Professional Documents

Culture Documents

Provide The Steps Required To Perform This Procedure.: 7. Step-By-Step Operating Procedure

Uploaded by

azini amizaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Provide The Steps Required To Perform This Procedure.: 7. Step-By-Step Operating Procedure

Uploaded by

azini amizaCopyright:

Available Formats

Rotary Evaporation (Rotovap) SOP

7. Step-by-step Operating Procedure

Provide the steps required to perform this procedure.

For a process: Write enough detailed description of the procedure to guide the user through the process

including details of startup, normal condition operation, temporary operation condition and emergency

shut-down, etc.

Also cover enough information as following:

1. Chemical concentrations, gas amount

2. Pressure limits, temperature ranges

3. Flow rates

4. Special safety equipment is to be utilized.

5. Schematics or pictures for complex setups.

6. Highlight safety precautions put in place

7. What to do when an upset condition occurs

8. What alarms and instruments are pertinent if an upset condition occurs

9. If lockout/tagout is required

Some tips:

Use numbers for steps and sub-steps that have to be performed in a specific sequence

Use bullets for steps or items that can be performed in any order.

Solicit ideas for other users.

Include a flow diagram to help interpret more complex procedures.

Include pictures and label different components.

For Equipment: Describe the step-by-step procedure for using the equipment properly. Include details

for potential equipment failure if something is done improperly in the procedure. Describe how to power

down the equipment at the end of use.

A basic procedure is supplied for you below, make sure to include a procedure for your specific

instrument and process.

BASIC OPERATING PROCEDURE

1. Read the SDS for all materials

2. Inspect the rotovap and all pieces of glassware to ensure that there are

no cracks, chips, or defects.

3. Make sure that the solvent trap and bump trap are empty and clean

4. Fill the hot water bath with DI water if not already filled.

5. Fill the cold trap (e.g., dry ice/acetone)

6. Cool the receiving flask

a. It is a good idea to cool the receiving flask (e.x. solvent reservoir);

it prevents any solvent from evaporating from the receiving flask,

especially for low boiling solvents (e.g. pentane).

7. Connect the bump trap to the rotovap and secure with the metal clip or a keck

clip depending on the model of rotovap (pictured below). The bump trap

should be kept clean, it provides a receptacle in case the solution splashes or

Rotary Evaporation SOP 7 Revised: Dec 2019 MTD

Rotary Evaporation (Rotovap) SOP

boils beyond the flask. A clean bump trap can allow for recovery of any solution that “bumps”.

8. Pre-weight a round bottom flask; fill it less than halfway with the solution to be evaporated.

9. Connect the round bottom flask containing the solvent to the bump trap and secure with a

Keck clip.

10. Turn on the vacuum. You should hear a hissing sound if the stopcock on the evaporator is

not closed. Slowly close the stopcock on the evaporator, once closed the sound should stop.

11. Begin rotating the flask. Ensure that the solution does not foam or boil too much.

12. Wait until the rotation and apparatus equilibrate to proper reduced pressure and speed.

Keep a watchful eye on the evaporation (boiling) of the solvent (vent or change speed as

needed).

13. Allow the solution to evaporate. The solvent should collect in the solvent reservoir.

14. Once the flask changes in temperature and becomes cool to the touch, lower the mechanism

into the water bath or lift the water bath to the evaporation flask (depending on the rotovap

you are using). Make sure that the solvent level is equal to the water bath level. Never put

the flask so low that the Keck clip touches the water.

Rotary Evaporation SOP 8 Revised: Dec 2019 MTD

Rotary Evaporation (Rotovap) SOP

15. If needed you should start to heat the water bath. [Keep in mind that the sample is under

vacuum, this will lower the boiling point]

a. Never have the water bath temperature higher than the boiling point of the solvent

16. Keep a watchful eye on the evaporation of the solvent.

a. If the sample is boiling too vigorously, remove it from the water bath, decrease the

temperature, or change the rotation speed.

17. Allow the solution to evaporate until the product has been isolated or until the desired

amount of volatiles have been removed.

a. When the sample appears to be completely done evaporating allow the flask to

remain at reduced pressure, while heating, and rotating for at least a few minutes to

ensure that all of the volatiles are removed.

18. Once the evaporation is complete conduct the same steps in the reverse order:

turn off the hot water bath, remove the flask from the water, stop the rotation,

turn off the vacuum, slowly open the stopcock to vent the system (remove

residual vacuum) while holding the flask (to avoid it falling and breaking), and

remove the flask.

19. Make sure to empty the solvent reservoir into the appropriate waste container and clean the

bump trap. Remove the water from the hot water bath when finished using the rotovap, this

will prevent it from evaporating and leaving behind a residue.

Emergency procedure (if safe to do so)

1. Turn off the vacuum. Vent to remove the residual vacuum.

2. Turn off power.

3. Unplug the electrical cord.

8. Special handling procedures, transport, and storage requirements

Describe special handling and storage requirements for hazardous chemicals/gases in the laboratory,

especially for highly reactive, unstable and highly flammable materials and corrosives. Describe

transport and secondary containment requirement, between the laboratories or between facilities.

9. Preventive Maintenance

Clean up and preventive maintenance is important for keeping equipment in safe working order. In this

section, describe any regular maintenance and / or calibration frequency for research equipment,

instrumentation and/or facilities.

Make sure to empty the solvent reservoir into the appropriate waste container and clean the bump

trap after each use.

Rotary Evaporation SOP 9 Revised: Dec 2019 MTD

You might also like

- Rotary Evaporator-Microplate ReaderDocument5 pagesRotary Evaporator-Microplate ReaderCharles EspiloyNo ratings yet

- Rotary Evaporator SafetyDocument3 pagesRotary Evaporator SafetyAbid ZiaNo ratings yet

- SOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Document4 pagesSOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Kimia AsikNo ratings yet

- A Beginner's Guide To The Rotary EvaporatorDocument4 pagesA Beginner's Guide To The Rotary EvaporatordominicbelawingNo ratings yet

- Storage Checklists: Short-Term Storage (Less Than 60 Days)Document7 pagesStorage Checklists: Short-Term Storage (Less Than 60 Days)Karatebird100% (2)

- SopvacuumDocument14 pagesSopvacuumapi-280316582No ratings yet

- APM002 Rotary EvaporatorDocument9 pagesAPM002 Rotary EvaporatorMukarram MudjahidNo ratings yet

- 09935289A MHS 15 Mercury Hydride System Quick ReferenceDocument18 pages09935289A MHS 15 Mercury Hydride System Quick Referencekariliz15No ratings yet

- How to Use Lab Tools Like Pipettes, Autoclaves and CentrifugesDocument7 pagesHow to Use Lab Tools Like Pipettes, Autoclaves and CentrifugesPrimoNo ratings yet

- 9E-A User Manuals and ServiceDocument10 pages9E-A User Manuals and Servicerponce161276No ratings yet

- Liquid Nitrogen SopDocument3 pagesLiquid Nitrogen SopSandeep ShettyNo ratings yet

- Standard Operating Procedure (Sop) A. TankDocument9 pagesStandard Operating Procedure (Sop) A. TankRESYNo ratings yet

- Dehumidifier: User'S ManualDocument20 pagesDehumidifier: User'S ManualgaberleNo ratings yet

- Lab Manual Separation Tech Jan 2021Document43 pagesLab Manual Separation Tech Jan 2021Abdul QayyumNo ratings yet

- User Manual: Refrigerant Recovery UnitDocument15 pagesUser Manual: Refrigerant Recovery UnitPlagiador UnadNo ratings yet

- WALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UseDocument8 pagesWALLACH LL100 TWO TRIGGER CRYOSURGICAL UNIT For N2O Instructions For UsePierre Richard MompremierNo ratings yet

- 1 Lab ReportDocument4 pages1 Lab ReportSasquatchCornNo ratings yet

- Lab Manual Separation Tech Jan 2020Document48 pagesLab Manual Separation Tech Jan 2020nisasoberi0% (1)

- Widepac Care and Use PDFDocument18 pagesWidepac Care and Use PDFel_tano33No ratings yet

- Rotary Evaporator: Low-Temp Solvent RemovalDocument3 pagesRotary Evaporator: Low-Temp Solvent RemovalAltaf Ur RehmanNo ratings yet

- Rotary EvaporatorDocument1 pageRotary EvaporatorChristine Mae MadriaNo ratings yet

- HandDocument4 pagesHandCharl BaranganNo ratings yet

- 86-51-IM Cooling Trap CT 60e - UKDocument10 pages86-51-IM Cooling Trap CT 60e - UKJdNo ratings yet

- Boiler Boilout by RentechDocument4 pagesBoiler Boilout by RentechRonald MesinaNo ratings yet

- Simple Distillation of Cyclohexane and Toluene MixtureDocument18 pagesSimple Distillation of Cyclohexane and Toluene MixtureAnonymous xfzNyyi4No ratings yet

- © Kamco: Guidance Notes On Descaling CalorifiersDocument2 pages© Kamco: Guidance Notes On Descaling CalorifiersKiran DuggarajuNo ratings yet

- Shark SC630 Manual enDocument23 pagesShark SC630 Manual enkrievkalnsgNo ratings yet

- Honeywell HEV320 Series Owner's Manual PDFDocument32 pagesHoneywell HEV320 Series Owner's Manual PDFJames LoewenNo ratings yet

- OT HowTo f02Document4 pagesOT HowTo f02iwancoc15100% (1)

- Notch Filter Experimental Manual FDocument9 pagesNotch Filter Experimental Manual FShoaib PathanNo ratings yet

- Instructions For Use of Rotary EvaporatorDocument2 pagesInstructions For Use of Rotary EvaporatorJulia PasqualeNo ratings yet

- Autoclave Manual PDFDocument14 pagesAutoclave Manual PDFmeongNo ratings yet

- Pyrophoric Vessel HandlingDocument4 pagesPyrophoric Vessel HandlinggshdavidNo ratings yet

- Germ-Free Warm Mist Humidifier Model V790: Read and Save These InstructionsDocument31 pagesGerm-Free Warm Mist Humidifier Model V790: Read and Save These InstructionsSean BrannenNo ratings yet

- All About Carbon DioxideDocument3 pagesAll About Carbon DioxideShiva RajNo ratings yet

- De Scaling Plate Heat ExchangersDocument2 pagesDe Scaling Plate Heat ExchangersKiran DuggarajuNo ratings yet

- Lake Sediment Phytolith Extraction Method: Laccore, National Lacustrine Core Facility July 2014Document14 pagesLake Sediment Phytolith Extraction Method: Laccore, National Lacustrine Core Facility July 2014Susie VanguardiaNo ratings yet

- Safety Talk On-Safety During ShutdownDocument10 pagesSafety Talk On-Safety During Shutdownchakri4all100% (1)

- Lab Manual Separation Tech February 2023Document41 pagesLab Manual Separation Tech February 2023Nurhanis DayanaNo ratings yet

- CHEM 110 Laboratory Assignment 3 Part I: The Hydrolysis of An Ester Part Ii: Spectroscopic Structure DeterminationDocument11 pagesCHEM 110 Laboratory Assignment 3 Part I: The Hydrolysis of An Ester Part Ii: Spectroscopic Structure DeterminationAngie UngNo ratings yet

- Autoclave ManualDocument14 pagesAutoclave ManualMigue ZabaletaNo ratings yet

- Installation, Operation & Maintenance ManualDocument4 pagesInstallation, Operation & Maintenance ManualgshdavidNo ratings yet

- Rotovap Procedure and RulesDocument2 pagesRotovap Procedure and RulesJia Hui TanNo ratings yet

- Vacuum Distillation of Plutonium Spent SaltsDocument12 pagesVacuum Distillation of Plutonium Spent SaltsJohn Mar OrnaNo ratings yet

- Midterm - Unit OpsDocument19 pagesMidterm - Unit OpsKrizzia Anne ShengNo ratings yet

- Service Manual I A Me RexDocument31 pagesService Manual I A Me Rexgabo2516100% (2)

- A Quan A No Marine 21022012Document10 pagesA Quan A No Marine 21022012thunderhossNo ratings yet

- Air Innovations WS30U-09B -ENGDocument12 pagesAir Innovations WS30U-09B -ENGluismontoy.pNo ratings yet

- Vacuum pumps SOP_0 (2)Document6 pagesVacuum pumps SOP_0 (2)kamleshkpatel114No ratings yet

- American Top Loader Washing Machine + SerialDocument67 pagesAmerican Top Loader Washing Machine + SerialMandragora officinarum100% (1)

- SOP LNFillStationDocument7 pagesSOP LNFillStationSandeep ShettyNo ratings yet

- Spray Drier Lab ManualDocument11 pagesSpray Drier Lab ManualJay Wong100% (1)

- Alkali Boil OutDocument4 pagesAlkali Boil OutAnsuman Sen SharmaNo ratings yet

- Vacuum Purging and Processing Tips - Skunk Pharm Research LLC PDFDocument46 pagesVacuum Purging and Processing Tips - Skunk Pharm Research LLC PDFAllery100% (1)

- Chem2 Laboratory Manual MLS - LA1 7 - PrelimDocument56 pagesChem2 Laboratory Manual MLS - LA1 7 - PrelimRalph Jan Torres Rio0% (1)

- DistillationDocument8 pagesDistillationRaz MahariNo ratings yet

- Laboratory Experiment #1 GuzmanDocument7 pagesLaboratory Experiment #1 GuzmanRHYL HARLAN GUZMANNo ratings yet

- Air Cooler: User ManualDocument10 pagesAir Cooler: User ManualmickNo ratings yet

- Batch and Semi-batch Reactors: Practical Guides in Chemical EngineeringFrom EverandBatch and Semi-batch Reactors: Practical Guides in Chemical EngineeringNo ratings yet

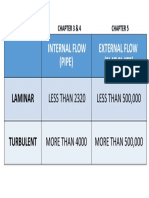

- Difference Between Kinematic and Dynamic ViscosityDocument3 pagesDifference Between Kinematic and Dynamic Viscosityazini amizaNo ratings yet

- Difference Laminar and Turbulent - Pipe and Flat PlateDocument1 pageDifference Laminar and Turbulent - Pipe and Flat Plateazini amizaNo ratings yet

- Calculation of Moisture ContentDocument1 pageCalculation of Moisture Contentazini amizaNo ratings yet

- Chapter 5 Boundary Layer Flow On A Flat PlateDocument44 pagesChapter 5 Boundary Layer Flow On A Flat Plateazini amizaNo ratings yet

- Chapter 5 Boundary Layer Flow On A Flat PlateDocument44 pagesChapter 5 Boundary Layer Flow On A Flat Plateazini amizaNo ratings yet

- Advanced Electronic ComponentsDocument17 pagesAdvanced Electronic Componentsprem_chandranNo ratings yet

- Quick Start - WireGuardDocument5 pagesQuick Start - WireGuardΚαωεη ΣηαδNo ratings yet

- Haryana City Gas Distribution LTD.: - A Summer Internship Project Presentation (June - July 2011)Document19 pagesHaryana City Gas Distribution LTD.: - A Summer Internship Project Presentation (June - July 2011)manish pantNo ratings yet

- Dti Oil and Gas Industry White PaperDocument36 pagesDti Oil and Gas Industry White PaperSoniya AgnihotriNo ratings yet

- Azeotropic DistillationDocument6 pagesAzeotropic DistillationDea YusufNo ratings yet

- INA FAG Corrosion Resistant Products RVSDocument140 pagesINA FAG Corrosion Resistant Products RVSYoga0% (1)

- AdheDocument225 pagesAdheMâñî MíghtyNo ratings yet

- SHPP GL Ch3.FullDocument417 pagesSHPP GL Ch3.FullLuis Faustino Rodriguez LopezNo ratings yet

- Assignment TMDocument3 pagesAssignment TMBeesam Ramesh KumarNo ratings yet

- Acp NotesDocument6 pagesAcp NotesAaronNo ratings yet

- Standard Specification For FRP Composite Utility Poles: First EditionDocument15 pagesStandard Specification For FRP Composite Utility Poles: First EditionMojtaba Mohammad PourNo ratings yet

- Rig Survay FormatDocument3 pagesRig Survay FormatKuOneMohdAzrulNo ratings yet

- CEA Safety Regulations 2010Document87 pagesCEA Safety Regulations 2010Abin MeetuNo ratings yet

- Watch HistoryDocument14 pagesWatch HistorySandana KasthuriNo ratings yet

- Lab Oven GC Operating Manual - REV F 0917Document4 pagesLab Oven GC Operating Manual - REV F 0917Oscar RojasNo ratings yet

- Electrical diagram of industrial motor control systemDocument1 pageElectrical diagram of industrial motor control systemHugo AcevedoNo ratings yet

- DM Plan Naogaon District - English Version-2014Document138 pagesDM Plan Naogaon District - English Version-2014CDMP BangladeshNo ratings yet

- FMC1278Document132 pagesFMC1278Herick Douglas PereiraNo ratings yet

- 1 s2.0 S2352012423002503 MainDocument14 pages1 s2.0 S2352012423002503 MainQuangNguyenVanNo ratings yet

- Paint Master Slurry - TDSDocument2 pagesPaint Master Slurry - TDSMichael JoudalNo ratings yet

- P1568Document9 pagesP1568Luis BarretoNo ratings yet

- Laminated Composite Stiffened Panels Application and BehaviourDocument46 pagesLaminated Composite Stiffened Panels Application and BehaviourHemendra Jain100% (1)

- An A CodDocument14 pagesAn A Codapi-3708589No ratings yet

- Outline of TransportDocument10 pagesOutline of Transportdobojac73No ratings yet

- Marine Seawater ValvesDocument8 pagesMarine Seawater ValvesPhornlert WanaNo ratings yet

- MT 5656Document2 pagesMT 5656Samuel LekhbakNo ratings yet

- Kodak Electra XD Thermal Plate: Media Technical NoteDocument12 pagesKodak Electra XD Thermal Plate: Media Technical NoteWilmer Eduardo Tasayco OrtizNo ratings yet

- InlineCheckValves PARKER PDFDocument8 pagesInlineCheckValves PARKER PDFOssemNo ratings yet

- TV Sharp 19K-M100 DiagramaDocument36 pagesTV Sharp 19K-M100 DiagramaJomasando10100% (1)

- Space Robotics: PreviewDocument21 pagesSpace Robotics: PreviewAnvit TiwariNo ratings yet