No ratings yet

- Ceph Reference ArchitectureDocument12 pagesCeph Reference ArchitectureGermgmaan100% (1)

- Guillain Barre 3Document6 pagesGuillain Barre 3YON LEANDRO VILLAMIL ROJASNo ratings yet

- Memories of HomeDocument14 pagesMemories of HomeMary Francis Edmer SayconNo ratings yet

- Encapsulation and Inheritance in Object-Orlented Programming LanguagesDocument8 pagesEncapsulation and Inheritance in Object-Orlented Programming Languageszsolt kormanyNo ratings yet

- A Robust Firearm Identification Algorithm ProposalDocument7 pagesA Robust Firearm Identification Algorithm ProposalEuneel EscalaNo ratings yet

- Acute Severe Asthma Hospital ManagementDocument1 pageAcute Severe Asthma Hospital ManagementItharshan IndreswaranNo ratings yet

- Cattlemans Steakhouse MenuDocument1 pageCattlemans Steakhouse Menuapi-300741654No ratings yet

- PMR205 DR Shawn BakerDocument31 pagesPMR205 DR Shawn Bakerspiridon_andrei2011No ratings yet

- OrlDocument186 pagesOrlMuli MaroshiNo ratings yet

- Validation of Correlations Between A NSPT PDFDocument12 pagesValidation of Correlations Between A NSPT PDFAgus WahyudiNo ratings yet

- Shock Classification and PathophysiologyDocument40 pagesShock Classification and PathophysiologyErick Anca100% (2)

- IGCSE Biology 4325 2H Mark SchemeDocument14 pagesIGCSE Biology 4325 2H Mark SchememuhajireenNo ratings yet