Professional Documents

Culture Documents

Design and Leak-Tightness Analysis of Volute Casing For Axially Split Multistage Centrifugal Pump

Uploaded by

Ahmed ShawkiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Leak-Tightness Analysis of Volute Casing For Axially Split Multistage Centrifugal Pump

Uploaded by

Ahmed ShawkiCopyright:

Available Formats

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

Design and Leak-tightness Analysis of Volute Casing for Axially Split

Multistage Centrifugal Pump

Aniket A. Pore 1, Nilesh R. Raykar 2, Nilesh Patil 3

1 M.Tech. Student (Machine Design), Department of Mechanical Engineering, Sardar Patel College of Engineering,

University of Mumbai, Mumbai, Maharashtra-400058, India

2 Professor, Department of Mechanical Engineering, Sardar Patel College of Engineering, University of Mumbai,

Mumbai, Maharashtra-400058, India

3 Assistant Manager (Engineering), Mechanical Department, Kirloskar Ebara Pumps Ltd, Kirloskarwadi, Sangli,

Maharashtra-416308, India

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract - In axially split centrifugal pumps, leakage 1. INTRODUCTION

of internal fluid along the casing flanges due to high A pump is machinery used to transfer the fluids such as

water, oil, chemicals, etc. One of the most common types of

pressure of fluid is an important factor which critically

pump used in industry is the centrifugal pump. Centrifugal

affects the pump performance. This paper deals with pumps can have single or multiple stages. For multistage

the design and leak-tightness analysis of four stage BB3 pumps, several impellers are mounted on a single shaft

pump casing. The design approach for pump and the stages operate sequentially, that is, the discharge

components depends on its type. American Petroleum from the first stage flows into the eye of the second stage,

Institute (API) Standard 610 is the international the discharge from the second stage flows into the eye of

standard used for classification, design and testing of the third stage, and so on. The flow rate is same through

all stages, but each stage develops an additional pressure

pumps. The pumps are classified into many types

rise to cumulatively develop the required total head. Thus,

depending on construction, geometrical features and a very large discharge pressure or head can be developed

working and centrifugal pump is one of the most by a multistage pump.

common types. As per API standard 610, BB3 is a

multistage axially split centrifugal pump which is American Petroleum Institute Standards-610 [1] is the

normally used in chemical industries. The casing of the international standard used for design and testing of

BB3 pump is designed on the basis of impeller outlet pumps. It also gives the pump classification and

identification of types As per API, the centrifugal pumps

parameters to satisfy both strength and leak tightness

are divided into three types on the basis of number of

criteria. Due to intricate profile of casing and sealing stages, orientation and the position of principal joint; the

gasket, the casing needs to be analyzed using three- three types are: overhung, between bearing (BB) and

dimensional (3D) stress analysis. Geometric modeling vertically suspended. Between bearing pumps are further

of top and bottom casings is done by using 3D modeling divided into BB1, BB2, BB3, BB4 and BB5. Type BB3 is a

software Creo 2.0 and analyzed for strength and leak multistage axially split centrifugal pump (Fig -1) which is

normally used in chemical industries, oil industries,

tightness against the maximum allowable working

descaling applications in steel industries, etc. The BB3

pressure using finite element code. The design pump is usually employed for high flow rates up to 1500

calculations are performed as per industry accepted m3/hr and high pressure heads up to 1650 m. One of the

handbook and API standard 610. The casing is analyzed major advantages of BB3 pump is its easy maintenance as

in 3D using commercial software ANSYS®. The compared to other types because the rotor can be

deflection and equivalent Von Mises stresses within removed by disassembling only upper half casing.

casing are studied. The equivalent Von Mises stress

API standard recommends that the pumps are to be

results are used to check the strength of the pump

designed for minimum service life is 20 years and for

casing. The deformation results on top and bottom uninterrupted operating service of at least for 3 years. The

flanges faces are evaluated for leak-tightness analysis. standard also includes basic design of pump casing. The

casing is designed to operate without leakage while

subjected to simultaneous action of maximum allowable

Key Words: API 610, BB3, Centrifugal pump, FEA, working pressure (MAWP) and maximum operating

temperature.

MAWP, volute.

© 2015, IRJET ISO 9001:2008 Certified Journal Page 73

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

The axially split construction of pump is prone to leakage

along the flange due to high working pressure and

intricate gasket profile (Fig -2). Analytical procedure to

check such leakage is complicated. The leak tightness

along the gasket is an important aspect of casing design.

Singer and Johne [9] have provided guidelines for rigorous

pump casing design include the methods for leak tightness

analysis.

Fig -1: Typical BB3 Pump [2] Path prone to

leakage

Proper selection of material is an important parameter

while designing the casing of the centrifugal pump. For

many pumping application, cast iron is preferred for pump

casings primarily on the basis of cost. For corrosive or

hazardous petroleum products, cast steel or cast stainless

steel is preferred [3].

While there are many methods to perform the design of

volute casing, the procedure recommended by Karassik Fig -2: Path prone to leakage of BB3 pump

[4] and Stepanoff [5] are widely used by industry.

Towards the end of the basic design for pump, preliminary In this paper, initially the basic geometry of pump casing is

drawings for volute casing are generated. At this stage, calculated using procedure suggested by Karassik [4].

detailed finite element analysis for the casing may be Later the CAD model for the pump volute casing is

carried out prior to release of production drawings. developed. This is used to create finite element model for

the casing. The casing is checked for induced stresses

The centrifugal pump design is typically verified by FE against the maximum allowable working pressure

techniques. Thin et al. carried out computational analysis (MAWP) with appropriate boundary conditions.

and performance analysis of centrifugal pump. Shock Deformations at critical regions are checked to analyze the

losses, impeller friction losses, volute friction losses, disk leak-tightness.

friction losses and recirculation losses of centrifugal pump

were considered in performance analysis of centrifugal 2. DESIGN OF CASING

pump. Prasad et al. [6] analyzed a centrifugal pump The present study is performed on a new model of four

impeller which is made of three different alloy materials, stage BB3 pump being developed by KEPL, Kirloskarwadi.

namely, Inconel 740, Incoloy 803 and Warpaloy to Material selected for BB3 pump casing is ASTM-A352-GR

estimate its performance. The investigation was done by LC3 Cast/carbon steel (yield strength = 275 Mpa) based on

using CATIA for modeling the impeller and ANSYS for API standard recommendation and customer requirement.

determination of the variation of stresses, strains and Design parameters for the pump are follows.

deformation across profile of the impeller. HYPER MESH Required head (H) = 520 m

9.0 was used to generate optimum FE discretization of the Required flow rate (Q) = 1040 m3/hr

impeller to obtain accurate results. A structural analysis Speed of Pump (N) = 1400 rpm

was carried out to investigate the stresses, strains and

displacements of the impeller and modal analysis was 2.1 Basic Design of Volute Casing

performed to investigate the frequency and deflection of First stage volute design:

the impeller. By comparing the results obtained for three For BB3 pump, first stage is having double suction

different alloys, the best alloy for impeller was suggested. impeller as per API standard.

Gowd et al. [7] carried out a finite element analysis for

some mechanical components of the high-pressure Specific Speed (Ns):

hydraulic pumps by ANSYS software. For obtaining some

proper results, the real model of the loading diagram had (1)

built. They found that the possibility of increasing the where

nominal operating pressure up to 420 bar, without Ns= specific speed

changing the materials. Mona Golbabaei Asl et al. [8] N= Speed of pump (r.p.m)

carried out experimental and FEM failure analysis for H1= Head developed by first impeller

optimization of a centrifugal-pump volute casing.

© 2015, IRJET ISO 9001:2008 Certified Journal Page 74

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

Ns = 23.040

Fig -3 correlates specific speed vs. ratio of throat velocity

to impeller peripheral speed [10]. From this Fig. 3, average

value for ratio, Tongue angle

øt

Cthr. = Throat velocity (m/s)

u2 = Impeller peripheral speed

Fig -4: Volute Casing

Intermediate areas can be calculated as follows,

(4)

Radius of intermediate area can be calculated as,

(5)

where

rθ = Radius of intermediate section of volute at angle θ

(mm)

Aθ = Area of intermediate section of volute at angle θ

(mm2)

θ = Central angle (degree)

The distances of section centre at angle θ from axis is

Fig -3: Specific speed vs. ratio of throat velocity to calculated as follows,

impeller peripheral speed [10] (6)

where

Hence, Cthr. = 23.804 m/s rθ' = Distance of section centre at angle θ from axis (mm)

Tentative throat area (Athr.):

First, the velocities of volute areas at angle θ are

(2) calculated, for which previously calculated distance of

centre of each section at angle θ from axis (rθ') are used.

Assuming a circular throat section, its radius is (7)

where

Cθ = Velocity of volute areas at angle θ (m/s)

(3) C = Constant factor

Cu3 = Peripheral component of impeller discharge velocity

(m/s)

Distance of the throat centre of the throat section from Intermediate areas can be calculated as follows,

axis is calculated as:

(8)

where

r₄= Distance of the throat centre from axis (mm) By Karassik method, the tentative choice of the throat

r₂= Radius of impeller (mm) velocity is checked by following equation,

t= Tongue distance (mm)

(9)

The intermediate volute areas are calculated on the basis where

of constant angular momentum. Stepanoff [10] C’u3 =Peripheral component of impeller discharge velocity

recommends a constant mean velocity for all volute (m/s)

sections, which results in volute areas being proportional

to the central angle θ (Fig. 4).

A modification of volute dimensions by considering the

effect of constant factor C is suggested by Karassik [4]. The

dimensions obtained for volute from above procedure

© 2015, IRJET ISO 9001:2008 Certified Journal Page 75

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

may be acceptable, but for smoother volute and

frictionless flow, factor C must be considered.

For frictionless flow, C=1, according to the law of constant

angular momentum. Experience has shown that C=1 is

indeed a good design value for volute of large pumps or

very smooth volutes of medium size pumps. For

commercially cast volutes of medium size and small

pumps, the value C=0.9 gives a reasonable approximation.

The value for constant factor C is calculated from equation

(9) is 1.2449. But according to the comment under volute

casing this appears to be a very reasonable factor C. So the

volute dimensions are modified from throat area which Fig -5: Trapezoidal shape for intermediate area of

will be modified by the throat velocity by considering volute[4]

frictionless flow i.e. constant factor C=1.

Hence, bmax ≈ 110(mm)

Putting the value of constant factor C=1 in equation (9)

and get modified throat velocity as follows The tongue angle ( ) may found by assuming that the

flow follows a logarithmic spiral.

(11)

Hence,

In this way, the throat velocity is modified. Here

comparing this modified throat velocity with previous And to avoid shock losses, consider the tongue angle

throat velocity, it is observed that the throat velocity are

decreased (Cthr.(Modified) = 19.120 m/s and Cthr. = 23.804

m/s). As the velocities near the tongue are decreased, this Calculation of 2nd, 3rd and 4th stage volute casing:-

implies that the throat area is increased, which is helpful Next three stages produce equal heads and their impeller

to avoid the excessive losses due to higher flow rates. By dimensions are same. Therefore the volute casing

using modified throat velocity and following the same geometry is same for 2nd, 3rd and 4th stage. And design

design, the final volute dimensions such as A θ and rθ are procedure is same as that for the first stage.

finalized after doing three iterations.

Design of pump casing volute thickness:

The trapezoidal shape for intermediate area of volute is The maximum discharge pressure is the maximum suction

selected for better efficiency (Fig -5). The trapezoidal pressure plus the maximum differential pressure that the

shape makes the entrance width of the volute to be pump is able to develop when operating with the rated

appreciably greater than the impeller discharge width (b2) speed and specified normal relative density. The

which leads to smooth flow. maximum discharge pressure is obtained from following

expression.

(10) (12)

where where

b3 = Minimum entrance width of volute casing (mm) Pd= Maximum discharge pressure (N/m2)

b2 = Width of impeller (mm) ρ= Density of pumping fluid (kg/m3)

bmax = Maximum entrance width of volute casing (mm) = 1000 kg/m3

q = Shroud thickness (mm) h = 630 (m) = Shut off head

x= Distance between any radius rθ and impeller radius r2

(mm) Pd= 1000*9.81*630 = 61.803 bar

Total head = Suction head + Max .Discharge Head +1.1% Pd

generally considered as 60 degree = 1000*9.81*11.7 + 61.803 + 1.1*61.803/100

= 63.629 bar

The pressure temperature rating chart given by American

Society of Mechanical Engineers (A.S.M.E.) B 16.5 [11] for

the given material is used to choose the pump rating class.

© 2015, IRJET ISO 9001:2008 Certified Journal Page 76

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

Table -1: Pressure-Temperature Ratings for Group 1.2 D = 1179.722 mm = 46.445 inches.

Materials [11]

From ASTM B16.47-2006, thickness of casing at 103.4 bar

pressure and at ambient temperature 46” class 600

Class flanges is 179.4 mm.

150 300 400 600 900

Temp. (° C)

The thickness of casing at maximum discharge pressure is

calculated as 110 mm.

-29 to 38 19.8 51.7 68.9 103.4 155.1

50 19.5 51.7 68.9 103.4 155.1 And by considering corrosion allowance and for more

safety thickness of casing is finalized as 140 mm.

100 17.7 51.5 68.7 103.0 154.6

The total separating force acting on casing halves is

150 15.8 50.2 66.8 100.3 150.5

calculated using total volute area and the pressure exerted

200 13.8 48.6 64.8 97.2 145.8 on volute. Size and minimum number of bolts required to

withstand this force is calculated as M48 x 52 numbers.

250 12.1 46.3 61.7 92.7 139.0

2.2 Structural Analysis of Casing Using Ansys

For maximum differential pressure Pd=63.629 bar and Geometric Modeling of casing is done using 3D modeling

operating temperature T= 65° C, 600 rating class is found software PTC Creo 2.0 and the geometry is imported in

suitable for the pump casing material (Table -1). The ANSYS software. Structural analysis of casing is performed

maximum working pressure for 600 rating class at to determine stresses and deformations induced in the

ambient temperature is considered as design pressure for casing. The details of FE analysis is summarized below.

the casing thickness calculations.

FE discretization of Top and Bottom models:

Maximum working pressure at ambient temperature for The details of discretization are given in Table -2.

600 rating class = 103.4 bar. Pump casing volute thickness

is calculated as per the rules of ASME section VIII, division- Table -2: Meshing specifications

2 [12].

Sr. Model Elements Nodes

Casing volute thickness is given by following equation. No.

1 Bottom Casing 2562765 3916206

(13)

where, 2 Top Casing 83824 143100

T = Casing volute thickness (m)

P = Maximum working pressure at ambient temperature

(N/m2) = 103.4 bar Figs. 6, 7 show FE discretization of bottom and top casing

respectively.

r = Maximum radius of impeller which can fit in casing

from volute CAD model (m) = 730 mm

= Casting factor = 0.8

σ = Design stress (N/m2)

Design stress value is taken as minimum value obtained

from 0.25 times the tensile strength and 0.67 times the

yield strength which is 1240 bar for casing material.

Thus, .

The provided thickness for volute casing is 52 mm.

Flange thickness calculation: Fig -6: FE model of Bottom Casing

Using the geometry of 3D-model of casing, total volute

area is calculated as,

Total Volute area = 1093074 mm2

Considering, Casing as a cylindrical body,

© 2015, IRJET ISO 9001:2008 Certified Journal Page 77

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

Maximum

deformation

of gasket

location is at

point A

Fig -10: Total deformation of top casing at gasket area

Fig -7: FE model of Top Casing

The inside surface of casing is subjected to the maximum

allowable working pressure of 103.4 bar (Figs. 8, 9). Both

top and bottom casings are analyzed independently. Both

top and bottom casing models are fixed in all degrees of

freedom at the bolt hole edges.

Fig -11: Von-Mises stresses in Top Casing

Deformation

Fig -8: Applied pressure on bottom casing of gasket

location at

Point A

Fig -12: Total deformation of Bottom casing at gasket area

Fig -9: Applied pressure on top casing

3. RESULTS AND DISCUSSIONS

The total deformation and equivalent Von Mises stresses

induced in the casing are shown in Figs. 10,11,12,13.

Fig -13: Von-mises stresses in Bottom Casing

Peak induced stress is observed at the bolt hole locations;

however it can be neglected since it includes stress

concentration effect due to fixity enforced on bolt hole

© 2015, IRJET ISO 9001:2008 Certified Journal Page 78

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

edges. Equivalent Von Mises stresses caused are given in within allowable limits thus indicating sufficiency of the

Table -4. And neglecting peak stresses and stresses at the strength of casing wall thickness.

boundary conditions, the maximum induced equivalent

Von Mises stress is 157.74 MPa which is less than material The total deformation along flange joint is found to be less

allowable stress 183.34 MPa. than the industry guideline, thus signifying leak-tightness

of the critical gasket joint. Also, the overall deformation of

Table -3: Equivalent Von Mises stresses on casing casing body is within the norm followed by manufacturer.

Casing Equivalent stresses Material Allowable This work successfully demonstrates a simplified method

(Von Mises) (Mpa) Stress to design volute body and to analyze leak tightness across

bolted flange joint of axially split centrifugal pump casing.

= (yield strength/1.5)

(Mpa) ACKNOWLEDGEMENT

Minimum Maximum The work is a part of project program supported by

Kirloskar Ebara Pumps Ltd., Kirloskarwadi, India. Authors

Top 0.00004 103.25 183.34 would like to thank Mr. Amit Modak and Mr. Yashodhan

casing Samak for their valuable support.

Bottom 0.001 157.74 183.34

casing REFERENCES

The total deformations in casing are given in Table -4. The [1] “American Petroleum Institute Standards-610,”

maximum deformations of top and bottom casings are (Pump Hand book), Eleventh Edition, September

0.29 mm and 0.33 mm respectively which are acceptable 2010

as per manufacturer’s norms. [2] http://kepl.in.net/products/pumps/api-process-

pumps/between-bearing-type/kb3s--kb3d-sp--spd-

Table -4: Total deformation of casing pump.html

[3] Khin Cho Thin, MyaMyaKhaing, and KhinMaung Aye

Casing Pressure Total deformation “Design and Performance Analysis of Centrifugal

(Maximum) (mm) Pump,” published on 2007

[4] Igor J. Karassik, Joseph P. Messina, Paul Cooper,

Minimum Maximum

Charles C. Heald “ Pump Hand Book,” TATA McGraw-

Hill, 3rd Edition 2001

Top casing 103.4 bar 00 0.29423

[5] Stepanoff A J”, “Centrifugal and Axial Flow Pumps”,

John Wiley and Sons Inc., London 1993 pp.

Bottom 103.4 bar 0.00004 0.32752

27,110,111,119

casing

[6] A Syam Prasad, BVVV LakshmipathiRao, A Babji, Dr P

Kumar Babu“Static and Dynamic Analysis of a

At gasket location, there are maximum deformations at

Centrifugal Pump Impeller” published on October,

point A in case of both top and bottom casings.

2013

[7] Dr. B. Uma MaheswarGowd and Dr. A. Chennakesava

To avoid leakage along flange joint, it is necessary to limit

Reddy “FINITE ELEMENT ANALYSIS OF AXIAL

the total deformation at gasket location, i.e., deformation

PISTON PUMPS USING ANSYS” published on JNTU

of bottom casing plus deformation of top casing flange at

College of Engineering

point A.

[8] Mona GolbabaeiAsl , RouhollahTorabi , S. Ahmad

Total Maximum deformation at flange (at point A)

Nourbakhsh, “Experimental and FEM failure analysis

=0.10917+0.098 (mm) = 0.20717 mm

and optimization of a centrifugal-pump volute

casing,”published on 10th February 2009

The maximum deflection at the flange joints of casings is

[9] Michael Singer and Torsten Johne “Design of Pump

0.21 mm which is less than gasket thickness of 0.50 mm.

Casings: Guidelines for systematic Evaluation of

As per prevailing industry guideline, the computed

Centrifugal Pump Pressure Boundary Failure Modes

deformation levels will restrict leakage at the flange joint.

and Their Mechanisms” published on October, 2013.

[10] Book (A H Church19) Centrifugal Pumps and Blowers

4. CONCLUSIONS willey 1944 pp. 142

The volute casing design for BB3 type multistage axially [11] “Pipe flanges & flange fittings” by, American Society

split centrifugal pump was successfully developed using for Mechanical Engineers (A.S.M.E.) B 16.5, published

procedure given by Karassik [4]. The stress values on 29, October 2004, pp. 2,6,8,12,36.

obtained from the finite element analysis results are

© 2015, IRJET ISO 9001:2008 Certified Journal Page 79

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395 -0056

Volume: 02 Issue: 05 | Aug-2015 www.irjet.net p-ISSN: 2395-0072

[12] American Society for Mechanical Engineers, “Boiler &

pressure vessel code” Section VIII, division 2.

BIOGRAPHIES

Mr. Aniket Ashok Pore

received BE in Mechanical

Engineering in 2013 from JSPM’s

Jayawantrao Sawant College of

Engineering, Pune and pursuing

Master of Technology in Machine

Design from Sardar Patel College

of Engineering, Mumbai.

Dr. Nilesh R. Raykar completed

his Ph.D. from IIT Bombay in

2013, M.Tech. from IIT Bombay in

1990 and graduated in

Mechanical Engineering from

VJTI in 1988. He is currently

working as Professor at Sardar

Patel College of Engineering,

Mumbai. He has 19 years of

industry experience with Larsen

and Toubro, Powai Campus,

Mumbai. His research interests

include modelling of

environmentally assisted

cracking, fatigue and fracture

based design and process

equipment and piping design.

Mr. Nilesh N. Patil received BE

in Mechanical Engineering in

2008 from Rajarambapu Institute

of Technology, Islampur. He is

having total 7 years of industrial

experience.

© 2015, IRJET ISO 9001:2008 Certified Journal Page 80

You might also like

- Piping Design Guide for PumpsDocument58 pagesPiping Design Guide for PumpsSkr9143 Shiv100% (1)

- Design and Performance Curve Generation by CFD Analysis of Centrifugal PumpDocument10 pagesDesign and Performance Curve Generation by CFD Analysis of Centrifugal Pumpبلال بن عميرهNo ratings yet

- Kolkata Pump Case Study 1 Cavitation ResistanceDocument11 pagesKolkata Pump Case Study 1 Cavitation ResistanceManimala MahatoNo ratings yet

- What Is New in API 610 11th EdDocument6 pagesWhat Is New in API 610 11th EdAnonymous 1XHScfCINo ratings yet

- 76 79Document4 pages76 79kirivNo ratings yet

- Study of The Flow in Centrifugal CompressorDocument12 pagesStudy of The Flow in Centrifugal CompressorWaqas AhmedNo ratings yet

- Hydraulic Piston Pump in Civil Aircraft: Current Status, Future Directions and Critical TechnologiesDocument15 pagesHydraulic Piston Pump in Civil Aircraft: Current Status, Future Directions and Critical TechnologiesVijet BhandiwadNo ratings yet

- Optimization of Base Frame of MultistageDocument4 pagesOptimization of Base Frame of MultistageAbderrahim AbarayNo ratings yet

- Design and Analysis of Mixed Flow Pump ImpellerDocument5 pagesDesign and Analysis of Mixed Flow Pump ImpellerEditor IJTSRDNo ratings yet

- Analysis of Piston of Two Stroke Engine: June 2014Document8 pagesAnalysis of Piston of Two Stroke Engine: June 2014Pratheep SekarNo ratings yet

- Influence of Impeller Diameter On The Performance of Centrifugal PumpsDocument11 pagesInfluence of Impeller Diameter On The Performance of Centrifugal PumpsKamendra KumarNo ratings yet

- Selecting The Best Slurry Pump For Specific Operating ConditionsDocument9 pagesSelecting The Best Slurry Pump For Specific Operating ConditionssmendozaNo ratings yet

- Review of Design and Other Parameters For Pump Selection - Part 1Document5 pagesReview of Design and Other Parameters For Pump Selection - Part 14114018No ratings yet

- Worm Gearbox Bearing Life PredictionDocument6 pagesWorm Gearbox Bearing Life Predictionhangmann169No ratings yet

- Analysis of Reciprocating Compressor ValveDocument9 pagesAnalysis of Reciprocating Compressor ValveIJRASETPublicationsNo ratings yet

- Simulador Qrod v3 para Bombeo MecanicoDocument3 pagesSimulador Qrod v3 para Bombeo MecanicobeymarNo ratings yet

- Hydraulic Piston Pump in Civil Aircraft Current Statu - 2020 - Chinese JournalDocument15 pagesHydraulic Piston Pump in Civil Aircraft Current Statu - 2020 - Chinese JournalPhạm ThiênNo ratings yet

- Supervisión Tremendo - PCPDocument17 pagesSupervisión Tremendo - PCPmanuel cabarcasNo ratings yet

- Pump Care ManualDocument3 pagesPump Care ManualGerencia Rigar Colombia SASNo ratings yet

- Elsiver Paper #2 PDFDocument9 pagesElsiver Paper #2 PDFSiva NarayanaNo ratings yet

- Study On Design of Casing of Steam TurbineDocument3 pagesStudy On Design of Casing of Steam Turbinesevero97No ratings yet

- 52-56Document5 pages52-56Aswin KarthickNo ratings yet

- 1242-Article Text-3448-1-10-20191209Document6 pages1242-Article Text-3448-1-10-20191209Arif FuadiantoNo ratings yet

- EM 1110-3-173 - Sanitary and Industrial Waste Water Pumping - Mobilization Construction - WebDocument38 pagesEM 1110-3-173 - Sanitary and Industrial Waste Water Pumping - Mobilization Construction - WebPDHLibraryNo ratings yet

- Performance and Analysis of Newly Designed Pump SeatingDocument33 pagesPerformance and Analysis of Newly Designed Pump SeatingaisyahNo ratings yet

- Analysis and Performance of Centrifugal Pump ImpellerDocument7 pagesAnalysis and Performance of Centrifugal Pump ImpellerMarcelo MachadoNo ratings yet

- LUF617 - DW - 8Hx11 - F Gas WellDocument10 pagesLUF617 - DW - 8Hx11 - F Gas WellJosé TimanáNo ratings yet

- Rod Pump& PCPDocument17 pagesRod Pump& PCPsouthliNo ratings yet

- Advanced Engineering Maximizes Efficiency and MTBR of Descaling PumpsDocument6 pagesAdvanced Engineering Maximizes Efficiency and MTBR of Descaling PumpsJJNo ratings yet

- Industrial Centrifugal Compressors Design Validation, Using Rapid Method Evolutionary Algorithms To Predict Map Characteristics EvaluationDocument12 pagesIndustrial Centrifugal Compressors Design Validation, Using Rapid Method Evolutionary Algorithms To Predict Map Characteristics EvaluationMustafa AliosmanoğluNo ratings yet

- CFD Analysis of Mixed Flow Impeller: Neelambika, VeerbhadrappaDocument7 pagesCFD Analysis of Mixed Flow Impeller: Neelambika, VeerbhadrappaAnilNo ratings yet

- CFD Analysis of Centrifugal Pump DesignDocument10 pagesCFD Analysis of Centrifugal Pump DesignSsheshan PugazhendhiNo ratings yet

- Modular Pump Skid Design Case StudyDocument5 pagesModular Pump Skid Design Case StudyMukesh ShettyNo ratings yet

- Damping HoleDocument11 pagesDamping HoleMurali K oe16d017No ratings yet

- Piping Stress AnalysisDocument16 pagesPiping Stress Analysischikimkong80% (5)

- Specification of Pumps For Stationary Fire Fighting InstallationsDocument14 pagesSpecification of Pumps For Stationary Fire Fighting InstallationsVaibhav Sawant100% (2)

- Energies 15 04266Document19 pagesEnergies 15 04266CHAVHAN NAYANNo ratings yet

- Optimised Pump RoutingDocument6 pagesOptimised Pump RoutingDhanushNo ratings yet

- Papaer Metalurgia Del BarrilDocument8 pagesPapaer Metalurgia Del BarrilRichard More LeonNo ratings yet

- Ensuring integrally-geared-compressor-reliability-API-617Document12 pagesEnsuring integrally-geared-compressor-reliability-API-617AbhijitNo ratings yet

- BB3 Catalogue 2015Document8 pagesBB3 Catalogue 2015nima hasanzadehNo ratings yet

- Mock Up of Tube To Tubesheet Joints in Shell and Tube Heat ExchangersDocument4 pagesMock Up of Tube To Tubesheet Joints in Shell and Tube Heat ExchangersBaher ElsheikhNo ratings yet

- Manual de ZB400Document35 pagesManual de ZB400marthos ericson muñoz castilloNo ratings yet

- Centrifugal PumpDocument3 pagesCentrifugal PumpJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Ijser: Parameters Influencing Connecting Rod: A ReviewDocument9 pagesIjser: Parameters Influencing Connecting Rod: A ReviewNurul'Ain Haniyun Mohamad FodziNo ratings yet

- Gouveia 2015Document15 pagesGouveia 2015Alexandre MartinsNo ratings yet

- Centrifugal Pump For Water ServiceDocument37 pagesCentrifugal Pump For Water ServiceAbdus Saboor KhalidNo ratings yet

- Stress Analysis of Mast Structure For Water-Well Drilling MachineDocument8 pagesStress Analysis of Mast Structure For Water-Well Drilling MachineBruno Santos100% (1)

- Design and Performance Prediction of Liquid Nitrogen Booster Pump For 80 Kelvin Thermal Shield Using CAE ToolsDocument3 pagesDesign and Performance Prediction of Liquid Nitrogen Booster Pump For 80 Kelvin Thermal Shield Using CAE ToolsKOWSHIK 4310No ratings yet

- A05. Water Circulating Pumps For Phase IV in Track Change Mode With Base of Phase III (With2 Option)Document15 pagesA05. Water Circulating Pumps For Phase IV in Track Change Mode With Base of Phase III (With2 Option)Hemanti SharmaNo ratings yet

- Curriculum Vitae: P.SathiyaprabhuDocument7 pagesCurriculum Vitae: P.SathiyaprabhusubNo ratings yet

- Design and Analysis of Skid Frame For Pumping StationDocument6 pagesDesign and Analysis of Skid Frame For Pumping StationtizioNo ratings yet

- Peristaltic Pump Design ParametersDocument4 pagesPeristaltic Pump Design ParametersPrajwal WakhareNo ratings yet

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingFrom EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingRating: 5 out of 5 stars5/5 (9)

- Usb Cable, Type B X1: Component DescriptionDocument1 pageUsb Cable, Type B X1: Component DescriptionAhmed ShawkiNo ratings yet

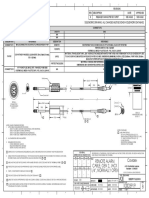

- Revisions: Notes: Unless Otherwise SpecifiedDocument2 pagesRevisions: Notes: Unless Otherwise SpecifiedAhmed ShawkiNo ratings yet

- Security Label Material Details: RevisionsDocument1 pageSecurity Label Material Details: RevisionsAhmed ShawkiNo ratings yet

- Specification:: A Release/Change Per Eco-R224554Document1 pageSpecification:: A Release/Change Per Eco-R224554Ahmed ShawkiNo ratings yet

- Specification:: A Release/Change Per Eco-R224554Document1 pageSpecification:: A Release/Change Per Eco-R224554zizouhicheNo ratings yet

- R/A Cable, Gen2, BLK Plastic Conn: FerriteDocument1 pageR/A Cable, Gen2, BLK Plastic Conn: FerriteAhmed ShawkiNo ratings yet

- LBL Product Id 3 X 1: RevisionsDocument2 pagesLBL Product Id 3 X 1: RevisionsAhmed ShawkiNo ratings yet

- Specification:: Bag, 8 X 10, ProtectiveDocument1 pageSpecification:: Bag, 8 X 10, ProtectiveNguyễn LucyNo ratings yet

- Pb500 Series Battery Tab, Extraction,: 10100902 ASSEMBLYDocument1 pagePb500 Series Battery Tab, Extraction,: 10100902 ASSEMBLYAhmed ShawkiNo ratings yet

- Blower Driver PCBA BOMDocument6 pagesBlower Driver PCBA BOMzizouhicheNo ratings yet

- 1/4", NORMALLY Remote Alarm Cable, Gen 2, JackDocument1 page1/4", NORMALLY Remote Alarm Cable, Gen 2, JackAhmed ShawkiNo ratings yet

- 1/4", Normally Open Cable, Gen 2, Jack Remote AlarmDocument1 page1/4", Normally Open Cable, Gen 2, Jack Remote AlarmAhmed ShawkiNo ratings yet

- Permissive License Open VentilatorDocument3 pagesPermissive License Open VentilatorborrellanoNo ratings yet

- Permissive License Open VentilatorDocument3 pagesPermissive License Open VentilatorborrellanoNo ratings yet

- PT00057819A00 Fixture, PB500 FRU Battery Assembly AidDocument1 pagePT00057819A00 Fixture, PB500 FRU Battery Assembly AidAhmed ShawkiNo ratings yet

- Pb540 Dual Bag: See PG 5/15 Part #2967200-BDocument15 pagesPb540 Dual Bag: See PG 5/15 Part #2967200-BzizouhicheNo ratings yet

- Notes: 1. 2. Solder Wire To USB GND Contact 3. Part/Component To Be Rohs CompliantDocument1 pageNotes: 1. 2. Solder Wire To USB GND Contact 3. Part/Component To Be Rohs CompliantAhmed ShawkiNo ratings yet

- 10025024C00 - Exhalation Control Valve Hardware Specification, PB 540Document6 pages10025024C00 - Exhalation Control Valve Hardware Specification, PB 540Ahmed ShawkiNo ratings yet

- 10025027e00 - Turbine Box Hardware Specification, PB 540Document7 pages10025027e00 - Turbine Box Hardware Specification, PB 540Ahmed ShawkiNo ratings yet

- Powersupplyboard-Tantalumless BomDocument40 pagesPowersupplyboard-Tantalumless BomAhmed ShawkiNo ratings yet

- 10025029e00 - Power Board Requirements Specification, PB 540Document19 pages10025029e00 - Power Board Requirements Specification, PB 540بدرالدين بن خليفةNo ratings yet

- Turbine Control Board SpecificationDocument8 pagesTurbine Control Board SpecificationAhmed ShawkiNo ratings yet

- Detail C-C Scale 2: 1: Cpu CardDocument1 pageDetail C-C Scale 2: 1: Cpu CardAhmed ShawkiNo ratings yet

- 10025029e00 - Power Board Requirements Specification, PB 540Document19 pages10025029e00 - Power Board Requirements Specification, PB 540بدرالدين بن خليفةNo ratings yet

- 3832100F00 - Software Reference Drawing PB540 Power SupplyDocument4 pages3832100F00 - Software Reference Drawing PB540 Power SupplyAhmed ShawkiNo ratings yet

- Turbine Control Board SpecificationDocument8 pagesTurbine Control Board SpecificationAhmed ShawkiNo ratings yet

- CPU Card BOM DetailsDocument30 pagesCPU Card BOM DetailsAhmed ShawkiNo ratings yet

- 10025027e00 - Turbine Box Hardware Specification, PB 540Document7 pages10025027e00 - Turbine Box Hardware Specification, PB 540Ahmed ShawkiNo ratings yet

- Permissive License Open VentilatorDocument3 pagesPermissive License Open VentilatorborrellanoNo ratings yet

- 10025029e00 - Power Board Requirements Specification, PB 540Document19 pages10025029e00 - Power Board Requirements Specification, PB 540بدرالدين بن خليفةNo ratings yet

- Sakurai 1997 PDFDocument8 pagesSakurai 1997 PDFMatiasNavarroQuilodránNo ratings yet

- HL 40 InsulationDocument2 pagesHL 40 InsulationSky MoonNo ratings yet

- Charcterization of Facial Tissue SoftnessDocument16 pagesCharcterization of Facial Tissue Softnessandy981No ratings yet

- FTM - HFV Frame Anchor - Complete VersionDocument6 pagesFTM - HFV Frame Anchor - Complete VersionTuấn Anh NguyễnNo ratings yet

- Stress Force F Area A: LasticityDocument6 pagesStress Force F Area A: LasticityLalunio Catapang JayveeNo ratings yet

- Design Calculations: For Steel StructureDocument46 pagesDesign Calculations: For Steel Structurethiện50% (2)

- 6 Session-2B-Allison-WP18-C4-1323 - FinalDocument24 pages6 Session-2B-Allison-WP18-C4-1323 - FinalAENo ratings yet

- 2925 Modeling of Anhydrite Swelling With FlacDocument9 pages2925 Modeling of Anhydrite Swelling With Flacjmhs31No ratings yet

- Concresive 1438 AseanDocument2 pagesConcresive 1438 Aseanapi-283891975No ratings yet

- Saving Pure Polypropylene Through Mechanical Recycling For Material Value ConservationDocument4 pagesSaving Pure Polypropylene Through Mechanical Recycling For Material Value ConservationSaikat BanerjeeNo ratings yet

- LITERATUREDocument27 pagesLITERATUREArun VNo ratings yet

- Strength Failure Modes Sandwich StructuresDocument6 pagesStrength Failure Modes Sandwich StructuresPrudvi Krishna MaladiNo ratings yet

- Composite Bridge Design PDFDocument50 pagesComposite Bridge Design PDFAminNo ratings yet

- Technical Manual: Made inDocument96 pagesTechnical Manual: Made inarhivojkanNo ratings yet

- Cantilever Retaining Wall ExampleDocument10 pagesCantilever Retaining Wall ExampleReab SimanthNo ratings yet

- D2105Document6 pagesD2105Mario LunaNo ratings yet

- 68407-Ch 03 PDFDocument12 pages68407-Ch 03 PDFBrian ReichelNo ratings yet

- Engineering Materials - Module 2Document5 pagesEngineering Materials - Module 2Albert Cereno SerranoNo ratings yet

- Influence of High Cutting SpeedsDocument114 pagesInfluence of High Cutting SpeedsNakarin X SumavongNo ratings yet

- Is 1570 2 1 1979Document23 pagesIs 1570 2 1 1979harshal161987No ratings yet

- 2.AISC-Beam DesignDocument85 pages2.AISC-Beam Designtekla gom-lua groupNo ratings yet

- Me6503 Dme023Document4 pagesMe6503 Dme023Bakkiya RajNo ratings yet

- Chap 4a PDFDocument25 pagesChap 4a PDFBolWolNo ratings yet

- Astm c297Document8 pagesAstm c297Lucero Ponce de LeónNo ratings yet

- Dokumen - Pub - Fatigue Durability and Fracture Mechanics Proceedings of Fatigue Durability India 2019 1st Ed 9789811547782 9789811547799Document645 pagesDokumen - Pub - Fatigue Durability and Fracture Mechanics Proceedings of Fatigue Durability India 2019 1st Ed 9789811547782 9789811547799nestorNo ratings yet

- Paper - Numerical Analysis of Buried PipesDocument22 pagesPaper - Numerical Analysis of Buried Pipeswebs.usuarioNo ratings yet

- FHWA-shallow FoundationDocument297 pagesFHWA-shallow FoundationENGIDA100% (1)

- COSTE53 ConferenceWarsaw Presentations All PDFDocument178 pagesCOSTE53 ConferenceWarsaw Presentations All PDFHrvoje AndrićNo ratings yet

- Strength of Material Question BaksDocument33 pagesStrength of Material Question Bakssom_bs79No ratings yet

- Final PDFDocument69 pagesFinal PDFKenneth CabarNo ratings yet