Professional Documents

Culture Documents

CONN-MacauV2 - 1226R1-H500 Brace Beam

Uploaded by

chirathip vasuvattakulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CONN-MacauV2 - 1226R1-H500 Brace Beam

Uploaded by

chirathip vasuvattakulCopyright:

Available Formats

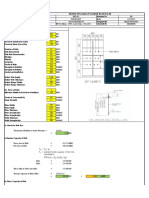

Connection Design according to Macau Design Code

Member MK. HM500x300x11x15

1.Properties

Bolt Plate Parameters of connection

Bolt size (d) 20 mm Plate thickness (tp) 20 mm End distance (e1) 40 mm

class 8.8 Ultimate tensile strength (fu,p) 310 N/mm2 Edge distance (e2) 40 mm

Number of bolts (n) 3 Yield strength (fy,p) 215 N/mm2 Longitudinal Bolts spacing (p1) 100 mm

αv 0.6 Tranverse Bolts spacing (p2) 0 mm

Ultimate tensile strength of bolts (fub) 800 N/mm2 Supported Beam Height of plate (hp) min. 280 mm

Tensile stress area (At) 245.0 mm2 Web thickness (tw,b1) 11 mm Gap (gh) 20 mm

Full bolt area (As) 314.3 mm2 Flange thickness (tf) 15 mm End distance (to edge of beam e1,b) 90 mm

Hole diameter (d0) 22 mm Depth (H) 500 mm Edge distance (to edge of beam e2,b) 40 mm

Number of horizontal bolt lines (n1) 3 Ultimate tensile strength (fu,b1) 310 N/mm2 Supporting to centre of bolt group (z) 60 mm

Number of vertical bolt lines (n2) 1 Yield strength (fy,b1) 215 N/mm2 Partial safety factors (γm0) 1.1

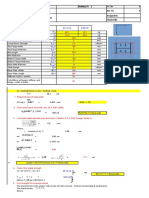

2.Ultimate Design Load Partial safety factors (γm2) 1.25

Axial force = 30 KN

Shear force = 8 KN

Combined force = 31.05 KN

3.Check shear capacity of bolts (Thread excluded in shear plane) 9.Check bearing capacity of supported beam

α = Z p2 / 2I = 0 Horizontal resistance ( Fb,Rd,hor ) = k1 αb fu,b1 d tw,b1 / γm2 = 82.67 KN

b = (n2= 1: 6z / n (n+1) p1 , n2=2 :z p1(n1-1)/2I) = 0.30 αb = min ( e2,b/3do ; fub / fu,b1 ; 1) = 0.61

I = 0.5 n1 p22 + n1( n12-1) p12 /6 = 40000 mm2 k1 = min ( 1.4 p1/do - 1.7 ; 2.5) = 2.50

shear resistance of a single bolt ( Fv,Rd ) = αv fub A /γm2 = 120.69 KN NRd,7 = n Fb,Rd,hor = 248.00 KN > 31.05 OK!

NRd,1 = n Fv,Rd = 362.06 KN > 31.05 OK!

10.Check net section tension capacity of supported beam

4.Check bearing capacity of plate Anet = tw,b1 ( hw,b1 - n1 d0) = 2354 mm2

Horizontal bearing resistance ( Fb,Rd,hor ) = k1 αb fu,p d tp / γm2 = 150.30 KN NRd,8 = 0.9 Anet fu,b1 / ( γm2) = 525.41 KN > 30 OK!

αb = min ( e2/3do ; fub / fup ; 1) = 0.61

k1 = min ( 2.8 e1/do - 1.7 ; 1.4 p1/do - 1.7 ; 2.5) = 2.50 11.Check gross section shear capacity of supported beam

NRd,2 = n Fb,Rd,hor = 450.91 KN > 31.05 OK! Av,b = H tw,b1 = 5500 mm2

VRd,9 = A v, b fy, b1

= 620.65 KN > 8 OK!

3 γm0

5.Check net section tension capacity of plate

Ap,net = tp ( hp - n1 d0) = 4280 mm2 12.Check net section shear capacity of supported beam

NRd,3 = 0.9 Anet fu,p / ( γm2) = 955.30 KN > 30 OK! Av,net = Av,b - n1 d0 tw,b1 = 4774 mm2

VRd,10 = Av,b,net fu,b1 / ( 3 γm2) = 683.56 KN > 8 OK!

6.Check gross section shear capacity of plate

VRd,3 = hp tp fy, p = 497.59 KN > 8 OK! 13.Check Block shear capacity of supported beam

1.27 3 γm0

Net area subjected to tension Ant = tw,b1( n1 p1-(n1- 1) d0) = 2816 mm2

7.Check net section shear capacity of plate Net area subjected to shear Anv = 2 tw,b1(e2,b - 0.5 d0) = 638 mm2

Av,net = tp ( hp - n1 d0) = 4280 mm2 NRd,9 = , + , = 770.36 KN > 31.05 OK!

√

VRd,4 = Av,net fu,p / ( 3 γm2) = 612.82 KN > 8 OK!

14.Check welds

8.Check Block shear capacity of plate Weld size = 8 mm

Net area subjected to tension Ant = tp ( n1p1- (n1-1) d0) = 5120 mm2 Throat size (a) = 5.66 mm

Net area subjected to shear Anv = 2 tp ( e2 - 0.5d0) = 1160 mm2 Weld Length = 560.00 mm min. 280x2

NRd,4 = , + , = 1400.66 KN > 31.05 OK! Correlation factor ( βw) = 0.9

√

Design strength of weld (Fvw.d) = = 159.09 N/mm2

shear capacity (Fw,Rd) = Fvw.d a L = 503.90 KN > 31.05 OK!

Capacity Ratio = 0.13

You might also like

- CONN-MacauV2 - 1226R1-2C Tie BeamDocument1 pageCONN-MacauV2 - 1226R1-2C Tie Beamchirathip vasuvattakulNo ratings yet

- One Side Beam-Beam ConnectionDocument1 pageOne Side Beam-Beam Connectionsamon.itc2019No ratings yet

- CONN MacauV2 - 1226R1 LugDocument1 pageCONN MacauV2 - 1226R1 Lugchirathip vasuvattakulNo ratings yet

- Fin Plate ConnectionDocument2 pagesFin Plate ConnectionSudhakar Krishnamurthy100% (1)

- Bracing ConnectionsDocument3 pagesBracing ConnectionspradeeshNo ratings yet

- Bracing Connection Design PDFDocument3 pagesBracing Connection Design PDFriaz16shaik100% (1)

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212No ratings yet

- Design of Isolated Footing For Security Room: Node No. XDDocument12 pagesDesign of Isolated Footing For Security Room: Node No. XDvenu manikantaNo ratings yet

- Cleat Angle ConnectionDocument3 pagesCleat Angle ConnectionSrishti Project ConsultantsNo ratings yet

- Isolated & Combined Footing Design BS8110.1985Document7 pagesIsolated & Combined Footing Design BS8110.1985carlosNo ratings yet

- Design Calculation For Splice & Bottom Plate of Vertical Column MembersDocument4 pagesDesign Calculation For Splice & Bottom Plate of Vertical Column Membersinnovativekarthi100% (1)

- Design of FootingDocument19 pagesDesign of Footingmohammad danishNo ratings yet

- Base Plate (ML Gambhir)Document6 pagesBase Plate (ML Gambhir)Prakash SinghNo ratings yet

- BP01Document4 pagesBP01Kumar Prasanna HNNo ratings yet

- Splice ConnectionDocument18 pagesSplice ConnectionAhmad Pooladi0% (1)

- Isolated Footing (4 Sides Wind)Document4 pagesIsolated Footing (4 Sides Wind)saiNo ratings yet

- UB406X178X85Document5 pagesUB406X178X85Uday UdmaleNo ratings yet

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmaleNo ratings yet

- Strut Waler Connection Design TemplateDocument1 pageStrut Waler Connection Design TemplateArjun Raja100% (1)

- THAIOIL - VER BRA (Co (ING-TEE SECTION - WELDED - 007 - Rev ADocument10 pagesTHAIOIL - VER BRA (Co (ING-TEE SECTION - WELDED - 007 - Rev ACivil StructureNo ratings yet

- RC Beam Design Using ACIDocument1 pageRC Beam Design Using ACIdantevariasNo ratings yet

- Base Plate DesignDocument21 pagesBase Plate Designtitir bagchi100% (1)

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- Design of Base Plate 1Document2 pagesDesign of Base Plate 1Andro RebuyasNo ratings yet

- He800b PDFDocument5 pagesHe800b PDFUday UdmaleNo ratings yet

- Fire 8: Fire Resistance and Protection of Partially Encased Composite Column (Tabulated Data Method)Document44 pagesFire 8: Fire Resistance and Protection of Partially Encased Composite Column (Tabulated Data Method)vedran100% (1)

- BoltDocument1 pageBoltvishal tomarNo ratings yet

- Shear Wall Design (IS 13920-2016)Document8 pagesShear Wall Design (IS 13920-2016)Sahil OzaNo ratings yet

- Cantiver Beam DesignDocument2 pagesCantiver Beam DesignRathinavel VenkateshwaranNo ratings yet

- Steel Connection - IS CodeDocument4 pagesSteel Connection - IS CodeAmit Ghosh75% (4)

- Sci Publication p387 Steel Building Desi 2Document4 pagesSci Publication p387 Steel Building Desi 2Visuvaratnam Suseendran100% (1)

- Isolated & Combined Footing Design Bs8110.1985Document6 pagesIsolated & Combined Footing Design Bs8110.1985EdwinNo ratings yet

- 4.4 Base Plate and Anchor Bolt CheckDocument1 page4.4 Base Plate and Anchor Bolt Checksrikanth varmaNo ratings yet

- Shear Connections AISC 360Document64 pagesShear Connections AISC 360jatinNo ratings yet

- 2.2.1 - DQR EM Capacity Rev BDocument61 pages2.2.1 - DQR EM Capacity Rev BSANDS ENGINEERING DESIGNS & CONSTRUCTION CO. LTD.No ratings yet

- Pad Footing 1Document4 pagesPad Footing 1John SmithNo ratings yet

- DESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomDocument11 pagesDESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomAsaru DeenNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Beam - Column Steel SpliceDocument20 pagesBeam - Column Steel SpliceAnsh SharmaNo ratings yet

- Circular Base PlateDocument6 pagesCircular Base Platesaptha7giriNo ratings yet

- Design of Purlin & Runner-Ro-Final-Rev-0Document8 pagesDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNo ratings yet

- 0.1 Eingangskennwerte: 0.1.1 AllgemeinesDocument7 pages0.1 Eingangskennwerte: 0.1.1 AllgemeineslöliNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Pinned Base (I-Section) : Design CapacitiesDocument8 pagesPinned Base (I-Section) : Design CapacitiesAwais HameedNo ratings yet

- Review Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsDocument2 pagesReview Module - Structural Engineering (Bolted and Welded Connections) Concentrically Loaded ConnectionsJoseph LantoNo ratings yet

- Aci 95Document14 pagesAci 95Joseph AsfourNo ratings yet

- DESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Document4 pagesDESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Mahananda RKNo ratings yet

- Header Plate ConnectionDocument7 pagesHeader Plate Connectioncretz2No ratings yet

- 1 - SPLICE-WPB 700X300X204.5 - DraftDocument7 pages1 - SPLICE-WPB 700X300X204.5 - DraftAvishek DeyNo ratings yet

- Base PlateDocument29 pagesBase PlateRakesh SharmaNo ratings yet

- 3) Corbel DesignDocument10 pages3) Corbel Designp_ignatiusNo ratings yet

- Modified RatiosDocument3 pagesModified RatiosBassem KhaledNo ratings yet

- Connection Design: Shear Force VDocument6 pagesConnection Design: Shear Force Vy2chongNo ratings yet

- Pad Eye Connected To Bottom PieceDocument7 pagesPad Eye Connected To Bottom PieceAsaru Deen0% (1)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- LUG Connection160727Document1 pageLUG Connection160727chirathip vasuvattakulNo ratings yet

- C10-Capacity Closely Space Check-ReportDocument1 pageC10-Capacity Closely Space Check-Reportchirathip vasuvattakulNo ratings yet

- Member Design Eurocode-MacauDocument1 pageMember Design Eurocode-Macauchirathip vasuvattakulNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakulNo ratings yet

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakul100% (1)

- Steel Design: Project Job Number EngineerDocument1 pageSteel Design: Project Job Number Engineerchirathip vasuvattakulNo ratings yet

- PHD Thesis On Corporate Social Responsibility PDFDocument6 pagesPHD Thesis On Corporate Social Responsibility PDFmichelejohnsonfargo100% (2)

- CBO9780511530159A007Document3 pagesCBO9780511530159A007Ali AzariunNo ratings yet

- Image-Based On-Line Measurement of Crepe Structure: White PaperDocument12 pagesImage-Based On-Line Measurement of Crepe Structure: White PaperAhmed AsforaNo ratings yet

- Assignment 2 With SolutionsDocument4 pagesAssignment 2 With SolutionsVenkat MacharlaNo ratings yet

- How The World WorksDocument9 pagesHow The World Worksapi-346324074No ratings yet

- EN 10168 - 2004 - Steel Products - Inspection Documents PDFDocument12 pagesEN 10168 - 2004 - Steel Products - Inspection Documents PDFBogdanNo ratings yet

- Rapid Load Testing On Piles Interpretation GuideliDocument19 pagesRapid Load Testing On Piles Interpretation GuidelifabulosofigueroaNo ratings yet

- Factors Crane PDFDocument11 pagesFactors Crane PDFpgt39_617429495No ratings yet

- OOP ReviewDocument23 pagesOOP ReviewDuy AnhNo ratings yet

- Lecture-2 HISTORY OF PHARMACY Regarding The Muslim ScientistDocument10 pagesLecture-2 HISTORY OF PHARMACY Regarding The Muslim ScientistHuda Qureshi Hashmi QureshiNo ratings yet

- Module # 14 - Learning Activity 1Document3 pagesModule # 14 - Learning Activity 1Kyla MiguelNo ratings yet

- Detection of Pyricularia Oryzae in Oryza Sativa (Rice) SeedDocument6 pagesDetection of Pyricularia Oryzae in Oryza Sativa (Rice) SeedMartinius TinNo ratings yet

- The National Atlas-Printable MapsDocument2 pagesThe National Atlas-Printable MapsAlexandre RodriguesNo ratings yet

- Consumers Health and ResponsibilitiesDocument6 pagesConsumers Health and Responsibilitiesmary rose ombrogNo ratings yet

- A Reconsideration of The Social RitualDocument16 pagesA Reconsideration of The Social RitualFedeNo ratings yet

- Ieq Micro ProjectDocument9 pagesIeq Micro ProjectVishal ManeNo ratings yet

- MotivationDocument11 pagesMotivationSherif AwadNo ratings yet

- Holiday Homework Class III (2016-17) Aravali Int. SchoolDocument12 pagesHoliday Homework Class III (2016-17) Aravali Int. SchoolRajan AroraNo ratings yet

- Guidelines On Tender Evaluation Using Weighted Criteria For Building Works and ServicesDocument11 pagesGuidelines On Tender Evaluation Using Weighted Criteria For Building Works and Serviceschristopher hersantNo ratings yet

- MOPIA Training Manual Official VersionDocument134 pagesMOPIA Training Manual Official VersionCvijic DejanNo ratings yet

- P11. Magnetism AnswersDocument4 pagesP11. Magnetism AnswersAndreas LambriasNo ratings yet

- Week 13 & 14 - LecturesDocument46 pagesWeek 13 & 14 - LecturesAmyHuiNo ratings yet

- Paper 20230906104745Document96 pagesPaper 20230906104745afifkadriNo ratings yet

- Chapter 2.3 - Relation and FunctionDocument12 pagesChapter 2.3 - Relation and FunctionPoeil Sergio MoldezNo ratings yet

- Instructor: Dipanjan Basu: Civil & Environmental Engineering University of Waterloo Waterloo, ON, CanadaDocument29 pagesInstructor: Dipanjan Basu: Civil & Environmental Engineering University of Waterloo Waterloo, ON, CanadaDamilare OlaniyanNo ratings yet

- Biology Module 1: Cells As The Basis of LifeDocument4 pagesBiology Module 1: Cells As The Basis of LifeDilan Karandana100% (1)

- Numerical Analysis and Statistical TechniquesDocument40 pagesNumerical Analysis and Statistical Techniquesyour friendNo ratings yet

- Ce Correl Ports and Harbor (B)Document5 pagesCe Correl Ports and Harbor (B)Glenn Frey Layug0% (1)

- Metaloceno Leucene HP1018BNDocument1 pageMetaloceno Leucene HP1018BNAngel Ramás Saint SeiyaNo ratings yet

- GUIDE Group Exercise #11: Problem-Solving PathDocument4 pagesGUIDE Group Exercise #11: Problem-Solving Pathnicole100% (1)