Professional Documents

Culture Documents

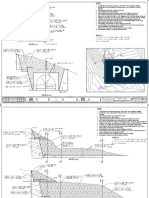

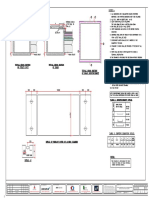

Type FRB1. 333 Ton Free Sliding Bearing Drawing

Uploaded by

Ankush SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Type FRB1. 333 Ton Free Sliding Bearing Drawing

Uploaded by

Ankush SharmaCopyright:

Available Formats

NOTES :

1.0 ALL DIMENSIONS ARE IN MM UNLESS OTHERWISE SPECIFIED.

±etrans. TRANSVERSE MOVEMENT ±etrans. D5 Ø = 350.0 dØ = 08 mm Round Bar 2.0 MATERIAL :

Welded on both sides 2.1 TOP PLATE PISTON & POT / BOTTOM PLATE WILL BE MADE UP OF CAST STEEL OF GRADE

Pth=50.0 340-570W OF IS : 1030.

c c Nt=28 (for Anti Rotation)

+0.0002 ROTATION -0.0002

A6=46

2.2 STAINLESS STEEL WILL CONFIRM TO AISI:316 WITH THE SLIDING SURFACE FINISHED SMOOTH.

AH1=71

2.3 SLIDING MATERIAL WILL BE PTFE AS PER THE CL. 4.2 & 4.2.1OF IRC : 83 (PART III) - 2018.

Lb / Ls = 160 / 160

SUPERSTRUCTURE

Lt=15

DØ 2.4 THE CONFINED ELASTOMER INSIDE POT WILL HAVE PROPERTIES SPECIFIED IN TABLE 4.3

OF IRC : 83 (PART III) - 2018.

2.5 ANCHOR BOLT MATERIAL AS PER GRADE 4.6 OF IS : 1367 & SLEEVE MATERIAL AS PER IS : 2062

A2=25 & DETAIL OF THREAD AS PER IS : 1367 & ACCESSORIES CONFIRMING TO IS : 2062.

2.6 THE STAINLESS STEEL WILL BE WELDED ON THE BACKING PLATE.

'D' A1 Ø / A7 Ø = 450.0 Ll=70 2.7 SUITABLE NOS. OF WASHERS ARE TO BE USED AS A PACKING TO TIGHTEN THE ANCHOR BOLTS WITH

BEARING TOP PLATE & BOTTOM PTATE.

160

STD. WASHER

TOTAL HEIGHT

SECTIONAL ELEVATION A-A OF POT 2.8 INTERNAL SEAL WILL BE PROVEN TYPE POLY OXY METHYLENE ( POM ) SEALING CHAIN.PROPERTIES

= 124.0+3.0

BfØ BOLT X lg AS SPECIFIED IN THE TABLE 4.4 OF IRC : 83 ( PART III ) - 2018.

2.9 EXTERNAL SEAL WILL BE GLUED WITH POT BY ADHESIVE MATERIAL.

ANCHOR SLEEVE 3.0 WELDING :

(For Top & Bottom) ALL WELDING WILL BE MANUAL METAL ARC PROCESS CONFIRMING TO IS : 816 & IS : 9595 WITH

04 LUGS FOR ANCHOR BOLTS ELECTRODE AS PER IS : 814.

4.0 TOLERANCES :

EQUIDISTANT AT A4 Ø = 520.0 P.C.D. GENERALLY MANUFACTURING TOLERANCES AS PER CL. 6.1 OF IRC : 83 (PART III) -2018.

160

5.0 FINISHING : (AS PER CL. NO. 6.3 OF IRC : 83 (PART III) - 2018)

1. ALL NON WORKING SURFACES WILL BE COATED WITH TWO COATS OF EPOXY PRIMER AND ONE OR

MORE COATS EACH OF HIGH BUILD EPOXY PAINT REINFORCED WITH MIO (MICACEOUS IRON OXIDE)

ANCHOR SLEEVE

& FINISH PAINT AFTER SHOT BLASTING TO SA 2 1/2 QUALITY AS PER IS : 9954. TOTAL DRY

FILM THICKNESS > / = 160 microns.

2. ANCHOR SLEEVES WILL BE GALVANISED PAINT BEFORE DESPATCH.

PEDESTAL

SECTIONAL ELEVATION X-X 18Ø MM HOLE FOR

6.0 INSTALLATION :

1. INSTALLATION AS PER CL. 9.4 OF IRC : 83 (PART III) -2018.

2. MATERIAL IN CONTACT WITH BEARING :

M16 ANCHOR BOLT

Ll=70

SUPERSTRUCTURE : CONCRETE ( M45 GRADE MIN. ) ; PEDESTAL : CONCRETE ( M45 GRADE MIN. )

90 12

° D5Ø 3. DISMANTLING OF BEARING AT SITE IS NOT RECOMMENDED. IF REQUIRED , SPECIAL CARE SHOULD

PISTON 28 BE TAKEN.

w=8 4. CLAMPS ( FOR TRANSPORTATION AND ERECTION ) ARE TO BE REMOVED AFTER INSTALLATION AT

TOP PLATE AN APPROPRIATE TIME.

POT 5. THE GROUT OF THE BEDDING MORTAR SHALL BE HIGH STRENGTH FREE FLOW NON SHRINK

GROUT SUCH AS CONBEXTRA - GP2 OR EQUIVALENT.

7.0 GREASING :

'A' 'A' DETAIL - E

±elong.

SILICON GREASE WILL BE APPLIED AT PTFE STAINLESS STEEL INTERFACE.

8.0 TESTS :

1. RAW MATERIALS : NECESSARY TEST CERTIFICATES FOR ALL RAW MATERIALS SHALL BE

FURNISHED BY MANUFACTURERS.

2. ACCEPTANCE TESTS ON BEARINGS SHALL BE CARRIED AS PER CL.7.4.3 OF IRC : 83 (PAR III)- 2018.

LONGITUDINAL MOVEMENT

2.1 BEARINGS WILL BE CHECKED FOR OVERALL DIMENSIONS.

2.2 BEARINGS WILL BE VERTICAL LOAD TESTED TO 1.5 x DESIGN VERTICAL LOAD IN SLS CONDITION.

2.3 A PAIR OF BEARINGS SELECTED AT RANDOM WILL UNDERGO TESTING IN ORDER TO DETERMINE

90 THE COEFFICIENT OF FRICTION AT DESIGN VERTICAL LOAD IN SLS CONDITION.

° 2.4 BEARINGS SELECTED AT RANDOM WILL BE TESTED FOR PERMISSIBLE ROTATION.

2.5 THE CERTIFICATES FOR LOAD TESTING AND DIMENSIONS OF ALL BEARINGS WILL BE SUBMITTED

tp= 8 mm THK. PTFE Sheet TO THE DEPARTMENT.

PLAN OF POT (Dimpled) 9.0 POT / PTFE BEARINGS WILL BE DESIGNED, MANUFACTURED & TESTED AS PER

5.0

3mm Protrusion IRC : 83 ( PART III ) - 2018 SPECIFICATION.

C2=40

'X' 'X'

2mm THK. S.S. PLATE Dp Ø = 346.0

BW = 480.0 'E'

B2=26 Ll=70 SECTIONAL ELEVATION C-C OF PISTON

Lt=15

±elong.

10 EXTERNAL SEAL ELASTOMER 1

LUGS CAST STEEL

9

(Ll x Ll x Lt)

70 x 70 x 15 (GRADE 340-570W) 8

SECTIONAL ELEVATION B-B OF TOP PLATE ELASTOMER

8 WIPER SEAL 8mm WIDE ALL AROUND PTFE 1

DIRECTION

7 INTERNAL SEAL POM SEAL

TRAFFIC

PLAN POT CAST STEEL

18Ø MM HOLE FOR 6

(A1Ø/A7Øx AH1/A6/A2)

450 Ø / 450 Ø x 71 / 46 / 25 (GRADE 340-570W) 1

( SHOWING HALF POT , HALF PISTON M16 ANCHOR BOLT ELASTOMERIC PAD

5

(D5 Ø x Nt)

350 Ø x 28 ELASTOMER 1

& TOP PLATE )

4 PISTON CAST STEEL 1

420 Ø x 346 Ø x 40

Ll=70

(C3 Ø x Dp Ø x C2) (GRADE 340-570W)

P.T.F.E. 380 Ø x 8.0 Grade A of

'C' 'C' 3

BS:3784 1

(L Ø x tp)

S.S. SHEET S.S.

2 470 x 440 x 2 1

(SSPl x SSPw x SSPt) AISI : 304

SSPl = 470.0

TOP PLATE CAST STEEL

430.0 c/c

1 500 x 480 x 26 (GRADE 340-570W) 1

(BL x BW x B2)

BL = 500.0

NO. DESCRIPTION SIZE MATERIAL QTY.

L Ø = 380.0

LIST OF MATERIAL

C3 ∅ = 420.0

hn=10

PLAN OF PISTON BEARINGS FOR MAJOR BRIDGE AT

CH: 2+120 BRAHMANI RIVER

'B' 'B'

SSPw = 440.0

PROJECT REHABILITATION AND UPGRADATION TO FOUR LANE OF

DIRECTION

TRAFFIC

BRIMITRAPUR - BRAHMANI BYPASS END OF NH - 23

( NEW NH - 143 ) KM.211.200 TO KM.217.100 & KM.0.000 TO

KM. 3.300 IN THE STATE OF ODISHA UNDER NHDP PHASE - IV

CLIENT NATIONAL HIGHWAYS AUTHORITY OF INDIA

DETAIL - D

EPC

CONTRACTOR

M/s GKC PROJECT LIMITED

550.0 c/c

SUB

M/s PRA PROJECTS PRIVATE LIMITED

CONTRACTOR

PLAN OF TOP PLATE

TITLE DETAIL OF 333 TON FREE SLIDING POT / PTFE BEARING

FREE SLIDING POT / PTFE BEARING DETAILS - TYPE FRB1

DYNAMIC PRESTRESS (I) PVT. LTD. SCALE :

TECHNICAL DATA Corporate Off. : 72, Mahavir Centre, Sector - 17 N. T. S

Vashi, Navi Mumbai - 400 705

ULS SLS DESIGN MOVEMENT SLEEVE ANCHOR POT PCD DIST. BETN. Tel : (022) 2789 1310 / 2628 Fax : 2789 1186 DESIGN BY :

SLEEVE LENGTH (L) TOTAL

(mm) DIAMETER BOLT Web Site : www.dynamicprestress.com KUNAL

FREE NORMAL SEISMIC NORMAL DESIGN A4Ø SIDE GUIDE BEARING

FOR BOTTOM / TOP BOTTOM(Lb) TOP(Ls) (BfØX lg) Email : dynamicmumbai@gmail.com, mumabi@dynamicprestress.com

SLIDING ROTATION EC THICKNESS

Max. Min. Design Max. Min. Design Max. Min. Design (DØ) (Gr. 4.6) Works : E-46, M.I.D.C. Satpur, Nasik - 422 007 CHECKED BY :

BEARING - (RADIANS)

Vertical Vertical Horizontal Vertical Vertical Horizontal Vertical Vertical Horizontal LONGITUDINAL TRANSVERSE Tel : (0253) 2351411, 660129, 6601628 Fax : 2361853

TYPE FRB1 Load Load Force Load Load Force Load Load Force

elong etrans 40.0 160.0 160.0 16Ø x 40 520.0±2.0 ----- 124.00 + 3.0 NOTE : E-mail : dynamic.nasik@gmail.com, nasik@dynamicprestress.com GIRISH

333.0 TON 0.00 kN 0.00 kN 0.00 kN ± 26.00 ± 0.0002 OTHER DETAILS OF BEARING THIS DRAWING IS THE PROPERTY OF DYNAMIC PRESTRESS (I) PVT. LTD. DRG. NO. REVISION DATE

196.0 TON 333.0 TON 196.0 TON 216.0 TON 143.0 TON ± 40.00

AND SHOULD NOT BE COPIED / USED WITHOUT PRIOR PERMISSION.

DPIL / PRA_ODISHA / BRAHMANI RIVER BRIDGE / CH: 2+120 / 333 TON FREE / TYPE FRB1 R0 30.06.2020

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chamba Tunnel DrawingsDocument51 pagesChamba Tunnel DrawingsAnkush Sharma100% (1)

- GalleyDesignandSystem - Vol. - 1 PracticalSailor PDFDocument41 pagesGalleyDesignandSystem - Vol. - 1 PracticalSailor PDFyigit100% (1)

- MGT 610 Strategic Management Mid Term Fall 2020Document2 pagesMGT 610 Strategic Management Mid Term Fall 2020NazibMahmudChowdhury0% (1)

- Massimo Bottura Recipes 01Document10 pagesMassimo Bottura Recipes 01Gustavo Hernandez100% (5)

- 40m STEEL COMPOSITE (4girder)Document3 pages40m STEEL COMPOSITE (4girder)Ankush SharmaNo ratings yet

- Type FXB1. 333 Ton Fixed Bearing DesignDocument7 pagesType FXB1. 333 Ton Fixed Bearing DesignAnkush SharmaNo ratings yet

- Property For 76 M TrusDocument1 pageProperty For 76 M TrusAnkush SharmaNo ratings yet

- 28m STEEL COMPOSITE (4 Girder)Document3 pages28m STEEL COMPOSITE (4 Girder)Ankush SharmaNo ratings yet

- P1 Pier-Circular 235.891.Document103 pagesP1 Pier-Circular 235.891.Ankush SharmaNo ratings yet

- Design of Precast Pier Cap - 1Document24 pagesDesign of Precast Pier Cap - 1Ankush SharmaNo ratings yet

- 255+ Abut. A1 FixDocument70 pages255+ Abut. A1 FixAnkush SharmaNo ratings yet

- Design of Superstructre 16.12.2020Document54 pagesDesign of Superstructre 16.12.2020Ankush SharmaNo ratings yet

- Type FRB1. 333 Ton Free Sliding Bearing DesignDocument8 pagesType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaNo ratings yet

- Temprorary Structure Design 30-07-2020Document15 pagesTemprorary Structure Design 30-07-2020Ankush SharmaNo ratings yet

- Design of Substructure and Foundations of Abutment - Ch. 420+400Document126 pagesDesign of Substructure and Foundations of Abutment - Ch. 420+400Ankush SharmaNo ratings yet

- Section 1-1: Concrete Grade - M40Document1 pageSection 1-1: Concrete Grade - M40Ankush SharmaNo ratings yet

- Design Report-Raturisera Landslide - 08.01.2022 (R1)Document213 pagesDesign Report-Raturisera Landslide - 08.01.2022 (R1)Ankush Sharma100% (1)

- PSCG 20m 35SK R0Document149 pagesPSCG 20m 35SK R0Ankush SharmaNo ratings yet

- Deck Design 17.12.2020Document7 pagesDeck Design 17.12.2020Ankush SharmaNo ratings yet

- Pile and Pile Cap Details (P1 To P15)Document1 pagePile and Pile Cap Details (P1 To P15)Ankush SharmaNo ratings yet

- 1.retaining Wall 9MDocument1 page1.retaining Wall 9MAnkush SharmaNo ratings yet

- 1X2X2 WITH 1M PrecastDocument56 pages1X2X2 WITH 1M PrecastAnkush SharmaNo ratings yet

- Typical Rock Bolt Pattern (Class-Ii) Typical Rock Bolt Pattern (Class - Iii)Document6 pagesTypical Rock Bolt Pattern (Class-Ii) Typical Rock Bolt Pattern (Class - Iii)Ankush Sharma100% (1)

- Cipld 1036 WW Flyover 313+850 ST DWG 301 PDFDocument3 pagesCipld 1036 WW Flyover 313+850 ST DWG 301 PDFAnkush SharmaNo ratings yet

- Cover PageDocument1 pageCover PageAnkush SharmaNo ratings yet

- North and South Portals and LayoutDocument6 pagesNorth and South Portals and LayoutAnkush SharmaNo ratings yet

- Gabion Wall Design - 4.0 MTR Above GLDocument8 pagesGabion Wall Design - 4.0 MTR Above GLAnkush SharmaNo ratings yet

- Typical Detail of Drain and Utility DuctDocument1 pageTypical Detail of Drain and Utility DuctAnkush SharmaNo ratings yet

- S.F (KN)Document1 pageS.F (KN)Ankush SharmaNo ratings yet

- Steel Rib Portal ReachDocument14 pagesSteel Rib Portal ReachAnkush Sharma100% (1)

- SandwichDocument12 pagesSandwichNeil Francis Yucot ValmoresNo ratings yet

- Heat and Temp QuizDocument2 pagesHeat and Temp QuizAna Marie RentonNo ratings yet

- Wood Conserving StovesDocument117 pagesWood Conserving Stovesalitoparana100% (1)

- 5.1 & 5.2 Metals & Non-MetalsDocument59 pages5.1 & 5.2 Metals & Non-MetalsphuctwoanNo ratings yet

- Tapayan JarDocument3 pagesTapayan JarRicoNo ratings yet

- User Manual: CCB 5140 XADocument16 pagesUser Manual: CCB 5140 XAMircea FrantNo ratings yet

- 90 Incredible QUICK BREAD Recipes!!!Document39 pages90 Incredible QUICK BREAD Recipes!!!rodrigues06100% (2)

- Panama: Packaging Information Technical SpecificationDocument1 pagePanama: Packaging Information Technical Specificationone borneoNo ratings yet

- Pot Bearings For Bridges and StructuresDocument10 pagesPot Bearings For Bridges and StructuresRatna Emmanuella NovitasariNo ratings yet

- Owners Manual WOC54EC0ASDocument32 pagesOwners Manual WOC54EC0ASAlex WellmanNo ratings yet

- Samsung Appliance Fer300sx Use and Care ManualDocument44 pagesSamsung Appliance Fer300sx Use and Care ManualAnonymous xpo7HAINo ratings yet

- Sports Nutrition Recipe BookDocument20 pagesSports Nutrition Recipe BookPetar GranićNo ratings yet

- Marbled Slipware1 PDFDocument5 pagesMarbled Slipware1 PDFPilar Vezzani VaillantNo ratings yet

- Uh Procedure Text XiDocument2 pagesUh Procedure Text XiMutia Chimoet100% (13)

- The Way of Tea CeramicsDocument3 pagesThe Way of Tea CeramicsdmicucciNo ratings yet

- Tle-Bpp 8-Q1-M3Document14 pagesTle-Bpp 8-Q1-M3IvanJosh Pangan13100% (3)

- Properties of Materials and Their UsesDocument45 pagesProperties of Materials and Their UsesEmely Balao-asNo ratings yet

- Food Recipes For Kids.Document10 pagesFood Recipes For Kids.Wijayasekara BuddhikaNo ratings yet

- Estufa Rangers GEDocument56 pagesEstufa Rangers GEVictor Manuel Valdez del BosqueNo ratings yet

- Quartermaster HandbookDocument9 pagesQuartermaster HandbookBen BandojoNo ratings yet

- Earn A Good Life With Tupperware.: Celebrating 25 Years in India and 75 Years GloballyDocument30 pagesEarn A Good Life With Tupperware.: Celebrating 25 Years in India and 75 Years GloballyKirtan J. PatelNo ratings yet

- Food Production X BookDocument60 pagesFood Production X BookSAM VISH85% (13)

- Mustard Chicken, Quick Dauphinoise, Greens, Black Forest AffogatoDocument2 pagesMustard Chicken, Quick Dauphinoise, Greens, Black Forest Affogatodjeff71No ratings yet

- Catalog AccuraDocument40 pagesCatalog AccuraHusnul Mariati, S.pdNo ratings yet

- Sporák Instalace A Pou Ití: Cooker Installation and Use Konyhabútor Beépítés És HasználatDocument44 pagesSporák Instalace A Pou Ití: Cooker Installation and Use Konyhabútor Beépítés És HasználatZbarl33chNo ratings yet

- China Pottery AnalysisDocument10 pagesChina Pottery AnalysisNikhil ToshniwalNo ratings yet

- Marinated Mussels With ChorizoDocument2 pagesMarinated Mussels With ChorizoPatrick ManahanNo ratings yet