Professional Documents

Culture Documents

I Xec: Improx (Ec) Ethernet Controller Installation Manual Specifications

Uploaded by

Viorel EnacheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

I Xec: Improx (Ec) Ethernet Controller Installation Manual Specifications

Uploaded by

Viorel EnacheCopyright:

Available Formats

MODEL NUMBER: XEC900-0-0-GB-XX

IPS970-0-0-GB-XX

IMPROX ECII

ImproX (ECII) Ethernet Controller

INSTALLATION MANUAL

SPECIFICATIONS

Working Environment

Aluminium Extruded Cabinet ..... Designed to work in an indoor (dry)

(XEC900) environment similar to IP30. The Controller is,

therefore, not sealed against water.

Power Supply Combo.................. Designed to work in an indoor (dry)

(IPS970) environment similar to IP20. The Power

Supply Combo is, therefore, not sealed against

water.

Power

Aluminium Extruded Cabinet (XEC900)

Input Voltage ................................ 10 V DC to 30 V DC.

Power Requirements Current (mA) Power (W)

Supply Voltage 10 V DC

(Maximum) ............................. 420 4.2

Supply Voltage 30 V DC

(Maximum) ............................. 140 4.2

System Battery

Battery Type ........................... 6 V 3 Ahr Sealed Lead Acid Battery.

Battery Life ............................. 4-6 Hours uninterrupted operation.

48 Hours Power Shutdown, Hibernation Mode.

Power Supply Combo (IPS970)

NOTE: The Power Supply Combo includes a 3 A Switch Mode Power Supply which

provides power for the (optional) internal unit and for charging the (optional)

backup Battery. As the Power Supply Combo needs no more than 1 A, you

may power extra devices using up to 2 A continuous current from the

provided connector block. DO NOT exceed this 2 A limit on continuous

current draw.

Devices with a high in-rush current demand, such as certain maglocks and

other electromechanical devices, can momentarily draw more than 3 A. The

Power Supply then effectively shuts down as directed by its built in

protection as exceeding the 3 A rating is considered a short-circuit.

Overcome this by installing the recommended 12 V 7 Ahr Battery to help

supplement the in-rush current such a device may draw on activation.

Power Input

Input Voltage 85 V AC to 265 V AC at 50/60 Hz.

Power Output

Output Voltage 13.8 V DC ±0.3 V DC.

(Mains Power On)

Output Current 2 A continuous (Power Output Terminals).

System Battery

Type ....................................... 6 V 3 Ahr (Max) Sealed Lead Acid Battery.

Approximate Length ............... 151 mm (6 in) (Max).

Approximate Width ................. 65 mm (3 in) (Max).

Approximate Height................ 99 mm (4 in) (Max) including the terminals.

The following specifications are common to both the Aluminium Extruded Cabinet and

the Power Supply Combo:

Real Time Clock (RTC) Backup

Battery

Battery Type ................... 1 x 3 V, CR2032, Lithium cell Battery.

Battery Life ..................... 2 Years with power OFF,

5 years with power ON,

5 years storage with Battery Tab in place.

Controller Communication

Ethernet Port

Connection ............................. Standard Ethernet RJ45 connector.

10/100/1 000 Mbps, half or full duplex.

NOTE: The ImproX ECII is rated to 100

MBps, however the Controller will

work on a 1 000 MBps (1 GB)

network.

Protocol .................................. TCP/IP, UDP.

NOTE: The RS485 1 (Controller) Port connection details only apply to ImproX ECII

Controllers with Firmware V7.16 upwards.

RS485 1 (Controller) Port

Configuration .......................... 38 400 Default.

Electrical Interface ................. RS485.

Baud Rates ............................ 9 600, 19 200, 28 800, 38 400 and 57 600

selectable via the Communications Protocol.

XEC300-0-0-GB-08 August 2011 Page 2

RS485 1 (Controller) Port (Continued)

Data Format ........................... 8 data bits, no parity, 1 stop bit.

Communications Protocol ...... ImproX Secure Communications Protocol.

Line Termination .................... Provision is made for line termination.

Default Mode .......................... Receive Mode.

Terminal Communication

RS485 2 (Terminal) Port

Configuration .......................... 38 400 Default.

Electrical Interface ................. RS485.

Baud Rates ............................ 9 600, 19 200, 28 800, 38 400, 57 600 and

76 800 selectable via the Protocol.

Data Format ........................... 8 data bits, no parity, 1 stop bit.

Communications Protocol ...... ImproX Secure Communications Protocol.

Line Termination .................... Provision is made for line termination.

Default Mode .......................... Receive Mode.

General

Memory

RAM (Non-volatile) ................. 64 MBytes.

Flash ROM ............................. 8 MBytes.

Diagnostic LED Indicators

Power-on LED ........................ Red LED (internally visible).

Incoming RS485 1 (Controller) Flashing Green LED (internally visible).

Outgoing RS485 1 (Controller) Flashing Red LED (internally visible).

Incoming RS485 2 (Terminal) .. Flashing Green LED (internally visible).

Outgoing RS485 2 (Terminal) .. Flashing Red LED (internally visible).

Link Speed LED (Ethernet) .... Flashing Red LED (internally visible).

Duplex Mode LED (Ethernet) . Flashing Red LED (internally visible).

Link Active LED (Ethernet) ..... Flashing Red LED (internally visible).

CPU Usage ............................ Red LED (internally visible).

On = Idle, Off = Busy.

CPU Running ......................... Red LED (internally visible).

On = Yes, Off = No.

CPU Fault .............................. Red LED (internally visible).

On = Fault Condition, Off = Ok.

Blank Space

XEC300-0-0-GB-08 August 2011 Page 3

INSTALLATION INFORMATION

Accessories

II

Find the following when unpacking the ImproX EC Controller:

II

Either, an ImproX EC Controller (XEC900) housed in a Black, powder-coated,

Aluminium extruded Cabinet. The Cabinet consists of a Top Cover and a Base

sealed at each end with a Mild Steel End Plate, secured with 5 Thread Cutter

Screws (M3 x 8 mm).

II

Or, an ImproX EC Controller (IPS970) housed in a Black Mild Steel, powder-

coated Cabinet. The Cabinet consists of a hinged Lid and a Base.

A 3 V, CR2032, Lithium cell Battery.

A 6 V 3 Ahr Sealed Lead Acid Backup Battery.

Four Combi Screws (No. 4 x 10 mm) (IPS970 Only).

A glass Fuse, Slow Blow, 3.15 A, 250 V (5 mm x 20 mm) (IPS970 Only).

A MAC Address Label.

An extra Fixed Address Label.

General

II

Remember the following when installing your ImproX EC Controller:

Communications Distance

RS485 1 (Controller Port) and RS485 2 (Terminal Port)

II

The RS485 communications distance between the ImproX EC Controller and the

LAST ImproX Unit in a cable run, MUST NOT exceed 1 km (1 090 yd). Achieve this by

using good quality screened twisted pair Mylar cable, EARTHED on one side.

Ethernet Port

The Ethernet Controller plugs into an Ethernet Switch or Hub (or other network device),

cable runs for this must conform to Ethernet cabling specifications.

Termination Resistors for RS485 Bus Communications

Long transmission lines or multiple “star” connections, may cause communication

problems. Placing the Terminating Resistor Jumper Link in the LAST UNIT AT THE

END OF THE CABLE RUN should solve the problem (depending on the bus). Refer to

Figure 1 on page 8.

EARTH Connection

II

In conditions where excessive noise is present connect the ImproX EC Controller to a

good EARTH point. Using either of the RS485 Ports, connect the EARTH Lead to the

“SHD” Terminal. Mains EARTH can be used, but electrical noise may persist. The

II

EARTH Lead to the ImproX EC Controller should have a minimum cross-sectional

2 2

area of 1 mm (0.001 in ) and can be either solid or stranded.

Blank Space

XEC300-0-0-GB-08 August 2011 Page 4

Installing the Real Time Clock (RTC) Backup Battery

CAUTION: Remove the Battery Tab for the Real Time Clock from the Battery

Holder BEFORE powering up the ImproX ECII.

Refer to Figure 1 for the location of the Real Time Clock Backup Battery Holder.

First Time Use

II

1. Access the ImproX EC Controller’s Printed Circuit Board (PCB):

For XEC900, remove the Controller’s Top Cover.

For IPS970, open the Lid of the Cabinet.

2. Locate the removable Battery Tab in the Real Time Clock Battery Holder (See

Figure 1 and Figure 2 for location).

3. Pull the removable Battery Tab out of the Battery Holder.

4. Complete installation by:

For XEC900, replace the Controller’s Top Cover.

For IPS970, close the Lid of the Cabinet.

Replacement

II

1. Access the ImproX EC Controller’s Printed Circuit Board (PCB):

For XEC900, remove the Controller’s Top Cover.

For IPS970, open the Lid of the Cabinet.

2. Remove the old 3 V, CR2032, Lithium cell Battery from the Battery Holder by

pulling the plastic retaining clip AWAY from the Battery Holder. The Battery Holder

is spring-loaded and will raise the Battery out of the Holder.

3. Slide the NEW 3 V, CR2032, Lithium cell Battery under the metal clip of the

Battery Holder, with the "+" Terminal facing UP.

4. Pull the plastic clip away from the Battery Holder and press the Battery firmly into

the Battery Holder.

5. Complete replacement by:

For XEC900, replace the Controller’s Top Cover.

For IPS970, close the Lid of the Cabinet.

Installing the 6 V 3 Ahr Sealed Lead Acid System Backup Battery

First Time Use

Aluminium Extruded Cabinet (XEC900)

1. Open the Controller’s Top Cover.

2. Attach the Battery Fly Lead to the System Backup Battery Connector (see Figure 1

for Key Component Positions).

3. Attach the Controller’s Top Cover.

Power Supply Combo (IPS970)

1. Open the Lid of the Cabinet.

2. Slide the Lid in an upwards direction and unhinge.

XEC300-0-0-GB-08 August 2011 Page 5

3. Place the Battery into the Cabinet with the Battery Terminals in an upwards

position.

4. Connect the Red Battery Terminal Lead to the Positive Battery Terminal.

5. Connect the Black Battery Terminal Lead to the Negative Battery Terminal.

6. Re-hinge the Lid and slide it in a downwards direction.

7. Close the Lid of the Cabinet.

Replacement

Aluminium Extruded Cabinet (XEC900)

1. Remove the Controller’s Top Cover.

2. Remove the Controller’s back End Plate.

3. Disconnect the Battery Fly Lead Spade Terminals from the old Battery.

4. Slide the old Battery out of the Battery Compartment.

CAUTION: Ensure that you maintain the correct polarity of the Battery Fly Lead

Spade Terminals. Red wire to Positive (+) and Black wire to

Negative (-).

5. Slide the new Battery into the Battery Compartment.

6. Reconnect the Battery Fly Lead Spade Terminals to the new Battery.

7. Attach the Controller’s back End Plate.

8. Attach the Controller’s Top Cover.

Database Backup (Battery Low)

On Battery Low, when the Controller reaches the end of its 48 Hour Hibernation Mode,

the Battery reaches a point where it cannot maintain the Database in the Controller’s

memory. To reduce the risk of losing the Controller’s Database, we recommend that

you backup the Database to a USB Flash Disk as follows:

NOTE: Acceptable Flash Disk sizes include 128 MB, 256 MB, 512 MB or 1 GB

(maximum usable size).

1. Format the Flash Disk in FAT32.

2. If already powered up, power down the Controller.

3. Plug the USB Flash Disk into the USB Host Port on your Controller.

4. Apply power thereby restarting the Controller.

NOTE: Ensure that the USB Flash Disk remains plugged into the USB Host Port on

the Controller for this feature to function correctly.

Mounting the Controller

CAUTION: Make certain that you mount the Controller on a vibration-free

surface.

II

Select the mounting position of the ImproX EC Controller, considering accessibility

and routing of wires. Secure the Controller to the mounting surface, using four suitable

screws and wall plugs, nuts and bolts or rivets.

XEC300-0-0-GB-08 August 2011 Page 6

Mounting the Power Supply Combo (IPS970)

NOTE: During mounting, we recommend removing the Power Supply Combo’s

Earth Strap. As indicated in Figure 2, locate and disconnect the Earth Strap

from the Lid of the Cabinet. This allows easy removal and replacement of

the Lid during installation. After installation, we strongly recommend you

reattach the Earth Strap to the Lid.

Use the supplied Connection Leads for the low voltage connections to the Power

Supply Combo. Using the supplied Quick Click Glands or Gland Breakouts, neatly lead

the wires out of the Cabinet.

1. Fix the Base to the wall using two suitable screws in the Mounting Key Holes.

2. Fix the third screw in the Mounting Slot, adjusting the position of the Base if

necessary.

Blank Space

XEC300-0-0-GB-08 August 2011 Page 7

ELECTRICAL CONNECTIONS

Key Component Positions

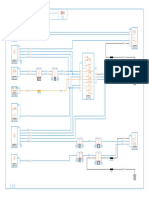

Figure 1: Key Component Positions

XEC300-0-0-GB-08 August 2011 Page 8

Figure 2: Power Supply Combo (IPS970) Layout Diagram – Top View

XEC300-0-0-GB-08 August 2011 Page 9

Connecting the ImproX ECII Controller

Figure 3 shows the Controller’s relationship with the rest of the ImproX product range.

Figure 3: Controller Configuration Options

XEC300-0-0-GB-08 August 2011 Page 10

II

Figure 4 shows typical connection options for the ImproX EC Controller.

Figure 4: Typical Electrical Connections

NOTE: DO NOT connect (daisy chain) additional RS485 Controllers on Port 2, as

the System will NOT Auto-ID these Controllers.

XEC300-0-0-GB-08 August 2011 Page 11

Settings Specific to the Power Supply Combo

WARNING: DO NOT REMOVE THE PLASTIC COVER PROTECTING THE

SWITCH MODE POWER SUPPLY. REMOVING THE COVER PUTS

YOU AT RISK OF ELECTRICAL SHOCK.

CAUTION: DO NOT exceed the Input Voltage specified.

Wiring the Mains Input Power Cord

WARNING: DO NOT TOUCH ANY PART OF THE CIRCUIT ONCE YOU’VE

APPLIED POWER TO THE POWER SUPPLY COMBO.

Figure 5: Mains Connections

Connect the Power Supply Combo to mains power as follows:

1. Open the Cabinet.

2. Using a suitable screwdriver, press and hold down the Push-button.

XEC300-0-0-GB-08 August 2011 Page 12

3. Insert the wire.

4. Release the Push-button.

5. Repeat steps 1 to 3 for each connection.

6. Attach a suitable Mains Input Power Plug using the following connections:

Live (Brown).

Neutral (Blue).

Earth (Yellow/Green).

7. Close the Cabinet.

Fuse Information

Fuse Type Purpose Rating

This fuse protects the Battery 3.15 A 250 V

Battery Fuse from overload as well as incorrect Slow-blow

polarity connection. (5 mm x 20 mm).

This fuse protects the Power

4 A 250 V Slow-blow

Power Supply Fuse Supply from overload as well as

(5 mm x 20 mm).

incorrect polarity connection.

Table 1: Fuse Ratings

NOTE: Because of the delicacy of the replacement procedure, we recommend you

contact your distributor before trying to replace the Power Supply Fuse.

Replacing the Battery Fuse

CAUTION: Ensure that you have disconnected the mains power supply to the

Power Supply Combo, and removed the Positive Lead from the

Battery before replacing the fuse.

1. Disconnect the mains power supply to the Power Supply Combo.

2. Open the Cabinet.

3. Disconnect the Positive Lead from the Battery.

Figure 6: Fuse Holder

4. Unscrew the Fuse Holder’s Lid from the Base.

5. Remove the old fuse.

6. Insert a new fuse into the longer end of the Fuse Holder.

7. Screw the Fuse Holder’s Lid onto the Base.

8. Reconnect the Positive Lead to the Battery.

9. Close the Cabinet.

10. Reconnect the mains power supply to the Power Supply Combo.

XEC300-0-0-GB-08 August 2011 Page 13

Power Shut Down

The ImproX ECII Controller’s 6 V 3 Ahr Sealed Lead Acid Backup Battery provides

between 4-6 hours of uninterrupted power. Five minutes after the Battery Low signal’s

received by the Controller, the Controller switches to Hibernation Mode (low power).

Hibernation Mode provides a further 48 hours of database (including transactions)

memory retention.

Master Reset

The ImproX ECII Controller can be restarted manually, without removing the power

connections, by pressing the Master Reset button (See Figure 1 for Key Component

Positions).

Restoring Factory Default Settings

If you assign an invalid IP address to the ImproX ECII Controller, it will not be able to

communicate. Restore the Controller’s factory default settings as follows:

CAUTION: This will restore the firmware to the version set when shipped from

the factory. If you have upgraded the Controller’s firmware since

installation, ensure that you upgrade again immediately.

1. With power applied to the ImproX ECII Controller, place a link across the pins of

the Factory Default Jumper Link (LK4). (See Figure 1 for Key Component

Positions).

NOTE: Take note of the Ethernet and CPU Diagnostic LEDs, the LEDs will switch

OFF then ON signaling that restoration has taken place.

2. Remove the link.

Unit Address Information

Fixed Address Label

The last 8 digits of the MAC Address, that is 4A-9A-BC-3D (see Figure 7), translate to

the products Fixed Address used by the System Software.

Attach the loose Fixed Address Label (packaged with the Controller) in position on the

Unit Location Chart (or your sketched site plan).

MAC Address Label

Figure 7: Sample MAC Address Label

II

Each ImproX EC Controller is supplied with a separate MAC Address Label, much like

the one shown in Figure 7, which uniquely identifies each Controller.

Attach the extra loose MAC Address Label, alongside the Fixed Address Label, to the

Unit Location Chart enclosed (or your sketched site plan).

XEC300-0-0-GB-08 August 2011 Page 14

When the system installation is complete and all the units are represented on the Unit

Location Chart (or your sketched site plan) by their Fixed Address and MAC Address

Labels, file the document for future reference.

IP Address

NOTE: All ImproX ECII Controllers have the same IP Address (192.168.100.1). In

the absence of a DHCP server, plug each Controller into the network

individually and set the static IP Address.

Unit Location Chart

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 15

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 16

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 17

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 18

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 19

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 20

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 21

Fixed Address Label Unique Location Description

XEC300-0-0-GB-08 August 2011 Page 22

Fixed Address Label Unique Location Description

Table 2: Unit Location Chart

GUARANTEE OR WARRANTY

This product conforms to our Guarantee or Warranty details placed on our Web Site, to

read further please go to www.impro.net.

USER NOTES

XEC300-0-0-GB-08 August 2011 Page 23

II

This manual is applicable to the ImproX (EC ) Ethernet Controller,

XEC900-0-0-GB-06 and IPS970-0-0-GB-05.

(The last two digits of the Impro stock code indicate the issue status of the product).

Aug ImproX ECII\English Manuals\LATEST ISSUE\

XEC300-0-0-GB-08 Issue 09 XECII-insm-en-09.docx

2011

XEC300-0-0-GB-08 August 2011 Page 24

You might also like

- Ecomax402502602 Service Manual PDFDocument36 pagesEcomax402502602 Service Manual PDFMihai LunguNo ratings yet

- Fette Compression Machine-PocketguideDocument22 pagesFette Compression Machine-Pocketguidemicrobiologist12583% (24)

- MEX816UDocument19 pagesMEX816USergeyNo ratings yet

- Renault UCH Pin Code Reading and Key ProgrammingDocument12 pagesRenault UCH Pin Code Reading and Key ProgrammingPerona PabloNo ratings yet

- Ixp220 Controller ManualDocument36 pagesIxp220 Controller ManualeneeascuNo ratings yet

- Specifications - IPL T PC1, IPL T PC1i: AC Control InterfaceDocument2 pagesSpecifications - IPL T PC1, IPL T PC1i: AC Control InterfacealochetNo ratings yet

- I Xec: Improx (Ec) Ethernet Advanced Controller Installation Manual SpecificationsDocument16 pagesI Xec: Improx (Ec) Ethernet Advanced Controller Installation Manual SpecificationsViorel EnacheNo ratings yet

- SMA1K-CP Technical DataDocument2 pagesSMA1K-CP Technical DataНатальяNo ratings yet

- Obd2 Elm327 120828010211 Phpapp01Document76 pagesObd2 Elm327 120828010211 Phpapp01Billysx CastillenseNo ratings yet

- d005dr SpecDocument5 pagesd005dr SpecDaniel SitumeangNo ratings yet

- Faults Detector For A Wiring System - Arduino-: University Politehnica of BucharestDocument11 pagesFaults Detector For A Wiring System - Arduino-: University Politehnica of BucharestIonut SimaNo ratings yet

- Installation Manual IO Module EN-125Document12 pagesInstallation Manual IO Module EN-125GabrielNo ratings yet

- Soekris Net 4501 ManualDocument12 pagesSoekris Net 4501 ManualcloudartisanNo ratings yet

- Manual Ad Rcsn422Document7 pagesManual Ad Rcsn422schatten_3No ratings yet

- TAC Xenta® 491/492Document2 pagesTAC Xenta® 491/492SswahyudiNo ratings yet

- PSL608 Technical ManualDocument32 pagesPSL608 Technical Manualade rohmanNo ratings yet

- 7805 Regulator DescriptionDocument4 pages7805 Regulator DescriptionyeateshwarriorNo ratings yet

- iR-ETN: User ManualDocument23 pagesiR-ETN: User ManualAlberto MolinaNo ratings yet

- Optocoupler Solutions Guide PDFDocument24 pagesOptocoupler Solutions Guide PDFBen Salah IssamNo ratings yet

- Galcon Manual UsuarioDocument65 pagesGalcon Manual Usuariopedro1981No ratings yet

- TrademarksDocument36 pagesTrademarksjokot42No ratings yet

- TrademarksDocument36 pagesTrademarksjokot42No ratings yet

- © 2004 - 2005 ... Future Technology Devices International LTDDocument29 pages© 2004 - 2005 ... Future Technology Devices International LTDreemaNo ratings yet

- TrademarksDocument32 pagesTrademarksjokot42No ratings yet

- TrademarksDocument32 pagesTrademarksjokot42No ratings yet

- Prepaid Energy MeterDocument131 pagesPrepaid Energy Metersatyajit_manna_2100% (1)

- VLT5000Document2 pagesVLT5000harrysmith2No ratings yet

- 3021 BuckPuckDocument8 pages3021 BuckPuckTom BeanNo ratings yet

- Amplificadpr 'PowerDocument29 pagesAmplificadpr 'PowerTony Richard Collazos AranaNo ratings yet

- 5.2 Cp0201, Cp0291, Cp0292: X20 Module - Compact Cpus - Cp0201, Cp0291, Cp0292Document9 pages5.2 Cp0201, Cp0291, Cp0292: X20 Module - Compact Cpus - Cp0201, Cp0291, Cp0292calripkenNo ratings yet

- Ele804 Lab Manual LnaDocument58 pagesEle804 Lab Manual Lnaanhnhamoi100% (1)

- Project Report of Robot 5 Semester Electronics: Sir Syed University of Engineering and TechnologyDocument16 pagesProject Report of Robot 5 Semester Electronics: Sir Syed University of Engineering and TechnologyFaraz Ali KhanNo ratings yet

- Sumi Proj Copyprojectdoc (Repaired)Document13 pagesSumi Proj Copyprojectdoc (Repaired)lucky jNo ratings yet

- DSC PC1616-PC1832-PC1864 - V4-2 - Saf - Im - 29007336R001 PDFDocument64 pagesDSC PC1616-PC1832-PC1864 - V4-2 - Saf - Im - 29007336R001 PDFEduardGoroNo ratings yet

- WiFlyGSX UmDocument28 pagesWiFlyGSX Umviki_05432No ratings yet

- Project FileDocument131 pagesProject FileshaanjalalNo ratings yet

- inBIO480 Installation Guide V2 1-20120105 PDFDocument2 pagesinBIO480 Installation Guide V2 1-20120105 PDFchilenoclNo ratings yet

- Invensys 244LDDocument14 pagesInvensys 244LDSijo XaviarNo ratings yet

- NTE363 Silicon NPN Transistor RF Power Amp, P 4W: O DescriptionDocument2 pagesNTE363 Silicon NPN Transistor RF Power Amp, P 4W: O Descriptionckean_ngNo ratings yet

- 24 C 32Document19 pages24 C 32teroplasNo ratings yet

- EV-100ZXT100-TROUBLESHOOTING AND Adjustment With A ComputerDocument21 pagesEV-100ZXT100-TROUBLESHOOTING AND Adjustment With A Computermirko coppiniNo ratings yet

- Ca 3083Document4 pagesCa 3083tabassam7801No ratings yet

- MT860 AngDocument2 pagesMT860 AngGuson KuntartoNo ratings yet

- MLX90288 DatasheetDocument18 pagesMLX90288 Datasheetser_qc81No ratings yet

- Epac 3000 Rev2 Hardware Manual Rev 1.0Document33 pagesEpac 3000 Rev2 Hardware Manual Rev 1.0Anonymous ouFzvkzNo ratings yet

- 6008 Data SheetDocument4 pages6008 Data SheetJorge SousaNo ratings yet

- EC6711-Embedded Laboratory Uploaded by PRABHU.SDocument66 pagesEC6711-Embedded Laboratory Uploaded by PRABHU.Sprabhu s100% (2)

- Circut Diagram For GlucometerDocument22 pagesCircut Diagram For GlucometerSaranyaNo ratings yet

- CLG BellDocument24 pagesCLG BellNikhil Kumar SinghNo ratings yet

- 10g Atca Dualstar BackplaneDocument5 pages10g Atca Dualstar BackplaneishaanguptaNo ratings yet

- Installation GuideDocument18 pagesInstallation Guidem3y54mNo ratings yet

- Cardinal 748Document48 pagesCardinal 748javierrecillas7259No ratings yet

- 1065 EC Installation ManualDocument24 pages1065 EC Installation ManualJonathan Pérez Salazar100% (1)

- ELM323 OBD (ISO) To RS232 Interpreter: Description FeaturesDocument11 pagesELM323 OBD (ISO) To RS232 Interpreter: Description FeaturesAdauto Augusto Nunes FilhoNo ratings yet

- 324 Cordex 125 220VDC 1 1kW Data SheetDocument2 pages324 Cordex 125 220VDC 1 1kW Data Sheetibs434No ratings yet

- RTU Frtu: Innovation, Passion, Collaboration, IntegrityDocument36 pagesRTU Frtu: Innovation, Passion, Collaboration, IntegrityPak ChannNo ratings yet

- FINAL Documentation For EmbdedDocument11 pagesFINAL Documentation For EmbdedakashkirtyNo ratings yet

- Acterna OLA-15B Optical Attenuator Data SheetDocument2 pagesActerna OLA-15B Optical Attenuator Data Sheetscribd01No ratings yet

- Dual Output Voltage Regulator With Power Saving: BA44W12SATDocument10 pagesDual Output Voltage Regulator With Power Saving: BA44W12SATBeatris Medellin MendozaNo ratings yet

- Installation Manual: Istsg Rev 00.01Document22 pagesInstallation Manual: Istsg Rev 00.01Viorel EnacheNo ratings yet

- Wondershare Video Converter Ultimate 8.4.0 Serial KeyDocument1 pageWondershare Video Converter Ultimate 8.4.0 Serial KeyViorel EnacheNo ratings yet

- Key Wondershare Video ConverterDocument1 pageKey Wondershare Video ConverterViorel EnacheNo ratings yet

- Component Codes Component TitlesDocument6 pagesComponent Codes Component TitlesJennifer BellNo ratings yet

- Quick Start Guide PDFDocument28 pagesQuick Start Guide PDFcpl sbNo ratings yet

- Product Specification CatalogueDocument6 pagesProduct Specification CatalogueStefyVladNo ratings yet

- MR312MEGANE1Document267 pagesMR312MEGANE1yiannisplymouth100% (2)

- Schema ElectricaDocument1 pageSchema ElectricaViorel EnacheNo ratings yet

- 1492 pp009 - en PDocument3 pages1492 pp009 - en PAngel MeauryNo ratings yet

- ESwitching PTAct 1 3 2Document3 pagesESwitching PTAct 1 3 2Wayne E. BollmanNo ratings yet

- Fast Floating Point Square Root: Thomas F. Hain, David B. MercerDocument7 pagesFast Floating Point Square Root: Thomas F. Hain, David B. MercerValentina NigaNo ratings yet

- GPS.G2 X 01003 BDocument101 pagesGPS.G2 X 01003 BRuddy MolinaNo ratings yet

- Device ListDocument9 pagesDevice ListOlambaNo ratings yet

- Revised Standards 2016 PDFDocument49 pagesRevised Standards 2016 PDFVasudev AgrawalNo ratings yet

- Cad Wor X Installation GuideDocument67 pagesCad Wor X Installation GuidePetros IosifidisNo ratings yet

- BD FACSAria Quick Reference GuideDocument6 pagesBD FACSAria Quick Reference GuidechinmayamahaNo ratings yet

- HP Manual PDFDocument1,616 pagesHP Manual PDFJoe BlackNo ratings yet

- Manual Urc8210 EnglishDocument58 pagesManual Urc8210 Englishkeefy100No ratings yet

- Harmony Easy Xa2 Xa2evm4lcDocument5 pagesHarmony Easy Xa2 Xa2evm4lcBNCHNo ratings yet

- AD5674 AD5674R AD5679 AD5679R: Data SheetDocument32 pagesAD5674 AD5674R AD5679 AD5679R: Data SheetPhamvandong TincayNo ratings yet

- Información Monitor - Samsumg LS27AG30xDocument27 pagesInformación Monitor - Samsumg LS27AG30xcuentasecundariaporbanNo ratings yet

- Tutorial CatiaDocument12 pagesTutorial Catiaandrea toroNo ratings yet

- Susol Ring Main Unit: User GuideDocument67 pagesSusol Ring Main Unit: User GuideM Kashif JunaidNo ratings yet

- Mill Street Elementary, Naperville District 203: School Supply List 2017-2018Document2 pagesMill Street Elementary, Naperville District 203: School Supply List 2017-2018CvenNo ratings yet

- VRAY Interiors TutorialDocument3 pagesVRAY Interiors Tutorialpublic17000No ratings yet

- Dell Latitude 3000 Series 3550 Spec SheetDocument2 pagesDell Latitude 3000 Series 3550 Spec SheetRupesh KumarNo ratings yet

- Legacy Migration IBM CICS COBOL DB2 TransformationDocument27 pagesLegacy Migration IBM CICS COBOL DB2 Transformationapi-3703652No ratings yet

- HDCP Support Firmware Upgrade Manual (Netflix)Document3 pagesHDCP Support Firmware Upgrade Manual (Netflix)Christopher BrownNo ratings yet

- TT31 Manual PDFDocument36 pagesTT31 Manual PDFIlyaNo ratings yet

- Nvidia t1000 Datasheet 1987414 r4Document1 pageNvidia t1000 Datasheet 1987414 r4wilsonNo ratings yet

- CounterDocument5 pagesCounterHaroon AmarkhilNo ratings yet

- GPIO Pin Numbers Power Wiring Diagram: RPI Disp SW Ext/ OFF 5VDocument1 pageGPIO Pin Numbers Power Wiring Diagram: RPI Disp SW Ext/ OFF 5VTimothy ScottNo ratings yet

- Oasis Montaj Complete Workflow PDFDocument0 pagesOasis Montaj Complete Workflow PDFErwin AnshariNo ratings yet

- Casio QT 6000 QT6600Document154 pagesCasio QT 6000 QT6600Ayumi AdiningtyasNo ratings yet

- SOC Design ProcessDocument63 pagesSOC Design ProcessPrabakaran EllaiyappanNo ratings yet

- C2000 Matlab InterfaceDocument21 pagesC2000 Matlab InterfaceThaworn HinsuiNo ratings yet

- Fit Bill BookDocument3 pagesFit Bill Bookarif waniNo ratings yet