Professional Documents

Culture Documents

อุปกรณ์ เช็คทูลสึก Digitalway WattPilote

Uploaded by

PTSC Channel Official Tooling and MetrologyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

อุปกรณ์ เช็คทูลสึก Digitalway WattPilote

Uploaded by

PTSC Channel Official Tooling and MetrologyCopyright:

Available Formats

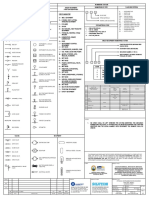

Evolution Model range

Machine control panel Electrical cabinet

NC

CNC Frequency

converter

24V

DC PLC

1A

WE-M10

WE-M10 WE-M01

RJ-P01 SW-A05 WP-CN-S032

Machine Tool

Laptop PC

(Backup) WP-Visu-C

Spindle

WL-E05

Single-spindle machine tool with numeric control

General characteristics Evolution

Drilling Max number of different machining cycles 120

Wear Minimum machining cycle time 0.07 sec.

Drill breakage Maximum machining cycle time 50 minutes

Missing tool Reaction speed 0.005 sec.

Saved machining cycle curves last 30

Saved faults last 30

Saved wear rate last 65,000

Power, derivative, energy control Simultaneous

Boring Measurement accuracy

0

0.01 /0

Wear

Double boring Technical characteristics Single

Reamer breakage Power supply 24 VDC r 10%, 0.5 A

Insert breakage PLC Protocol - Fieldbus ProfiNet IO-RT

Profibus-DP I/O Slave

DeviceNet Slave

Ethernet/IP

Tapping EtherCat

Wear Smart (Digital I/O)

Double tapping Supervision interface Ethernet, 10/100 Base TX

Tap breakage Fast Inputs 24 VDC type II, 15 mA

Fast Outputs Work contact static relay 24VDC

Ambient temperature 0 ... 50°C

Assembly Symmetrical rail DIN EN50 023

Dimensions L 170 mm, W 105 mm, H 96 mm

Deep hole Protection rating IP 20

drilling Weight 1kg 260

Wear

Drill breakage

WattPilote Single Evolution reference Part Nr.

Missing tool WP–C X – X 000

ProfiNet IO-RT : N 000 : Power rating in kW

ProfiBus DP Slave : B S : Three-phase spindle motor

Milling DeviceNet Slave : D H : High-frequency three-phase spindle motor

Wear Ethernet TCP/IP : E A : Three-phase axis motor

Double milling Smart Interface : S D : Direct current motor

Insert breakage Example - WP-CN-S032 : WattPilote Single Evolution – 32KW three-phase spindle – ProfiNet interface

Evolution Model range

Machine control panel Electrical cabinet

NC

CNC Frequency Frequency Frequency Frequency

converter converter converter converter

24V

DC PLC

3A

SW-A05

WE-M10

WE-M10 WE-M01

RJ-P01 WP-QN-S032

Laptop PC Machine Tool

(Backup)

WP-Visu-C

Spindle Spindle Spindle Spindle

WL-E05

4 spindle machine tool with numeric control

General characteristics Evolution

Drilling Max number of different machining cycles 4 x 120

Wear Minimum machining cycle time 0.07 sec.

Drill breakage Maximum machining cycle time 50 minutes

Missing tool Reaction speed 0.005 sec.

Saved machining cycle curves 4 x last 30

Saved faults 4 x last 30

Saved wear rate 4 x last 65,000

Power, derivative, energy control Simultaneous

Boring Measurement accuracy

0

0.01 /0

Wear

Double boring Technical characteristics Quad

Reamer breakage Power supply 24 VDC r 10%, 1.7 A

Insert breakage PLC Protocol - Fieldbus ProfiNet IO-RT

Profibus-DP I/O Slave

DeviceNet Slave

Ethernet/IP

Tapping EtherCat

Wear Smart (Digital I/O)

Double tapping Supervision interface Ethernet - 10/100 Base TX

Tap breakage Fast Inputs 24 VDC type II, 15 mA

Fast Outputs Work contact static relay 24VDC

Ambient temperature 0 ... 50°C

Assembly Symmetrical rail DIN EN50 023

Dimensions L 536 mm, W 105 mm, H 96 mm

Deep hole Protection rating IP 20

drilling Weight 3kg 820

Wear

Drill breakage

WattPilote Quad Evolution reference Part Nr.

Missing tool WP–Q X – X 000

ProfiNet IO-RT : N 000 : Power rating in kW

ProfiBus DP Slave : B S : Three-phase spindle motor

Milling DeviceNet Slave : D H : High-frequency three-phase spindle motor

Wear Ethernet TCP/IP : E A : Three-phase axis motor

Double milling Smart Interface : S D : Direct current motor

Insert breakage Example - WP-QN-S032 : WattPilote Quad Evolution – 4 x 32KW three-phase spindle – ProfiNet interface

Evolution Model range

Electrical cabinet Electrical cabinet – Unit 1 Electrical cabinet – Unit 2 Electrical cabinet – Unit 3

PLC WE-M20

WE-M15

WE-M02 WE-M10

Frequency Frequency Frequency

SW-A05 converter converter converter

RJ-P01

WE-M05

WP-TN-S016 WP-TN-S016 WP-TN-S016

WL-E05

WP-Visu-C

Spindle Spindle Spindle

WM-B10

Laptop PC

(Backup) Electrical cabinet Machine Tool

Transfer machine, 3 units with supervision on WM-B10 monitor

General characteristics Evolution

Drilling Max number of different machining cycles 15

Wear Minimum machining cycle time 0.07 sec.

Drill breakage Maximum machining cycle time 50 minutes

Missing tool Reaction speed 0.005 sec.

Saved machining cycle curves last 30

Saved faults last 30

Saved wear rate last 65,000

Power, derivative, energy control Simultaneous

Boring Measurement accuracy

0

0.01 /0

Wear

Double boring Technical characteristics Transfer

Reamer breakage Power supply 24 VDC r 10%, 0.5A

Insert breakage PLC Protocol - Fieldbus ProfiNet IO-RT

Profibus-DP I/O Slave

DeviceNet Slave

Ethernet/IP

Tapping EtherCat

Wear Smart (Digital I/O)

Double tapping Supervision interface Ethernet - 10/100 Base TX

Tap breakage Fast Inputs 24 VDC type II, 15 mA

Fast Outputs Work contact static relay 24VDC

Ambient temperature 0 ... 50°C

Assembly Symmetrical rail DIN EN50 023

Dimensions L 170 mm, W 105 mm, H 96 mm

Deep hole Protection rating IP 20

drilling Weight 1kg 260

Wear

Drill breakage

WattPilote Transfer Evolution reference Part Nr.

Missing tool WP–T X – X 000

ProfiNet IO-RT : N 000 : Power rating in kW

ProfiBus DP Slave : B S : Three-phase spindle motor

Milling DeviceNet Slave : D H : High-frequency three-phase spindle motor

Wear Ethernet TCP/IP : E A : Three-phase axis motor

Double milling Smart Interface : S D : Direct current motor

Insert breakage Example - WP-TN-S016 : WattPilote Transfer Evolution – 16KW three-phase spindle – ProfiNet interface

Evolution Model range

Machine control panel Electrical cabinet

NC

CNC

24V Frequency Frequency Frequency

DC PLC converter converter converter

3A

SW-A05

WE-M10

WE-M10 WE-M01

RJ-P01 WP-LN-S032/A008

Machine Tool

Laptop PC

(Backup) WP-Visu-C

X Z Main

WL-E05 Axis Axis Spindle

Turning center with 30kW spindle and 10A axis motors.

General characteristics Evolution

Max number of different machining cycles 120

Slide-turning

Tool wear Minimum machining cycle time 0.07 sec.

Maximum machining cycle time 50 minutes

Insert chipping

Reaction speed 0.005 sec.

Insert breakage Saved machining cycle curves last 30

Missing tool Saved faults last 30

Raising Saved wear rate last 65,000

Tool wear Power, derivative, energy control Simultaneous

0

Insert chipping Measurement accuracy 0.01 /0

Insert breakage Technical characteristics Turning

Missing tool Power supply 24 VDC r 10%, 1.3 A

Slicing/Cut-off PLC Protocol - Fieldbus ProfiNet IO-RT

Tool wear Profibus-DP I/O Slave

DeviceNet Slave

Insert chipping

Ethernet/IP

Insert breakage EtherCat

Missing tool Smart (Digital I/O)

Supervision interface Ethernet - 10/100 Base TX

Drilling

Tool wear Fast Inputs 24 VDC type II, 15 mA

Fast Outputs Work contact static relay 24VDC

Drill breakage Ambient temperature 0 ... 50°C

Missing tool Assembly 4 x screw M5

Boring Dimensions L 292 mm, W 105 mm, H 135 mm

Tool wear Protection rating IP 20

Weight 2kg 560

Insert chipping

Insert breakage WattPilote Turning Evolution reference Part Nr.

Missing tool

WP–L X – S 000 / A000 / S000

Threading Optional driven tool

ProfiNet IO-RT : N 000 Power rating in kW

Tool wear ProfiBus DP Slave : B X and Z Axis

Insert chip DeviceNet Slave : D 000 Power rating in kW

Insert breakage Ethernet TCP/IP : E Main spindle

Missing tool Smart Interface : S 000 Power rating in kW

Example - WP-LN-S032/A008 : WattPilote Turning Evolution - 32 kW Main Spindle / 12 A axis – ProfiNet interface

Tool wear and breakage monitoring system WattPilote

w w w . d i g i t a l w a y g r o u p . c o m

WattPilote - the perfect solution for

every type of machine and every application

Transfer

Contact

Turning

Single

Triple

Quad

Easy

Dual

Selection guide

Automatic boring machines with single tools - - -

Boring / deep hole drilling machines or multi-spindle machines - -

Transfer machines and multi-station special machines - -

Fully automatic milling machines -

Single-spindle machining centers and special machines -

Machines

Double-spindle machining centers and special machines -

Three-spindle machining centers and special machines -

Four-spindle machining centers and special machines -

Fully automatic turning machines and turning centers -

Special turning machines . . . -

Surface, cylindrical, internal, and centerless grinding machines - -

Balancing machines - -

Shaving machines -

Gear cutting machines -

Boring or deep hole drilling with single tools - - - - - - -

Boring, drilling or tapping using a multi-spindle head - - - - -

Machining / Applications

Drilling with a boring bar or a tool with multiple inserts - - - - - -

Machining with complex cutting tools - - - - - -

Boring with ¾ borer - - - - -

Rough machining, machining of raw parts - - - - -

Finishing milling - - - - - /

Turning / rough milling, turning work on a rough part . . -

Finish turning work . . . -

Detection of contact tool / part - - - -

Detection of contact tool / part + tool breakage and wear detection - - -

Machining of sandwiched materials (detecting each material change) - - -

Beam drilling (cycle optimization) - - /

Crankshaft shaving -

Gear cutting - -

- : Optimal performance

. : Works under certain circumstances

/ : Not recommended

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Critical Wear Areas & Vacuum Test Locations: Upper Valve Body - U760E ShownDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Upper Valve Body - U760E ShownДенис ЕфрахимNo ratings yet

- WeaponsDocument2 pagesWeaponsdirtyharrygulshanNo ratings yet

- PL1000E Install Guide REHS2362-00Document20 pagesPL1000E Install Guide REHS2362-00Teguhprabowo CenaNo ratings yet

- Maximus Product CatalogDocument78 pagesMaximus Product Catalogapi-155731311No ratings yet

- How To Thread PipeDocument9 pagesHow To Thread Pipenurlisa khaleedaNo ratings yet

- How To Use Test PenDocument2 pagesHow To Use Test PenrkhayrenNo ratings yet

- SET48 230-4KLC User ManualDocument10 pagesSET48 230-4KLC User ManualFebrianto HermawanNo ratings yet

- Single-Phase Ups: For Cabinet Applications 19 Inch Wall RACKSDocument4 pagesSingle-Phase Ups: For Cabinet Applications 19 Inch Wall RACKSRodri GonzalezNo ratings yet

- Nx2000 AC Drive FlyerDocument4 pagesNx2000 AC Drive FlyerAmit KumarNo ratings yet

- Doepke 09700111 DBL enDocument2 pagesDoepke 09700111 DBL enVladimir PanuchNo ratings yet

- Pluto DatasheetDocument2 pagesPluto DatasheetflynlowNo ratings yet

- Thera TM015XP PDFDocument2 pagesThera TM015XP PDFAlvin Novandi Ega PradanaNo ratings yet

- 3vu1300-1mj00 2.4-4amp Siemens Manual DatasheetDocument7 pages3vu1300-1mj00 2.4-4amp Siemens Manual DatasheeteleazarNo ratings yet

- ASCO Series 230 Automatic Transfer SwitchDocument14 pagesASCO Series 230 Automatic Transfer SwitchjayNo ratings yet

- Belimo NV24-MFT - T Datasheet En-GbDocument5 pagesBelimo NV24-MFT - T Datasheet En-GbAndrzej KrzyżanowskiNo ratings yet

- VSB SeriesDocument3 pagesVSB SeriesCubix AutomationNo ratings yet

- Voltage Transducer DVL 1000 V 1000 VDocument8 pagesVoltage Transducer DVL 1000 V 1000 Vnaveen kumarNo ratings yet

- Intelidrive Lite DatasheetDocument4 pagesIntelidrive Lite DatasheetArnoud NegraoNo ratings yet

- Eaton 048878 DILET11 30 A en - GBDocument6 pagesEaton 048878 DILET11 30 A en - GBTum BeginsNo ratings yet

- Product Data Sheet 3NP4270-0CA01Document3 pagesProduct Data Sheet 3NP4270-0CA01Eliseu Rodrigues PereiraNo ratings yet

- Siemens 4AM3842 4TN00 0EA0 DatasheetDocument3 pagesSiemens 4AM3842 4TN00 0EA0 DatasheetSamuel Mur BonifacioNo ratings yet

- Finder 80 91 0 240 0000 16a Monofunction Modular Timer SPDT Co 400vac Ip20 80 91 0 240 0000 Hoja de DatosDocument8 pagesFinder 80 91 0 240 0000 16a Monofunction Modular Timer SPDT Co 400vac Ip20 80 91 0 240 0000 Hoja de DatosMario LopezNo ratings yet

- Datasheet BES01PY 247507 enDocument2 pagesDatasheet BES01PY 247507 endhananjay_hawaldarNo ratings yet

- Finder Relays Series 80Document7 pagesFinder Relays Series 80rg cpeccNo ratings yet

- Eaton 278760 FAZ C16 2 en - GBDocument9 pagesEaton 278760 FAZ C16 2 en - GBAntony SánchezNo ratings yet

- A Drives Company: Frequency InverterDocument2 pagesA Drives Company: Frequency InverterLaurentiu LapusescuNo ratings yet

- Eaton 066166 EMT6 en - GBDocument3 pagesEaton 066166 EMT6 en - GBSiva RamanNo ratings yet

- I08H026Document2 pagesI08H026Dulce Martinez TolentinoNo ratings yet

- Data Sheet Inverter 5kVA SetecDocument10 pagesData Sheet Inverter 5kVA SetecFadkhuli Sholih FahmiNo ratings yet

- Eaton 171890 Emt62 DB en GBDocument3 pagesEaton 171890 Emt62 DB en GBAriel TorresNo ratings yet

- Belimo AFRX24-MFT N4 Datasheet En-UsDocument3 pagesBelimo AFRX24-MFT N4 Datasheet En-UsEdmond AndresNo ratings yet

- Brosur Emmerich PDFDocument2 pagesBrosur Emmerich PDFAlan Ibrahim100% (1)

- Brosur EmmerichDocument2 pagesBrosur Emmerichpiki99No ratings yet

- AUIR3330S: Automotive GradeDocument30 pagesAUIR3330S: Automotive GradeAlfredo Valencia RodriguezNo ratings yet

- LMT102 01 - en UsDocument3 pagesLMT102 01 - en UsSoumyabrata PradhanNo ratings yet

- Air Circuit Breaker Catalog71Document8 pagesAir Circuit Breaker Catalog71david.darmaji011No ratings yet

- Vips 98Document1 pageVips 98santhoshNo ratings yet

- AD100 Series AC Drive Operation ManualDocument67 pagesAD100 Series AC Drive Operation ManualSegundo Tumalie100% (1)

- S80ENDocument12 pagesS80ENshamim ahmedNo ratings yet

- Datasheet BES00FC 263017 enDocument2 pagesDatasheet BES00FC 263017 endhananjay_hawaldarNo ratings yet

- Vips 98Pf Digital Earth Leakage Relay: FeaturesDocument1 pageVips 98Pf Digital Earth Leakage Relay: FeaturessanthoshNo ratings yet

- AC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesDocument2 pagesAC Current Transducer AP-B10 I 10 .. 400 A: Electrical Data FeaturesCESAR BARROSO NO HAY QUE SER UN EXPERTO.No ratings yet

- ASCO Series 230 Automatic Transfer Switch 2017Document18 pagesASCO Series 230 Automatic Transfer Switch 2017Anonymous SDeSP1No ratings yet

- WECON LX3V ModulesDocument8 pagesWECON LX3V ModulesJorriqueNo ratings yet

- Ie5 DatasheetDocument2 pagesIe5 DatasheetMohammad KazimNo ratings yet

- 1 General Information: Nettime Timestamp For OutputDocument8 pages1 General Information: Nettime Timestamp For OutputOscar Enríquez MorenoNo ratings yet

- Digital Protection RelayDocument8 pagesDigital Protection RelayHeiderPulecioGuzmanNo ratings yet

- Igbt - 2sp0115t2a0-Cm600dx-24t-1093489Document9 pagesIgbt - 2sp0115t2a0-Cm600dx-24t-1093489Hector Zenteno RodriguezNo ratings yet

- Modular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Document2 pagesModular Inverter Datasheet Media TSI 48Vdc - 230vac - 1.5kVA EN v1.3Charmer JiaNo ratings yet

- Eaton RCDDocument3 pagesEaton RCDDavid LimNo ratings yet

- Datasheet BES00AF 183469 enDocument2 pagesDatasheet BES00AF 183469 endhananjay_hawaldarNo ratings yet

- 2945466Document9 pages2945466Marian NNo ratings yet

- B0505XT 1WR3LDocument3 pagesB0505XT 1WR3LHugues YoudaNo ratings yet

- SmartStep Servo-Drives R7D-APSRDocument10 pagesSmartStep Servo-Drives R7D-APSRLukasz TestoweNo ratings yet

- SO24V120Document4 pagesSO24V120birinderNo ratings yet

- LS Inverter Series: Variable Frequency DriveDocument16 pagesLS Inverter Series: Variable Frequency DriveAlistair CiantarNo ratings yet

- MONT70 Configuration PDFDocument9 pagesMONT70 Configuration PDFQuang LêNo ratings yet

- Holbright Hb-8212Document1 pageHolbright Hb-8212Eliana Cristina100% (1)

- 1SVR740884R4300 CM Mps 43pDocument4 pages1SVR740884R4300 CM Mps 43pMostafa A.WNo ratings yet

- Programmable Frequency-To-Current Converter: 1 OLED Display 2 Programming Buttons 3 LedsDocument3 pagesProgrammable Frequency-To-Current Converter: 1 OLED Display 2 Programming Buttons 3 LedsAhmad DagamsehNo ratings yet

- Eaton 186094 DC1 S2011FB A20CE1 en - GBDocument7 pagesEaton 186094 DC1 S2011FB A20CE1 en - GBLucian LupuNo ratings yet

- Amfandmains Parallel Controller Deepseaelectronics: DescriptionDocument2 pagesAmfandmains Parallel Controller Deepseaelectronics: DescriptionpikaNo ratings yet

- ตัวแทนจำหน่าย Tungaloy cuttingtiol domrecDocument16 pagesตัวแทนจำหน่าย Tungaloy cuttingtiol domrecPTSC Channel Official Tooling and MetrologyNo ratings yet

- TSC Outing ShirtDocument1 pageTSC Outing ShirtPTSC Channel Official Tooling and MetrologyNo ratings yet

- ถุง Ptsc FinalDocument2 pagesถุง Ptsc FinalPTSC Channel Official Tooling and MetrologyNo ratings yet

- Xpress by PTSCDocument8 pagesXpress by PTSCPTSC Channel Official Tooling and MetrologyNo ratings yet

- คัตติ้งทูลทำเกลียว Vargus Spotlight byDocument6 pagesคัตติ้งทูลทำเกลียว Vargus Spotlight byPTSC Channel Official Tooling and MetrologyNo ratings yet

- เครื่องวัด Camshaft Opticline CS การวัดเพลาแบบออปติคัล by PTSCDocument12 pagesเครื่องวัด Camshaft Opticline CS การวัดเพลาแบบออปติคัล by PTSCRenishaw-ThaiNo ratings yet

- PH10 Motorised Heads and Controllers: Installation GuideDocument74 pagesPH10 Motorised Heads and Controllers: Installation GuidePTSC Channel Official Tooling and MetrologyNo ratings yet

- กล้องไมโครสโคป Tvm Brochure จาก Vision Engineering by Ptsc 02-3704900Document4 pagesกล้องไมโครสโคป Tvm Brochure จาก Vision Engineering by Ptsc 02-3704900PTSC Channel Official Tooling and MetrologyNo ratings yet

- CA General Notes ApprovedDocument6 pagesCA General Notes ApprovedSal ShamNo ratings yet

- Book 1Document12 pagesBook 1niheskuNo ratings yet

- Dito Tower PlanDocument43 pagesDito Tower PlanMary Dorothy GajoNo ratings yet

- Pressure Regulator ARGOS SeriesDocument24 pagesPressure Regulator ARGOS Seriescassio_tecdrawNo ratings yet

- CDU Plant Pipe & Instrumentation Diagram 9 Dec 2021Document4 pagesCDU Plant Pipe & Instrumentation Diagram 9 Dec 2021Aimal HakeemiNo ratings yet

- JMG Systems Reomte Control System 2Document3 pagesJMG Systems Reomte Control System 2Fredy RoaNo ratings yet

- PSCRB+ Exit Exam Q & A - 2Document4 pagesPSCRB+ Exit Exam Q & A - 2Nima KamalNo ratings yet

- BRAUER Toggle ClampsDocument2 pagesBRAUER Toggle Clampsdhaval_trivedi_3No ratings yet

- EXX050BRBT06 Bending Head SystemDocument1 pageEXX050BRBT06 Bending Head SystemManuel MartinezNo ratings yet

- Compressed Cylinder SafetyDocument31 pagesCompressed Cylinder SafetycarolNo ratings yet

- Product Branded PDF 56fe1b7687e7e 111Document538 pagesProduct Branded PDF 56fe1b7687e7e 111Parmod KumarNo ratings yet

- AJ401Document36 pagesAJ401luis javier munoz berdugoNo ratings yet

- 938H Hidraukico JKM01569Document12 pages938H Hidraukico JKM01569Jonny Zambrano MeraNo ratings yet

- Braden BG8 Winch User ManualDocument32 pagesBraden BG8 Winch User ManualRonald Prieto100% (1)

- Brosur Inflatable Liferaft - YoulongDocument1 pageBrosur Inflatable Liferaft - YoulongSANTOSA MARINENo ratings yet

- Levido Round: 901594.002.1 - Recessed DownlightsDocument1 pageLevido Round: 901594.002.1 - Recessed DownlightsKaide Johar BohraNo ratings yet

- Linear Heat Detection For Coal ConveryorsDocument6 pagesLinear Heat Detection For Coal ConveryorsPeter K PaulNo ratings yet

- 2.1-3 Ethernet Cable ConfigurationDocument12 pages2.1-3 Ethernet Cable ConfigurationMaykel Uryeta MamitzNo ratings yet

- Annexure For MCB RCCB RcboDocument2 pagesAnnexure For MCB RCCB Rcboprince sisodiaNo ratings yet

- Belimo Piv Brochure En-UsDocument8 pagesBelimo Piv Brochure En-UsJoão AlvesNo ratings yet

- Chapter 5.2 PIPE DRAFTINGDocument29 pagesChapter 5.2 PIPE DRAFTINGJack SantosNo ratings yet

- Advanced Photoelectric Smoke Detectors: FeaturesDocument8 pagesAdvanced Photoelectric Smoke Detectors: FeaturesoscarninanNo ratings yet

- Utp Category 5E Lan Cable (Solid) - Li5704001-Pvc: Cables Superiores Ltda - ColombiaDocument1 pageUtp Category 5E Lan Cable (Solid) - Li5704001-Pvc: Cables Superiores Ltda - ColombiabernardoNo ratings yet

- (123doc) Tai Lieu Omnireach FTTX SolutionsDocument12 pages(123doc) Tai Lieu Omnireach FTTX SolutionsChi NguyenNo ratings yet