Professional Documents

Culture Documents

5.9: What Is SCM?: EDI Formats

Uploaded by

Towhid IslamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5.9: What Is SCM?: EDI Formats

Uploaded by

Towhid IslamCopyright:

Available Formats

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

5.9: What is SCM?

In commerce, supply chain management (SCM), the management of the flow of goods and services,

involves the movement and storage of raw materials, of work-in-process inventory, and of finished

goods from point of origin to point of consumption.

5.10: Electronic Data Interchange (EDI)

Electronic Data Interchange, commonly shortened to EDI, is a standard format for exchanging

business data.

EDI transactions are a type of electronic commerce that companies use for transactions such as

when one company wants to electronically send a purchase order to another. EDI transactions

were designed to be independent of the communications used by companies or the software

technology that generates the EDI data.

EDI Formats

EDI works based on standards which determine how each message should be formatted.

Four EDI standards exist: UN/EDIFACT, which is the only internationally-recognized standard,

used mostly outside of North America; ANSI ASC X12, used within North America,

TRADACOM, used by British retail companies, and ODETTE, which is used by European

automakers.

The implementation of EDI is important for companies as it can significantly reduce the cost of

sending documents.

EDI Costs Versus Benefits

A paper purchase order requires resources to print the document, fax it, or post it to the vendor.

EDI automatically sends the electronic document to the vendor thus reducing the cost of sending

the PO. Studies of the cost savings of implementing EDI have been performed, including a report

from the Aberdeen group in 2008, which highlighted that in the US it cost $37.45 to produce and

send a paper PO, while it only cost $23.83 to send it using EDI.

Not all companies use EDI. There is a cost to implement and maintain the technology required to

perform EDI. Each trading partner that a company wants to use EDI with may require resources

to set up and this can be cost-prohibitive for smaller companies or companies without technical

resources.

Nazmul Hussain Siddique FCA

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

Some companies who profess to use EDI may receive orders electronically but are unable to

automatically load those orders into their sales systems. The EDI orders are printed out and

manually entered into their computer systems.

This situation is common where companies have aging order systems that do not have the

capability to accept or generate EDI orders.

EDI How It Works

There are a number of ways EDI messages are transmitted between trading partners. The most

common method was to use a value-added network or VAN. This allowed companies to send a

transmission which was then reviewed by the VAN and then sent to the correct recipient.

More recently a new method for EDI transmission is being used. This is called AS2, which

stands for Applicability Statement 2, and was championed by Wal-Mart, who requires all of their

vendors to use this method. Using AS2, the EDI documents are transmitted across the internet

and the security of the document is achieved by encryption and the use of digital certificates.

There are dozens of EDI documents that can be implemented by a company and their trading

partners. Under the ANSI ASC X12 standard, EDI documents are part of a series, for example,

such as an order series, a warehousing series, or a financial series.

In addition, a number of series that relate to specific industries such as government, insurance,

mortgage and automotive.

Many companies will only implement a small number of EDI documents with their trading

partners, commonly in the ordering series, material handling series and the delivery series.

For example a company who is implementing EDI between themselves and a third party logistics

company may only implement five EDI documents such as an EDI 940 for a warehouse shipping

order, EDI 943 for a warehouse stock transfer shipment advice, EDI 944 for a warehouse stock

transfer receipt advice, EDI 945 for a warehouse shipping advice, and EDI 947 for a warehouse

inventory adjustment advice.

Nazmul Hussain Siddique FCA

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

5.11 The Importance of Supply Chain Management

It is well known that supply chain management is an integral part of most businesses and is essential to

company success and customer satisfaction.

Boost Customer Service

Customers expect the correct product assortment and quantity to be delivered.

Customers expect products to be available at the right location. (i.e., customer satisfaction

diminishes if an auto repair shop does not have the necessary parts in stock and can’t fix your

car for an extra day or two).

Right Delivery Time – Customers expect products to be delivered on time (i.e., customer

satisfaction diminishes if pizza delivery is two hours late or Christmas presents are delivered on

December 26).

Right After Sale Support – Customers expect products to be serviced quickly. (i.e., customer

satisfaction diminishes when a home furnace stops operating in the winter and repairs can’t be

made for days)

Reduce Operating Costs

Decreases Purchasing Cost – Retailers depend on supply chains to quickly deliver expensive

products to avoid holding costly inventories in stores any longer than necessary. For example,

electronics stores require fast delivery of 60” flat-panel plasma HDTV’s to avoid high inventory

costs.

Decreases Production Cost – Manufacturers depend on supply chains to reliably deliver

materials to assembly plants to avoid material shortages that would shutdown production. For

example, an unexpected parts shipment delay that causes an auto assembly plant shutdown can

cost $20,000 per minute and millions of dollars per day in lost wages.

Decreases Total Supply Chain Cost – Manufacturers and retailers depend on supply chain

managers to design networks that meet customer service goals at the least total cost. Efficient

supply chains enable a firm to be more competitive in the market place. For example, Dell’s

revolutionary computer supply chain approach involved making each computer based on a

specific customer order, then shipping the computer directly to the customer. As a result, Dell

was able to avoid having large computer inventories sitting in warehouses and retail stores

which saved millions of dollars. Also, Dell avoided carrying computer inventories that could

become technologically obsolete as computer technology changed rapidly.

Improve Financial Position

Increases Profit Leverage – Firms value supply chain managers because they help control and

reduce supply chain costs. This can result in dramatic increases in firm profits. For instance, U.S.

consumers eat 2.7 billion packages of cereal annually, so decreasing U.S. cereal supply chain

Nazmul Hussain Siddique FCA

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

costs just one cent per cereal box would result in $13 million dollars saved industry-wide as 13

billion boxes of cereal flowed through the improved supply chain over a five year period.

Decreases Fixed Assets – Firms value supply chain managers because they decrease the use of

large fixed assets such as plants, warehouses and transportation vehicles in the supply chain. If

supply chain experts can redesign the network to properly serve U.S. customers from six

warehouses rather than ten, the firm will avoid building four very expensive buildings.

Increases Cash Flow – Firms value supply chain managers because they speed up product flows

to customers. For example, if a firm can make and deliver a product to a customer in 10 days

rather than 70 days, it can invoice the customer 60 days sooner.

Lesser known, is how supply chain management also plays a critical role in society. SCM

knowledge and capabilities can be used to support medical missions, conduct disaster relief

operations, and handle other types of emergencies.

Whether dealing with day-to-day product flows or dealing with an unexpected natural disaster,

supply chain experts roll up their sleeves and get busy. They diagnose problems, creatively work

around disruptions, and figure out how to move essential products to people in need as efficiently

as possible.

5.12 Societal Roles of SCM

Ensure Human Survival

SCM Helps Sustains Human Life – Humans depend on supply chains to deliver basic necessities

such as food and water. Any breakdown of these delivery pipelines quickly threatens human life.

For example, in 2005, Hurricane Katrina flooded New Orleans, LA leaving the residents without a

way to get food or clean water. As a result, a massive rescue of the inhabitants had to be made.

During the first weekend of the rescue effort, 1.9 million meals and 6.7 million liters of water

were delivered.

SCM Improves Human Healthcare – Humans depend on supply chains to deliver medicines and

healthcare. During a medical emergency, supply chain performance can be the difference

between life and death. For example, medical rescue helicopters can save lives by quickly

transporting accident victims to hospitals for emergency medical treatment. In addition, the

medicines and equipment necessary for treatment will be available at the hospital as a result of

excellent supply chain execution

SCM Protects Humans from Climate Extremes – Humans depend on an energy supply chain to

deliver electrical energy to homes and businesses for light, heat, refrigeration and air

conditioning. Logistical failure (a power blackout) can quickly result in a threat to human life. For

example, during a massive East Coast ice storm in January 1998, 80,000 miles of electrical power

lines fell resulting in no electricity for 3,200,000 Montreal, Quebec residents. Due to extreme

cold, 30 died and 25% of all Quebec residents left home to seek heated shelter. In addition,

economic costs included $3 billion in lost business, $1 billion in home damage and $1 billion in

government expenditures.

Nazmul Hussain Siddique FCA

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

Improve Quality of Life

Foundation for Economic Growth – Societies with a highly developed supply chain

infrastructure (modern interstate highway system, vast railroad network, numerous modern

ports and airports) are able to exchange many goods between businesses and consumers

quickly and at low cost. As a result, the economy grows. In fact, the one thing that most poor

nations have in common is no or a very poorly developed supply chain infrastructure.

Improves Standard of Living – Societies with a highly developed supply chain infrastructure

(modern interstate highway system, vast railroad network, numerous modern ports and

airports) are able to exchange many goods between businesses and consumers quickly and at

low cost. As a result, consumers can afford to buy more products with their income thereby

raising the standard of living in the society. For instance, it is estimated that supply chain costs

make up 20% of a product’s cost in the U.S. but 40% of a product’s cost in China. If transport

damage is added in, these costs make up 60% of a product’s cost in China. The high Chinese

supply chain cost is a major impediment to improving the standard of living for Chinese citizens.

Consequently, China has embarked on a massive effort to develop its infrastructure.

Job Creation – Supply chain professionals design and operate all of the supply chains in a society

and manage transportation, warehousing, inventory management, packaging and logistics

information. As a result, there are many jobs in the supply chain field. For example, in the U.S.,

logistics activities represent 9.9% of all dollars spent on goods and services in 2006. This

translates into 10,000,000 U.S. logistics jobs.

Opportunity to Decrease Pollution – Supply chain activities require packaging and product

transportation. As a by-product of these activities, some unwanted environmental pollutants

such as cardboard waste and carbon dioxide fuel emissions are generated. For example, paper

and paperboard accounted for 34% of U.S. landfill waste in 2005. Only 50% of the 84 million

tons of paper and paperboard waste were recycled. Also, carbon dioxide emissions from

transportation accounted for 33% of total U.S. CO2 emissions in 2005. As designers of the

network, supply chain professionals are in a key position to develop more sustainable processes

and methods.

Opportunity to Decrease Energy Use – Supply chain activities involve both human and product

transportation. As a by-product of these activities, scarce energy is depleted. For example,

currently transportation accounts for 30% of world energy use and 95% of global oil

consumption. As designers of the network, supply chain professionals have the role of

developing energy-efficient supply chains that use fewer resources.

Protect Cultural Freedom and Development

Defending Human Freedom – Citizens of a country depend on military logistics to defend their

way of life from those who seek to end it. Military logisticians strategically locate aircraft, ships,

tanks, missiles and other weapons in positions that provide maximum security to soldiers and

other citizens. Also, superior logistics performance yields military victory. For example, the B-2

Stealth Bomber is able to deliver bombs to target without being detected by enemy radar.

Nazmul Hussain Siddique FCA

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

Protects Delivery of Necessities – Citizens of a country depend on supply chain managers to

design and operate food, medicine and water supply chains that protect products from

tampering. Sophisticated packaging techniques, state of the art surveillance cameras, global

positioning systems and RFID inventory tracking are some of the methods used to deter

terrorists from accessing these vital logistics systems.

5.13 The Benefits of a Globalized Supply Chain

Globalization has unlocked a plethora of new opportunities for supply chain management, from

expanded sourcing opportunities to expanded markets. These opportunities beget two larger

opportunities: the chance to save money and the chance to increase efficiency. Let’s take a closer

look:

1. Expanded sourcing opportunities. A world market offers businesses opportunities to secure a

diverse selection of workers, materials, and products. This larger selection of goods and services

often means the opportunity to select higher-quality or lower-cost options.

2. The opportunity to reach new customers in new markets. Just as globalization offers more

materials and laborers, it also offers new customers in new locations with new needs.

3. More room to grow. New technologies and a shrinking globe mean that it is easier for

companies to grow generally: to produce more, offer more, and sell more. Expanding borders

also means expanding businesses and corporations.

4. More opportunities to save money. Globalization’s biggest benefit is that increases options:

options for source materials, options for workers, and options for transportation. More options

mean more chances to save on spending and increase profits.

5.14 The Drawbacks of a Globalized Supply Chain

Although the new opportunities associated with a global marketplace are numerous,

globalization also presents a new set of challenges for supply chain management, from how to

increase the scale of operations to how to manage the risks that come along with crossing borders

and circumnavigating the globe. To successfully take advantage of the positive aspects of

globalization, those working in the supply chain must first overcome the following negatives:

1. Large-scale management issues. The opportunity to grow business goes hand-in-hand with the

issue of greatly increased supply chain complexity when it comes to management. Companies

must scale up all aspects of their business as it grows across borders, which can cause problems

that stretch the globe. Inventory issues and distribution issues are high on the list of problems

encountered by going global.

2. Greater risk. Having materials, factories, and customers all over the world means being at the

mercy of global events, from natural disasters, to port closures, to political uprisings.

Globalization requires that supply chain managers have detailed risk management plans in place

and that they are prepared when disaster strikes.

3. Global competition. You are not the only entity with access to supplies, products, and labor

around the world – you now have a lot of competition scattered across the globe. Globalization

Nazmul Hussain Siddique FCA

Information Technology

Certificate level

Lecture-6

Chapter-5: Enterprise Business Systems

necessitates that supply chains are highly efficient and and well-run in order to stay competitive

in a global market.

4. Information collection challenges. With different aspects of your supply chain scattered around

the world, and with an increasingly complex process for getting products to customers, data

collection and oversight can be huge new challenges. While big data analytics is helping some

supply chain managers tackle the issue of information collection, it is still a large problem that

has emerged alongside globalization.

5. Legal issues. Operating across borders means operating in countries that very likely have

different laws and regulations. For example, secret product details may not be safe in China,

where they have less stringent intellectual property laws. In another example, a country where

you have a factory may have very different employment laws than another where you have an

identical factory.

Ultimately, it is vital to understand that globalization is not going away time soon. Because this

trend is here to stay, supply chain managers must create frameworks and systems that take

advantage of the opportunities that globalization has to offer while seriously confronting the

parallel challenges that arise.

ContractRoom is a negotiation and deal / contract lifecycle management software system that

helps procurement professionals improve the way they do deals and make decisions around the

needs of their supply chain.

Collected from http://blog.contractroom.com

Nazmul Hussain Siddique FCA

You might also like

- Electronic Data Interchange (An in Depth Analysis of Technological and Security Issues)Document30 pagesElectronic Data Interchange (An in Depth Analysis of Technological and Security Issues)Mustafa HussainNo ratings yet

- Auditing Electronic Data IntergrationDocument4 pagesAuditing Electronic Data Intergrationmountain girlNo ratings yet

- Ebusiness A Canadian Perspective For A Networked World Canadian 4th Edition Trites Solutions ManualDocument26 pagesEbusiness A Canadian Perspective For A Networked World Canadian 4th Edition Trites Solutions Manualexoynambuj7100% (27)

- AST 0161980 Idc Business Value WhitepaperDocument15 pagesAST 0161980 Idc Business Value WhitepaperPrashantKNo ratings yet

- Udbhava May 2011Document14 pagesUdbhava May 2011Rahul Singh ChoudharyNo ratings yet

- Dreamorbit Softech Private LimitedDocument54 pagesDreamorbit Softech Private LimitedjayeshNo ratings yet

- ImDocument16 pagesImMadhumay PanigrahiNo ratings yet

- EDI Detailed WriteupDocument3 pagesEDI Detailed WriteupAbhishekJindalNo ratings yet

- EBusiness A Canadian Perspective For A Networked World Canadian 4th Edition Trites Solutions Manual 1Document25 pagesEBusiness A Canadian Perspective For A Networked World Canadian 4th Edition Trites Solutions Manual 1ronald100% (30)

- Ebusiness A Canadian Perspective For A Networked World Canadian 4Th Edition Trites Solutions Manual Full Chapter PDFDocument36 pagesEbusiness A Canadian Perspective For A Networked World Canadian 4Th Edition Trites Solutions Manual Full Chapter PDFdiane.brown661100% (12)

- IT Role SCMDocument36 pagesIT Role SCMManoj Kumar ParasNo ratings yet

- Idc Business Value Whitepaper PDFDocument15 pagesIdc Business Value Whitepaper PDFDaniloNo ratings yet

- Advantages of EDIDocument6 pagesAdvantages of EDIKhalid JamalNo ratings yet

- 7 Mini Case Studies - Successful Supply Chain Cost Reduction and ManagementDocument16 pages7 Mini Case Studies - Successful Supply Chain Cost Reduction and ManagementBidyut Bhusan PandaNo ratings yet

- CH 10Document31 pagesCH 10Soumo PathakNo ratings yet

- Marketsn WhitepaperDocument26 pagesMarketsn WhitepaperRohan Gulati100% (1)

- Ford Motor Corp FinalDocument38 pagesFord Motor Corp FinalKumar Vikas0% (1)

- Ibm CompanyDocument20 pagesIbm CompanyAnirud KumarNo ratings yet

- CHP8Document41 pagesCHP8Akmal AkramNo ratings yet

- Dairy Farm GroupDocument6 pagesDairy Farm GroupAkash MishraNo ratings yet

- Video Case Answers ESS11 - REV 2-14-14Document43 pagesVideo Case Answers ESS11 - REV 2-14-14Ahamed NajathNo ratings yet

- Electronic Data InterchangeDocument15 pagesElectronic Data InterchangeShivam DahiyaNo ratings yet

- Supply Chain ManagementDocument9 pagesSupply Chain Managementsharminie ravinNo ratings yet

- Wa0013.Document2 pagesWa0013.dhruv MehtaNo ratings yet

- How To Reduce IT Costs in 2024Document5 pagesHow To Reduce IT Costs in 2024k224827 Anum AkhtarNo ratings yet

- Electronic Data InterchangeDocument22 pagesElectronic Data InterchangeWaheed FridiNo ratings yet

- The Strategic and Financial Justification For: IP CommunicationsDocument13 pagesThe Strategic and Financial Justification For: IP CommunicationsBernard MerindolNo ratings yet

- Dell Supply ChainDocument27 pagesDell Supply ChainRicken Gala0% (1)

- Free Research Papers Supply Chain ManagementDocument5 pagesFree Research Papers Supply Chain Managementfvet7q93100% (1)

- White Paper Business Value of Managed ServicesDocument17 pagesWhite Paper Business Value of Managed Servicescharanmann9165No ratings yet

- Micron PCDocument19 pagesMicron PCIch GuNo ratings yet

- Dell Value ChainDocument27 pagesDell Value ChainVed Prakash TiwariNo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument11 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentJasonch26No ratings yet

- Vendor Managed InventoryDocument8 pagesVendor Managed Inventoryzafer nadeemNo ratings yet

- Electronic Data Interchange (EDI)Document39 pagesElectronic Data Interchange (EDI)bhadoria9No ratings yet

- Electronic Data InterchangeDocument12 pagesElectronic Data Interchangeanudagra03No ratings yet

- DellDocument38 pagesDellMishra SukeshNo ratings yet

- Bis Lol Lol Cases-DimampatkanDocument46 pagesBis Lol Lol Cases-DimampatkanIzatti AyuniNo ratings yet

- Chap 002Document21 pagesChap 002mynameSchool100% (12)

- Warehouse AutomationDocument6 pagesWarehouse AutomationIJRASETPublicationsNo ratings yet

- HND Shipping Adminstration /transport and Logistics ManagementDocument86 pagesHND Shipping Adminstration /transport and Logistics ManagementTambe Chalomine AgborNo ratings yet

- MIS-Chapter 07 Electronic Business SystemDocument43 pagesMIS-Chapter 07 Electronic Business SystemrashidalikhanNo ratings yet

- DSK QV Frachise FFDocument14 pagesDSK QV Frachise FFQuikr DeskNo ratings yet

- Dr. Samim Al Azad (SAA2) : Chapter-1: Information Systems in Business TodayDocument29 pagesDr. Samim Al Azad (SAA2) : Chapter-1: Information Systems in Business TodayNirob AlecNo ratings yet

- Chap 16 of Hill's Internation BusinessDocument28 pagesChap 16 of Hill's Internation BusinessSazib Shohidul IslamNo ratings yet

- Next-Gen Connected Vehicle & Asset Management Technology: 2020 Buyer'S GuideDocument9 pagesNext-Gen Connected Vehicle & Asset Management Technology: 2020 Buyer'S GuideMpho Daniel PuleNo ratings yet

- Management Information Systems Managing The Digital Firm Canadian 7th Edition Laudon Solutions ManualDocument19 pagesManagement Information Systems Managing The Digital Firm Canadian 7th Edition Laudon Solutions Manualannerobinsonebnxfojmza100% (37)

- Intranet, Extranet, EDI, E-Commerce StrategyDocument28 pagesIntranet, Extranet, EDI, E-Commerce StrategyBrad LawrenceNo ratings yet

- EDI FundamentalsDocument19 pagesEDI FundamentalsSowmya NadimintiNo ratings yet

- Lesson 10: Electronic Data Interchange: TopicDocument3 pagesLesson 10: Electronic Data Interchange: Topicsay2shekhar3062No ratings yet

- Module 2 E - Commerce & Digitital MarketingDocument5 pagesModule 2 E - Commerce & Digitital MarketingSatyam singhNo ratings yet

- Management Information Systems Managing The Digital Firm Canadian 7Th Edition Laudon Solutions Manual Full Chapter PDFDocument40 pagesManagement Information Systems Managing The Digital Firm Canadian 7Th Edition Laudon Solutions Manual Full Chapter PDFelizabethciaraqdcank100% (13)

- EdiDocument25 pagesEdiDebdatta ChakrabortyNo ratings yet

- Dell'S Value Chain: MIS 517 Advanced Operations ManagementDocument6 pagesDell'S Value Chain: MIS 517 Advanced Operations ManagementAgnes LiewNo ratings yet

- Topics For KalpathaDocument11 pagesTopics For KalpathaShanthi UnnithanNo ratings yet

- Two Case Studies On Collobarative Manufacturing With Respect To Automobile Industries by Angadi.VDocument7 pagesTwo Case Studies On Collobarative Manufacturing With Respect To Automobile Industries by Angadi.VNikhil Raj TNo ratings yet

- EDI and ERPDocument26 pagesEDI and ERPIsaac Owusu100% (1)

- E-Supply Chain Management: Presented byDocument56 pagesE-Supply Chain Management: Presented byMohamed ElhariryNo ratings yet

- Digital Success: A Holistic Approach to Digital Transformation for Enterprises and ManufacturersFrom EverandDigital Success: A Holistic Approach to Digital Transformation for Enterprises and ManufacturersNo ratings yet

- 5.5: What Is ERP?: Enterprise Resource Planning (ERP) Is The Integrated Management of Core Business ProcessesDocument5 pages5.5: What Is ERP?: Enterprise Resource Planning (ERP) Is The Integrated Management of Core Business ProcessesTowhid IslamNo ratings yet

- 4.6: Trends of E-CommerceDocument5 pages4.6: Trends of E-CommerceTowhid IslamNo ratings yet

- Lesson To Understand: 1.1: Why Study Information System and Information Technology?Document12 pagesLesson To Understand: 1.1: Why Study Information System and Information Technology?Towhid IslamNo ratings yet

- 5.1: What Is CRM?: I. Contact and Account ManagementDocument4 pages5.1: What Is CRM?: I. Contact and Account ManagementTowhid IslamNo ratings yet

- 4.5 Essential E-Commerce Process: Process-1: Access Control and SecurityDocument3 pages4.5 Essential E-Commerce Process: Process-1: Access Control and SecurityTowhid IslamNo ratings yet

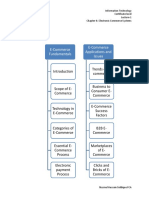

- Topics at A Glance: E-Commerce Fundamentals E-Commerce Applications and IssuesDocument8 pagesTopics at A Glance: E-Commerce Fundamentals E-Commerce Applications and IssuesTowhid IslamNo ratings yet

- IT in BusinessDocument72 pagesIT in BusinessTowhid IslamNo ratings yet

- FIN201 Presentation Ratio AnalysisDocument40 pagesFIN201 Presentation Ratio AnalysisTowhid IslamNo ratings yet

- Population and EnvironmentDocument14 pagesPopulation and EnvironmentTowhid IslamNo ratings yet

- Urbanization and EnvironmentDocument20 pagesUrbanization and EnvironmentTowhid IslamNo ratings yet

- Presentation - Environment and DevelopmentDocument29 pagesPresentation - Environment and DevelopmentTowhid IslamNo ratings yet

- UrbanisationDocument8 pagesUrbanisationTowhid IslamNo ratings yet

- Globalization and EnvironmentDocument15 pagesGlobalization and EnvironmentTowhid IslamNo ratings yet

- COGMDocument2 pagesCOGMKalai MugilanNo ratings yet

- Za Government Gazette Dated 2023-04-28 No 48483 Part 1Document1,024 pagesZa Government Gazette Dated 2023-04-28 No 48483 Part 1karim karimNo ratings yet

- Assignment-2 TPDocument2 pagesAssignment-2 TPvivek singhNo ratings yet

- P5-6 Dan P5-8Document13 pagesP5-6 Dan P5-8rama100% (1)

- MX-PBC-PSC: Express EasyDocument3 pagesMX-PBC-PSC: Express EasyTypes LucyNo ratings yet

- Cost AnalysisDocument30 pagesCost AnalysisPooja SheoranNo ratings yet

- Project Report On RetailDocument33 pagesProject Report On RetailAmitabh Kumar100% (1)

- Prepared by Lemma Tadesse BosonDocument75 pagesPrepared by Lemma Tadesse BosonDame TolossaNo ratings yet

- Module 3 Accounting For Raw MaterialsDocument42 pagesModule 3 Accounting For Raw MaterialsColeng RiveraNo ratings yet

- Purchase Goods and ServicesDocument18 pagesPurchase Goods and ServicesYaregal Yeshiwas100% (3)

- Activity Audit in InventoryDocument4 pagesActivity Audit in InventoryKizzea Bianca GadotNo ratings yet

- Naukri KishoreAakula (3y 0m)Document3 pagesNaukri KishoreAakula (3y 0m)E jyothibasNo ratings yet

- Chapter 1 and 2 InsertDocument32 pagesChapter 1 and 2 InsertZoe Vera S. AcainNo ratings yet

- WDA Masterclass - SnOPDocument2 pagesWDA Masterclass - SnOPshetupucNo ratings yet

- Solman de Leon 2016 PDFDocument95 pagesSolman de Leon 2016 PDFZo Thelf0% (1)

- MH&L - Designing of Agility (The Facility Group)Document26 pagesMH&L - Designing of Agility (The Facility Group)ajayvgNo ratings yet

- Receipt: Customer Details: INVOICE NUMBER: C11067 / 2021 / 247Document1 pageReceipt: Customer Details: INVOICE NUMBER: C11067 / 2021 / 247Mirella DánielNo ratings yet

- Pt. Gapeksindo Jaya Bersama 3 RevisionDocument3 pagesPt. Gapeksindo Jaya Bersama 3 Revisionrachel tobingNo ratings yet

- 9 Daftar PustakaDocument4 pages9 Daftar Pustakaimam budy prastiyoNo ratings yet

- Grocery Clerk Resume SampleDocument7 pagesGrocery Clerk Resume Sampleafjwfugcueaonf100% (2)

- Apics CSCP Module 1 Chapter 1 SummaryDocument4 pagesApics CSCP Module 1 Chapter 1 SummaryJohnatas MontezumaNo ratings yet

- Chapter - 1: Introduction To ProjectDocument46 pagesChapter - 1: Introduction To ProjectJasmandeep brar100% (3)

- MKG MixDocument6 pagesMKG Mixvinit_shah90100% (1)

- Employment Application FormDocument6 pagesEmployment Application FormAbdilahi abdiNo ratings yet

- Chapter 4 6eDocument9 pagesChapter 4 6emahnoor javaidNo ratings yet

- Issues in Supply Chain Mangement Lambert and Cooper 2000Document19 pagesIssues in Supply Chain Mangement Lambert and Cooper 2000kriastNo ratings yet

- Business Studies Class 12 Project On PackagingDocument8 pagesBusiness Studies Class 12 Project On PackagingDivyansh AroraNo ratings yet

- Consolidated Electric Case StudyDocument4 pagesConsolidated Electric Case Studyirwind27100% (1)

- Shan FoodsDocument40 pagesShan Foodshamnah lateefNo ratings yet

- Loreal Distribution Channel PDF FreeDocument32 pagesLoreal Distribution Channel PDF Freehdrth wftNo ratings yet