100% found this document useful (1 vote)

4K views11 pagesGeneral Instruction Manual: Gas Testing Using Portable Gas Monitors

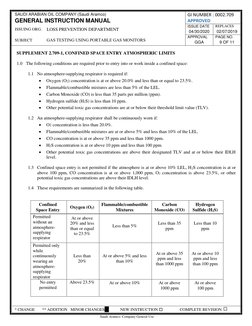

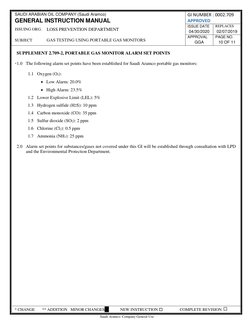

This document provides instructions for gas testing using portable gas monitors at Saudi Aramco facilities. It outlines the purpose, scope, references, definitions, and responsibilities related to gas testing. The purpose is to test for gases like hydrogen sulfide, oxygen concentration, and combustible gases before and during work to ensure safety. Portable gas monitors and their accessories are used to continuously monitor air for combustible gases, toxic substances, and oxygen levels. Calibration and function checks of the monitors must be done according to the equipment manuals and corporate standards.

Uploaded by

khrayzie bhoneCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

4K views11 pagesGeneral Instruction Manual: Gas Testing Using Portable Gas Monitors

This document provides instructions for gas testing using portable gas monitors at Saudi Aramco facilities. It outlines the purpose, scope, references, definitions, and responsibilities related to gas testing. The purpose is to test for gases like hydrogen sulfide, oxygen concentration, and combustible gases before and during work to ensure safety. Portable gas monitors and their accessories are used to continuously monitor air for combustible gases, toxic substances, and oxygen levels. Calibration and function checks of the monitors must be done according to the equipment manuals and corporate standards.

Uploaded by

khrayzie bhoneCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd