Professional Documents

Culture Documents

Project Template 2

Uploaded by

Jamiu LateefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Template 2

Uploaded by

Jamiu LateefCopyright:

Available Formats

CIKITUSI JOURNAL FOR MULTIDISCIPLINARY RESEARCH ISSN NO: 1301-2746

A Comparative Study on Rubber Concrete over

Conventional Concrete

Malathi R1, Vime Gold V2, Divya C3

1

Assistant professor, Department of Civil Engineering, Sri Ramakrishna Institute of Technology, Coimbatore, Tamil Nadu, Email ID:

malub18@gmail.com

2

Student, Department Of Civil Engineering, Sri Ramakrishna Institute of Technology, Coimbatore, Tamil Nadu, Email

ID:goldvime@gmail.com

3

Student, Department Of Civil Engineering, Sri Ramakrishna Institute of Technology, Coimbatore, Tamil Nadu, Email

ID:divimohan2401@gmail.com

ABSTRACT: Waste tyre treatment is now a serious global threat. Waste tyre dumping, disposal of these materials or burning these

tyres cause serious environmental and health problems. One of the solutions suggested is the use of tyre rubber aggregates as additive

in cement based material. Waste tyres are cut into small pellets of size matching the nominal aggregate size and are used to replace the

coarse aggregate used in concrete. For comparative analysis, concrete mix of M30 grade is prepared for various concrete mixes by

varying percentage replacement of mineral coarse aggregates by 0, 5, 10 and 15 rubber aggregates and the mechanical properties of

rubber concrete are compared with that of conventional concrete. The results showed that despite a great loss in strength, this type of

concrete was acceptable for various applications requiring medium to low compressive strength. Hence, this project is selected to

reduce the environmental pollution and wastage of natural resources.

KEY WORDS: Waste tyre rubber aggregate, Mechanical Properties, Mechanical tests, Eco-friendly,concrete

1. INTRODUCTION

Cement and aggregate, which are the most important constituents used in concrete production, are the vital materials needed

for the construction industry. This inevitably led to a continuous and increasing demand of natural materials used for their production.

On the other hand, tyre wastes are increasing annually because of the increase in the vehicle usage now-a-days. These tyres are used

for various purposes. These wastes are shredded to the size of coarse aggregates to partially replace coarse aggregate in concrete.

The public, governments and industry are all greatly interested in green environment and engineering approaches towards

better sustainable development. At the same time, these studies can help to make the environment clean and minimize waste. An

emerging use is the production of concrete, in which rubber tyre particles partially replace natural coarse aggregates. This has the

additional advantage of saving in natural aggregates and to reduce impact of quarrying dust used in the production of concrete which

are becoming increasingly scarce. This experiment investigated a wide range of physical, chemical and mechanical properties of

concrete containing recycled rubber tyre aggregates assess its suitability as a construction material.

Millions of waste tyres are generated and stock piled every year in an uncontrolled manner causing a major environmental

problem. The disposal of tyres in landfills is the major issue handled by local municipalities and government sectors. As tyres are non-

biodegradable, they remain in dump sites with little degradation overtime, presenting a continuing environmental hazard. Dumping or

disposal of these materials causes environmental and health problems. Waste tyre management is a serious global concern. Therefore

recycling of Waste materials plays a vital role in concrete. One of the solutions suggested is the use of waste rubber as partial

replacement of coarse aggregates in concrete which has become highly expensive and also scarce. The utilization of waste tyres has

been focused on waste minimization and for environmental management.

Federal regulations classify waste tyres as non-hazardous waste. However, the stockpiles are depleting land resources, and

they are vulnerable to fire. The combustion of tyres releases volatile gases, heavy metals, oil, and other hazardous compounds. In

addition, the stockpiles disposal provides breeding grounds for rats, mosquitoes, and other vermin. Some innovative solutions have

been developed to meet the challenge of waste tyre stockpiling problem.

Volome 7, Issue 4, 2018 28 http://adalyajournal.com/

CIKITUSI JOURNAL FOR MULTIDISCIPLINARY RESEARCH ISSN NO: 1301-2746

Whole tires could be used as tyre bales for highway embankments and retaining wall construction. Granulated rubber could

be incorporated to asphalt binders for asphalt pavement. It has been successful to incorporate waste tyres in asphalt pavement. Also it

is estimated that more than 1.2 billion waste tyre are produced globally every year. This waste being non-biodegradable poses severe

fire, environmental and health risks. Aside from tyre derived fuel, the most promising use of recycled tyres is in engineering

applications such as artificial reefs, erosion control and aggregates for asphalt and concrete.

For partially replace the coarse aggregate with the waste rubber tyre at different percentages in concrete and to determine its

Compressive strength, Split-tensile strength and Flexural strength and to study the properties of concrete by casting cubes, cylinders

and beams and to compare the strength of rubber concrete with the conventional concrete.

2. LITERATURE REVIEW

[1]

B.Damodhara Reddy, S.Aruna Jyothy, P.Ramesh Babu have performed the study to evaluate the properties of concrete when

recycled rubber from automotive tyres were used as a partial coarse aggregate. The percentages of rubber replacement were 10%, 15%

by weight of coarse aggregate and tests were performed for all replacement levels of junk rubber aggregate. The replacement of coarse

aggregate by junk rubber in concrete was found to result in reduced compressive strength and density. It was also found that the

reduction in compressive strength depended on the amount of rubber added.

[2]

C.Eldhose, Dr.T.G.Soosan investigated the wide range of physical and mechanical properties of concrete containing waste tyre

aggregates and assessed its suitability as a construction material. The waste tyre aggregates were added as 2%, 4%, 6%, 10% and 12%

to replace the fine aggregate in M35 mix and investigated the optimal use of waste tyre aggregate as fine aggregate in concrete

composite. Test results showed that upto 8% of rubber aggregate can be added to concrete for structural constructions mainly for rigid

pavement construction which proves economical and eco-friendly.

[3]

K.Nithya, R.Kalpana performed a comparative study on early age concrete with waste rubber aggregate and the conventional

concrete. The percentage of replacement of coarse aggregate was 0%, 10% and 12% and the curing was done with acids like HCl and

HS2O4. Compressive strength, Split-tensile strength and Flexural strength for specimens with normal curing and acid curing were

compared. The test results showed that acid curing and percentage increase of rubber aggregate the compressive strength. However the

rubber concrete reduces the environmental pollution and wastage of natural resources. Despite the loss in strength, this type of

concrete was acceptable for various applications requiring medium to low compressive strength.

[4]

Tomas U.Ganiron concluded that adding cut rubber tyre pellets in concrete mixes significantly reduce the amount of standard coarse

aggregates used in concrete which results in more economical and cost efficient project in the future. Further this study aids in the

disposal of excess and/or “discarded” transportation vehicle rubber tyres in the environment and help ensure that the construction era

of the future will be an environmentally friendly one. Also stated that, the lesser unit weight of the pelletized rubber being added to the

concrete mix replacing some volume of gravel reduce the weight of the concrete mix. Reduction is at least within the range of 10% -

20% by weight more or less.

[5]

K.Rajendra Prabhu, Subhash C Yaragal and Katta Venkataramana searched for alternative materials, which can replace existing

ingredients in cement concrete construction partially or fully, thereby reducing energy consumption and reduced CO2 emission. One

of the materials suggested was Waste Tyre Rubber. They concluded the following as advantages of rubberized concrete. Firstly due to

less unit weight with high air entrainment, these type of concrete are easily pumped at higher flow rates and provide improved levels

of thermal or acoustic insulation and they also improve the insulation of floorings in buildings. Secondly, rubberized concrete provide

significantly improved loading behavior and vibration or impact absorption characteristics and also increased toughness, impact

resistance and ductility. Also it provides an attractive solution for shrinkage cracking and strain failure.

[6]

Kotresh K.M, Mesfin Getahun Belachew identified the potential application of waste tyre rubber in civil engineering projects by

casting specimens of M25 grade with 10, 20 and 30 percent of rubber aggregate replacing coarse aggregate and compared the

mechanical properties with the regular M20 grade concrete. Also the unit weight of rubcrete were determined at 0%, 5%, 10% and

15% of rubber aggregates. Finally they concluded that rubcrete is best suitated for roof top surfaces in buildings for insulation and

waterproofing purposes.

[7]

M.Mavroulidou, J.Figueiredo performed slump test to determine the workability of rubber concrete with 0, 10, 20, 30 and 40

percent of tyre rubber aggregate both fine and coarse rubber aggregate. They also made an experimental study to compare the

variations in mechanical properties of 7th and 28th day rubber concrete with fine rubber aggregate and rubber concrete with coarse

rubber aggregate. Finally they concluded that both cube compressive strength and Split Tensile strength of concrete with coarse rubber

aggregate was higher than that with fine rubber aggregate. But the flexural strength test results showed that the strength of rubber

concrete with fine rubber aggregate was higher than that with coarse rubber aggregate.

Volome 7, Issue 4, 2018 29 http://adalyajournal.com/

CIKITUSI JOURNAL FOR MULTIDISCIPLINARY RESEARCH ISSN NO: 1301-2746

[8]

S.M.Dumne carried out the study using tests such as slump, unit weight and compressive strength on different concrete mixes in

order to determine properties of concrete mix. For comparative analysis, concrete mix of M20 grade was prepared for various concrete

mixes by varying percentage replacement of mineral coarse aggregates by 0, 5, 10 and 15 rubber aggregates. The test results showed

that rubberized concrete gave lesser unit weight in addition to the reduction in workability. It was also observed that there was a

reduction in compressive strength of rubberized concrete which restrict its structural applications but it preserves some desirable

characteristics. Overall, results of experimental test reflected that it is possible to use discarded rubber tyre aggregates in concrete as a

partial replacement to mineral coarse aggregates but percentage replacement should be limited in order to restrict its application.

3. METHODOLOGY

3.1 Cement

Cement is one of the most common building materials and plays an important role in the construction field. The cement used is OPC

53(DALMIA). The Ordinary Portland Cement of 53 grade confirming to IS 8112/1989 has been used.

3.2 Fine Aggregate

The sand used for the experimental procedure was locally procured and confirmed to grading zone II as per IS: 383-1970. Fine

aggregates passing through 2.36mm sieve is used. Tests were conducted on fine aggregate like specific gravity and fineness modulus.

3.3 Coarse Aggregate

The coarse aggregate is the strongest and least porous component of concrete. Coarse aggregate in cement concrete contributes to the

heterogeneity of the concrete and there is weak interface between cement matrix and aggregate surface in cement concrete. This

results in lower strength of concrete by restricting maximum size of the aggregate and also by making the transition zones stronger.

Coarse aggregate of size 20mm is used. Tests were conducted on coarse aggregate like specific gravity and bulk density.

3.4 Rubber Aggregate

In this study, source of rubber aggregates is the discarded truck tyre which is collected from the local market and rubber tyre

aggregates are prepared manually.

3.1 WASTE TYRE RUBBER AGGREGATE

In general, discarded tyre rubber aggregates are available in the range of grading from 0.5 mm to 30 mm. The rubber aggregates used

in the present study are prepared manually by cutting the tyre to maximum nominal size equal to 20 mm and kept for air drying after

cleaning with potable water.

Volome 7, Issue 4, 2018 30 http://adalyajournal.com/

CIKITUSI JOURNAL FOR MULTIDISCIPLINARY RESEARCH ISSN NO: 1301-2746

Parameter Values

Specific gravity 1.06–1.1

Specific heat 0.28–0.85 al/gr/ºC

Molecular weight 3×105-1×105

Hydraulic conductivity 0.2-0.85 cm/s

Thermal expansion 5.9-7.9×10-4/ºC

Thermal conductivity 0.330-0.515×10-3 g-

cal/s/cm/ºC

Dynamic viscosity 500-250000 mpa

Ductility 80-158 mm

Flammability 582ºF

Thermal insulation 0.0838-0.147 cal/m-hr-

ºC

Moisture absorption 2-4%

Stability temperature 200ºC

Heat temperature 150-316ºC

Density 7.5 lbs/cu.foot

TABLE NO. 3.1 PHYSICAL PROPERTIES OF WASTE RUBBER TYRES

Parameter Values

Angle of friction 15-32º

Cohesion 349-394 N/m2

Total organic carbon 22.7-3.1 ppm

Turbidity 254-99 NTU

Gradation 50-300 mm

Dynamic viscosity 500-250000 mpa

Ductility 80-158 mm

Flammability 582ºF

Thermal insulation 0.0838-0.147 cal/m-hr-

ºC

Moisture absorption 2-4%

Softening point 38-125 C

Breaking point 12-30ºC

Penetration 15-2500.1 mm

Chemical degradation 100-300ºC

Mechano-chemical disper 100-200ºC

TABLE NO. 3.2 CHEMICAL PROPERTIES OF WASTE RUBBER TYRES

Samples Percentage of rubber aggregate

added

1 0%

2 5%

3 10%

4 15%

TABLE NO. 3.3 PERCENTAGE MIX RATIO OF WASTE RUBBER TYRE AGGREGATE

S.No Properties Values

1 Specific Gravity 2.87

2 Fineness Modulus 3.485

TABLE NO. 3.4 PHYSICAL PROPERTIES OF FINE AGGREGATES

S.No Properties Values

1 Water absorption of 0.673%

aggregate

TABLE NO. 3.4 PHYSICAL PROPERTIES OF COARSE AGGREGATES

Volome 7, Issue 4, 2018 31 http://adalyajournal.com/

CIKITUSI JOURNAL FOR MULTIDISCIPLINARY RESEARCH ISSN NO: 1301-2746

Water Cement Fine aggregate Coarse

(kg) (kg) aggregate

(kg)

197.16 394.32 759.36 1151.24

0.5 1 1.93 2.92

TABLE NO. 3.5 MIX PROPORTION OF M30 GRADE

4. RESULT AND DISCUSSION

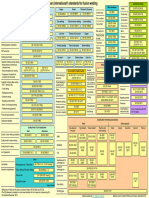

Initially standard specimens of conventional concrete M30 grade were cast. The specimens include cubes(150×150×150mm), cylinders

(150mm dia., 300mm height) and prisms(500×100×100mm). They were cured for different periods (3, 7, 14 and 28 days).

Rubber concrete specimens were prepared by adding 5%, 10% and 15% as increment of rubber aggregates replacing coarse

aggregates in concrete and were cured for same curing period to make a comparative study. Then the mechanical tests were conducted

on the specimens and the results were plotted in the form of a bar chart as shown in figure.

COMPRESSIVE STRENGTH

TEST ON CUBES

40

Compressive Strength (N/mm2)

35

30

25

20 0%

15 5%

10

10%

5

0 15%

3 days 7 days 14 28

days days

Curing period (days)

4.1 COMPRESSIVE STRENGTH TEST ON CUBES

SPLIT TENSILE STRENGTH

TEST ON CYLINDERS

5

Split-tensile Strength (N/mm 2 )

4

3 0%

2 5%

1 10%

0

15%

3 days 7 days 14 28

days days

Curing period (days)

4.2 SPLIT TENSILE STRENGTH TEST ON CYLINDERS

Volome 7, Issue 4, 2018 32 http://adalyajournal.com/

CIKITUSI JOURNAL FOR MULTIDISCIPLINARY RESEARCH ISSN NO: 1301-2746

FLEXURAL STRENGTH TEST ON

CYLINDERS

5

Flexural Strength (N/mm 2)

4

3 0%

2 5%

1 10%

0 15%

3 days 7 days 14 days 28 days

Curing period (days)

4.3 FLEXURAL STRENGTH TEST ON BEAMS

5. CONCLUSION

From the study we concluded that the compressive strength of specimen with tyre rubber aggregate at the end of 7th, 14th and 28th day

reduced by about 10, 20 and 30 percent for every 5% increment of tyre rubber aggregates respectively.

The Split Tensile strength of specimen with tyre rubber aggregate at the end of 7th,14th and 28th day reduced by about 8% for

every 5% increment of tyre rubber aggregates respectively. The flexural strength of the specimen at the end of 7th, 14th and 28th day

reduced by about 6% for every 5% increment of tyre rubber aggregates respectively. Despite the decrease in the mechanical strength

of the specimens this type of rubber concrete is greatly employed in low to medium strength concrete applications which include

pavement construction, false facades, stone baking, trench filling and roof top surfaces. Hence it is suitable especially for architectural

and secondary structural elements.

Finally the rubberized concrete not only reduces the cost and environmental impacts of concrete, but also it eliminates the

waste tyre stockpiles and its potential threats to the environment. Hence this study helps in improved environmental protection and

reduction in wastage of the natural resources

REFERENCES

[1]. B.Damodhara Reddy, S.Aruna Jyothy, P.Ramesh Babu (2013), Experimental Investigation on Concrete by Partially Replacement of Ware Aggregate with Junk

Rubber‟, International Journal Of Engineering And Science, Vol.2, pp.61-65.

[2]. Eldhose C., Dr. Soosan T. G. (2014), Studies on Scrap Tyre Added Concrete for Rigid Pavements, International Journal of Engineering Research, Vol.3, pp.777-

779.

[3]. K.Nithya, R.Kalpana (2014), Material Investigation Of Partial Replacement Of Coarse Aggregate By Rubber Tyre, International Journal of Science and

Engineering Research, Vol.2.

[4]. Tomas U.Ganiron (2014), Pelletized Cut Rubber: An Alternative Coarse Aggregate for Concrete Mixture, International Journal of Advanced Science and

Technology, Vol.64, pp.21-30.

[5]. K.Rajendra Prabhu, Subhash C Yaragal and Katta Venkataramana (2013), In Persuit Of Alternative Ingredients To Cement Concrete Construction,

International Journal of Research in Engineering and Technology, Vol.2, pp.404-410.

[6]. Kotresh K.M, Mesfin Getahun Belachew (2014), Study On Waste Tyre Rubber As Concrete Aggregate, International Journal of Scientific Engineering and

Technology, Vol.3, pp.433-436.

[7]. M.Mavroulidou, J.Figueiredo (2010), Dicarded Tyre Rubber As Concrete Aggregate: A Possible Outlet For Used Tyres, Global NEST Journal (Vol.12), pp.359-

367.

[8]. S.M.Dumne (2013), An Experimental Study on Performance of Recycled Tyre Rubber-Filled Concrete‟, International Journal of Engineering Research and

Technology (Vol.2), pp.766-

Volome 7, Issue 4, 2018 33 http://adalyajournal.com/

You might also like

- New PPT 1 Rubber WasteDocument16 pagesNew PPT 1 Rubber WasteStark Azim67% (6)

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Kublaikhan: Enterprise LTDDocument1 pageKublaikhan: Enterprise LTDeddyrasmadiNo ratings yet

- Department of Civil Engineering, SNP College, RamanagaraDocument26 pagesDepartment of Civil Engineering, SNP College, RamanagaraChaithra ShreeNo ratings yet

- Use of Waste Tyre Rubber in A Partial Replacement of Aggregate in ConcreteDocument54 pagesUse of Waste Tyre Rubber in A Partial Replacement of Aggregate in ConcreteDurgesh PardeshiNo ratings yet

- Eng 2341472 Peer Review v2Document14 pagesEng 2341472 Peer Review v2Vander AlkminNo ratings yet

- Strength of Concrete by Replacement of Coarse Aggregates With Waste Rubber and Demolished Waste MaterialsDocument10 pagesStrength of Concrete by Replacement of Coarse Aggregates With Waste Rubber and Demolished Waste MaterialsInder KumarNo ratings yet

- 2023 V14i260Document11 pages2023 V14i260D. AnweshNo ratings yet

- Jsjsjs PDFDocument17 pagesJsjsjs PDFKlisman A. Flores DurandNo ratings yet

- Akshay Final 2Document43 pagesAkshay Final 2Durgesh PardeshiNo ratings yet

- To Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao DeshmukhDocument11 pagesTo Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao Deshmukhmukesh poundekarNo ratings yet

- Concrete Project ReportDocument16 pagesConcrete Project ReportMayur Madhukar Mankar100% (1)

- Literature Review On Concrete Containing Crumb Rubber - Bharuch2k15c0107 - (Pg. 22-24)Document3 pagesLiterature Review On Concrete Containing Crumb Rubber - Bharuch2k15c0107 - (Pg. 22-24)Er Devraj Khandelwal67% (3)

- Experimental Investigation of The Performance of Rubberized Concrete Mixtures Without AdditivesDocument15 pagesExperimental Investigation of The Performance of Rubberized Concrete Mixtures Without AdditivesIAEME PublicationNo ratings yet

- Ijciet 09 12 073Document12 pagesIjciet 09 12 073Nandkumar GowdaNo ratings yet

- A Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumDocument2 pagesA Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumNipuna WanninayakeNo ratings yet

- Use of Waste Rubber Tyres in Construction of Bituminous Road - An OverviewDocument3 pagesUse of Waste Rubber Tyres in Construction of Bituminous Road - An OverviewInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Experimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesDocument5 pagesExperimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniumDocument2 pagesA Study On Crumb Rubber: Opportunities For Development of Sustainable Concrete in The New MillenniummurkyNo ratings yet

- Tyre For ConcreteDocument4 pagesTyre For ConcreteNoble Obeng-AnkamahNo ratings yet

- WTR Crumb RubberDocument15 pagesWTR Crumb RubberMark BitoonNo ratings yet

- TSP JRM 22846Document32 pagesTSP JRM 22846karima GadriNo ratings yet

- J Conbuildmat 2017 02 107Document7 pagesJ Conbuildmat 2017 02 107Jerson SotoNo ratings yet

- Journal Printabs 4haug14esrDocument11 pagesJournal Printabs 4haug14esrBruno CarleteNo ratings yet

- Utilization of Rubber Waste in Flexible Pavement ConstructionDocument8 pagesUtilization of Rubber Waste in Flexible Pavement Constructionathirah mfNo ratings yet

- Partial Replacement of Coarse AggregateDocument8 pagesPartial Replacement of Coarse AggregateNgala KennethNo ratings yet

- Chapter 1 (Revised Objectives) - 1Document9 pagesChapter 1 (Revised Objectives) - 1Adriel PerezNo ratings yet

- Case Studies in Construction Materials: Najib N. Gerges, Camille A. Issa, Samer A. FawazDocument16 pagesCase Studies in Construction Materials: Najib N. Gerges, Camille A. Issa, Samer A. FawazAkshaykumar IngleNo ratings yet

- Mohamed Elfatih - TechnicalDocument11 pagesMohamed Elfatih - Technical6qwhnq9z4h100% (1)

- PROJECTDocument24 pagesPROJECTMr Kalyan100% (1)

- Using Recycled Waste Tyre in Concrete Paving BlocksDocument14 pagesUsing Recycled Waste Tyre in Concrete Paving BlocksTung-Chai LingNo ratings yet

- Study On Crumb Rubber Concrete Using Ggbs & Nano-Tio: Shreyas L. BedagkarDocument7 pagesStudy On Crumb Rubber Concrete Using Ggbs & Nano-Tio: Shreyas L. BedagkarAniruddha DalviNo ratings yet

- Project Proposal: Study On Waste Tyre Rubber As Concrete AggregatesDocument7 pagesProject Proposal: Study On Waste Tyre Rubber As Concrete AggregatesshuhaibNo ratings yet

- Partial Replacement of Rubberized Material As Coarse Aggregate in ConcreteDocument6 pagesPartial Replacement of Rubberized Material As Coarse Aggregate in ConcreteD. AnweshNo ratings yet

- Resistance To Acid Attack of Cement Concrete Containing Discarded Tire RubberDocument11 pagesResistance To Acid Attack of Cement Concrete Containing Discarded Tire RubberSanil JNo ratings yet

- Utilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesDocument8 pagesUtilization of Scrap Tyre Rubber in The Form of Aggregates As Partial Exchange With Existing AggregatesEditor IJTSRDNo ratings yet

- Propiedades Mecanicas y Ecuaciones Constitutivas de Concreto Que Contiene Un Bajo Volumen de Particulas de NeumaticoDocument18 pagesPropiedades Mecanicas y Ecuaciones Constitutivas de Concreto Que Contiene Un Bajo Volumen de Particulas de NeumaticoraspaflowNo ratings yet

- Editorirjmt, IRJMT 68 Paper EditDocument6 pagesEditorirjmt, IRJMT 68 Paper EditgunaNo ratings yet

- Mechanical Properties of M 25 Grade Concrete With Partially Replacement of Waste Rubber As Coarse AggregateDocument6 pagesMechanical Properties of M 25 Grade Concrete With Partially Replacement of Waste Rubber As Coarse AggregateJamiu LateefNo ratings yet

- Experimental Investigation On Concrete by Partially Replacement of Ware Aggregate With Junk RubberDocument5 pagesExperimental Investigation On Concrete by Partially Replacement of Ware Aggregate With Junk RubbertheijesNo ratings yet

- Effect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesDocument9 pagesEffect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesMaridil IsidroNo ratings yet

- Construction and Building Materials: Aly Muhammed Aly, M.S. El-Feky, Mohamed Kohail, El-Sayed A.R. NasrDocument9 pagesConstruction and Building Materials: Aly Muhammed Aly, M.S. El-Feky, Mohamed Kohail, El-Sayed A.R. NasrYeluri Sesha ChoudaryNo ratings yet

- Utilization of Recycled Crumb Rubber As Ne Aggregates in Concrete Mix DesignDocument6 pagesUtilization of Recycled Crumb Rubber As Ne Aggregates in Concrete Mix DesignGuzalgNo ratings yet

- CT AssignmentDocument1 pageCT AssignmentU ABHAY SHENOY CVE20BNo ratings yet

- Rice - Husk - Abhishek (1) .Docx 21Document29 pagesRice - Husk - Abhishek (1) .Docx 21Abhi ShekNo ratings yet

- Jaswanth Document OrgDocument54 pagesJaswanth Document OrgNaga KiranNo ratings yet

- Theuseof Ceramic Tileswastein Concreteas Partial Replacementof Fine AggregatesDocument10 pagesTheuseof Ceramic Tileswastein Concreteas Partial Replacementof Fine AggregatesSHARAN PATILNo ratings yet

- Chapter 2 - Conceptual Framework Review of Related Literature and StudiesDocument8 pagesChapter 2 - Conceptual Framework Review of Related Literature and StudiesraifelNo ratings yet

- Experimental Study On Comparison of Conventional Concrete With Waste Rubber Tyre ConcreteDocument17 pagesExperimental Study On Comparison of Conventional Concrete With Waste Rubber Tyre ConcreteMr KalyanNo ratings yet

- Study of Structural Performance and Durability of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Document5 pagesStudy of Structural Performance and Durability of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Innovative Research PublicationsNo ratings yet

- Irjet V5i1240Document8 pagesIrjet V5i1240Aman raj singhNo ratings yet

- Experimental Study On The Partial Replacement of The Cement With Waste Marble Dust and Fine Aggregate With CRT WasteDocument9 pagesExperimental Study On The Partial Replacement of The Cement With Waste Marble Dust and Fine Aggregate With CRT WasteIJRASETPublicationsNo ratings yet

- Wearing Surface Technology Individual Project: Recycling Plastic Into Hotmix AsphaltDocument10 pagesWearing Surface Technology Individual Project: Recycling Plastic Into Hotmix AsphaltOpaqueNo ratings yet

- Performance of High Strength Concrete Containing Recycled RubberDocument10 pagesPerformance of High Strength Concrete Containing Recycled RubberFIRDHOUZ MOHAMED RNo ratings yet

- Thesis ProposalDocument7 pagesThesis ProposalMEHIDE HASANNo ratings yet

- 145-P4-s2.0-S0141029618327810-mainDocument17 pages145-P4-s2.0-S0141029618327810-mainfikrampanawaNo ratings yet

- Fatigue Performance of Waste Rubber Concrete for Rigid Road PavementsDocument10 pagesFatigue Performance of Waste Rubber Concrete for Rigid Road PavementsPin LopezNo ratings yet

- A Study of Adding Recycled Rubber Tire As Substitute Aggregate On Gravel RevisionDocument12 pagesA Study of Adding Recycled Rubber Tire As Substitute Aggregate On Gravel RevisionJo Crisley T. PasayanNo ratings yet

- (2020) Beycioğlu, A.Document15 pages(2020) Beycioğlu, A.Ilyas H. AliNo ratings yet

- Template Notice of Delay Letter Wmb7ufDocument2 pagesTemplate Notice of Delay Letter Wmb7ufJamiu Lateef100% (1)

- ARIPO Young Professionals Programme 2023Document2 pagesARIPO Young Professionals Programme 2023Jamiu LateefNo ratings yet

- BOQSwimming Pool Phase 2Document51 pagesBOQSwimming Pool Phase 2Jamiu LateefNo ratings yet

- Site Inspection Report 1az7hyDocument47 pagesSite Inspection Report 1az7hyJamiu Lateef0% (1)

- PAYGB Quotation Sample 2019Document53 pagesPAYGB Quotation Sample 2019Jamiu LateefNo ratings yet

- Schooling Without Learning TemplateDocument8 pagesSchooling Without Learning TemplateJamiu LateefNo ratings yet

- Scofield Stamped SpecDocument7 pagesScofield Stamped SpecJamiu LateefNo ratings yet

- CGD Report Highlights Learning Crisis in EducationDocument40 pagesCGD Report Highlights Learning Crisis in EducationJamiu LateefNo ratings yet

- Consequence of Schooling Without LearningDocument1 pageConsequence of Schooling Without LearningJamiu LateefNo ratings yet

- Foundation Design Course OverviewDocument4 pagesFoundation Design Course OverviewJamiu LateefNo ratings yet

- HRC Highlink Estate BemeDocument1 pageHRC Highlink Estate BemeJamiu LateefNo ratings yet

- An Integrated Planning Concept For The Emerging Underground Urbanism: Deep City Method Part 1 Concept, Process and ApplicationDocument16 pagesAn Integrated Planning Concept For The Emerging Underground Urbanism: Deep City Method Part 1 Concept, Process and ApplicationJamiu LateefNo ratings yet

- Performance and Evaluation of Rubber As Concrete MaterialDocument7 pagesPerformance and Evaluation of Rubber As Concrete MaterialAnonymous CUPykm6DZNo ratings yet

- AStamped Concrete Rev 71210 PDFDocument4 pagesAStamped Concrete Rev 71210 PDFJamiu LateefNo ratings yet

- Mechanical Properties of M 25 Grade Concrete With Partially Replacement of Waste Rubber As Coarse AggregateDocument6 pagesMechanical Properties of M 25 Grade Concrete With Partially Replacement of Waste Rubber As Coarse AggregateJamiu LateefNo ratings yet

- Research Methodology ProjectsDocument7 pagesResearch Methodology ProjectsJamiu Lateef100% (1)

- Project TemplateDocument83 pagesProject TemplateJamiu LateefNo ratings yet

- List of Courses - 1ST & 2ND SemesterDocument1 pageList of Courses - 1ST & 2ND SemesterJamiu LateefNo ratings yet

- En Art02Document21 pagesEn Art02Md Kaiser HamidNo ratings yet

- Impacts of Construction Activities On The Environment: The Case of GhanaDocument10 pagesImpacts of Construction Activities On The Environment: The Case of GhanaMd Kaiser HamidNo ratings yet

- Cec 405 - Advanced Reinforced & Prestressed Concrete DesignDocument3 pagesCec 405 - Advanced Reinforced & Prestressed Concrete DesignJamiu Lateef50% (2)

- Crumb Rubber ConcreteDocument6 pagesCrumb Rubber ConcreteJamiu LateefNo ratings yet

- CONSOLIDATION TestDocument6 pagesCONSOLIDATION TestJamiu LateefNo ratings yet

- ICI Site Visit B.G.Shirke Taloja Plant Mumbai - 24.03.18 PDFDocument8 pagesICI Site Visit B.G.Shirke Taloja Plant Mumbai - 24.03.18 PDFKiran KumarNo ratings yet

- Construction Cost Estimating Guide For Civil WorksDocument183 pagesConstruction Cost Estimating Guide For Civil WorksJake Jacobs89% (9)

- Cleaner Engineering and Technology: Mohammed B. Al RayaanDocument6 pagesCleaner Engineering and Technology: Mohammed B. Al Rayaanchemist.msalehNo ratings yet

- Open Rack Vaporizer Mass and Energy BalanceDocument12 pagesOpen Rack Vaporizer Mass and Energy BalanceMuhammad Nanda100% (1)

- Lecture 13 - MetamaterialsDocument31 pagesLecture 13 - MetamaterialsAaa MmmNo ratings yet

- Treating Sullage Water Using Natural and Chemical CoagulantsDocument5 pagesTreating Sullage Water Using Natural and Chemical CoagulantsMuhammad Ramadhan SaputraNo ratings yet

- D4373 Contenido Carbonato en SueloDocument5 pagesD4373 Contenido Carbonato en SueloDaniela Bernal100% (1)

- STERIS - 6 Hydrogen Peroxide WFI Sterile Solution - TDS - 420 100 0202ADocument2 pagesSTERIS - 6 Hydrogen Peroxide WFI Sterile Solution - TDS - 420 100 0202AJoffrey AntonNo ratings yet

- Calculating A PH Slope Percentage Hanna Instruments PDFDocument2 pagesCalculating A PH Slope Percentage Hanna Instruments PDFamerican_guy10No ratings yet

- Determining The Inclusion Content of Steel: Standard Test Methods ForDocument19 pagesDetermining The Inclusion Content of Steel: Standard Test Methods ForMarconi CosmeNo ratings yet

- Handbook of Sic Properties For Fuel Performance ModelingDocument49 pagesHandbook of Sic Properties For Fuel Performance ModelingAbhiraj MeenaNo ratings yet

- Alucobond ContemporaryColorChart Jan 2016 PDFDocument2 pagesAlucobond ContemporaryColorChart Jan 2016 PDFcathes231No ratings yet

- Q4 Science 7 - Module 3Document18 pagesQ4 Science 7 - Module 3Maria Conxedes GudesNo ratings yet

- Chapter 1: Boilers and ComponentsDocument12 pagesChapter 1: Boilers and ComponentseugeneNo ratings yet

- FerrousDocument538 pagesFerrousPutoy Itoy100% (1)

- ANT Stabilizer 28-04-2022Document8 pagesANT Stabilizer 28-04-2022Manoj AhirwarNo ratings yet

- Calflo Heat Transfer FluidDocument4 pagesCalflo Heat Transfer FluidderekfisherNo ratings yet

- Unit 2 Solutions Key ConceptsDocument32 pagesUnit 2 Solutions Key ConceptsChitrasen WangNo ratings yet

- WELDING Book AWSD1.1 Rev-3ADocument35 pagesWELDING Book AWSD1.1 Rev-3AFerdie OS100% (1)

- SDS R1234zeDocument15 pagesSDS R1234zeRafaelDutraNo ratings yet

- Meq431 NotesDocument578 pagesMeq431 NotesAlif SyafiqNo ratings yet

- 122Document10 pages122Bayangan HatiNo ratings yet

- Comfort Air PDFDocument79 pagesComfort Air PDFSunny OoiNo ratings yet

- Fabrication and Welding Manual SectionsDocument4 pagesFabrication and Welding Manual SectionsSudhir DwivediNo ratings yet

- Euronorme SuduraDocument1 pageEuronorme SuduragulieionutNo ratings yet

- DDS Duct Deluge System For The Protection of Ventilation Ductwork Handling Corrosive Gases General DescriptionDocument6 pagesDDS Duct Deluge System For The Protection of Ventilation Ductwork Handling Corrosive Gases General DescriptionhungNo ratings yet

- Engineering Materials MCQs PDFDocument41 pagesEngineering Materials MCQs PDFRamesh KondriNo ratings yet

- Intro To Viscosity PDFDocument2 pagesIntro To Viscosity PDFTunji AminuNo ratings yet

- Crossword Puzzle MatterDocument1 pageCrossword Puzzle MatterRajat AnandNo ratings yet

- A Modified Two-Step Sequential Spin-Coating Method For Perovskite Solar Cells Using CsI Containing Organic Salts in Mixed Ethanol Methanol SolventDocument7 pagesA Modified Two-Step Sequential Spin-Coating Method For Perovskite Solar Cells Using CsI Containing Organic Salts in Mixed Ethanol Methanol Solvent北科大-洪珮倫No ratings yet

- Enzyme Catalysis RatesDocument12 pagesEnzyme Catalysis RatesSiddharth KumraNo ratings yet