Professional Documents

Culture Documents

Specific Gravity Test of Bitumen

Uploaded by

Dipankar NathOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specific Gravity Test of Bitumen

Uploaded by

Dipankar NathCopyright:

Available Formats

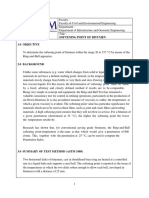

Chapter 10 Standard Test Procedures

Tests For Bitumen & Bituminous Materials

10.3 Specific Gravity Test of Bitumen

10.3.1 Introduction

It is often required to know the specific gravity of straight run and cut-back bitumen

for purposes of calculating rates of spread, asphaltic concrete mix properties etc.

The standard specific gravity test is carried out at a temperature of 25 0C. However, if

cooling facilities are not available, a temperature of 35 0C may be used, although this

must be clearly stated in the result. For some purposes the specific gravity at

elevated temperatures is required, as it is not possible to measure this directly an

approximate value may be obtained by calculation using the value determined at a

lower temperature.

10.3.2 Apparatus

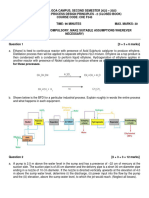

a) The apparatus for the test consists of a standard pycnometer as shown in Figure

10.3.1.

22 to 26 mm. 22 to 26 mm.

1.0 to 2.0 mm. 1.0 to 2.0 mm.

4.0 to 6.0 mm....................................4.0 to 6.0 mm.

Figure 10.3.1 Suitable Pycnometers

b) A constant temperature water bath is also required.

c) A 600 ml glass beaker.

MAY 2001 Page 10.1

10.3.3 Sample preparation

The sample obtained in accordance with Chapter 2 is heated carefully in an oven or

on a hotplate until it has become sufficiently fluid to pour. When using a hotplate, the

bitumen should be stirred as soon as possible to prevent local overheating. In no

case should the temperature be raised more than 90 0C the softening point and

sample must not be heated for more than 30 minutes.

10.3.4 Test procedure

a) The clean, dry pycnometer, complete with stopper, should be weighed to the

nearest 0.001 gram., weight A.

b) A 600 ml glass beaker should be partly filled with freshly boiled distilled water

which has been allowed to cool in a stoppered flask. The beaker should then be

immersed to a depth of at least 100mm. in a water bath which is maintained at the

required temperature ± 0.10C for a period of at least 30 minutes. The top of the

beaker should be above the level of the water in the bath.

c) The weighed pycnometer should then be filled with the boiled distilled water and

the stopper placed loosely in position, taking care to expel all air from the

pycnometer. The pycnometer should then be submerged in the beaker of water

to a depth above the stopper of at least 40mm and the stopper firmly pushed into

position. The beaker and pycnometer must remain in the water bath for at least

30 minutes after which the pycnometer is removed. The top of the pycnometer

should first be dried with one stroke of a dry clean cloth and the remainder of the

pycnometer is then dried as quickly as possible prior to weighing, weight B. Note

that if a droplet of water forms on the stopper after drying, the stopper should not

be re-dried, the volume of water in the pycnometer on immediately, leaving the

water is the required value, any subsequent changes should not affect the result.

On completion of weighing the pycnometer should be thoroughly dried.

d) The pycnometer is then filled about three quarters full with the sample of bitumen.

The bitumen should be carefully poured into the pycnometer ensuring that no air

becomes trapped below the bitumen and there are no air bubbles in the sample.

The sample should be poured into the center of the pycnometer so that the sides

or neck of the pycnometer above the level of the bitumen are not contaminated.

The pycnometer and bitumen should then be allowed to cool in air for a period of

at least 40 minutes, after which the weight is determined, weight C.

e) The pycnometer is then topped up with the boiled distilled water and the stopper

loosely placed in position, taking care to expel all air from the pycnometer. The

pycnometer should then be submerged in the beaker of water to a depth above

the stopper of at least 40mm and the stopper firmly pushed into position. The

beaker and pycnometer must remain in the water bath for at least 30 minutes

after which the top and sides of the pycnometer are dried as before, prior to

weighing, weight D.

f) At least two separate determinations should be made.

10.3.5 Calculation

The specific gravity of the bitumen is given by:

(C - A)

S.G = (B - A) - (D - C)

The average value of two or more results should be quoted.

A typical calculation sheet is included as Form 10.3.1.

The specific gravity is valid only at the temperature of the test. If, however, the

specific gravity is required at other temperature, the following approximate

relationship should be used:-

S.G at temperature, T = (S.G at test temperature, t) - (0.0006 x (T-t))

10.3.6 Reporting of results

The specific gravity of the bitumen should be reported to three decimal places,

together with the temperature of the test.

If the specific gravity is calculated for any other temperature, the fact that this is an

approximate calculated value should be stated.

You might also like

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Specific Gravity Test of Bitumen PDFDocument3 pagesSpecific Gravity Test of Bitumen PDFArham SheikhNo ratings yet

- S.G of AsphaltDocument5 pagesS.G of AsphaltShaker ArabiatNo ratings yet

- D70, Specific GravityDocument3 pagesD70, Specific GravityAldwiNo ratings yet

- D70.1737-1-Density of Semi-Solid Bituminous Materials (Pycnometer)Document3 pagesD70.1737-1-Density of Semi-Solid Bituminous Materials (Pycnometer)Devela AvinashNo ratings yet

- Density of Semi-Solid Bituminous Materials (Pycnometer Method)Document4 pagesDensity of Semi-Solid Bituminous Materials (Pycnometer Method)NuMbNo ratings yet

- Test On Bitumen PDFDocument12 pagesTest On Bitumen PDFIrfan NazirNo ratings yet

- Specific Gravity and Softening Point of A Bitumen SampleDocument9 pagesSpecific Gravity and Softening Point of A Bitumen Samplemwaqas250No ratings yet

- Highway Paving Materials Laboratory Manual: Prepared By: Yazid Al-MomaniDocument28 pagesHighway Paving Materials Laboratory Manual: Prepared By: Yazid Al-MomaniMohammad AlmafrajiNo ratings yet

- Test On BitumenDocument15 pagesTest On BitumenMukil PrasathNo ratings yet

- Specific Gravity of SoilsDocument5 pagesSpecific Gravity of Soilspriyaprasad367792No ratings yet

- Mid-Term Test (2022-2023) CHE F343Document2 pagesMid-Term Test (2022-2023) CHE F343Vehaan HandaNo ratings yet

- Bituminous TestsDocument23 pagesBituminous TestsikreddyNo ratings yet

- Viscosity Lab ReportDocument7 pagesViscosity Lab Reportcharishma takkallapalliNo ratings yet

- Lab-Work Department: 1. Binder Analysis TestsDocument15 pagesLab-Work Department: 1. Binder Analysis TestsRotich VincentNo ratings yet

- Quality of Bitumen & Modified BitumenDocument48 pagesQuality of Bitumen & Modified BitumenBilal Ahmed BarbhuiyaNo ratings yet

- $rif4foj (2017 - 11 - 27 15 - 16 - 35 Utc)Document4 pages$rif4foj (2017 - 11 - 27 15 - 16 - 35 Utc)Rob DamhuisNo ratings yet

- Fluid PropertiesnumericalsDocument10 pagesFluid PropertiesnumericalsMishell Rubio100% (1)

- Standard M Ethod of Test For: Specific Gravity of SoilsDocument3 pagesStandard M Ethod of Test For: Specific Gravity of SoilsJoRge BaRriosNo ratings yet

- Sir Hadi Job 10Document6 pagesSir Hadi Job 10zaynNo ratings yet

- ASTM ViscosityDocument4 pagesASTM ViscositywilNo ratings yet

- Penetrometer Test PDFDocument4 pagesPenetrometer Test PDFAshishJamadarNo ratings yet

- Performance Test of Air CompressorDocument30 pagesPerformance Test of Air CompressorJ Kristan AlmonteNo ratings yet

- Appendix C-1 Laboratory Test On Asphalt Cement, Emulsified Asphalt and Bituminous MixDocument47 pagesAppendix C-1 Laboratory Test On Asphalt Cement, Emulsified Asphalt and Bituminous MixMae Ann GonzalesNo ratings yet

- Kinematic ViscometryDocument3 pagesKinematic ViscometryDhananjay KadamNo ratings yet

- Softening PointDocument6 pagesSoftening PointMohd Zairul Shafiq ZakariaNo ratings yet

- 1 Final - Babujan SirDocument30 pages1 Final - Babujan SirAmeen PattuparaNo ratings yet

- Determination of PenetrationDocument57 pagesDetermination of Penetrationtunlaji0% (2)

- Chapter12 - Testing of Cement 1Document7 pagesChapter12 - Testing of Cement 1piratekANo ratings yet

- Asphalt Laboratory ManualDocument26 pagesAsphalt Laboratory ManualSanthaKumar Muthu ThankaveluNo ratings yet

- Material TestingDocument7 pagesMaterial TestingNavneet SinghNo ratings yet

- Transportation LabDocument32 pagesTransportation LabBiplob GhoshNo ratings yet

- Cover Page For Uche NwokoroDocument6 pagesCover Page For Uche NwokoroShammah ChidiNo ratings yet

- IMO MSC Circ.670Document11 pagesIMO MSC Circ.670Mihailescu IulianNo ratings yet

- .Archivetemptest 3 - Ductility of Bituminous MaterialsDocument7 pages.Archivetemptest 3 - Ductility of Bituminous MaterialsSadon B AsyNo ratings yet

- Laboratory Manual: Concrete and AggregateDocument20 pagesLaboratory Manual: Concrete and AggregateBatepola BacNo ratings yet

- ITS Wet and Dry SubsetDocument4 pagesITS Wet and Dry SubsetanjanaNo ratings yet

- Ri Preboard - April - 2023 - Hge PDFDocument6 pagesRi Preboard - April - 2023 - Hge PDFRichelle Faye VillaverdeNo ratings yet

- 1.5.2 Gases 00-10Document13 pages1.5.2 Gases 00-10Murray PhysicsNo ratings yet

- Blaine Apparatus ProcedureDocument7 pagesBlaine Apparatus ProcedureVivek Pandey100% (3)

- Chemeng 3035/7050: Multi-Phase Fluid & Particle Mechanics: Tutorial Problems 3Document2 pagesChemeng 3035/7050: Multi-Phase Fluid & Particle Mechanics: Tutorial Problems 3Nhut NguyenNo ratings yet

- Iraq University College: Name StageDocument24 pagesIraq University College: Name Stageأحمد جاسم محمدNo ratings yet

- 2019 Hyd MayDocument13 pages2019 Hyd MayChantal Faye GacusanNo ratings yet

- 25) Softening Point of BitumenDocument5 pages25) Softening Point of BitumenPn Ekanayaka100% (4)

- Me Me 2102Document20 pagesMe Me 2102Ariyan Abrar SaifNo ratings yet

- Softening N Penetration Test (Bitumen)Document11 pagesSoftening N Penetration Test (Bitumen)Thamilaarasan SonOf Nathan29% (7)

- KT 39Document6 pagesKT 39nischal_babuNo ratings yet

- Scalding Tank DesignDocument25 pagesScalding Tank DesignSyakila Iksan100% (3)

- Thermal Control in ConcreteDocument14 pagesThermal Control in ConcreteDeshapriyaNo ratings yet

- 1 Penetration and Softening PointDocument5 pages1 Penetration and Softening PointHassan MohsenNo ratings yet

- FINENESSDocument25 pagesFINENESSDanao ErickNo ratings yet

- Agriculture Engg. and ScienceDocument90 pagesAgriculture Engg. and ScienceArvind Verma100% (2)

- BoardDocument8 pagesBoardJerald ManlangitNo ratings yet

- Determination of Some Properties of Concrete Aggregates According To ASTM StandardsDocument5 pagesDetermination of Some Properties of Concrete Aggregates According To ASTM StandardsSude FilizNo ratings yet

- Test For BentoniteDocument3 pagesTest For BentoniteNay Win SheinNo ratings yet

- Lab Exercise Chapter 2 3Document8 pagesLab Exercise Chapter 2 3Andy BirdieNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- TulipDocument1 pageTulipDipankar NathNo ratings yet

- Final Syllabus-RS&GISDocument131 pagesFinal Syllabus-RS&GISDipankar NathNo ratings yet

- Design of Truss-Bridge: Bachelor of Technology, 4th Semester Mini ProjectDocument17 pagesDesign of Truss-Bridge: Bachelor of Technology, 4th Semester Mini ProjectDipankar NathNo ratings yet

- Analysis of Indian Education System: Sampriti Chatterjee (Great Learning)Document20 pagesAnalysis of Indian Education System: Sampriti Chatterjee (Great Learning)Dipankar NathNo ratings yet

- Filariasis: Dr.T.V.Rao MDDocument62 pagesFilariasis: Dr.T.V.Rao MDDipankar NathNo ratings yet

- Surface Water Hydrology (Runoff) : Prepared byDocument19 pagesSurface Water Hydrology (Runoff) : Prepared byDipankar NathNo ratings yet

- Laboratory Manual: Name: Roll No.: Semester: Academic YearDocument58 pagesLaboratory Manual: Name: Roll No.: Semester: Academic YearDipankar NathNo ratings yet

- Man Bahadur Rana BPH, Acas, NepalDocument34 pagesMan Bahadur Rana BPH, Acas, NepalDipankar NathNo ratings yet

- Water Resources Engineering-IDocument3 pagesWater Resources Engineering-IDipankar NathNo ratings yet

- Name: Kandlakuti Vasanth Kumar: Scholar Id: 18-11-042 Civil: A SecDocument10 pagesName: Kandlakuti Vasanth Kumar: Scholar Id: 18-11-042 Civil: A SecDipankar NathNo ratings yet

- Simulation of Fluid Sloshing in A Tank: June 2010Document7 pagesSimulation of Fluid Sloshing in A Tank: June 2010Dipankar NathNo ratings yet

- Man Bahadur Rana BPH, Acas, NepalDocument34 pagesMan Bahadur Rana BPH, Acas, NepalDipankar NathNo ratings yet

- Name: Kandlakuti Vasanth Kumar: SC Id: 1811042Document6 pagesName: Kandlakuti Vasanth Kumar: SC Id: 1811042Dipankar NathNo ratings yet

- Exercise Book - 03 - Bricks (Ddpanda)Document6 pagesExercise Book - 03 - Bricks (Ddpanda)Dipankar NathNo ratings yet

- CFD Analysis of Sloshing Within TankDocument6 pagesCFD Analysis of Sloshing Within TankDipankar NathNo ratings yet

- Exercise Book - 08 - Miscellaneous Topics (Ddpanda)Document4 pagesExercise Book - 08 - Miscellaneous Topics (Ddpanda)Dipankar NathNo ratings yet

- CH 3 Theory - Book Calculus (Ddpanda)Document17 pagesCH 3 Theory - Book Calculus (Ddpanda)Dipankar NathNo ratings yet

- Modelling of Fluid Sloshing in Tank 77Document20 pagesModelling of Fluid Sloshing in Tank 77Dipankar NathNo ratings yet

- Modal Modelling of The Nonlinear Resonant Fluid SLDocument24 pagesModal Modelling of The Nonlinear Resonant Fluid SLDipankar NathNo ratings yet

- WGRFDocument128 pagesWGRFDipankar Nath100% (1)

- Building Repairs and Maintenance ServicesDocument2 pagesBuilding Repairs and Maintenance ServicesSyed Mohd MehdiNo ratings yet

- De Wisdom International SchoolDocument8 pagesDe Wisdom International Schoolsamezfastlink666666No ratings yet

- IndividualAssignmentUber YapChoonMing MITDocument6 pagesIndividualAssignmentUber YapChoonMing MITjycm2001100% (1)

- 10 October 1994Document124 pages10 October 1994Monitoring TimesNo ratings yet

- Codigos KoTOR I - Serie Caballeros de La Antigua República - Clan DLANDocument16 pagesCodigos KoTOR I - Serie Caballeros de La Antigua República - Clan DLANLeonardo EspinozaNo ratings yet

- Supply Chain Management-DefinitionsDocument4 pagesSupply Chain Management-DefinitionsrominamyNo ratings yet

- BSI - The Keystone' of PSA MultiplexingDocument3 pagesBSI - The Keystone' of PSA MultiplexingCelia Thomas100% (1)

- Carbonation Chloride Penetration of Concrete StructuresDocument4 pagesCarbonation Chloride Penetration of Concrete StructuresAshrafNo ratings yet

- 1 - Pdfsam - JSN-20-008-LOP-WPS3-OS-001 Rev 00Document1 page1 - Pdfsam - JSN-20-008-LOP-WPS3-OS-001 Rev 00ibnu rizalNo ratings yet

- RIEGL VZ-4000: Terrestrial Laser ScanningDocument6 pagesRIEGL VZ-4000: Terrestrial Laser ScanningIgnacioDuartet100% (1)

- Connell Cross Parry 2Document12 pagesConnell Cross Parry 2Javier Maquera JmrNo ratings yet

- Unitwise Objective Question With AnswerDocument19 pagesUnitwise Objective Question With AnswerKutty ShivaNo ratings yet

- 3D Sound Field Recording With Higher Order Ambisonics - Objective Measurements and Validation of Spherical Microphone PDFDocument24 pages3D Sound Field Recording With Higher Order Ambisonics - Objective Measurements and Validation of Spherical Microphone PDF郭俊麟No ratings yet

- 15cs34 Module 2Document123 pages15cs34 Module 2Anonymous aPFl2oNo ratings yet

- Tutorial 2Document3 pagesTutorial 2kz_kamranNo ratings yet

- PacemakersDocument6 pagesPacemakersFirst LastNo ratings yet

- Weller Efficiency - The Most Powerful Station in Its ClassDocument5 pagesWeller Efficiency - The Most Powerful Station in Its ClassCharles AustinNo ratings yet

- WorkForce Planning Guide 9Document102 pagesWorkForce Planning Guide 9PrashantRanjan2010No ratings yet

- Honda IzyDocument16 pagesHonda IzyTerry FordNo ratings yet

- 7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantDocument9 pages7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantAra SanirapNo ratings yet

- Variable Displacement Pump A4VSO: RE 92 050/09.97 1/40 Replaces: 03.97 and 11.95Document40 pagesVariable Displacement Pump A4VSO: RE 92 050/09.97 1/40 Replaces: 03.97 and 11.95nguyễn văn dũngNo ratings yet

- Epcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitDocument7 pagesEpcc-04 Package - Delayed Coker Unit (Dcu) With Unsaturated LPG Treating UnitKunalNo ratings yet

- Biochrom Microplate-Washers Atlantis ManualDocument73 pagesBiochrom Microplate-Washers Atlantis ManualPaulo Henrique EvangelistaNo ratings yet

- Sep 13 10 - 56 AMDocument5 pagesSep 13 10 - 56 AMQuang Đăng NguyễnNo ratings yet

- G0002ec: Atx Guide For Instrument and Junction BoxesDocument16 pagesG0002ec: Atx Guide For Instrument and Junction BoxesRichard GriffithNo ratings yet

- Copenhagen SchemaDocument56 pagesCopenhagen Schemaraaj9850100% (1)

- Demag Drives: Keeping Things On The MoveDocument28 pagesDemag Drives: Keeping Things On The MoveAbdulah TaufikNo ratings yet

- Imo Rules Submersible VehiclesDocument24 pagesImo Rules Submersible VehiclesMerrelNo ratings yet

- Cassandra: Wa'el Belkasim Arash Akhlaghi Badrinath JayakumarDocument37 pagesCassandra: Wa'el Belkasim Arash Akhlaghi Badrinath JayakumarrickitNo ratings yet

- Lte Tracking Area Update PDFDocument3 pagesLte Tracking Area Update PDFAnonymous SuO1HHNo ratings yet